Abstract

Geosynthetic-reinforced and pile-supported (GRPS) embankments are becoming more popular as a solution for addressing soil structural instability. The interaction between the geosynthetic-pile-subsoil-embankment elements is crucial to the load transfer mechanism and performance of GRPS embankments. Several analytical models for GRPS embankment design have been proposed, but their performance and applicability still require further validation. This research presents a three-dimensional numerical investigation of the load transfer mechanism of GRPS embankments using the finite difference approach, considering the combined interaction between the soil embankment, geosynthetics, pile, and subsoil. The importance of these crucial aspects in the GRPS embankment design technique is highlighted, as well as their influence and sensitivity. The following elements, in descending order, influence the load and settlement efficacies of the GRPS embankments: soft soil stiffness, embankment height, geosynthetic stiffness, and embankment soil density, according to this research. Furthermore, the use of geosynthetics reduces differential settlements and mitigates soil yielding above the pile heads. The numerical findings are then compared to four well-known design standards, with the subsurface stiffness, geosynthetic stiffness, embankment height, and fill soil density all being varied simultaneously to measure their performance. The findings of the comparison revealed that these techniques differ greatly in their ability to forecast load efficacy and differential settlement. Depending on the geometric properties of the embankment and material properties, all of the selected design methods produce over-predictions or under-predictions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

GRPS (geosynthetic-reinforced and pile-supported) embankments have proven to be excellent and cost-effective options for soft ground improvement. The GRPS technology is now widely employed in practice for a wide range of applications, including dams, high embankments, highways, slopes, and bridge approach systems. The GRPS approach has the advantage of greatly lowering total and differential settlements while also boosting embankment stability. GRPS embankments have been used successfully in many history cases (Pham and Dias 2021a; Pham 2022a).

The pile elements are installed through the soft soil down to a stiff layer in GRPS embankments, and one or more geosynthetic layers are placed atop the pile head. Because these components function together as a composite system, the performance of GRPS embankments is determined by the interaction of piles, geosynthetics, and soils. The four primary acts of (i) embankment arching, (ii) tensioned geosynthetic membrane effect, (iii) subsoil support, and (iv) frictional interaction are attributed to load transfer mechanisms in GRPS embankments. Several analytical models for the GRPS embankments study were presented based on these actions (Terzaghi et al. 1943; Hewlett and Randolph 1988; Low et al. 1994; NGG 2005; Hong et al. 2007; Abusharar et al. 2009; BS8006 2010; EBGEO 2011; Van Eekelen et al. 2013; Zhuang et al. 2014; Zhang et al. 2021; Filz et al. 2019; Rui et al. 2020; Pham 2020a, b; Lai et al. 2021; Pham et al. 2022a; Pham and Dias 2022). However, in their implementation, not all of these analytical methods adequately examined the interaction processes. Instead, some simplified assumptions were established in order to create simple and appealing techniques for designers, which have a substantial impact on the correctness of the outcomes.

Numerical modelling is a powerful and useful tool for investigating the behaviour of piled embankments because of the complicated interaction mechanism of the soil-structure system as well as the limits of analytical models. When compared to field experiments, physical models, or centrifuge tests, numerical studies are more cost-effective, time-efficient, and versatile. Many numerical studies on geosynthetic-reinforced and pile-supported embankments have been reported to provide insights and increase load transfer mechanism understanding (Han and Gabr 2002; Jenck et al. 2009; Lo et al. 2010; Yoo 2010; Fattah and Majeed 2012; Yapage and Liyanapathirana 2014; Ariyarathne and Liyanapathirana 2015; Bhasi and Rajagopal 2015; Rowe and Liu 2015; Das and Deb 2017; Yu and Bathurst 2017; Pham 2019; Wijerathna and Liyanapathirana, 2020; Lee et al. 2021; Pham and Dias 2021b; Rui et al. 2021; Smith et al. 2021; Pham et al. 2022b; Guo et al. 2022; Guo et al. 2023). Finite element, finite difference, and discrete element methods are extensively employed in numerical approaches for piled embankments. The finite element method (FEM) and the finite difference method (FDM) both investigate continuum mechanics at the macroscopic level, whilst the discrete element method (DEM) offers an alternative for studying granular soils at the particle scale (Le Hello and Villard 2009; Indraratna et al. 2015; Gholaminejad et al. 2020; Tran et al. 2021; Pham et al. 2021b). Numerical assessments of piled embankments can be done in two-dimensional (2D), three-dimensional (3D), unit cell, or full-width models. Among many techniques, designers prefer the 3D unit cell model because it provides more accurate results than the 2D models that address plane strain conditions. The unit cell technique is appealing because it allows for faster calculation while capturing the behaviour of a basic volume cell in a larger 3D model. The 3D unit cell model also has the ability to reduce complexity and processing needs, allowing it to be used in a variety of applications.

According to the literature evaluation, current numerical studies place a strong emphasis on load transfer processes and thus focus on a few examples. Furthermore, the majority of these researchers focused on the effect of a single parameter on GRPS embankment load–deflection behaviour. They frequently modified only one aspect while keeping the others constant. The GRPS embankment, on the other hand, required contemporaneous connected interactions between soils, geosynthetics, and piles. As a result, predicting the sensitivity of some significant elements on the load–deflection behaviour of GRPS embankments proved problematic. In addition, the performance of analytical models should be compared to the performance of numerical models in order to assess their applicability and limitations.

This research gives a three-dimensional numerical investigation of the behaviour of geosynthetic-reinforced and pile-supported embankments using the finite difference approach. The impact and sensitivity of numerous key parameters on geosynthetic load–deflection behaviour are highlighted. To evaluate their performance, the numerical results are then broadened by comparing them to analytical models. A statistical study of the 216 numerical examples is also performed to assess the sensitive factors for each analytical model.

