Abstract

High product diversity, dynamic market conditions, and a lack of skilled workers are current challenges in manufacturing. Industrial robots autonomously planning and completing upcoming production tasks can help companies address these challenges. In this publication, we focus on autonomous task planning within industrial robotics and investigate how to facilitate the use of automated planning techniques from the field of artificial intelligence for this purpose. First, we present a novel methodology to automatically adapt abstractly modeled planning domains to the characteristics of individual application cases a user intends to implement. A planning domain is a formalized representation of the robot’s working environment that builds the basis for automated planning. Second, we integrate this approach into the procedure for developing skills-based industrial robotic applications to enable them to perform autonomous task planning. Finally, we demonstrate the use of the methodology within the application field kitting in two reference scenarios with a mobile robot and a stationary robot cell. Using our methodology, persons without expertise in automated planning can enable a robot for autonomous task planning without much extra effort.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Due to current challenges, such as high product variety, unpredictable market dynamics, or the shortage of skilled workers, manufacturing companies must establish and integrate new strategies based on technological innovations into their procedures (Koren et al., 2018; Peichl et al., 2022). In this context, industrial robots are considered enablers: They can enable flexible production processes, help companies become resilient to variations in demand, and increase productivity by supporting workers with tiresome tasks (International Federation of Robotics, 2020).

However, programming industrial robots with conventional procedures (e.g., teach-in) still requires specialized knowledge and is time-consuming (Hägele et al., 2016). New programming paradigms, for instance, skills-based procedures, aim to simplify programming industrial robots. The approach of skills-based robot programming typically applies at least a tripartite structure (Pantano et al., 2022; Pedersen et al., 2016; Thomas et al., 2013): The general idea is to encapsulate the robot’s functionalities into parameterizable function blocks, so-called skills, that can be composed over different abstraction levels. In this way, users have a set of primitives (e.g., moving a robot or opening/closing a gripper) at their disposal, which they can use to create manifold higher-value skills (e.g., picking or assembling a part). Based on these skills, users instruct the robot to complete various tasks (e.g., pick a part and assemble it or place it at another location). As skills are reusable in diverse tasks and the abstraction level for programming increases, users require less expertise and time to program a robot (Heuss et al., 2022; Pedersen et al., 2016; Thomas et al., 2013). In this way, using industrial robots for high product variety and smaller batch sizes is becoming increasingly profitable. Drag&bot and FRANKA EMIKA already offer commercially available solutions for programming robots similar to a skills-based approach and, thus, demonstrate its industrial applicability and potential (drag & bot GmbH, 2023; FRANKA EMIKA GmbH, 2023). Nevertheless, for the robot to perform a task, users still have to build the complete skills sequence and parameterize each individual skill. This leads to a huge workload when tasks become more complex, increasing the number of skills required to complete them, or when tasks change frequently (see also Huckaby et al. (2013)).

In that case, the extension of skills-based robots by automated planning from the field of artificial intelligence has great potential for simplifying task instruction (Huckaby et al., 2013; Pedersen et al., 2016; Rovida et al., 2017). Then, users only need to specify the goal to be achieved by the robot, while the robot autonomously plans the necessary skills sequence to get there. In this way, robots can also be used in applications where each task differs from the previous one (e.g., batch size one production). One example here, which we will continue to address in this publication, is a mobile robot for kitting tasks: The robot is handed over a list of parts that it has to deliver to different workplaces. Based on this information, the robot autonomously plans and performs the necessary actions for collecting requested parts from a storage site and delivering these to workplaces.

In order to use automated planning for robot task planning within industrial robotics, it is necessary to understand its basic functionality. This can be broken down into three main steps (Ghallab et al., 2016): Firstly, the application and its characteristics (e.g., the kitting application) are described in a descriptive model called the planning domain. The planning domain relates to a state-transition system. It defines the possible states of a system, the actions that can be performed, and a related state-transition function. Secondly, based on the planning domain, a planning problem can be described by the current initial state and the previously mentioned goal to be accomplished. Thirdly, an automated planning system takes the specified planning domain and problem as input and solves the planning problem by finding an action sequence for proceeding from the initial state to the goal. A robot can then execute the found action plan with its skills.

The just-introduced planning formalism is domain-independent (Ghallab et al., 2016). Thus, it is suitable for various application fields. However, modeling planning domains is challenging (Kootbally et al., 2015; Ortiz et al., 2013; Rovida et al., 2017; Vaquero et al., 2013): It is complex and has to be conducted by a person with expertise in automated planning and the application. In addition, this mainly manual specification process is error-prone and time-consuming. In the future, widespread and flexible use of industrial robots is predicted. If we want to widely deploy robots that autonomously plan their tasks here, underlying planning domains must be modeled or adapted individually for the various robot applications. However, this is not feasible and profitable for manufacturing companies. First, manufacturing companies lack the required expertise in automated planning. Second, recurring need for modeling and adapting planning domains would cause frequent and rapidly increasing workloads.

The overall objective of our work presented in this publication is to reduce manual effort and the expertise required for describing planning domains when initially setting up an industrial robot for a new application case or reconfiguring it for another one. Our novel idea is to automatically generate a suitable planning domain for an individual application case to be implemented by adapting an abstractly modeled planning domain to the requirements of the specific application case. For this, we present a new methodology and demonstrate its integration into the procedure for developing skills-based industrial robot applications. In this publication, we investigate this approach on a conceptual basis and conduct a feasibility study based on two reference scenarios. The presented work contributes to the area of applied science by introducing a new concept of how to use automated planning from the field of artificial intelligence within industrial robotic scenarios. By utilizing our approach, we support manufacturing companies to enable their robots for autonomous task planning more easily and efficiently. In this way, companies will benefit from more flexible application possibilities of industrial robots that will help them to increase their productivity and competitiveness in the long term.

In the next section, we review the state of the art. Then, we present our methodology in “Methodology” section and its application within two reference scenarios in “Reference scenarios” section. Afterward, we discuss both in “Discussion” section. Finally, we conclude our work in “Conclusion and outlook” section.

State of the art

Potentials of automated planning for task planning of skills-based robots

We like to start the analysis of state of the art with a summary of the potential of automated planning for skills-based robots based on previous works in this field:

-

Wide applicability in diverse applications: The subject area of planning distinguishes between domain-specific and domain-independent procedures (Ghallab et al., 2016): Domain-specific approaches address topic-specific problems and are tailored to solving these. This field includes, for example, motion planning or simulation-based process planning. Domain-independent planning abstracts these topic-specific characteristics and provides algorithms that build on the commonalities of diverse planning problems. This domain-independent character makes automated planning applicable far beyond the boundaries of individual thematic application areas. This is especially promising for industrial robotics, as we assume to use future robots in various manufacturing applications that we may even be aware of today.

-

Suitability for planning action sequences based on the robot’s current set of skills: When it comes to task planning for skills-based robots, we aim to find a sequence of skills to complete a task specified at an abstract level. This is precisely the planning problem that automated planning methods address. Previous works demonstrated the suitability of automated planning for this purpose and showed that planned actions can be directly mapped to robot skills (e.g., Pedersen et al. (2016)). In this case, skills implement a similar interface as the actions used for planning based on defined input parameters and a set of preconditions and effects for describing the state change they perform.

