Abstract

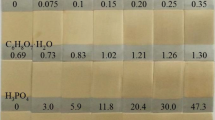

The electrodeposition of a Cu–Sn binary alloy on stainless steel from a cyanide-free alkaline electrolyte containing EDTA·2Na and C4H4O6KNa was investigated to explore the possibility of a cyanide-free double complexing system that maintains the decorative quality and coating performance. The Cu–Sn co-deposition occurred at −0.95 Vvs.Hg|HgO, and the height of cathode peak A from the BR bath was −0.0280 A. EDTA·2Na could simultaneously complex with Cu ions and Sn ions, while C4H4O6KNa could only complex with Cu ions, which was shown through the analysis of the cyclic voltammetry (CV) curves together with the nuclear magnetic resonance (NMR) results. The molar concentration ratio and sum of the two main salts or the two complexing agents, and the pH of the electroplating solutions were shown to influence the surface micromorphology, composition and phase structure of the Cu–Sn coatings. The scanning electron microscopy (SEM) analysis showed that the Cu–Sn coating obtained from the bath with EDTA-tartrate double complexing agents exhibited smaller grain sizes than that obtained from the bath with the single EDTA or tartrate complexing agent, and the smallest grain size of 0.2 μm was obtained from the BR bath. In addition to being smaller than the others, this coating contained uniform particle sizes. The energy-dispersive X-ray spectroscopy (EDS) analysis indicated that the composition of the Cu–Sn coating obtained from the BR bath was 92.8 wt% Cu and 7.2 wt% Sn, and this coating was golden in colour. X-ray diffraction (XRD) showed that the Cu–Sn coatings were crystalline and were composed of a mixture of Cu, Cu6Sn5, [Cu, Sn] and Cu10Sn3 phases, indicating the formation of Cu–Sn binary alloy. These results may provide theoretical guidance for the electrodeposition technology of other alloy coatings.

Graphic abstract

Similar content being viewed by others

References

Heidari G, Mousavi Khoie SM, Abrishami ME, Javanbakht M (2015) Electrodeposition of Cu–Sn alloys: theoretical and experimental approaches. J Mat Sci Mat Electr 26:1969–1976

Jung M, Lee G, Choi J (2017) Electrochemical plating of Cu–Sn alloy in non-cyanide solution to substitute for Ni undercoating layer. Electrochim Acta 241:229–236

Zanella C, Xing S, Deflorian F (2013) Effect of electrodeposition parameters on chemical and morphological characteristics of Cu–Sn coatings from a methanesulfonic acid electrolyte. Surf Coat Technol 236:394–399

Walsh FC, Low CTJ (2016) A review of developments in the electrodeposition of copper-tin (bronze) alloys. Surf Coat Technol 304:246–262

Szpyrkowicz L, Zilio-Grandi F, Kaul SN (2000) Copper electrodeposition and oxidation of complex cyanide from wastewater in an electrochemical reactor with a Ti/Pt anode. Ind Eng Chem Res 39:2132–2139

Clauwaert K, Binnemans K, Matthijs E, Fransaer J (2016) Electrochemical studies of the electrodeposition of copper–zinc–tin alloys from pyrophosphate electrolytes followed by selenization for CZTSe photovoltaic cells. Electrochim Acta 188:344–355

Meng GZ, Sun FL, Wang SJ, Shao YW, Zhang T, Wang FH (2010) Effect of electrodeposition parameters on the hydrogen permeation during Cu–Sn alloy electrodeposition. Electrochim Acta 55:2238–2245

Jung H, Myung NV (2011) Electrodeposition of antimony telluride thin films from acidic nitrate–tartrate baths. Electrochim Acta 56:5611–5615

Melo LC, Pedro DLN, Adriana NC (2011) The influence of citrate and tartrate on the electrodeposition and surface morphology of Cu–Ni layers. J Appl Electrochem 41:415–422

Zheng JW, Chen HB, Cai W, Qiao L, Ying Y, Li WC, Yu J, Jiang LQ, Che SL (2017) Reaction mechanisms of copper electrodeposition from 1-hydroxyethylidene-1, 1-diphosphonic acid (HEDP) solution on glassy carbon. Mater Sci Eng, B 224:18–27

Pecequilo CV, Panossian Z (2010) Study of copper electrodeposition mechanism from a strike alkaline bath prepared with 1-hydroxyethane-1,1-diphosphonic acid through cyclic voltammetry technique. Electrochim Acta 55:3870–3875

Ding LF, Liu F, Cheng J, Niu YL (2018) Effects of four N-based additives on imitation gold plating. J Appl Electrochem 48:175–185

Carlos IA, Almeida MRHD (2004) Study of the influence of the polyalcohol sorbitol on the electrodeposition of copper-zinc films from a non-cyanide bath. J Electroanal Chem 562:153–159

Almeida MRHD, Barbano EP, Carvalho MFD, Tulio PC, Carlos IA (2015) Copper-zinc electrodeposition in alkaline-sorbitol medium: electrochemical studies and structural, morphological and chemical composition characterization. Appl Surf Sci 333:13–22

Rubin W, Oliveira EMD, Carlos IA (2012) Study of the influence of a boric-sorbitol complex on Zn–Mn electrodeposition and on the morphology, chemical composition, and structure of the deposits. J Appl Electrochem 42:11–20

Almeida MRHD, Barbano EP, Zacarin MG, Brito MMD, Tulio PC, Carlos IA (2016) Electrodeposition of CuZn films from free-of-cyanide alkaline baths containing EDTA as complexing agent. Surf Coat Technol 287:103–112