2 Numerical Simulation

2.1 3D Unit Cell Model

When GRPS embankment might be viewed as the deep and axisymmetric foundation elements, the concept of a "unit cell model" has been the most popular method for numerically simulating the response of geosynthetic-reinforced and pile-supported embankment. Application of 2D and 3D unit cell models for GRPS embankment have been reported by many researchers in literature (Han and Gabr 2002; Jenck et al. 2009; Yoo and Kim 2009; Almeida et al. 2013; Bhasi and Rajagopal 2015; Khabbazian et al. 2015; Yu and Bathurst 2017; Lee et al. 2021; Pham et al. 2021; Pham et al. 2022b; Dar and Shah 2021; Vibhoosha et al. 2022). Considering the symmetries of the network of piles, the 3D model seems to be the most relevant to describe correctly the load transfer mechanisms between piles. A number of studies have shown that for the same embankment, utilizing a typical unit cell can result in substantially different results from those obtained using a full-width model. The outcomes of the axisymmetric, 3D unit cell, and fully 3D models of a pile-supported embankment were compared by Yoo and Kim (2009). They found that axisymmetric modelling tended to produce results that were 10–20% greater than those from 3D models, particularly for lateral deformation of the granular columns, and that the results of 3D unit cell analyses were in good agreement with those from the full 3D model. In their studies of the performance of GRPS embankments using numerical full-width and typical unit cell models, Bhasi and Rajagopal (2015) and Khabbazian et al. (2015) also discovered that the reinforcing tensile loads using the typical unit cell were significantly lower than those using the full-width model. This is because the typical unit cell model with fixing side boundaries was not able to consider for the lateral spreading of foundation soil and embankment fill.

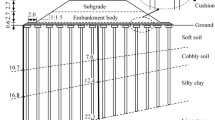

The main objective of this paper is to investigate the combined interaction between structure elements and its influence on the performance of GRPS embankments, rather than concentrating on the total settlement of embankment. According to the above review, the 3D unit cell is believed to be a suitable approach, as it can provide both quality results and computational performance. In this study, the 3D numerical models are implemented using an explicit finite difference program (Flac3D). As shown in Fig. 1, the piled embankment model consists of four elements: pile, soft soil, geosynthetic, and embankment. The thickness of the embankment varies between 0.75 m, 1.5 m, 2.25 m, and 3 m, with a 3 m spacing between the two piles. The pile is rectangular, having a 0.6 × 0.6 m cross-section. It is equivalent to a 4% area ratio. Due to the symmetry constraint, only a 1.5 × 1.5 m box is simulated. The mound of soft soil is modelled using elastic materials for the sake of simplicity.

2.2 Elastic Model for the Soft Soil, Pile

The subsoil influence on the geosynthetic deflection is often considered through the elastic modulus parameter in current design methods (EBGEO 2011; Van Eekelen et al. 2013; Filz et al. 2019; Pham 2020c). Because one of the objectives of this study is to compare the numerical results with one obtained from analytical approaches, the subsoil reaction needs to be treated equivalently. The advantage of the elastic-perfectly plastic model is allowing to easily modify of the subsoil elastic modulus during parametric studies. Furthermore, the linear elastic-perfectly plastic model uses only five well-known parameters. An elastic constitutive model was therefore used to represent the soft soil and piles, which is similar to some previous research (Yu and Bathurst 2017; Anh Tran et al. 2019; Pham and Dias 2021a, b; Pham 2022b). The soft soil thickness (\(h_{c}\)) was set to 1 m with varying Young's modulus (\(E\)) values ranging from 0.05 to 1 MPa, and the pile modulus was set at 20,000 MPa. From the oedometric modulus (\(E_{oed}\)), Young's modulus (\(E\)) and Poisson's ratio (\(\nu\) = 0.3) are calibrated as follows:

where \(K\) = subgrade reaction modulus.

2.3 Geogrid Element for the Geosynthetics Reinforcement

The geosynthetics can be represented in FLAC3D using an isotropic linear elastic material with Young's modulus and a Material thickness. The geogrid element, as demonstrated by Tran et al. (2021), is capable of accurately capturing the geosynthetic behaviour. As a result, it was chosen to represent geosynthetics in this study. The assumption of an isotropic linear elastic material to represent the mechanical behavior of the geosynthetic is not fully justified since geogrids or reinforced geosynthetics most often have two preferred directions of reinforcement. The calibration of the elastic parameters of the geosynthetic was made based on the results of a DEM tool (Tran et al. 2021; Anh Tran et al. 2020) which allows taking into account the anisotropic fiber nature of the geosynthetic and the directions of reinforcement. This tool was moreover previously validated by confrontation with experimental data (Le Hello and Villard 2009). To represent the different values of tensile stiffness of the geosynthetics, the sets of parameters comprising Young's modulus and thickness of the geosynthetics are calibrated from the Discrete Element Model (Tran et al. 2021; Anh Tran et al. 2019). The geosynthetics' thickness is set to 0.01 m, and Young's modulus is varied to match the Discrete Element Model. The equivalent tensile stiffness value is o.6 times the product of Young's modulus and the thickness of the geosynthetics. In comparison to the Discrete Element Model, this value is ideal for finite-difference computations since these parameters can reproduce the deflection of the geosynthetics for varied geometries and loadings.

2.4 Cap Yield Model for the Embankment

A modified variant of the double-yield model is the cap yield model (Itasca Consulting Group 2009). Both of these models are part of the cap model group and are formulated in the context of plasticity theory. The difference between cap models and other types of models is that the Cap model family uses two different yield functions rather than one.