-

Modular structure and exchangeability of planning models and algorithms: As introduced in “Introduction” section, the general structure of automated planning systems is simple and modular: Domain-specific content is described in the planning domain and problem. Domain-independent planning algorithms take this information as input and output a plan. Through the introduction of the Planning Domain Definition Language (PDDL) (Ghallab et al., 1998) also exists a commonly used quasi-standard for describing planning domains and problems. This allows easy exchange of planning models and algorithms (Ghallab et al., 1998). Over time, PDDL and related planning algorithms have constantly evolved (e.g., see Ghallab et al. (2016) and Green et al. (2023)) for a more thorough overview). The field of industrial skills-based robotics can benefit from this easy set-up and defined interfaces of automated planners and the variety of existing PDDL versions and planning algorithms. Planning models can be shared between various robot applications, and different planning algorithms can be tested against each other to find the best-fitting approach for a specific scenario. For instance, in the skills-based robot architecture from Rovida et al. (2017), users can easily integrate the planning algorithm of their preference.

-

Checking and optimizing planned action sequences: Manual specifying skill sequences is often characterized by time-consuming trial and error to find consistent and optimized plans. This can be counteracted using automated planning because the previously mentioned formal specification of action’s state changes prevents inconsistencies in found plans, and there exist planners supporting metrics and optimization (Huckaby et al., 2013).

To sum up, automated planning in combination with PDDL holds excellent potential for task planning of skills-based robots in manufacturing applications. For this reason, we put it in the focus of this work.

Introducing the planning domain definition language

After the short introduction of PDDL in the previous section, we describe its basic syntax based on Ghallab et al. (1998) in this section: Within a planning domain in PDDL, states are represented by types and predicates. Types are similar to classes in object-oriented programming. The type object is a built-in type. New custom types can be subordinated to it and may, in turn, have subtypes. Predicates are used to describe the characteristics of a state, taking the previously defined types as arguments. Predicates can be either true or false. Actions can be executed to change the state of a system. Each action takes a set of parameters as input that refer to the previously defined types. In addition, an action definition consists of a list of preconditions and effects. Preconditions describe the state that must be met for an action to be executable. Effects specify the state change after completing an action. Based on the formal definition of a planning domain, a planning problem can be described. For this, actual objects of the types defined in the planning domain are initialized. Based on these, the initial state and goal to be reached are described by means of a list of declared predicates. The planning domain and problem are described in two separate files and are handed over to an automated planning system for solving the planning problem.

For an easier understanding, we exemplify this theoretical introduction by means of a robotic pick-and-place application. Figure 1a shows a simple exemplary planning domain in PDDL. We define the robot’s gripper, considered parts, and areas where parts can be located as types (lines 2–4). To model possible states, we specify predicates to define the area a part is located in (part-in-area), to show if a part is gripped by the robot, and to indicate if the robot’s gripper is free (lines 5–9). With the action pick, the robot can pick up a specified part from the area it is currently located in with its gripper (lines 10–22). Based on this planning domain, Fig. 1b illustrates a planning problem in PDDL. In the initial state, the robot’s gripper is free, and there is one part in the area in front of it (lines 8–11). In the goal state, the part should be gripped by the robot (lines 16–18). The resulting plan to complete this planning problem consists of just one action. The robot needs to pick up the part.

Simple exemplary planning domain (a) and planning problem (b) written in PDDL (Ghallab et al., 1998). In PDDL planning domains, arguments of predicates and parameters of actions are described by the variable name indicated by a preceding question mark and a type. In the planning problem, we additionally visualized the initial state and goal

Applying automated planning for task planning of industrial robots

Automated planning has to be incorporated into the robot’s system architecture if it is to be used for task planning by industrial robots. For this, we present three exemplary works. The SkiROS architecture focuses on the requirements of production industry and provides a software framework for organizing robot knowledge and skills (Rovida et al., 2017). It simplifies software integration and allows one to develop robots with improved reasoning functionalities. In previous work, we presented the REpac framework, a skills-based architecture for developing intelligent and easily configurable industrial robot applications (Heuss et al., 2022). Here, we integrated modules from ROSPlan for task planning. ROSPlan is a more general architecture for integrating task planning into various robotic applications in the Robot Operating System (ROS) (Cashmore et al., 2015).

Generally, the underlying functionality of all three system architectures is similar: In order to maintain the knowledge relevant for planning, the robot has an internal knowledge base (also called world model). The task planning system takes as input a goal to be reached by the robot, extracts the initial state from the robot’s internal knowledge base, and writes both information into a planning problem. The task planning system then calls an automated planner to generate an action sequence based on this planning problem and a planning domain. Both the planning problem and domain are written in PDDL. The actions, modeled within the planning domain, match the robot's skills. Thus, the robot executes the planned action sequence using its skills. Simultaneously, it constantly updates its internal knowledge base. This general approach for the system structure of a robot is usable in various application fields. Also, all approaches allow one to easily exchange the used automated planning system as long as it supports the PDDL version used for modeling the planning domain. To build a robot to work in a specific application case, developers mainly need to formalize the knowledge required therein by the robot for planning or other reasoning purposes and implement the skills the robot needs to execute planned actions and update its internal knowledge base.

Creating a planning domain for an application case

The previous section shows that formalizing relevant knowledge of an application case within a PDDL planning domain is essential for utilizing automated planning for autonomous task planning by robots. However, manual modeling planning domains in PDDL is challenging (see also Kootbally et al., 2015; Ortiz et al., 2013; Rovida et al., 2017; Vaquero et al., 2013)): Firstly, modeling planning domains is error-prone and work-intensive. Secondly, this requires specialized knowledge about automated planning, PDDL, and the industrial application case. In this section, we review related works to simplify the modeling and adjustment of PDDL planning domains for various robotic application cases. Thereby, we focus on works in the field of industrial robotics and in those that use PDDL. We identified three research directions and use these as a classification to present related works.

The first research direction addresses the general modeling of planning domains in PDDL for industrial robot applications (A1). Kootbally (2016) shows how to model robot capabilities for classifying industrial robots in order to select the most suitable robot for a certain task in the application field of kitting. Pane et al. (2021) examine the modeling of and planning with actions to be performed simultaneously (e.g., to avoid collisions while moving to a grasp pose when a disturbance occurs). With a wider scope, Huckaby et al. (2013) consider the application field of assembly. They present a task modeling framework that they use with automated planning. Based on a taxonomy of skills that a robot requires to operate in the application field, they provide a suitable planning domain. In a similar way, Bezrucav and Corves (2022) present a generic planning domain for industrial scenarios with mobile manipulators which they can manually configure for different instances of the generic scenario.