Juškėnas R, Karpavičienė V, Pakštas V, Selskis A, Kapočius V (2007) Electrochemical and XRD studies of Cu–Zn coatings electrodeposited in solution with d-mannitol. J Electroanal Chem 602:237–244

Slupska M, Ozga P (2014) Electrodeposition of Sn–Zn–Cu alloys from citrate solutions. Electrochim Acta 141:149–160

Salhi Y, Cherrouf S, Cherkaoui M, Abdelouahdi K (2016) Electrodeposition of nanostructured Sn–Zn coatings. Appl Surf Sci 367:64–69

Whang TJ, Hsieh MT, Kao YC (2010) Studies of single-step electrodeposition of CuInSe2 thin films with sodium citrate as a complexing agent. Appl Surf Sci 257:1457–1462

Ballesteros JC, Chainet E, Ozil P, Trejo G, Meas Y (2010) Initial stages of the electrocrystallization of copper from non-cyanide alkaline bath containing glycine. J Electroanal Chem 645:94–102

Pewnim N, Roy S (2013) Electrodeposition of tin-rich Cu–Sn alloys from a methanesulfonic acid electrolyte. Electrochim Acta 90:498–506

Whang TJ, Hsieh MT, Kao YC, Lee SJ (2009) A study of electrodeposition of CuInSe2 thin films with triethanolamine as the complexing agent. Appl Surf Sci 255:4600–4605

Rudnik E, Wloch G (2013) Studies on the electrodeposition of tin from acidic chloride-gluconate solutions. Appl Surf Sci 265:839–849

Kamysheva KA, Shekhanov RF, Gridchin SN et al (2020) Electroplating of zinc and tin alloys with nickel and cobalt from ammonium oxalate electrolytes . Surf Eng Appl Electrochem 69(7):1272–1278

Volov I, Sun XX, Gadikota G, Shi P, West AC (2013) Electrodeposition of copper-tin film alloys for interconnect applications. Electrochim Acta 89:792–797

Barbano EP, Oliveira GMD, Carvalho MFD, Carlos IA (2014) Copper-tin electrodeposition from an acid solution containing EDTA added. Surf Coat Technol 240:14–22

Carvalho MFD, Barbano EP, Carlos IA (2013) Influence of disodium ethylenediaminetetraac -etate on zinc electrodeposition process and on the morphology, chemical composition and structure of the electrodeposits. Electrochim Acta 109:798–808

Zhao X, Zhang JJ, Qu JH (2015) Photoelectrocatalytic oxidation of Cu-cyanides and Cu-EDTA at TiO2 nanotube electrode. Electrochim Acta 180:129–137

Joint Committee on Powder Diffraction Standards, JCPDS (2000) Powder diffraction file-PDF-2, Database Sets 1–49. ICDD, Pennsylvania, (CDROM)

He XC, Shen HL, Wang W, Pi JH, Hao Y, Shi XB (2013) Synthesis of Cu2ZnSnS4 films from co-electrodeposited Cu–Zn–Sn precursors and their microstructural and optical properties. Appl Surf Sci 282:765–769

Xue L, Fu Z, Yu Y, Tao H, Yu A (2010) Three-dimensional porous Sn–Cu alloy anode for lithium-ion batteries. Electrochim Acta 55:7310–7314

Orhan G, Gezgin GG (2011) Response surface modeling and evaluation of the influence of deposition parameters on the electrolytic Cu–Sn alloy powders production. Metallurg Mat Transact B 42:771–782

Murase K, Ito A, Ichii T, Sugimura H (2011) Preparation of Cu–Sn layers on polymer substrate by reduction-diffusion method using ionic liquid baths. J Electrochem Soc 158:335–341

Ai Q, Yang ZJ, Zeng XQ, Zheng YL, Hu PY (2013) Study on the FTIR spectra of OH in olivines from mengyin kimberlite. Spectrosc Spectral Anal 33:2374

Yan JJ, Chang LC, Lu CW, Dow WP (2013) Effects of organic acids on through-hole filling by copper electroplating. Electrochim Acta 109:1–12

Schah-Mohammedi P, Shenderovich IG, Detering C, Limbach HH, Tolstoy PM, Smirnov SN, Golubev NS (2000) Hydrogen/deuterium-isotope effects on NMR chemical shifts and symmetry of homoconjugated hydrogen-bonded ions in polar solution. J Am Chem Soc 122:12878–12879

Mcewen I (2010) Broadening of 1H NMR signals in the spectra of heparin and OSCS by paramagnetic transition metal ions. The use of EDTA to sharpen the signals. J Pharmaceut Biomed Anal 51:733–735

Potvin PG, Fieldhouse BG (2011) An NMR study of mixed, tartrate-containing TiIV complexes. Can J Chem 73:401–413

Acknowledgements

This work was supported by the National Natural Science Foundation of China (NSFC51604180), Cultivate Scientific Research Excellence Programs of Higher Education Institutions in Shanxi (CSREP2019KJ038), General Project of Shanxi Province Key R & D Plan (Social Development Field, 201903D321068), the Applied Basic Research Programs of Science and Technology Department of Shanxi Province (201701D221036), Scientific and Technological Innovation Programs of Higher Education Institutions in Shanxi (2019L0235).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ding, L., Li, Q., Cheng, J. et al. The electrodeposition of low-Sn imitation gold Cu–Sn alloy from EDTA-tartrate double complexing agents. J Appl Electrochem 51, 473–487 (2021). https://doi.org/10.1007/s10800-020-01500-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-020-01500-6