The strain-hardening and softening constitutive model used in this work is characterized by a frictional Mohr–Coulomb shear envelope (zero cohesion) and an elliptic volumetric cap (Tran et al. 2021; Anh Tran et al. 2019). The model is calibrated using a Discrete Element Method simulation in order to accurately replicate the behaviour of loose, medium, and dense sand. This kind of model enables straightforward reproduction of the mechanical behaviours at various density levels of a particular granular material by altering the initial porosity of the DEM granular particles. Friction hardening and softening laws were defined in this model using a non-associated flow rule, as shown in Fig. 2. To capture the dilatancy phenomenon during shearing, the friction angle and dilatancy angle are related using the Rowe stress-dilatancy hypothesis. To model the loose soil, moderately dense, and dense soils, three sets of parameters are used (Table 1).

2.5 Discussion of Numerical Model

It should be noted that this study is focused on examining the impact of interactions between soil-structure factors on the behaviour of GRPs embankments rather than the deformation of the embankment. Additionally, a numerical model must accurately represent the comparable behaviour of the subsoil throughout the simulation in order to evaluate the accuracy of analytical models. For example, the subsoil consolidation issue and construction process were not incorporated into analytical methods. On the other hand, geosynthetic reinforcement products exhibit time- and strain-dependent behaviour under load when they are rate-dependent polymeric materials (creep). The geosynthetic tensile stiffness is frequently taken into account as a strain function for an isochronous curve with a hyperbolic shape, as noted by Bathurst and Naftchali (2021) and Pham et al. (2022a, b). This approximation led to the use of a constant (elastic) stiffness value in the current investigation. The impact of geogrid creep, however, was quite intricate and outside the scope of this study. The unit cell and several simplified assumptions were as a result created. Due to this, it is difficult to replicate a real project. However, as previously stated, this study is more concerned with considering the tendency of results and the impact of soil-structure interaction on GRPS embankment behaviour than it does with precise value.

3 Review of the Different Design Methods

In the literature, several design methods for the study and design of geosynthetic-reinforced and pile-supported embankments have been presented. Although not all of these procedures were designed specifically for engineering GRPS embankments, some were eventually utilized. In some recent discussions, these design methodologies were described and examined (Sloan 2011; Pham 2020c; Pham and Dias 2021a; Pham et al. 2021). The Nordic design guideline (NGG 2005), the British standard (BS8006 2010), the German design guideline (EBGEO 2011), and the Dutch design guideline (CUR226 2016), also known as the Van Eekelen et al. (2013) technique, were chosen for comparison in this work.

3.1 Efficacy Definition

In embankment layers, soil arching is frequently mobilized, resulting in a stress redistribution effect (Fig. 3). Arching transfers a portion of the load to the pile cap, while the remaining load is transmitted to the geosynthetic and subsoil. The area of a square pile cap, the contributory area of a pile, and the area of subsoil in this study are defined as follows:

where Ac = area of a pile cap; A = contributory area of a pile; As = area of subsoil; s = center-to-center pile spacing; a = width of pile cap.

The term effectiveness is used to describe the degree of arching, which is defined as the proportion of the fill carried by the pile cap by weight. If there is no arching, \(E_{a} = 0\), and if there is complete arching, \(E_{a} = 1\).

where \(E_{a}\) = arching efficacy; γ = embankment unit weight; H = embankment height; q = surcharge; \(\sigma_{c}\) = vertical stress acting on the pile cap area by arching; \(\sigma_{s}\) = average vertical stress acting on the soft soil area by arching.

3.2 Nordic Design Guideline (NGG 2005)

The soil arching calculation model utilized in the Nordic design Guideline is depicted in Fig. 4. The vertical load transfer is considered in this design method by forming an arch in between the pile caps, which spreads the soil load over the pile caps. A soil wedge with a 30° angle is used to estimate the soil cross-sectional area under the arch, which is the load borne by the reinforcement.

Calculation model used in NGG (2005)

The following formula is used to calculate the average residual vertical tension acting on the geosynthetic and subsoil (\(\sigma_{s}\)), and the arching efficacy (\(E_{a} )\) is then determined by applying Eq. (3b).

The expression for determining the geosynthetic deflection, y, with a constant geosynthetic design strain of 5% is:

where y = maximum geosynthetic deflection; \(\varepsilon\) = geosynthetic strain. It should be noted that the default design strain value for geosynthetic in this design approach is 5% (\(\varepsilon = 0.05\)) in all circumstances. This is due to the fact that this design method was unable to account for the geosynthetic tensioned membrane effect during calculation. The results of the estimate may be greatly overpredicted as a result.

The vertical load causes the tensile force in the geosynthetic reinforcement, \(T\), to be computed using the equation:

3.3 British Design Standard (BS 8006 2010)

The approach of Hewlett and Randolph (1988) for GRPS embankment design was introduced in an upgraded edition of the British Standard (BS 8006) released in 2010. The efficacy at the arch crown and the column top can be determined using this method as follows (Fig. 5):

where \(K_{p}\) = passive earth pressure coefficient,

Calculation model used in BS8006 (2010)

The lowest of the two values is the critical pile efficacy, which is utilized as a basis for comparison throughout the entire study. The minimum value is also used to determine the vertical stress acting on the geosynthetic reinforcement.

By substituting the value of \(\sigma_{s}\) from Eq. (12), which is employed in this design technique, with an assumed design strain of 5%, Eq. (5) is used to compute the geosynthetic deflection or differential settlement. The definition of geosynthetic tensile force follows the same formula, Eq. (6).

3.4 German Design Guideline (EBGEO 2011)

The principles of the EBGEO method are adopted from the multi-arching equilibrium model (Fig. 6) that was proposed by Kempfert et al. (2004). To investigate the bearing mechanism of the pile-geosynthetic-soils systems, a triangular pressure distribution is assumed for the calculations, and elastic subsoil support is suggested.