The second research direction considers the learning of action models within a planning domain (A2). Hofmann et al. (2017) record a set of plans within which they determine recurring action sequences. From this, they learn macro actions with preconditions and effects that represent the previously identified action sequences. Subsequently, planning times can be reduced by applying the macro actions in the planning domain. However, the planning system takes the planning domain as input, so it still needs to be modeled a priori. Ortiz et al. (2013) and Liang et al. (2019) apply a learning-by-demonstration approach. Ortiz et al. (2013) use a sensor network to recognize subordinate actions and states of a task demonstrated by a human. Based on that, they learn the action’s preconditions and effects. In the context of simplifying robot programming, Liang et al. (2019) use a programming-by-demonstration approach to simultaneously learn low-level actions by kinesthetic teaching and the parameters, preconditions, and effects of high-level actions through visual perception.

The third research direction deals with automatically translating PDDL planning domains from other knowledge formats and models (A3). Here, the most widespread approach is to store necessary knowledge for a robot application in an OWL ontology and derive PDDL files for task planning from this. This approach is applied in the previously presented SkiROS framework (Crosby et al., 2016; Rovida et al., 2017) or a robotic assembly pipeline based on the Factory of the Future (FoF) ontology (Schäfer et al., 2021). Kootbally et al. (2015) store relevant knowledge for robotic kitting applications in OWL and XDSL/XML files from which they can automatically generate planning domains and problems in PDDL. In addition, individual alternative approaches were also examined: The project itSIMPLE provides a design environment that supports users in specifying planning domains and problems using UML diagrams that are then automatically translated into PDDL (Vaquero et al., 2013). SmartPM is a process management system that uses automated planning to find recovery plans in case of execution failure (Marrella et al., 2018). SmartPM assists users in specifying domain knowledge via graphical interfaces, uses situation calculus and IndiGolog for internal knowledge management and translates between these formalisms and PDDL files to integrate automated planning.

Evaluation and contribution

Based on the presentation of related works in the previous section, we identified three approaches for creating PDDL planning domains that are possible for the scenario we are considering. We evaluate these with regard to our work and with a focus on workload and required expertise:

-

A1

Modeling planning domains in PDDL: As already stated, manual modeling and adjusting planning domains in PDDL is time-consuming and requires specialized expertise about the application case, automated planning, and PDDL. Huckaby et al. (2013) and Bezrucav and Corves (2022) discussed the idea of modeling a generic planning domain based on general production skills and using this in multiple diverse application cases. However, Huckaby et al. (2013) mention that connecting planned high-level actions to lower-level executing skills is challenging. We agree with this: Modeling just one planning domain for an application field (e.g., kitting or assembly) and using this in different application cases is not practicable. In reality, the use cases to be implemented differ from each other (e.g., consider diverse objects, skills, or subordinate characteristics) and, consequently, will always necessitate recurring manual and work-intensive adjustments of the planning domain. Bezrucav and Corves (2022) address the manual modification of a generic planning domain for different application instances. However, their focus is on modeling the generic scenario and its planning domain in PDDL. In contrast to this work, we will focus on the automated adaption of generic planning domains to individual robotic application cases in this publication.

-

A2

Learning action models by demonstration: This approach, as shown by Ortiz et al. (2013) and Liang et al. (2019), simplifies creating and modifying a planning domain in a known operating environment. New actions can be easily added to the planning domain by demonstrating these to the learning system. However, if the structure and characteristics of the operating environment change (e.g., other objects or characteristics of these should be considered), major efforts arise. First, types and predicates for representing the new objects and characteristics must be defined in advance. Second, depending on the objects and related characteristics one wants to capture, different sensors and computation algorithms (e. g., for image processing) are suitable. These must conscientiously be selected and designed. This can be extremely laborious and requires appropriate expertise.

-

A3

Translating from other knowledge representations: All works presented under this research direction have in common that knowledge required for planning is specified in some format that is not PDDL (e.g., OWL, XML, UML) and then automatically translated into a PDDL planning domain. This reduces the required expertise and effort compared to manual modeling planning domains directly in PDDL. Users might be more familiar with the respective knowledge format, be supported by graphical interfaces, and formalized knowledge might be used for different purposes. Nevertheless, all necessary information needs to be stated explicitly. Thus, workloads remain that are not to be underestimated. In addition, one must be proficient with the used alternative knowledge representations (e.g., OWL, XML, UML) and interfaces.

To conclude, related works have mainly investigated how to support users in modeling PDDL planning domains. The widespread and diverse use of industrial robots is predicted in the future. To establish automated planning for task planning of robots in manufacturing, we need to consider the requirements of diverse and evolving application cases in different variants of the underlying planning domains. For this, adjustments must be frequently integrated into the planning domains. However, the support of existing approaches is not sufficient for this. First, existing approaches require an expert of the application case itself with additional specialized knowledge in a minimum of one discipline (e.g., automated planning and PDDL in A1, sensors and computing algorithms in A2 when new objects or characteristics must be captured, or another knowledge representation in A3). Persons who set up robotic applications in manufacturing companies often do not have this additional specialized knowledge. Second, the expected need for continuous evolution and maintenance of planning domains causes recurring and accumulating workloads that counteract the efficiency gains of automated task planning by robots. If the planning domain is modeled manually (A1) or translated from another knowledge representation (A3), the related knowledge must be explicitly specified at some point. This results in workloads that constantly increase with the number of adjustments. When action models are learned from demonstration (A2), setting up sensors and programming computing algorithms may cause high workloads.

To overcome these drawbacks, we present a new and alternative approach to the discussed problem. Our novel idea is to share and reuse PDDL planning domains in different robotic application cases by automatically adapting these to the individual requirements of an application case. Previous works mentioned that specified planning domains can be reused for different application cases. However, none has focused considered how to efficiently share planning domains between diverse application cases. In this context, the automatic adaption represents the novelty of our work. We assume that therefore required information is already specified during the general development procedure of robotic applications, can be extracted from this process, and used for automatically adapting an abstract planning domain for the specific application case. In this way, we expect that we can provide an expert in the application case a planning domain with further decreased work effort. The presented work aimed to investigate this novel idea in the context of skills-based industrial robotics. For this purpose, we elaborated a concept for this and conducted a feasibility study. Our resulting scientific contribution can be summarized as follows:

-

We introduce a novel methodology for the automated adaption of abstract planning domains for specific application cases, and

-

demonstrate its integration into the development procedure of skills-based robot applications.

Methodology

We begin the presentation of the novel methodology by defining its detailed objectives. Then, we introduce our terminology for this publication, give an overview of the methodology and describe it in more detail in the succeeding sections.

Preliminary considerations, objectives, and industrial example of use

Preliminary considerations

The objectives of our methodology are based on three observations that we would like to present in advance based on preliminary considerations:

-

C1

Application fields of industrial robots: The application fields of robots in production can be classified and specified. Today’s top three application fields for industrial robots are handling, welding, and assembly (International Federation of Robotics, 2022). The tasks occurring in them are well studied and described in classic production literature. We see handling and assembly as promising application fields for the work we present in this publication.

