Abstract

With the rapid urbanization and development of metropolises, urban road tunnels have been constructed at an increasing rate, significantly alleviating urban traffic pressure, and improving urban resilience. Fire hazards have become a major threat to modern road tunnels due to the growing popularity of electric vehicles and high-density transportation of goods, particularly flammable materials. Asphalt pavements, as an essential component of road tunnels, may release harmful effluences and smoke under high temperatures, exacerbating the fire and adding risk to life safety. It is hence critical to investigate fire-retarding asphalt materials and their potential use in urban road tunnels pavements. This paper provides a comprehensive review of fire-retarding asphalt pavements for urban road tunnel pavements. The review covers tunnel fire generation mechanisms, evaluation methods, flame retardants for asphalt pavements, and recent developments in flame retardant technologies. By investigating these aspects, this paper aims to better understand the flammability of asphalt mixtures and asphalt pavements in urban road tunnels, promote the research of flame-retardant technology, and ultimately reduce the damage and loss caused by asphalt road tunnel fire accidents. Additionally, this study identifies the limitations of current research and provides an outlook for future research to contribute to the resilience of urban road tunnel structures and the longer service life of asphalt pavement in semi-closed road tunnels.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The rapid development of metropolises and urbanization has created numerous challenges for contemporary cities, including a shortage of land resources, traffic congestion, and high-density buildings [1,2,3]. In some international mega-cities like Shanghai and New Delhi, these problems are particularly acute, as the urban construction area is projected to expand much more quickly (276% by 2030) than population growth (66% by 2030) [4]. These issues exacerbate the trade-off between population growth and land resources and contribute to increased carbon emissions. As a result, there is a need to explore alternative living spaces and resources. One approach to alleviate urban traffic pressure, resolve long-term traffic congestion problems, and improve urban resilience is to develop underground transportation space, such as constructing urban road tunnels [5, 6]. Asphalt pavement is an essential component of urban road tunnels, particularly in China, where asphalt pavement constitutes 90% of the total pavement structures, and in the USA, where over 94% of pavements are surfaced with asphalt or bituminous mixtures [7,8,9,10]. Asphalt pavement is favored for its good skid resistance, low noise, and ease of rehabilitation and maintenance compared to cement concrete pavement [11]. However, as urban road tunnels increase in length, burial depth, and diameter, asphalt pavement’s flammable nature presents a potential safety risk during a fire accident [12,13,14,15].

Asphalt is a complex hydrocarbon mixture that is flammable, and its volatile content increases with temperature due to its combustible nature [16, 17]. As shown in Figure 1 [18, 19], the sharp temperature rise in the tunnel fire can cause pyrolysis and burning of asphalt, producing toxic volatile substances and fumes that hinder evacuation and rescue processes [20]. The fire in the road tunnel creates a complex environment involving chemical reactions, turbulence, and radiation that are influenced by various parameters such as geometry, tunnel slope, ventilation velocity, sidewall restriction, and passing air pressure [21, 22]. Additionally, the toxic fumes distributed throughout the tunnel can be more harmful than the fire itself [23,24,25]. As shown in Figure 2, exposure to complex volatile organic compounds (VOCs) will cause headaches, nausea, vomiting, fatigue and other serious symptoms in body health [26]. The aforementioned facts necessity the need to understand the pyrolysis of asphalt, the combustion behavior of bituminous mixtures, and the release of hazardous fumes. Therefore, research on the measurement, emission characteristics, and control methods of emissions generated from asphalt pavements in urban road tunnels during a fire is currently receiving significant attention.

Road tunnel fires are low-probability but high-consequence incidents [18, 27,28,29,30]. To minimize the impact of fire accidents in road tunnels, fire-retarding or fire-proof asphalt pavement has been investigated since the 1950s [31]. The fire-retarding mechanisms typically fall into three categories: free radical, physical covering, and thermal barrier mechanisms. Researchers have also explored various flame-retardant additives for road asphalt pavement [11, 32]. However, evaluating the effectiveness of these materials for urban road tunnels is challenging due to the unique semi-closed environment. Therefore, there is an urgent need to develop safe and effective fire-retarding asphalt materials, evaluation methods, and standards for road tunnel fire safety. Despite the importance of this topic, limited research is available to provide a comprehensive review and systematic summary.

To fill the research gap, this paper aims to enhance our understanding of the flammability of asphalt mixtures and asphalt pavement in urban road tunnels, and to promote the development of flame-retardant technology for road tunnel asphalt pavement. By doing so, the damage and loss caused by asphalt road tunnel fires can be minimized. The paper provides a comprehensive and detailed review of fire-retardant asphalt pavement for urban road tunnels, covering various topics. Firstly, the paper presents a brief introduction to the mechanism and combustion behaviors of urban road tunnel fires, setting the stage for a review of existing measures to improve the fire resistance of asphalt pavement. The paper then delves into various evaluation methods of flame retardancy, as well as a thorough discussion of the existing development of fire-retardant technology for urban road tunnel asphalt pavement. Additionally, the paper explores the feasibility of using nanotechnology to enhance the fire retardancy of road tunnel asphalt pavement. Finally, the paper concludes with a summary of current research limitations and recommendations for future research directions. To provide an overview of the topics covered, Figure 3 presents a clear framework for this comprehensive review.