Calculation model used in EBGEO (2011)

The vertical stress acting on the soft subsoil by the arching effect,\(\sigma_{s}\), is determined by following equations while the arching efficacy (\(E_{a} )\) could be determined by applying Eq. (3b):

where hg = arching height, sd = diagonal distance between piles, sx and sy = center-to-center pile spacing in directions x and y.

Unlike the BS8006 and NGG methods, which neglected subsoil support, the EBGEO method considers the influence of soft soil bearing between piles by applying a subgrade reaction modulus. A dimensionless design chart can be used to calculate the maximum geosynthetic reinforcement strain, taking into account the relationship between geosynthetic tensile stiffness, soil subgrade response modulus, and total vertical load. The geosynthetic strain value is then substituted into Eq. (5) to obtain the geosynthetic deflection.

3.5 Dutch Design Guideline (CUR 226, 2016)

The Concentric arches model suggested by Van Eekelen et al. (2013) is used in the Dutch Design Guideline CUR 226 for the design of piled embankments. The vertical load calculation is based on a collection of 2D and 3D concentric arches, according to the concentric arches model (Fig. 7). Van Eekelen et al. (2013) describe the concentric arches model in detail. Only the final equation is represented in this paper.

where Pc = load transferred directly to the pile by arching effect (kN), Ps = load resting on the geosynthetic and subsoil (kN); FGRsquare = total vertical load exerted by the 3D hemisphere on their square subsurface (kN); FGRstrip = total vertical load exerted by the 2D arches on the GR strips (kN).

Calculation model used in CUR226 (2016)

The geosynthetic strain for the CUR 226 approach is likewise determined using the dimensionless design chart or a computation spreadsheet, where the geosynthetic deflection is an output from the force balancing equations, similar to the EBGEO method.

4 Numerical Result Discussion

The efficacy and differential settlement are two of the most interesting characteristics for geotechnical engineers in this section, which discusses the load–deflection behaviour of the GRPS embankment.

4.1 Efficacy and Load Transfer Mechanism

Figure 8 depicts the efficacy variation with subsoil stiffness (Ks) and fill soil densities as a function of embankment height. It is worth noting that efficacy rises as embankment height rises, which is consistent with previous research (Le Hello and Villard 2009; Van Eekelen et al. 2013). With increasing subsoil stiffness, however, the effect of embankment height on efficacy becomes less essential. For subsoil stiffness of 0.05 MPa, 0.2 MPa, and 1 MPa, the efficacy is expected to rise by 73%, 63%, and 31%, respectively, when the embankment height (dense soil) is increased from 0.75 m to 3 m. Soil arching is a stress re-distribution phenomenon that is dependent on the shear resistance mobilization of the fill soils. As the height of the embankment rises, more shear resistance accumulates, enhancing soil arching formation and therefore improving efficacy. When the embankment height continues to rise, the efficacy approaches a limiting point (approximately half of the diagonal in this analysis). This trend may be seen in all cases, regardless of the density of the fill soils.

For three distinct geosynthetic tensile stiffnesses, a numerical analysis was performed to investigate the link between efficacy and embankment heights. Figure 9 shows the final results. The efficacy increases with embankment height and is substantially influenced by tensile geosynthetic stiffness, especially for low-height embankments. It enables the explanation of geosynthetics’ unique role. The entire efficacy, which includes efficacy from soil arching and efficacy from the tensioned geosynthetic membrane, is calculated using numerical modelling. Differential settlements are minor for low-height embankments, and they are insufficient to mobilize the soil arching and tensioned geosynthetic membrane effect. Increasing embankment heights, as well as arching and geosynthetic work, to improve the load transfer mechanism onto the embankment. It is also worth noting that, for high embankments, the soil density effect on arching growth becomes more essential, while the role of geosynthetics reduces. For low-height embankments with minimal arching mobilization, the geosynthetic contribution becomes increasingly essential. Furthermore, the stiffness of geosynthetics has a major impact on improving efficacy. When the geosynthetic stiffness is increased from 50 to 6000 kN/m for a 3 m embankment height, the efficacy rises by 36%. Through the tensioned geosynthetic membrane effect, the geosynthetic plays a vital role in boosting the loads transferred onto the pile.

With modifications in embankment height and soil density, Fig. 10 depicts the dependent relationship between efficacy and subsurface stiffness. With increasing subsoil stiffness, efficacy declines in a highly nonlinear relationship. The differential in stiffness between the pile member and the subsoil reduces as the subsoil stiffness increases. As a result, the arching mobilization reduces. On the other hand, increasing subsurface stiffness reduces differential settlements, resulting in a less tensioned geosynthetic membrane effect that transfers loads to piles. These parameters can be used to explain why the efficacy decreases as the subsoil stiffness increases. When the stiffness of the subsoil is increased to 0.5 MPa, which is equivalent to the stiffness ratio between pile and subsoil of 4000 in this analysis, the efficacy approaches a stable value. It's also worth noting that as the density of fill soils and the height of the embankment increase, the effect of subsoil stiffness on efficacy becomes increasingly substantial. The efficacy reduction is projected to be 47% at embankment heights of 0.75 m to 54% at embankment heights of 3 m when subsoil stiffness is increased from 0.01 to 1 MPa.

Because of the unique role of geosynthetics in the load transfer mechanism of the GRPS embankment, its tensile stiffness has a significant impact on efficacy, as illustrated in Fig. 11. It can be shown that as the geosynthetic stiffness grows, the efficacy increases as well, but when the stiffness exceeds 1000 kN/m, the efficacy approaches a constant value. It is important to note that this numerical result agrees well with the conclusions of Pham (2020a, b). The total force operating on the pile, according to Pham (2020a), is caused by two mechanisms: soil arching in the embankment and the tensioned geosynthetic membrane effect. When the tensile geosynthetic stiffness is increased, more load is transferred to the pile by the geosynthetic, but soil arching is reduced. The inverse relationship between arching and geosynthetic membrane effects results in a geosynthetic stiffness critical condition.

