Abstract

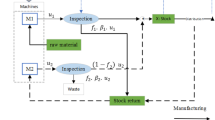

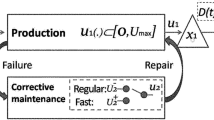

This paper presents an integrated model for the simultaneous production and repair activity planning of a manufacturing system whose performance output is subject to progressive deterioration. In this context, an appropriate joint control strategy is critical to reduce costs and remain competitive. The obtained control policy balances the amount of maintenance activities needed to increase the availability and reduce defects against the increase in the total cost from downtime and deterioration. The production system consists of an unreliable machine that produces one product type and where unmet demand is backlogged. The rate of defects of the machine depends on its level of deterioration, which is defined through a set of multiple operational states and the age of the machine. Additionally, an intensity control model is adapted to define the repair efficiency applied to the system, aiming to mitigate the effect of deterioration that is mainly observed on the failure intensity of the system. The solution is obtained numerically through the formulation of a Hamilton–Jacobi–Bellman equation. A numerical example is provided and an extensive sensitivity analysis is conducted to validate the obtained results.

Similar content being viewed by others

References

Ahmadi R, Newby M (2011) Maintenance scheduling of a manufacturing system subject to deterioration. Reliab Eng Syst Saf 96:1411–1420

Assid M, Gharbi A, Hajji A (2015) Joint production, setup and preventive maintenance policies of unreliable two-product manufacturing systems. Int J Prod Res 53(15):4668–4683

Bock S, Briskorn D, Horbach A (2012) Scheduling flexible maintenance activities subject to job-dependent machine deterioration. J Sched 15(5):565–578

Boukas EK, Hauire A (1990) Manufacturing flow control and preventive maintenance: a stochastic control approach. IEEE Trans Autom Control 33:1024–1031

Colledani M, Tolio T (2011) Integrated analysis of quality and production logistics performance in manufacturing lines. Int J Prod Res 49(2):485–518

Colledani M, Tolio T, Fisher A, Lung B, Lanza G, Schmitt R, Váncza J (2014) Design and management of manufacturing systems for production quality. CIRP Ann Manuf Technol 63:773–796

Colledani M, Horvath A, Angius A (2015) Production quality performance in manufacturing systems processing deteriorating products. CIRP Ann Manuf Technol 64:431–434

Dehayem-Nodem FI, Kenné JP, Gharbi A (2011) Simultaneous control of production, repair/replacement and preventive maintenance of deteriorating manufacturing systems. Int J Prod Econ 134:271–282

Farahani P, Grunow M, Günter HO (2012) Integrated production and distribution planning for perishable food products. Flex Serv Manuf J 24:28–51

Gershwin SB (2002) Manufacturing systems engineering. Massachusetts Institute of Technology, Cambridge, MA

Kellerer H, Rustogi K, Strusevich VA (2013) Approximation schemes for scheduling on a single machine subject to cumulative deterioration and maintenance. J Sched 16(6):675–683

Kenné JP, Dejax P, Gharbi A (2012) Production planning of a hybrid manufacturing-remanufacturing system under uncertainty within a closed-loop supply chain. Int J Prod Econ 1(35):81–93

Khatab A, Ait-Kadi A, Rezg N (2014) Availability optimization for stochastic degrading systems under imperfect preventive maintenance. Int J Prod Res 52(14):4132–4141

Kouedeu AF, Kenne JP, Dejax P, Songmene V, Polotski V (2014) Stochastic optimal control of manufacturing systems under production-dependent failure rates. Int J Prod Econ 150:174–187

Kouedeu AF, Kenne JP, Dejax P, Songmene V, Polotski V (2015) Production and maintenance planning for a failure-prone deteriorating manufacturing system: a hierarchical control approach. Int J Adv Manuf Technol 76:1607–1619

Njike A, Pellerin R, Kenné JP (2009) Simultaneous control of maintenance and production rates of a manufacturing system with defective products. J Intell Manuf 23(2):323–332

Radhoui M, Rezg N, Chebim A (2010) Joint quality control and preventive maintenance strategy for imperfect production processes. J Intell Manuf 21(2):205–212