2 Urban Road Tunnel Fire

2.1 Mechanisms of Road Tunnel Fire

Road tunnel fires are primarily caused by vehicle combustion resulting from collisions and rollovers (e.g. rear-end and side-impact collisions) as well as spontaneous combustion [15]. Studies have shown that asphalt mixtures are less prone to burning due to their high proportion of inert aggregates [33, 34]. As shown in Figure 4, the combustion process in a road tunnel primarily involves the burning of solid and liquid materials. The leakage of liquid fuels such as gasoline, diesel, and lubricating oil can cause fires to spread to nearby vehicles, becoming uncontrollable. Moreover, burning fuel that spreads on the ground may ignite bituminous pavement. Table 1 provides a summary of critical road tunnel fire accidents and their causes in China over the past two decades.

Combustion of a vehicle in a road tunnel [19]

2.2 Characteristics of Road Tunnel Fires

The semi-enclosed environment of a road tunnel can lead to the accumulation of smoke and heat, which can cause heavy smoke, low visibility, and high temperatures. These factors can greatly impede escape and rescue efforts [18, 40]. The typical characteristics of a road tunnel fire can be summarized as follows:

-

(1)

Road tunnel fires occur randomly in terms of time and location.

-

(2)

Low visibility is expected due to the fast generation of smoke and fumes in the enclosed space of a road tunnel.

-

(3)

Rescue efforts can be extremely challenging due to the large amount of harmful and poisonous smoke and fumes generated by the fire, which can spread rapidly. Furthermore, firefighting equipment may have difficulty reaching the accurate location of the fire, and the flames can easily spread from vehicle to vehicle due to fiery air flows, making firefighting efforts even more challenging.

2.3 Combustion Behavior of Road Tunnel Asphalt Pavement

As previously mentioned, the leakage of liquid fuels can exacerbate the fire by heating and igniting the asphalt pavement. Figure 5 depicts the development of asphalt pavement burning in the urban road tunnel fire. The high temperature near the fire location initiates pyrolysis reactions in asphalt, resulting in the production of a large amount of flammable and toxic gas products. The combustion of flammable gases produces heat, which intensifies the burning of asphalt and leads to the release of additional heat and toxic fumes [41, 42]. Furthermore, the negative impact on the ecological environment and human health resulting from the fume toxicity can impede the escape of trapped individuals and make rescue operations more challenging, as depicted in Figure 6.

Main process of asphalt pavement burning in a road tunnel fire [43]

During a road tunnel fire accident, heated and ignited asphalt pavement induces volatile substances and smoky particles (fumes), as shown in Figure 7 [50, 51]. Volatile substances are semi-volatile vapor-phase compounds, while asphalt fumes are aerosol-phase particles. When asphalt is heated, heating asphalt leads to the release of a range of volatile substances, including inorganic gases, suspended particles, VOCs, and condensed vapors. Additionally, asphalt fumes and similar emissions (such as smoke, gas, VOCs, aerosols, and mists resulting from their condensation after volatilization) can be highly odorous and potentially harmful. Asphalt VOC is comprised of a mixture of alkanes, sulfur hydrocarbons, polycyclic aromatic hydrocarbons, benzopyrene, anthracene, naphthalene, acridine, pyridine, and phenols.

3 Evaluation Methods for Flame Retardancy of Asphalt Materials

The investigation into evaluation methods for measuring flame retardancy in asphalt materials is crucial to ensure their suitability and accuracy, thereby enhancing the safety of road tunnels. Currently, there are two main categories of evaluation methods for assessing asphalt flame retardancy: equipment-based methods, including the flash point test, oxygen test, cone calorimeter (CCA), mass spectrometry (MS), and analytical methods such as Fourier transform infrared spectroscopy (FTIR), gas chromatography (GC), and thermogravimetric analysis (TGA) [52]. This section aims to provide a comprehensive overview of testing methods for fire-retarding asphalt materials, offering a reference and guideline for future experimental programs.

3.1 Flash Point Test

The flash point test measures the temperature at which asphalt continues to burn for more than 5 s, according to the JTG E20-2011 (Chinese Standard). A higher flash point indicates better flame retardancy. This test is typically used to assess the safety of asphalt during storage, delivery, and pavement construction.

3.2 Oxygen Test

The oxygen test, conducted according to the ASTM D-2863 standard, is used to evaluate the burning capacity of asphalt. The Limited Oxygen Index (LOI) is used to assess the effectiveness of flame retardants and the intrinsic flammability of the source materials. The LOI (see Equation 3-1) indicates the minimum oxygen concentration required for burning, based on the volume of oxygen and nitrogen at critical oxygen concentration.

where [O] represents the volume of oxygen at critical oxygen concentration and [N] represents the volume of nitrogen at critical oxygen concentration.