4.2 Differential Settlements

The difference in pile and subsurface settling at the pile head level is referred to as differential settlement. As a dependent relationship with the tensile geosynthetic force, differential settling was chosen to be described in this section. Figure 12 depicts the variation in differential settlement with embankment height for various fill soil densities and subsurface stiffnesses. It can be shown that as the embankment height rises, the differential settlement increases dramatically. However, the differential settlement ratio over the embankment height is highly influenced by the stiffness of the subsoil and the density of the fill soils. It also is worth noting that, in the case of loose soils, the differential settlement increases dramatically as the embankment height rises. In the case of dense soil, it is less affected. When the embankment height is increased from 0.75 to 3 m, the increase is projected to be 21.5% for thick soils and 73.5% for loose soils. Another intriguing observation is that the effect of subsurface stiffness on settlement reduction is greater than the density of the fill soil. When fill soils transition from a loose to a dense state, differential settlement is almost constant for large subsoil stiffness. When the subsoil stiffness is increased, less arching occurs. This could explain why the influence of fill soil density on high subsurface stiffness values is insignificant.

The relationship between differential settlements and embankment heights as a function of geosynthetic tensile stiffness variation is shown in Fig. 13. It should be observed that as the geosynthetic stiffness is increased, the differential settling falls dramatically. When comparing high and low-height embankments, the geosynthetic role in settlement mitigation is more essential. The differential settlement is expected to grow by 81 mm when the embankment height is increased from 0.75 to 3 m with a tensile stiffness of 50 kN/m, but only 32 mm at a tensile stiffness of 6000 kN/m. As the embankment height rises, additional stresses act on the subsurface, causing the geosynthetic to be used more extensively to reduce differential settlements. The findings of the investigation reveal that geosynthetics are effective in decreasing embankment differential settlements.

Figure 14 depicts the link between differential settlements and subsoil stiffness when various embankment heights and fill soil density changes are taken into account. Following a very nonlinear relationship, the differential settlement diminishes dramatically as the subsoil stiffness increases. When the subsoil stiffness exceeds 0.2 MPa in this analysis, however, the effect of subsoil stiffness on differential settlement becomes less important. When the subsoil stiffness is increased from 10 to 200 kPa, the differential settlement falls by 94%, while the reduction ratio is only 98.5% when the subsoil stiffness is increased to 1 MPa. The numerical findings further reveal that the influence of subsoil stiffness on differential settlement reduction is greater than the influence of embankment height and fill soil density parameters.

For various embankment heights, Fig. 15 depicts the link between differential settlement and geosynthetic tensile stiffness. It can be shown that as the geosynthetic tensile stiffness is increased, the differential settling falls dramatically. The effectiveness of the geosynthetic in reducing settlement is, however, dependent on the embankment height. A settlement reduction of 30 mm for an embankment height of 0.75 m to 91 mm for an embankment height of 3 m is estimated. Because of the increased differential settlement caused by the higher embankment height, the geosynthetic tension is more mobilized to reduce differential settlements. The results showed that for the design of GRPS embankments, the embankment height and geosynthetic tensile stiffness are the most significant characteristics to consider.

5 Comparison of Numerical and Analytical Models

5.1 Efficacy Comparison

Table 2 shows a comparison of the efficacy of the design methods for the combined effect of subsoil stiffness, soil density, and embankment height. The findings revealed that for all circumstances, none of the chosen design strategies produce outcomes that are in good and consistent agreement with the three-dimensional model results. The efficacy calculated using the NGG approach is independent of embankment height and considerably underestimates efficacy. In GRPS embankments, the NGG approach does not perform well in predicting load distribution. The BS8006 technique also significantly underestimates efficacy in all circumstances, especially for low-height embankments. For the efficacy calculation, the BS8006 approach used the three-dimensional model of Hewett and Randolph (1988). Hewett and Randolph's model failed to satisfy the limit equilibrium condition, which could explain why BS8006's efficacy is so low. Negative numbers can also be reported for very low embankment heights. Because of this constraint, the BS8006 approach is not recommended for low-height embankment design. The EBGEO and CUR226 design approach accords better with the numerical results for accurate prediction than the BS8006 and NGG methods. Unlike the BS8006 and NGG methods, the EBGEO and CUR226 methods take into account an arching critical height as well as the limit equilibrium stress state in the embankment. In order to develop a reliable design technique, these two conditions appear to be essential. The main distinction is that the EBGEO approach uses a multi-arching model, whereas the CUR226 method employs a Concentric arch model.

Table 2 further shows that in the case of low subsoil stiffness (200 kPa/m), all four design methods underestimate efficacy, but overestimate efficacy in the case of high subsoil stiffness (1000 kPa/m). Furthermore, the design approaches accord better with the numerical results for high-height embankments than for low-height embankments, and for dense soils than for loose soils. As a result, it can be stated that as the subsurface stiffness, embankment height, and fill soil density decrease, the prediction performance of analytical methods decreases.

Table 3 compares numerical results and design methods for the combined effect of geosynthetic stiffness, soil density, and embankment height on arching efficacy. Arching is assumed to be independent of geosynthetic stiffness in all known analytical models. As a result, the efficacy derived from all of the specified design methods remains constant as the tensile geosynthetic stiffness increases. The numerical results, on the other hand, demonstrated that efficacy rises as geosynthetic stiffness rises. As a result, as the geosynthetic tensile stiffness increases, the discrepancy between analytical and numerical results becomes increasingly severe.