-

C2

Required skills within an application field: Different works have studied and described the skills that occur in diverse application fields, for example, for assembly (Hammerstingl & Reinhart, 2018) or logistics and assistive robot applications (Bøgh et al., 2012). These works show that the skills required by a robot to work within a certain application field can be abstracted into a defined set. However, we think that due to differences in the implementation, there will be different instances of a skill in real-world robotic applications (e.g., depending on an object’s characteristics, a suitable gripping principle has to be selected; see also Heuss et al. (2018)).

-

C3

Sharing of robot skills and related knowledge: A common idea in skills-based industrial robotics is to reduce development efforts by sharing skills and related knowledge between different robots via a central market-place/database (Stenmark & Malec, 2015; Wenger et al., 2016). Users can select appropriate skills for an application case from the central skills database to modularly combine these within the robot system or use offered knowledge services.

Objectives

Based on our conclusion from the state of the art, our overall objective is to reduce manual efforts and required expertise for specifying planning domains when configuring industrial robots for diverse application cases. Compared to the approaches in the state of the art, our novel idea is to improve the sharing of planning domains between different robotic application cases by automatically adapting abstractly modeled planning domains to the characteristics of specific individual application cases. For this, we present a new methodology. We structure our approach based on four technical sub-objectives:

-

O1

Modeling of abstract planning knowledge: Based on C1 and C2, we aim to model planning knowledge about typical application fields of industrial robots in an abstract way so that we can adapt it to the requirements of specific application cases later on. This abstract planning knowledge should be stored in a central database analogously to C3.

-

O2

Expansion of abstract planning knowledge by relevant information from specific skill instances: Based on the considered abstract skills, developers can implement different specific instances of these to address application-specific requirements (see C2) and share these via a central skills database (see C3). During this process, we aim to automatically acquire information relevant to planning and expand the abstract knowledge models of O1 by this specific planning knowledge.

-

O3

Automated generation of planning domains for specific application cases: As described in C3, users download relevant skills onto a robot to implement an intended application case. Based on this selection of specific skill instances and the central knowledge modeling build based on O1 and O2, we aim to simultaneously and automatically generate a suitable planning domain for the specific application case.

-

O4

Enabling industrial robots for autonomous task planning: By providing users with a specific planning domain, we aim to support users who are not experts in automated planning to enable their robot to autonomously plan its task in individual application cases.

Industrial example of use based on the FORobotics project

During the presentation of the methodology, we utilize an example of use to clarify our explanations. In this section, we introduce the example of use to which we will refer in the rest of this publication. The research project FORobotics considered the kitting of parts as a suitable application field for autonomous mobile robots (Berger et al., 2021). Figure 2a illustrates the application field kitting in a generalized manner as we derived it from the FORobotics project and consider it for the presented work. The mobile robot consists of a mobile platform, a manipulator equipped with a gripper, and various sensors for capturing its environment. With the aim of its mobile platform, the robot can drive between locations. At these locations, as well as on the robot’s mobile platform, are areas for storing parts. The robot can pick and place parts from these areas with its gripper. Thus, it can deliver parts between different locations and areas.

The FORobotics project involved several industrial partners who have this application case in different forms in their production. We base our example of use on the application case from Mey Maschinenbau Prien GmbH & Co. KG (Berger et al., 2021). Here, the robot is tasked with delivering boxes between shelves in a storage site and workplaces. Based on this, we describe the slightly adapted application case we assume for this publication. Figure 2b schematically illustrates the setup. For this application case, the robot is equipped with a specialized boxgripper. On the shelves and at the workplaces are defined surfaces to store boxes. On its mobile platform, the robot has a set of fixtures for transporting the boxes. In the robot’s navigation software, waypoints can be defined, which the robot can drive to afterward.

Terminology

In this section, we clarify the terminology we use in this publication. First, we introduce our general definition of tasks and skills. Then, we present the terminology used for describing planning domains in the context of this publication.

Tasks and skills

We use the terminology for tasks and skills which was derived in a previous work of the authors (Heuss et al., 2022):

-

A mission specifies the overall task for the robot in the form of the desired goal to be achieved. (e.g., a list of parts with goal areas to which these should be delivered)

-

An action plan is a sequence of actions to be performed to achieve a mission. Each action in the plan is linked to a robot skill that can execute it.

-

A skill is a parameterizable functional capability offered by the robot system. Skills can be orchestrated over multiple levels. Primitive skills are the functional building blocks at the lowest level and directly communicate with and control the robotic system components (e.g., move with a manipulator to a specified pose). Composite skills are higher-level complex process flows that result from the combination of lower-level skills (e.g., pick an object).

In this publication, we use composite skills to execute the planned actions of an action plan. Thus, and for an easier understanding, in the following, we refer to a composite skill when we use the term skill. Only if the distinction is relevant do we differ between primitive and composite skills.

Planning domains for robotic applications

To enable the robot to autonomously determine an action plan to complete a mission handed over to it, we use automated planning as introduced in “Introduction” section. For this, the automated planner needs a planning domain as a basis. Referring to our considerations and stated objectives in the previous section, we aim to model a planning domain for an application field in a generalized manner so that it can be automatically adapted to specific application cases in the real world. In that way, we consider robotic applications at different abstraction levels:

-

An application field describes a suitable task range for a robot in a generalized manner (e.g., kitting, assembly). At this abstract level, we abstract the specific setup of a robot platform, the implementation details of skills, or the characteristics of the objects in the robot’s surroundings. Thus, we can model generalized knowledge for an application field valid for different application cases.

-

An application case relates to a real implementation of a robotic system within an application field (e.g., box kitting). At this specific level, we focus on one actual application case within an application field. For this, we take the previously mentioned details into account as these are relevant for the correct execution of actual application cases.

We transfer these abstraction levels to the modeling of planning domains and skills. Figure 3 illustrates the related meta-model on the left side and exemplifies it on the right side. We start with the terminology for planning domains:

-

The abstract planning domain formalizes the required planning knowledge for a robot to complete typical missions in a defined application field in a generalized manner. For example, the kitting domain describes the knowledge for the application field of kitting in an abstract manner.

-

The specific planning domain extends the abstract planning domain to represent additional knowledge required by the robot in an actual application case. Related to our example of use, we aim to automatically derive the specific box kitting domain from the abstract kitting domain for the application case of kitting boxes.

The robot executes derived action plans by means of its skills. Thus, each planning domain can be linked to a defined set of skills to execute the actions modeled in this planning domain. We have already considered the distinction between abstract and specific skills in previous work (Heuss et al., 2018) and are now integrating this into the view of application fields and lower-level application cases:

-

Abstract skills are the functional capabilities generally required by a robot to operate in a specified application field. Pick is an exemplary abstract skill the robot needs to operate in the application field of kitting.

-

Specific skills refer to the actual implementations of abstract skills that a robot needs to complete application cases in reality. Thus, specific skills take characteristics such as the setup of a robot system, related kinematics, or functional principles into account. For example, when handling boxes, the robot must always hold them the right way up to prevent the box’s content from falling out. In comparison, this is not necessary for the handling of solid objects. Further, the motion sequence and skill parameters differ when picking up a box from a fixture or a surface. This is because the fixtures on the robot’s mobile platform are permanently fixed in relation to its manipulator. Thus, the robot can request the box’s pose from its internal knowledge base and, based on that, directly pick it up. In contrast, when the box is located at a surface not on the robot’s mobile platform, the robot needs to capture the box’s pose with its camera before it can pick up the box. Thus, in our example of use, the robot requires the two individual specific skills pick box from surface and pick box from fixture.

