Abstract

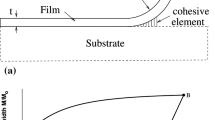

The paper investigates the peel test of an elastic–plastic film on an elastic substrate. The case of a film material presenting a saturation of the yield stress is considered. Based on earlier approaches of the literature, see for instance Kim and Aravas (Int J Solids Struct 24:417–435, 1988), a semi-analytical expression for the work done by bending plasticity is proposed. The validity of the present expression is established based on finite element calculations. It is shown that for the interpretation of the results of peel test at 90\(^{\circ }\) when the peel force and the curvature are measured, the present approach can provide a precise value of the interface fracture energy.

Similar content being viewed by others

References

ABAQUS (2013) Abaqus v6.13 User’s Manual, version 6.13 edn. ABAQUS Inc., Richmond, USA

Aravas N, Kim K, Loukis M (1989) On the mechanics of adhesion testing of flexible films. Mater Sci Eng 107:159–168

Girard G, Jrad M, Bahi S, Martiny M, Mercier S, Bodin L, Nevo D, Dareys S (2018) Experimental and numerical characterization of thin woven composites used in printed circuit boards for high frequency applications. Compos Struct 193:140–153

Hill R (1950) The mathematical theory of plasticity. Oxford University Press, Oxford

IPC (1994) Peel strength of metallic clad laminates, IPC-TM-650 2.4.8, Institute for interconnecting and packaging electronic circuits, www.ipc.org/TM/2.4.8c.pdf

Kendall K (1973) Shrinkage and peel strength of adhesive joints. J Phys Appl Phys 6(15):1782–1787

Kendall K (1975) Thin-film peeling-the elastic term. J Phys Appl Phys 8(13):1449–1452

Kim J, Kim K, Kim Y (1989) Mechanical effects in peel adhesion test. J Adhesion Sci Technol 3:175–187

Kim K, Aravas N (1988) Elastoplastic analysis of the peel test. Int J Solids Struct 24:417–435

Kim K, Kim J (1988) Elasto-plastic analysis of the peel test for thin film adhesion. Trans ASME 110:266–273

Kinloch A, Lau C, JG W (1994) The peeling of flexible laminates. Int J Fract 66:45–70

Martiny P, Lani F, Kinloch A, Pardoen T (2008) Numerical analysis of the energy contributions in peel tests : a steady-state multilevel finite element approach. Int J Adhes Adhes 28:222–236

Moidu K, Sinclair A, Spelt J (1998) On the determination of fracture energy using the peel test. J Testing Eval 26:247–254

Molinari A, Ravichandran G (2008) Peeling of elastic tapes: effects of large deformations, pre-straining, and of a peel-zone model. J Adhes 84(12):961–995

Ortiz M, Pandolfi A (1999) Finite-deformation irreversible cohesive elements for three-dimensional crack-propagation analysis. Int J Numer Methods Eng 44:1267–1282

Rivlin R (1944) The effective work of adhesion. Paint Technol 9:215–218

Song J, Yu J (2002) Analysis of T-peel strength in a Cu/Cr/polyimide system. Acta Mater 50:3985–3994

Thouless MD, Yang QD (2008) A parametric study of the peel test. Int J Adhes Adhes 28:176–184

Tvergaard V, Hutchinson J (1993) The influence of plasticity on mixed mode interface toughness. J Mech Phys Solids 41:1119–1135

Voce E (1948) The relationship between stress and strain for homogeneous deformations. J Inst Metals 74:537–562

Wei Y (2004) Modeling non linear peeling of ductile thin films—critical assessment of analytical bending models using FE simulations. Int J Solids Struct 41:5087–5104

Wei Y, Hutchinson J (1998) Interface strength, work of adhesion and plasticity in peel test. Int J Fract 93:315–333

Wei Y, Zhao H (2008) Peeling experiments of ductile thin films along ceramic substrates—critical assessment of analytical models. Int J Solids Struct 45:3779–3792

Williams J, Kauzlarich J (2005) The influence of peel angle on the mechanics of peeling flexible adherends with arbitrary load—extension characteristics. Tribol Int 38:951–958

Yang QD, Thouless MD, Ward SW (2000) Analysis of the symmetrical \(90^{\circ }\)-peel test with extensive plastic deformation. J Adhes 72:115–132

Yang QD, Thouless MD (2001) Mixed-mode fracture analyses of plastically-deforming adhesive joints. Int J Fract 110:175–187

Zhao H, Wei Y (2007) Determination of interface properties between micron-thick metal film and ceramic substrate using peel test. Int J Fract 144:103–112

Acknowledgements

The authors acknowledge the support of Agence Nationale de Recherche through the program Labcom LEMCI ANR-14-LAB7-0003-01. The research leading to these results has received funding from the European Union’s Horizon 2020 research and innovation programme (Excellent Science, Marie Sklodowska-Curie Actions) under REA Grant Agreement 675602 (OUTCOME project).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A: Derivation of the expression for the work done by bending plasticity

Appendix A: Derivation of the expression for the work done by bending plasticity

The present appendix provides some details concerning the derivation of the expression for the work done by bending plasticity \({\varPsi }\) along the loading path (OABCD). From the elastic response of the film along path (OA), as depicted in Fig. 1b, one obtains based on Eq. (6):

Since for a thin copper film, the curvature \(K_B\) is larger than \(K_e\), one needs to evaluate the contribution to \({\varPsi }\) along (AB). The relationship between the moment M and the curvature K is given by Eq. (10). With the definition \(F\left( -\frac{2 \gamma K}{\sqrt{3}}, \frac{t}{2}\right) {=} -\exp \left( {-}\frac{\gamma K t}{\sqrt{3}}\right) \left( \frac{t\sqrt{3}}{4\gamma K}+\frac{3}{4 \gamma ^2 K^2}\right) \), and with a change of variable \(u=\frac{\gamma K t}{\sqrt{3}}\), one easily gets:

where \(G(x,y) =\frac{\exp (xy)}{y}\). The contribution linked to the term \(F\left( -\frac{2 \gamma K}{\sqrt{3}}, h\right) \) with \(h=\frac{\sigma _o \sqrt{3}}{2 E K}\) is evaluated in a straightforward manner, so the work done by bending plasticity along the path (AB) is:

For the unloading path (BC), the contribution to \({\varPsi }\) is readily obtained:

The last term corresponding to the reverse plastic loading phase (CD) is the most complex contribution. Indeed, the expression of M is given by Eq. (15) where an integral term is already present. In addition, it is related to the position of the elastic–plastic transition surface \(h^{'}\) defined by an implicit relation (13). Therefore one can simply notice that:

where the term I is defined by Eq. (22). As mentioned in Sect. 2, for a metallic film with large values of \(K_B\) and \(\gamma \), the accumulated strain Eq. (14) (resp. \(h^{'}\)) can be approximated as proposed in Eq. (16) (resp. by \(h^{'}= \frac{\sqrt{3} \alpha }{E (K_B-K)}\)). After a standard mathematical development, the integral term I is evaluated and the approximate closed form expression Eq. (23) is found.

Rights and permissions

About this article

Cite this article

Simlissi, E., Martiny, M., Mercier, S. et al. Elastic–plastic analysis of the peel test for ductile thin film presenting a saturation of the yield stress. Int J Fract 220, 1–16 (2019). https://doi.org/10.1007/s10704-019-00393-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-019-00393-7