Abstract

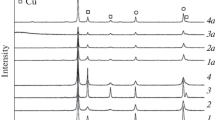

We developed a copper/tungsten (Cu/W) composite for mesoscale Materials Science applications using the novel High-Energy Diffraction Microscopy (HEDM) technique. Argon-atomized copper powder was selected as the starting raw powder and screened to remove the extremely large particle fraction. Tungsten particles were collected by milling and screening the −325 mesh tungsten powder between 500 and 635 mesh sieves. Hot pressing of screened Cu powder was performed at 900 °C in Ar/4 %H2 atmosphere. XRD and ICP results show that the hot-pressed Cu sample consists of about 5 vol% Cu2O, which is caused by the presence of oxygen on the surface of the starting Cu powder. Hot pressing the copper powder in a pure hydrogen atmosphere was successful in removing most of the surface oxygen. This process was also implemented for hot pressing the Cu/W composite. The density of the Cu/W composites hot pressed at 950 °C in pure hydrogen was about 94 % of the theoretical density (TD). The hot-pressed Cu/W composites were further hot isostatic pressed at 1050 °C in argon atmosphere, which results in 99.6 % of the TD with the designed Cu grain size and W particle distribution. Tensile specimens with D-notch were machined using the wire EDM method. The processing and consolidation of these materials will be discussed in detail. The HEDM images are also showed and discussed.

Similar content being viewed by others

References

Maire E, Bouaziz O, Di Michiel M, Verdu C (2008) Initiation and growth of damage in a dual-phase steel observed by X-ray microtomography. Acta Mater 56:4954–4964

Lauridsen EM, Dey SR, Fonda RW, Juul-Jensen D (2006) Nondestructive approaches for 3-D materials characterization. JOM 58:40–44

Oddershede J, Schmidt S, Poulsen HF, Margulies L, Wright J, Moscick M, Reimers W, Winther G (2011) Grain-resolved elastic strains in deformed copper measured by three-dimensional X-ray diffraction. Mater Charact 62:651–660

Lauridsen EM, Schmidt S, Suter RM, Poulsen HF (2001) Tracking: a method for structural characterization of grains in powders or polycrystals. J Appl Cryst 34:744–750

Atkinson HV, Davies S (2000) Fundamental aspects of hot isostatic pressing: an overview. Metall Mater Trans A 31A:2981–3000

Chang L-S, Straumal B, Rabkin E, Lojkowski W, Gust W (2007) Hot isostatic pressing of Cu–Bi polycrystals with liquid-like grain boundary layers. Acta Mater 55:335–343

Correia JB, Freitas P, Santos JA, Bessa Sousa J, Davies HA (2002) Magnetisation and magnetoresistance of a Cu-5%Co alloy produced via powder metallurgy. Key Eng Mater 230–232:110–113

Jech D, Sepulveda JL, Traversone A (1997) Process for making improved copper/tungsten composites. US Patent #: 5,686,676

Larson AC, Von Dreele RB (1986) General structure analysis system; Unpublished Report LAUR 86-748, National Laboratory, Los Alamos

Poulsen HF et al (2001) Three-dimensional maps of grain boundaries and the stress state of individual grains in polycrystals and powders. J Appl Crystallogr 34:751–756

Suter RM, Hennessy D, Xiao C, Lienert U (2006) Forward modeling method for microstructure reconstruction using X-ray diffraction microscopy: single crystal verification. Rev Sci Instrum 77:123905

Withers PJ, Preuss M (2012) Fatigue and damage in structural materials studied by X-ray tomography. Annu Rev Mater Res 42:81–103

ICSD; 172174 Cu2O. http://icsd.fiz-karlsruhe.de/icsd/

ICSD; 64699 Cu. http://icsd.fiz-karlsruhe.de/icsd/

Acknowledgements

This work was financially supported by LANL’s Laboratory Directed Research and Development (LDRD) program (Project 20140114DR). The authors would like to thank Franklin Fierro for allowing the use of wire EDM for the samples and specimens as well as the tensile testing performed by Manny Lovato. The use of F2 Beamline at CHESS is acknowledged. The authors also thank Darren Dale for assisting with HEDM measurements at CHESS, and M.K.A. Koker for assisting with FABLE software.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, CF., Pokharel, R., Brand, M.J. et al. Processing and consolidation of copper/tungsten. J Mater Sci 52, 1172–1182 (2017). https://doi.org/10.1007/s10853-016-0413-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0413-7