Table 3 also shows that almost all analytical models treated arching mobilization as a separate mechanism from subsoil settlements. The analytical models did not account for either subsurface stiffness or geosynthetic stiffness when calculating efficacy. As a result, the efficacy estimated from analytical models remains constant as the geosynthetic stiffness increases. When the geosynthetic stiffness is raised, the design methods provide a higher agreement with numerical results, according to the findings. With increasing soil density and decreasing embankment height, the influence of geosynthetic stiffness on analytical model prediction performance becomes increasingly significant.

5.2 Differential Settlement Comparison

Table 4 compares numerical and analytical differential settlements for various embankment heights with fill soil density and subsurface stiffness variations. The BS8006 and NGG approaches for geosynthetic design use a constant geosynthetic strain to calculate differential settlement. It explains why, as the embankment height rises, the vertical displacements obtained from these two methods remain constant. As a result, these approaches are ineffective for predicting GRPS embankment differential settlements. For circumstances when the subsoil stiffness is equal to 200 kPa/m, the EBGEO and CUR226 approaches yield a good agreement with the numerical results. However, when the subsoil stiffness is equivalent to 1000 kPa/m, the findings from these two approaches dramatically overpredict. It was also discovered that as the density of the fill soils increases, the prediction performance of the design methods decreases.

The comparison results in Table 4 further show that as the subsoil stiffness diminishes, the analytical models' performance decreases dramatically. In circumstances where the subsurface stiffness is low, the EBGEO and CUR226 techniques greatly underpredict the differential settlements. For large subsoil stiffness, however, these two techniques produce a better agreement with numerical results. The results also show that the BS8006 and NGG approaches have poor prediction performance, especially when the subsoil stiffness is increased.

When the embankment height changes from 0.75 to 3 m, Table 5 shows a differential settlement comparison of the design approaches for varying geosynthetic stiffness. The EBGEO and CUR226 approaches, according to the findings, show better agreement with numerical data than other methods. The level of agreement between these design methodologies and the numerical model, on the other hand, changes dramatically with embankment height and geosynthetic stiffness. For low embankment heights, there is an underestimation, while for high ones, there is an overestimation. As shown in Table 5, the BS8006 and NGG techniques considerably overestimate differential settlement.

6 Conclusions

The findings of three-dimensional numerical modelling for geosynthetic-reinforced and pile-supported embankments are presented in this work. The research was then broadened to include a comparison of four currently available methods for GRPS embankment design. In this parametric analysis, the subsoil stiffness, geosynthetic stiffness, embankment height, and density of fill soils are all considered. The following are some of the main conclusions:

The numerical results showed that increasing the density of the embankment soils, increasing the geosynthetic stiffness, increasing the embankment height, and decreasing the subsoil stiffness improve the load transfer mechanism effectiveness in GRPS embankments. Current design methods and analytical models, however, frequently overlook the impacts of geosynthetic stiffness and subsoil stiffness on soil arching efficacy. The numerical findings further show that through the geosynthetic tensioned membrane effect, the geosynthetic plays an essential role in boosting the loads transferred onto the piles. The incorporation of geosynthetics reduces differential settlements and the potential of soil giving above the pile heads.

The numerical findings reveal that the parameters under consideration have a substantial impact on the load transfer mechanism and settlement reduction efficiency. The following elements, in descending order, influence the loading efficacy and settlement efficacy of the GRPS embankments: soft soil stiffness, embankment height, geosynthetic stiffness, and embankment soil density, according to this study. With increasing fill soil density and embankment height, the influence of subsoil stiffness on efficacy becomes more substantial. As a result, the effect of subsoil stiffness on arching and settlement prediction in analytical models must be taken into account.

In this paper, the results of the four design methods were compared to numerical modelling. These techniques differ significantly when predicting efficacy and differential settlement, according to the findings. Depending on the geometric properties of the embankments and material properties, all of the selected design methodologies produce over-predictions or under-predictions. When compared to other approaches, the CUR226 method has the best performance in predicting soil arching and geosynthetic deformations.

Data availability

Enquiries about data availability should be directed to the authors.

References

Abusharar SW, Zheng JJ, Chen BG, Yin JH (2009) A simplified method for analysis of a piled embankment reinforced with geosynthetics. Geotext Geomembr 27(1):39–52. https://doi.org/10.1016/j.geotexmem.2008.05.002

Almeida MSS, Hosseinpour I, Riccio M (2013) Performance of a geosynthetic-encased column (GEC) in soft ground: numerical and analytical studies. Geosynth Int 20(4):252–262. https://doi.org/10.1680/gein.13.00015

Anh Tran Q, Villard P, Dias D (2019) Discrete and continuum numerical modeling of soil arching 895 between piles. Int J Geomech 19(2):04018195

Ariyarathne P, Liyanapathirana DS (2015) Review of existing design methods for geosynthetic-reinforced pile-supported embankments. Soils Found 55(1):17–34. https://doi.org/10.1016/j.sandf.2014.12.002

Bathurst RJ, Naftchali FM (2021) Geosynthetic reinforcement stiffness for analytical and numerical modelling of reinforced soil structures. Geotext Geomembr 49(4):921–940. https://doi.org/10.1016/j.geotexmem.2021.01.003

Bhasi A, Rajagopal K (2015) Numerical study of basal reinforced embankments supported on floating/end bearing piles considering pile–soil interaction. Geotext Geomembr 43(6):524–536. https://doi.org/10.1016/j.geotexmem.2015.05.003

BS 8006-1 (2010) Code of practice for strengthened/reinforced soils and other fills. British Standards Institution BSI, London, UK. ISBN 978-0-580-53842-1

Das AK, Deb K (2017) Modeling of stone column-supported embankment under axi-symmetric condition. Geotech Geol Eng 35:707–730. https://doi.org/10.1007/s10706-016-0136-1