Methodology overview

The overall objective of the introduced methodology is to simplify the use of automated planning in skills-based robotic applications by automatically providing specific planning domains for individual application cases. In the past, we presented the first concept for integrating autonomous task planning based on automated planning into skills-based robotics (Heuss & Reinhart, 2020). In the present publication, we work out this approach. For this purpose, we present the PDDLAutoGen tool, a tool for supporting users in creating specific PDDL planning domains for their individual robotics application cases based on an Automated Generation of these. Furthermore, we presented a software framework for developing skills-based robot applications in previous works (Heuss et al., 2019; 2022). This framework provides a skills control platform and can be extended by a task planning system based on automated planning. Building on this and the life cycle of skills-based robotic applications therein, we demonstrate the use of the PDDLAutoGen tool. Figure 4 gives an overview. To introduce our methodology, we split the life cycle of a skills-based robotic application into three phases skill development, application case configuration, and robot operation. These three phases are illustrated at the top of the figure.

Skill development: First and foremost are skill developers who design and implement specific skills (1). During this activity, they describe a specific skill and all its parameters based on the template of a superordinate abstract skill. In addition, they implement the specific skill’s process flow. We took over this procedure for developing skills from our previous work (Heuss et al., 2022) and extended it by using the template of superordinate abstract skills. The PDDLAutoGen tool takes the description of a new specific skill as input (2). From this, it automatically extracts knowledge relevant to task planning and integrates it into the planning knowledge base (3). All developed specific skills are uploaded to the specific skills database by skill developers and so are provided for the later implementation of various robotic application cases (4).

Application case configuration: In the second step, system integrators are engaged to configure a specific application case. At this point, we assume that the robot system has already been physically built and software core components (e.g., 3D model of the system setup), as well as our skills-based software framework (Heuss et al., 2022) have been set up. Now, the PDDLAutoGen tool supports system integrators to enable their robot for autonomous task planning. Based on the intended application field, they select the specific skills the robot requires to operate in the application case (5). Based on this input, the PDDLAutoGen tool automatically generates a specific planning domain (6). For this, it uses the information stored in its internal database, which consists of predefined abstract planning domains for defined application fields and the planning knowledge base. The planning knowledge base links the extracted information from previously integrated specific skills to the planning knowledge modeled in the abstract planning domains. System integrators can then follow the procedure for configuring an application case based on our skills-based robot software framework (Heuss et al., 2022). System integrators can directly use the output specific planning domain to configure the robot’s task planner (7). In addition, system integrators download required specific skills and related software components from the specific skills database onto the robot and configure these for the intended application case (8). In this context, the skills are also extended by preconditions and effects as modeled in the specific planning domain. Moreover, initial knowledge of the application case for the robot can be described in the robot’s internal knowledge base if required.

Robot operation: Finally, the robot can flexibly complete various tasks during operation. Our skills-based robot framework (Heuss et al., 2022) offers the functionalities needed for this and works as generally illustrated in “Applying automated planning for task planning of industrial robots” section. Workers instruct the robot at a high abstraction level by specifying the goal to be achieved by the robot in a mission (9). The robot’s task planner takes this as input and creates a planning problem by combining the current state stored in its internal knowledge base with the previously specified goal in the mission (10). Subsequently and with the aim of the specific planning domain, the task planner derives an action plan to solve the generated planning problem by internally calling an automated planning system. The action plan is forwarded to the task controller that subordinately controls its execution by calling the robot’s skills (11). In that way, the robot executes each individual action using the related specific skill (12).

In this publication, we introduce the PDDLAutoGen tool as a stand-alone system. This way, we can better describe its system boundaries and interfaces to other components. However, it could also be integrated into an overall software environment for developing specific skills and configuring application cases coupled with a skills database. In addition, the three considered user roles, skill developer, system integrator, and worker, can be performed by different persons or just one person depending on the persons qualifications and personnel resources in a company. Furthermore, the PDDLAutoGen tool could be used with another skills-based robot architecture that supports automated planning or just a stand-alone automated planning system. In the following sections, we describe the structure and functioning of the PDDLAutoGen tool in detail. For this, we start with the illustration of how to use the PDDLAutoGen tool from the perspective of skill developers and system integrators (user input layer) in “Using the PDDLAutoGen tool” section. Then, we describe the internal functionality and database structure of the PDDLAutoGen tool (logic and data layers) in “Internal functionality and database structure of the PDDLAutoGen tool” section.

Using the PDDLAutoGen tool

Based on the methodology overview in the previous section, we describe in this section how to utilize the PDDLAutoGen tool from users’ perspectives. Thereby, we go through the phases of skill development and application case configuration and describe in more detail how skill developers and system integrators interact with the PDDLAutoGen tool.

Developing a specific skill and integrating it into the PDDLAutoGen tool

Figure 5 illustrates the procedure for developing specific skills. We base it on the procedure we previously introduced in the context of our skills-based software framework for robotic applications (Heuss et al., 2022) and extend it so that specific skills are derived from abstract skills. We have marked the steps and information that also represent the inputs of the PDDLAutoGen tool (see step 2 in Fig. 4). In the following, we present the procedure step-by-step:

-

1.

Initialization of the specific skill: To initialize a new specific skill, skill developers select the abstract skill to which a specific skill is to be subordinated and name it uniquely. All abstract skills are predefined within the planning knowledge base of the PDDLAutoGen tool. For example, the specific skill pick box from surface is derived from the abstract skill pick.

-

2.

Description of the specific skill parameters: We describe skills in an object-centered manner. We assume that skills are applied to physical objects and, thus, can be parameterized related to these. For example, the abstract skill pick can be used to pick a part from an area with the robot’s gripper. In this context, each skill parameter is defined by an object class (e.g., part) and a unique parameter name (e.g., ?part). Within the PDDLAutoGen tool, we apply the convention to name skill parameters based on their object class and a prefix. In addition, within the scope of this publication, we indicate these, similarly to PDDL, by a preceding question mark. Now, during the description of the skill, skill developers specify the classes of the specific objects that a specific skill should be applicable to. Hereby, the specific object class is always a subclass of an abstract object class. For example, the skill pick box from surface can be utilized to pick up a box from a surface using a boxgripper. Based on that, the specific skill parameters become uniquely named analogously to the related abstract parameters (e.g., ?box). Furthermore, users can specify individual input and output object parameters representing additional characteristics relevant to skill execution. For example, the skill pick box from surface needs a viewpose of the surface as input. From this pose, it can overview the surface where the box is located to visually determine the box’s actual pose with the aim of a camera.

-

3.