Rivera-Gómez H, Gharbi A, Kenné JP (2013) Production and quality control policies for deteriorating manufacturing system. Int J Prod Res 51(11):3443–3462

Samet S, Chelbi A, Ben-Hmida F (2012) Optimal preventive maintenance strategy using two repair crews having different efficiencies: a quasi renewal process based modelling approach. Int J Prod Res 50(13):3621–3629

Senanayake CD, Subramaniam V (2013) Analysis of a two-stage, flexible production system with unreliable machines, finite buffers and non-negligible setups. Flex Serv Manuf J 25:414–442

Sethi SP, Thompson GL (2000) Optimal control theory: applications to management science and economics. Kluwer Academic, Dordrecht

Shamsaei F, Van-Vyve M (2016) Solving integrated production and condition-based maintenance planning problems by MIP modeling. Flex Serv Manuf J 2:184–202

Tsao YC, Chen TH (2011) A production policy considering reworking of imperfect items and trade credit. Flex Serv Manuf J 23:48–63

Yulan J, Zuhua J, Wenrui H (2008) Multi-objective integrated optimization research on preventive maintenance planning and production scheduling for a single machine. Int J Adv Manuf Technol 39:954–964

Author information

Authors and Affiliations

Corresponding author

Appendix: Optimality conditions

Appendix: Optimality conditions

The value function \(V(\alpha ,x,a)\) defined in Eq. (17) provides the viscosity solution that satisfies the HJB Equations (18). The relevance of Eq. (18) is that it defines the optimality conditions of the model that are necessary and sufficient for an optimum. The HJB equations can be derived by the principle of optimality: if \(V(\cdot,t)\) denotes a cost-to-go function at time t, then the value function \(V(\alpha ,x,a)\) between t and \(t + \delta t\) can be replaced by:

Since the integral in the interval \(\left[ {t,\infty } \right]\) is the value function, we obtain the one-step counterpart of \(V\left( {\alpha \left( t \right),x\left( t \right),a\left( t \right),t} \right)\) in the interval \(\left[ {t,t + \delta t} \right]\) for transforming the discount rate \(\rho\).

The variables \(u\left( s \right)\) and \(v\left( s \right)\) are treated as constants in the interval \(t \le s \le t + \delta t\). We can further reduce Eq. (32) if we use the conditional expectation operator \(\tilde{E}\). For instance, for any function \(H\left( \alpha \right)\), the operator \(\tilde{E}\) is defined as follows:

Therefore, upon using the conditional expectation operation \(\tilde{E}\) we obtain Eq. (34):

We can expand the conditional expectation in Eq. (34), with the following expression:

The second term in Eq. (34) denotes the derivative of \(V\left( {\alpha ,x,a} \right)\), so its full derivative can be applied. Thus, after some transformations we get:

In Eq. (36) the expectation symbol is replaced by the summation term. Moreover, we can replace \(\delta x\left( t \right)\) by \(\delta x\left( t \right) = \dot{x}\left( t \right)\delta t\) and \(\delta a\left( t \right)\) by \(\delta a\left( t \right) = \dot{a}\left( t \right)\delta t\), so that after some standard transformations we have:

By considering that a steady-state distribution exists for α and that \(V\left( {\alpha ,x,a,t} \right) \to V\left( {\alpha ,x,a} \right)\) and \(\partial /\partial t \to 0\) as \(t \to \infty\), we finally obtain the so-called Hamilton–Jacobi–Bellman (HJB) equations:

Equation (38) can be further simplified:

The minimization of \(u\left( t \right)\) is performed in the \(n\) operational states, the repair efficiency is determined in the failure mode and \(\varphi \left( {\xi ,a} \right)\) denotes the reset function that describes the benefit of the repair.

The control polices obtained from Eq. (39) are optimal, since the HJB Equations are a sufficient condition for optimality, as indicated by Gershwin (2002) and Sethi and Thompson (2000).

Rights and permissions

About this article

Cite this article

Rivera-Gómez, H., Lara, J., Montaño-Arango, O. et al. Joint production and repair efficiency planning of a multiple deteriorating system. Flex Serv Manuf J 31, 446–471 (2019). https://doi.org/10.1007/s10696-018-9313-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10696-018-9313-2