Dar LA, Shah MY (2021) Three dimensional numerical study on behavior of geosynthetic encased stone column placed in soft soil. Geotech Geol Eng 39(3):1901–1922. https://doi.org/10.1007/s10706-020-01594-x

CUR 226 (2016). Design guideline basal reinforced piled embankments. In: Design guideline basal reinforced piled embankments. CRC press

EBGEO (2011) Recommendations for design and analysis of earth structures using geosynthetic reinforcements—EBGEO. Digital in English. German geotechnical society, Berlin, Germany

Fattah MY, Majeed QG (2012) Finite element analysis of Geogrid encased stone columns. Geotech Geol Eng 30:713–726. https://doi.org/10.1007/s10706-011-9488-8

Filz GM, Sloan JA, McGuire MP, Smith M, Collin J (2019) Settlement and vertical load transfer in column-supported embankments. J Geotech Geoenviron Eng 145(10):04019083. https://doi.org/10.1061/(ASCE)GT.1943-5606.0002130

Gholaminejad A, Mahboubi A, Noorzad A (2021) Hybrid continuous-discrete modeling of an ordinary stone column and micromechanical investigations. Geotech Geol Eng 39(4):3249–3264. https://doi.org/10.1007/s10706-021-01692-4

Guo X, Pham TA, Dias D (2022) Probabilistic analysis of geosynthetic-reinforced and pile-supported embankments. Comput Geotech 142:104595. https://doi.org/10.1016/j.compgeo.2021.104595

Guo X, Pham TA, Dias D (2023) Multi-objective optimization of geosynthetic-reinforced and pile-supported embankments. Acta Geotech. https://doi.org/10.1007/s11440-022-01782-4

Han J, Gabr MA (2002) Numerical analysis of geosynthetic-reinforced and pile-supported earth platforms over soft soil. J Geotech Geoenviron Eng 128(1):44–53. https://doi.org/10.1061/(ASCE)1090-0241(2002)128:1(44)

Hewlett WJ, Randolph MF (1988) Analysis of piled embankments. Int J Rock Mech Min Sci Geomech Abstr 25(6):297–298

Hong WP, Lee JH, Lee KW (2007) Load transfer by soil arching in pile-supported embankments. Soils Found 47(5):833–843. https://doi.org/10.3208/sandf.47.833

Indraratna B, Ngo NT, Rujikiatkamjorn C, Sloan SW (2015) Coupled discrete element–finite difference method for analysing the load-deformation behaviour of a single stone column in soft soil. Comput Geotech 63:267–278. https://doi.org/10.1016/j.compgeo.2014.10.002

Itasca F (2009) Fast Lagrangian analysis of continua in 3 dimensions, Version 4.0. Minneapolis, Minnesota, Itasca Consulting Group, USA

Jenck O, Dias D, Kastner R (2009) Three-dimensional numerical modeling of a piled embankment. Int J Geomech 9(3):102–112. https://doi.org/10.1061/(ASCE)1532-3641(2009)9:3(102)

Kempfert HG, Gobel C, Alexiew D, Heitz C (2004) German recommendations for soil reinforcement above pile-elements. In: EUROGeo3, third geosynthetic conference, Munchen, vol 1, pp 279–283

Khabbazian M, Kaliakin VN, Meehan CL (2015) Column supported embankments with geosynthetic encased columns: validity of the unit cell concept. Geotech Geol Eng 33:425–442. https://doi.org/10.1007/s10706-014-9826-8

Lai HJ, Zheng JJ, Cui MJ (2021) Improved analytical soil arching model for the design of piled embankments. Int J Geomech 21(3):04020261. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001929

Le Hello B, Villard P (2009) Embankments reinforced by piles and geosynthetics—numerical and experimental studies dealing with the transfer of load on the soil embankment. Eng Geol 106(1–2):78–91. https://doi.org/10.1016/j.enggeo.2009.03.001

Lee T, Van Eekelen SJ, Jung YH (2021) Numerical verification of the concentric arches model for geosynthetic-reinforced pile-supported embankments: applicability and limitations. Can Geotech J 58(3):441–454. https://doi.org/10.1139/cgj-2019-0625

Lo SR, Zhang R, Mak J (2010) Geosynthetic-encased stone columns in soft clay: a numerical study. Geotext Geomembr 28(3):292–302. https://doi.org/10.1016/j.geotexmem.2009.09.015

Low BK, Tang SK, Choa V (1994) Arching in piled embankments. J Geotech Eng 120(11):1917–1938. https://doi.org/10.1061/(ASCE)0733-9410(1994)120:11(1917)

NGG (Nordic Geosynthetic Group) (2005) Nordic guidelines for reinforced soils and fills. Nordic Geosynthetic Group of the Nordic Geotechnical Societies, Nordic Industrial Fund

Pham TA (2022a) Design and analysis of geosynthetic-reinforced and floating column-supported embankments. Int J Geotech Eng 16(10):1276–1292. https://doi.org/10.1080/19386362.2021.1997209

Pham TA (2022b) Micromechanical-based shear strength equation considering the stress-state effect for unsaturated soils. Int J Geomech 22(9):06022022. https://doi.org/10.1061/(ASCE)GM.1943-5622.0002495

Pham TA, Guo X, Dias D (2022a) Internal stability analysis of column-supported embankments: Deterministic and probabilistic approaches. Transp Geotech 37:100868. https://doi.org/10.1016/j.trgeo.2022.100868

Pham TA, Wijesuriya K, Dias D (2022b) Analytical model for the design of piled embankments considering cohesive soils. Geosynth Int 29(4):369–388. https://doi.org/10.1680/jgein.21.00034

Pham TA, Dias D (2022) A simplified model for the analysis of piled embankments considering arching and subsoil consolidation. Geotext Geomembr 50(3):408–431. https://doi.org/10.1016/j.geotexmem.2021.12.003