Implementation of the specific skill process flow: Based on the specified parameters of the specific skill, skill developers implement its internal process flow. Our skills-based software framework offers two options for this purpose. The process flow can either be modeled using a state machine or scripted using Python. The state of the art also applies further approaches (e.g., behavior trees (Paxton et al., 2016)). For the scope of this publication, we decided to use state machines as these are widely known and used. However, other procedures can, in principle, also be combined with the presented methodology. As mentioned in “Tasks and skills” section, composite skills combine subordinate, mostly primitive skills to execute a complex behavior. In this context, the nodes of the state machine describe the actions to be achieved by subordinate skills, and the transitions define the action’s order. Additionally, skill developers have to specify the handling of the subordinate skill’s parameters. In this way, internal process flows of skills can be easily designed in an intuitive manner. Subordinate skills for modeling the process flow are also made available via the skills database. Depending on the system’s components used, these can be downloaded and integrated to build composite skills as needed. Figure 5 illustrates the process flow of the skill to pick up a box from a surface. Firstly, the robot moves to the surface viewpose to measure the box pose and calculate the related grasp pose. Then, the robot moves into a prepose from which it can thread into the box handle with two linear movements to lift it. Since the boxgripper works similarly to a hook, no explicit closing function is necessary. In Fig. 5, parameters adjacent to the bounding box (e.g., surface viewpose) relate to the skill parameters described in the previous step and are passed to the skill externally when called. The other parameters are either predefined (e.g., direction) or determined by one skill at runtime and passed to a succeeding one (e.g., box pose).

When implementing specific skills, skill developers should consider two aspects. First, abstract planning domains and related abstract skills have a defined validity range (see also “Abstract planning domains” section). This validity range ensures compatibility between abstract planning domains/skills with derived specific planning domains/skills. In this context and based on the related validity range, abstract skills provide requirements to be fulfilled by the implementation of subordinate specific skill instances (e.g., to use a robot with one gripper). These implementation requirements should be considered and fulfilled by skill developers. Second, specific skills should provide self-contained and safe functional behaviors. This means that skills must check their executability in advance and control their correct execution to detect errors when necessary. In this way, skills can be called independently from a higher level. If a skill fails to execute a requested action in a plan, it proceeds to a safe failure state and returns an error message. The higher level can then initiate error handling or replanning.

Generating a specific planning domain for an application case

In this section, we detail the procedure for generating a specific planning domain with the PDDLAutoGen tool during the application case configuration phase from the perspective of system integrators (see step 5 in Fig. 4). We superficially presented the procedure for the holistic implementation of an application case using our skills-based robot software framework in “Methodology overview” section. For a more detailed view on this topic, we refer the interested reader to Heuss et al. (2022). In the following and based on Fig. 6, we describe the procedure within the PDDLAutoGen tool step-by-step:

-

1.

Initialization of the specific skill: To initialize a new specific skill, skill developers select the abstract skill to which a specific skill is to be subordinated and name it uniquely. All abstract skills are predefined within the planning knowledge base of the PDDLAutoGen tool. For example, the specific skill pick box from surface is derived from the abstract skill pick.

-

2.

Selection of the specific skills: The required abstract skills are defined in the planning knowledge base for each application field. Subordinate to abstract skills, all previously integrated specific skills are further described in the planning knowledge base. Thus, based on the application field selected, in the first step, the PDDLAutoGen tool shows system integrators which abstract skills are required and offers them all subordinate, available specific skills. From these, system integrators select all the specific skills they need to implement the intended application case. For our example, the robot requires skills for driving between different waypoints as well as picking and placing boxes. Figure 6 shows the user’s subordinate selection of specific skills.

Based on this input information, the PDDLAutoGen tool automatically generates a specific planning domain for the intended application case and outputs it to system integrators. We present the detailed procedure for this in the next section. In the further course of implementing the application case, users can configure any automated planning system with the specific planning domain that supports the PDDL version and subordinate requirements of the specific planning domain.

Internal functionality and database structure of the PDDLAutoGen tool

In this section, we describe the internal functionalities and structure of the PDDLAutoGen tool. We start with an insight into the modeling of abstract planning domains. Based on that, we analyze necessary adaptions between abstract and specific planning domains. We then explain how necessary information from the implementation of specific skills is stored in the internal planning knowledge base. Finally, we describe the algorithm for generating a specific planning domain for an application case.

Abstract planning domains

We introduced our definition for abstract planning domains in “Planning domains for robotic applications” section. The basic idea is to generalize planning knowledge that a robot requires to operate in an application field into an abstract planning domain. Thus, we aim to specify one abstract planning domain for each intended application field (e.g., kitting, assembly, machine loading). When modeling domain-specific application fields, assumptions are usually made (e.g., a robot with one gripper system is considered). These assumptions should be specified in the form of a validity range to be considered when implementing subordinate specific skills and generating specific planning domains. At this point, we would like to mention that the adaption of abstract planning domains to specific application cases is the novelty of this publication. This requires modeling planning domains, but this is not the focus. In order to demonstrate our methodology’s structure and functionality in the further course of this publication, we modeled an exemplary abstract planning domain for the application field of kitting based on our example of use from “Industrial example of use based on the FORobotics project” section. We introduce it based on Fig. 7.

In its upper part, the figure shows the object types and predicates of the abstract planning domain for the application field kitting. The lower part of the figure illustrates the extended specific planning domain for the application case box kitting and will be described later on in “Extension of an abstract planning domain to a specific planning domain” section. We created four types, location, area, part, and gripper, subordinate to the general type object. The object types in the abstract planning domain represent the previously mentioned object classes. By means of predicates, we model the object type’s relevant characteristics. The robot can be at a location (robot-at), and a set of areas can be assigned to each location (area-at-location). All areas assigned to a location where the robot is currently located, as well as areas on the robot’s mobile platform, are reachable for the robot by means of its manipulator. One part can be placed in each area (part-in-area). If a part is placed in an area, the area is occupied. If the robot has picked up a part, it is gripped. The predicate free indicates weather the robot has a part in its gripper or not. To deliver parts between different areas and locations, we modeled in the abstract planning domain that the robot can execute the three actions, pick, place, and drive, by means of its corresponding skills. Figure 8a shows the definition of the abstract action pick as an example. The action takes the gripper to be used, the part to be picked up, and the area where the part is currently located as input. All parameters must be named uniquely within the definition of the action. As already mentioned earlier, we name these based on their abstract type and a prefix if required. This way, the names of specific skill parameters can be determined automatically (see also “Developing a specific skill and integrating it into the PDDLAutoGen tool” section), and the mapping between abstract and specific skill parameters can be automatically looked up in the planning knowledge base later on. All preconditions must be fulfilled for the robot to perform the action. Thus, to pick up a part, the robot’s gripper must be free, the area must be reachable for the robot, and the part must be in the area. In the same way, the effects represent the state change after executing the action.

Abstract action pick (a) in the abstract planning domain kitting and specific action pick box from surface (b) in the specific planning domain box kitting. Modifications in the specific action definition compared to the abstract action definition are written italic. Extensions of the specific action definition are additionally grey colored

Extension of an abstract planning domain to a specific planning domain

This section analyzes the necessary adaptions from an abstract to a specific planning domain. As introduced in “Planning domains for robotic applications” section, specific planning domains extend abstract planning domains to represent individual characteristics of an application case. Thus, the basic structure of the abstract planning domain remains in the specific planning domain. Within an application field, we consider the objects the robot interacts with and the skills it uses for this purpose at an abstract level. In contrast, within an application case, the robot is equipped with specific skills tailored for handling objects of defined specific object classes. Below, we go through the sections of a planning domain and describe the necessary adaptations. The modifications result from the specific skills that system integrators have chosen for their particular application case. Thus, we start with the actions section.

Actions section: To consider the selected specific skill set for task planning, each specific skill must be represented by a specific action in the specific planning domain. We create each specific action based on its superordinate abstract action. The general structure of the abstract action with its parameters, preconditions, and effects remains as it is valid for all subordinated specific actions. Based on the skill’s specific implementation, two modifications must be conducted between an abstract action and its derived specific action. Figure 8b illustrates these modifications for the already considered specific skill pick box from surface. First, it must be considered that specific skills can only be applied to objects of the specific object classes specified in their parameters. To address this, we replace the abstract types with related specific types in the definition of the action’s parameters (e.g., area by surface) and rename the variables accordingly (e.g., ?area to ?surface). To keep the action’s definition consistent, this renaming must further be performed for the variables of all specific action’s preconditions and effects. Second, specific skill parameters can be characterized during skill implementation by additional object parameters required for the skill’s execution (e.g., the previously considered viewpose of a surface). Consequently, and in the case of an input object parameter, the presence of this information is a further prerequisite for the executability of a specific skill respectively action. This can be considered within the specific action’s definition by adding additional preconditions. Thus, we create for each input object parameter a precondition using a predicate of the form [specific object class]-has-[object parameter] (e.g., surface-has-viewpose). In the same way, we create additional effects in the specific action’s definition for considering output object parameters.

Types section: All specific types we introduced in the parameter definition of specific actions must also be incorporated into the types section of the specific planning domain. During skill implementation, skill developers derived the specific object classes from the defined abstract object classes (e.g., surface from area). In the same way, we now integrate the specific object types as subtypes of the related abstract object types. In this way, specific object types also inherit the predicates of superordinate abstract types. Figure 7 illustrates this for our example of use in its lower part.

Predicates section: Finally, to keep the description of the specific planning domain consistent, we must also add the newly defined predicates for describing the additional preconditions and effects of specific actions to the predicates section (see also the lower part of Fig. 7).

To sum up, a specific planning domain extends an abstract planning domain. The types and predicates sections contain the abstract elements and additional specific types and predicates. The abstract actions are replaced by specific actions that the robot can execute using its specific skills.

Storing of planning knowledge from the implementation of specific skills in the planning knowledge base

To automatically adapt abstract planning domains for individual specific application cases, we extract relevant information during the implementation of specific skills and store it in the central planning knowledge base for later access (see step 3 in Fig. 4). This section describes the general structure of the planning knowledge base and how information from the implementation of specific skills is stored in it. The planning knowledge base is composed of three modules (see Fig. 4). The planning ontology links considered skills and object classes in the abstract planning domains to their specific instances. In addition, the skills and objects libraries store additional characteristics of the specific skills and object classes. We start by introducing the planning ontology as the central component based on Fig. 9.

The planning ontology consists of three base classes application field, skill, and object. We create a subclass to the application field base class for each considered application field. Analogously, the skill and object base class have a subclass for each abstract skill that relates to an action in an abstract planning domain respectively for each object class that occurs as an object type in an abstract planning domain. In Fig. 9, this is again exemplified for the application field kitting. The correlations between application fields, abstract skills, and abstract object classes are further specified by three types of object properties. The properties has [abstract skill name] skill and has [abstract object class name] object link an application field to the abstract skills the robot requires for operating in it respectively the abstract object classes occurring therein. Further, the property has [abstract skill parameter name] parameter refers from an abstract skill to the abstract object classes, which the skill takes as input parameters. Within all three types of object properties, the placeholders […] become replaced by the respective name of the abstract skill, object class, or skill parameter. As mentioned earlier, for example, the abstract skill pick takes the part to be picked up, its area, and the gripper to be used as input. Within the use of the PDDLAutoGen tool during skill implementation, diverse specific skill instances and related specific object classes are added to the planning ontology as individuals. Figure 9 exemplifies this for the specific skill pick box from surface in its lower part. Individuals inherit the object properties of their parent classes. In this context, we reuse the object property has [abstract skill parameter name] parameter to additionally link the specific skill to the specific object classes representing its specific parameters and thus map the relationship between abstract and specific skill parameters.

The skills and objects libraries supplement the planning ontology. In the basic setup, we create one category for each abstract skill as well as object class occurring in the planning ontology. Later during skill implementation, each newly created specific skill, including all its parameters, gets subordinated to its abstract parent element in the skills library. Similarly, specific objects and for these created subordinate characterizing parameters are integrated into the objects library.

Automated generation of specific planning domains during robot configuration

System integrators use the PDDLAutoGen tool to generate a specific planning domain for their intended application case during the configuration of the robot application (see “Generating a specific planning domain for an application case” section). For this, system integrators specify the intended application field of their application case, the name of the specific planning domain to be generated, and the specific skills their robot requires to operate in the application case. Then, the PDDLAutoGen tool uses this information to adapt the abstract planning domain of the considered application field for the specific application case (see step 6 in Fig. 4). We illustrated the necessary adaptions from an abstract to a specific planning domain in “Extension of an abstract planning domain to a specific planning domain” section. In this section, we summarize the algorithm that performs these adaptions. Figure 10 illustrates its flow. The algorithm’s input data specified by the system integrators is summarized on the left side of the figure. In addition, the algorithm utilizes the internal data of the PDDLAutoGen tool stored in its database to look up relevant information that was extracted during the implementation of specific skills. The expected output is the specific planning domain, as illustrated on the right side of the figure. In the following, we go through the algorithm's steps in the figure's center. The specific planning domain is initialized based on the related abstract planning domain and named accordingly (1). In the next step, the algorithm adds the specific actions the robot can execute using the selected specific skills (2). For this, the algorithm performs the same steps for each action: It initializes the specific action based on its superordinate abstract action (2a), replaces/renames the parameters and variables of the specific action accordingly to the related specific skill (2b), and adds preconditions and effects for considering additional object parameters characterizing the specific skill’s parameters (2c). The abstract actions are removed after all specific actions have been added because the robot cannot directly execute these (3). All new specific types that occur in the definition of a specific action are added as a subtypes of the related abstract types (4). All specific predicates newly created in step 2c are added to the predicates “Discussion” section.

Reference scenarios

In this section, we present the application of the previously introduced methodology in three different application cases spread over two reference scenarios. Then, based on the generated results, we conduct the evaluation of our methodology. For the use of the PDDLAutoGen tool in the reference scenarios, we implemented it as a software demonstrator. In the database, we described the abstract planning domain in PDDL 2.2 (Edelkamp & Hoffmann, 2004), the planning ontology as OWL ontology, and the skills and objects libraries using JSON. Based on that, we implemented the logic within the PDDLAutoGen tool and a user interface with Python 3. Here, Owlready2 (Lamy, 2017) was used for manipulating OWL ontologies. We modeled one abstract planning domain for the application field of kitting, as already introduced in “Abstract planning domains” section, and integrated it into the database of the PDDLAutoGen tool. Afterward, the PDDLAutoGen tool was used to generate specific planning domains for the application cases of the reference scenarios.