Pham TA, Tran QA, Villard P, Dias D (2021) Geosynthetic-reinforced pile-supported embankments−3D discrete numerical analyses of the interaction and mobilization mechanisms. Eng Struct 242:112337. https://doi.org/10.1016/j.engstruct.2021.112337

Pham TA, Dias D (2021a) Comparison and evaluation of analytical models for the design of geosynthetic-reinforced and pile-supported embankments. Geotext Geomembr 49(3):528–549. https://doi.org/10.1016/j.geotexmem.2020.11.001

Pham TA, Dias D (2021b) 3D numerical study of the performance of geosynthetic-reinforced and pile-supported embankments. Soils Found. https://doi.org/10.1016/j.sandf.2021.07.002

Pham TA (2020a) Load-deformation of piled embankments considering geosynthetic membrane effect and interface friction. Geosynth Int 27(3):275–300. https://doi.org/10.1680/jgein.19.00030

Pham TA (2020b) Analysis of geosynthetic-reinforced pile-supported embankment with soil-structure interaction models. Comput Geotech 121:103438. https://doi.org/10.1016/j.compgeo.2020.103438

Pham TA (2020c) Behaviour of piled embankment with multi-interaction arching model. Géotech Lett 10(4):582–588. https://doi.org/10.1680/jgele.20.00084

Pham TA (2019) Analysis of soil-foundation-structure interaction to load transfer mechanism in reinforced piled embankments. Aust Geomech J 54(1):85–100

Rui R, Han J, Zhang L, Zhai Y, Cheng Z, Chen C (2020) Simplified method for estimating vertical stress-settlement responses of piled embankments on soft soils. Comput Geotech 119:103365. https://doi.org/10.1016/j.compgeo.2019.103365

Rowe RK, Liu KW (2015) Three-dimensional finite element modelling of a full-scale geosynthetic-reinforced, pile-supported embankment. Can Geotech J 52(12):2041–2054. https://doi.org/10.1139/cgj-2014-0506

Rui R, Ye YQ, Han J, Zhai YX, Wan Y, Chen C, Zhang L (2021) Two-dimensional soil arching evolution in geosynthetic-reinforced pile-supported embankments over voids. Geotext Geomembr. https://doi.org/10.1016/j.geotexmem.2021.09.003

Saboya F, Tibana S, Reis RM, Fonte-Boa T, de Almeida MDSS, Marques MES (2021) Centrifuge modeling of soft soil reinforced with granular columns. Geotech Geol Eng 39(4):2955–2967. https://doi.org/10.1007/s10706-020-01671-1

Schanz T (1999) Formulation and verification of the Hardening-Soil Model. RBJ Brinkgreve, Beyond 2000 in Computational Geotechnics, 281-290. Balkema, USA

Smith E, Bouazza A, King L, Rowe RK (2021) New insights into soil arching behaviour in column supported embankments. Can Geotech J. https://doi.org/10.1139/cgj-2021-0186

Sloan JA (2011) Column-supported embankments: full-scale tests and design recommendations, Doctoral dissertation, Virginia Tech, Blacksburg, Virginia, USA

Tran QA, Villard P, Dias D (2021) Geosynthetic reinforced piled embankment modeling using discrete and continuum approaches. Geotext Geomembr 49(1):243–256. https://doi.org/10.1016/j.geotexmem.2020.10.026

Terzaghi K (1943) Theoretical soil mechanics. John Wiley & Sons, New York, pp 11–15

Van Eekelen SJM, Bezuijen A, Van Tol AF (2013) An analytical model for arching in piled embankments. Geotext Geomembr 39:78–102. https://doi.org/10.1016/j.geotexmem.2013.07.005

Wijerathna M, Liyanapathirana DS (2020) Load transfer mechanism in geosynthetic reinforced column-supported embankments. Geosynth Int 27(3):236–248. https://doi.org/10.1680/jgein.19.00022

Yoo C, Kim SB (2009) Numerical modeling of geosynthetic-encased stone column-reinforced ground. Geosynth Int 16(3):116–126. https://doi.org/10.1680/gein.2009.16.3.116

Yu Y, Bathurst RJ (2017) Modelling of geosynthetic-reinforced column-supported embankments using 2D full-width model and modified unit cell approach. Geotext Geomembr 45(2):103–120. https://doi.org/10.1016/j.geotexmem.2017.01.002

Yapage NNS, Liyanapathirana DS (2014) A parametric study of geosynthetic-reinforced column-supported embankments. Geosynth Int 21(3):213–232. https://doi.org/10.1680/gein.14.00010

Yoo C (2010) Performance of geosynthetic-encased stone columns in embankment construction: numerical investigation. J Geotech Geoenviron Eng 136(8):1148–1160. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000316

Vibhoosha MP, Bhasi A, Nayak S (2022) Analysis of geocell-reinforced stone column-supported embankment considering soil-structure interaction. Transp Infrastruct Geotechnol. https://doi.org/10.1007/s40515-021-00158-7

Zhang Z, Tao FJ, Han J, Ye GB, Cheng BN, Xu C (2021) Arching development in transparent soil during multiple trapdoor movement and surface footing loading. Int J Geomech 21(3):04020262. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001908

Zhuang Y, Wang KY, Liu HL (2014) A simplified model to analyze the reinforced piled embankments. Geotext Geomembr 42(2):154–165. https://doi.org/10.1016/j.geotexmem.2014.01.002

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have not disclosed any competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pham, T.A., Tran, QA., Villard, P. et al. Numerical Analysis of Geosynthetic-Reinforced and Pile-Supported Embankments Considering Integrated Soil-Structure Interactions. Geotech Geol Eng 42, 185–206 (2024). https://doi.org/10.1007/s10706-023-02564-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-023-02564-9