Reference scenario 1: commissioning of parts by an autonomous mobile robot

In the first reference scenario, we aimed to evaluate the general functionalities of the PDDLAutoGen tool, including its benefits and limitations. For this, we build on the FORobotics project that we introduced in the context of the example of use in “Industrial example of use based on the FORobotics project” section. To evaluate the PDDLAutoGen tool, we derived two exemplary application cases in the kitting application field from the industrial partners of the FORobotics project. In the following, we introduce our setup and procedure within this reference scenario before describing the application cases in detail and presenting our results.

Setup and procedure

Our setup consisted of the PDDLAutoGen tool and a stand-alone automated planning system. We used the fast downward planning system (Fast Downward, 2023) as an automated planner. The fast downward planning system supports PDDL 2.2 as well as subordinate requirements, which we used for modeling the abstract planning domain and is frequently used in other research works.

Based on this setup, we proceeded for each application case as follows: First, we identified and designed specific skills that the robot requires to operate in the respective application case and integrated these into the PDDLAutoGen tool following the procedure for implementing skills from “Developing a specific skill and integrating it into the PDDLAutoGen tool” section. If possible, we reused specific skills from previous application cases. Within the first reference scenario, we have not implemented specific skills in software. Second, we used the PDDLAutoGen tool to generate a specific planning domain for the considered application case, as described in “Generating a specific planning domain for an application case” section. Third, we configured the automated planning system with the specific planning domain generated in the previous step. Fourth, we planned five exemplary missions per application case. For this, we specified related planning problems and called the automated planner to solve one after the other.

We have refrained from the full implementation of the application cases in this reference scenario, as the feasibility of the basic motion sequences to realize the application cases have already been demonstrated in the FORobotics project (Berger et al., 2021; Heuss & Reinhart, 2020). Furthermore, we present an overall implemented skills-based robot application in the second reference scenario.

Application case 1: transporting of boxes between a storage and working site

The first application case relates to our example of use from “Industrial example of use based on the FORobotics project” section, which is based on the application case of the industrial FORobotics project partner Mey Maschinenbau Prien GmbH & Co. KG (Berger et al., 2021). Here, a mobile robot should transport boxes between a storage site and workplaces. In terms of our work, the robot needs five specific skills to operate in this application case. The robot must be able to drive between different waypoints as well as pick up and place boxes from/on surfaces or fixtures on its mobile platform.

Based on the automatically generated planning domain, we specified five planning problems. The initial state of one exemplary planning problem is illustrated in Fig. 2b. For each mission, we specified six boxes that should be moved to a different surface from the storage site to a workplace or the other way. Figure 11 illustrates one exemplary mission. We integrated these missions as goals into the planning problems. The five planning problems differ in the initial areas of the boxes, the starting waypoint of the robot, and the missions to be completed by considering different boxes and delivery areas.

Application case 2: delivering motors from a storage site to workplaces

We derived the second application case from the industrial FORobotics project partner Krones AG (Berger et al., 2021). Here, the robot is tasked with transporting motors instead of boxes from shelves in a storage site to different workplaces and assisting a human by assembling the motors. In terms of the publication, we do not consider the cooperative assembly and assume that the robot only delivers the motors to the workplaces. In the following, we introduce the application case as considered within the scope of this work and as illustrated by way of the example in Fig. 2c. Similar to the first application case, we assume that the shelves, as well as workplaces, can be reached by the robot from predefined waypoints and have defined surfaces for storing the motors. We use the same mobile platform and manipulator as in the first application case. This time, the robot is equipped with a specially designed motorgripper, a camera, and a construction with holders to store the motors during transport on its mobile platform. We identified five specific skills the robot requires to act in this application case. For driving between different waypoints, the robot can reuse the specific skill from the first application case. In addition, this time, the robot requires specific skills for picking and placing motors from/on surfaces and holders. Picking and placing motors from/into holders relates to a peg-in hole insertion and, thus, needs a different motion sequence compared to picking and placing motors from/on surfaces.

To illustrate the structure of the specified planning problems, Fig. 2c presents the initial state of one planning problem. In this application case, we change between the five planning problems in the initial state the number of motors present in the storage site, the areas occupied by them, and the starting waypoint of the robot. For each mission, we specify six motors to be delivered from the storage site to various surfaces at the workplaces. We integrated these missions as goals into the planning problems. The five missions differ in the considered motors and delivery surfaces.

Generated specific planning domains and planning results

In this section, we summarize the results of both application cases. We first manually checked the generated specific planning domains. Both specific planning domains have been correctly adapted for the application cases from the abstract planning domain by the PDDLAutoGen tool. We already used the resulted specific planning domain for the first box-kitting application case as illustrating example in “Methodology” section. Figure 7 illustrates all types and predicates of the specific planning domain. All types and predicates of the abstract planning domain remain. Specific object types for specifying specific actions’ parameters have been added as subtypes of the related abstract types. Furthermore, all new predicates used to define additional preconditions and effects in specific actions’ definitions have been created. The actions section contains the five selected specific actions for driving to different waypoints, picking up boxes from surfaces and fixtures, and placing boxes on surfaces and into fixtures. These have been created based on the superordinate abstract actions with correct adaptions. Figure 8b shows by way of example the definition of the specific action for picking a box from a surface.

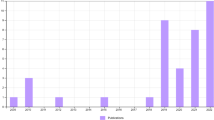

Second, we look at the workload we save using the PDDLAutoGen tool compared to manually adapting the planning domains. For this, we analyzed the structure of the generated specific planning domains. In the following, we describe the procedure used here and the results. Comparable to the code excerpts in this publication (see Fig. 1 and Fig. 8), each line of the generated specific planning domains contains a type/predicate definition, an action’s precondition/effect, etc. We reviewed each specific planning domain and counted the lines directly adopted from the abstract planning domain, adopted with modification, and newly added by our algorithm. We skipped empty lines or lines with only a parenthesis. Figure 12 presents the results for all application cases. In the first two application cases, the specific planning domains were successfully composed of the abstract planning domain, with 62 modifications in each case (45 lines modified and 17 lines newly added). The PDDLAutoGen tool created the specific planning domains for the application cases automatically based on the chosen application field, the specified application case names and selected specific skills. In contrast, without the PDDLAutoGen tool, one must manually assemble the specific planning domains and incorporate relevant modifications in an error-prone and test-intensive procedure. Thus, this analysis demonstrates the high efficiency of the PDDLAutoGen tool compared to manually adapting the PDDL planning domains. Important to mention that when the robot’s skills set becomes more extensive, the size of specific planning domains and necessary adjustments to be incorporated increase significantly more compared to the input information of the PDDLAutoGen tool.