The sample size used in the oxygen test is typically 100 mm × 10 mm × 6 mm, as shown in Figure 8. The LOI value indicates the minimum concentration of oxygen required for burning, with higher values indicating better intrinsic fire resistance. Materials with an LOI value lower than 22% are considered flammable, while those with an LOI value above 27% are considered flame-retardant. For materials falling within the intermediate LOI range of 22%–27%, such as this modified asphalt, combustion is difficult to achieve [53].

Oxygen test: (a) oxygen index apparatus; (b) standard sample; (c) burning sample [17]

3.3 Vertical and Horizontal Flammability Test

The UL 94 standard includes both vertical and horizontal flammability tests to measure the self-extinguishing time of asphalt specimens in each orientation. These tests evaluate the burning and afterglow times, as well as the dripping of the burning specimen. Table 2 provides the evaluation criteria for assessing asphalt’s performance under fire conditions in a road tunnel. There are three classifications for flammability, known as V-0, V-1, and V-2. The V-0 rating indicates that the flame must extinguish within 10 s and there should be no dripping during the test. The V-1 rating requires that the flame extinguishes within 30 s, with no dripping allowed. The V-2 rating permits dripping during the test, but the flame must extinguish within 10 s. These ratings are used to assess the flammability of materials and are commonly referenced in safety standards and regulations.

3.4 Cone Calorimeter Apparatus (CCA)

The cone calorimeter (CCA) is a bench-scale apparatus for combustion testing based on the principle of oxygen consumption and is a modified form of a truncated cone heater. The CCA test is conducted according to ASTM E-1354 Standard [57,58,59], as shown in Figure 9. The standard specimen size for CCA testing is 10 × 10 × 5 cm3. The asphalt specimen is wrapped in aluminum foil, leaving only the top surface exposed. The top surface is then ignited with a spark igniter, causing the specimen to pyrolyze and release volatile substances [60]. To evaluate the combustion behavior of asphalt, the heat release rate (HRR) is analyzed under various thermal radiation conditions, which is influenced by the concentration of oxygen required for combustion. In addition to HRR, the Cone Calorimeter Apparatus (CCA) test provides valuable data on smoke parameters such as specific extinction area (SEA), smoke production rate (SPR), total smoke production (TSP), and the volume of carbon monoxide (CO) and carbon dioxide (CO2) emitted during combustion [50, 51]. The CCA test can be used to simulate the combustion of asphalt in an enclosed environment, making it a suitable method for evaluating the behavior of asphalt during a road tunnel fire.

Compared to traditional methods such as the flash point test and oxygen test, the CCA test has several advantages, particularly when it comes to evaluating the behavior of asphalt during a road tunnel fire. The CCA test can provide a more comprehensive set of evaluation indicators all at once, as well as a more practical simulation of the road tunnel fire scenario. Furthermore, the quantitative results obtained from the CCA test can be used for further analysis and applied to theoretical models, providing a more nuanced understanding of the behavior of asphalt during a fire.

3.5 Fourier Transform Infrared Spectroscopy (FTIR)

Given the complex and rapidly changing chemical reactions and concentrations of fire effluences induced by asphalt during a road tunnel fire, it is critical to use a highly sensitive and accurate test method to analyze their composition. FTIR gas analysis can effectively address these issues by detecting the components of fire effluences and their concentration changes. Moreover, FTIR can capture spectral information of previously unknown components, providing valuable insights into their toxicity. Previous studies have used FTIR to analyze burning asphalt, and Table 3 summarizes the parameters of FTIR tests.

Many researchers have recently used FTIR to investigate flame-retardant asphalt [72,73,74,75] However, there have been limited studies using FTIR to analyze the toxicity of road tunnel pavement during burning. Nowadays, FTIR coupled with DSC curves is a popular technique used to study the main representative volatiles such as CO, CO2, SO2, and CH4. The concentration of these compounds can be calculated based on the absorption peak area corresponding to the temperature of the maximum exothermic peak. In addition, TG-FTIR analysis is a widely used method to study the thermal decomposition of asphalt materials, as illustrated in Figure 10. The sample is heated uniformly under controlled conditions, and TGA records the mass loss of the sample, which provides information about the composition of volatiles and inert fillers. The evolved gases are analyzed using FTIR spectroscopy in a beam-conforming flow cell, where the FTIR molecular fingerprinting detects different components. By collecting and processing the FTIR spectra, TG coupled with FTIR spectroscopy can identify gases released during sample decomposition, such as volatile compounds, solvents, and polymers [76]. To evaluate the volatile releasing characteristics, TG/derivative TG (DTG)-FTIR can be used. This technique allows for the real-time measurement of various gas compounds released during the pyrolysis process by detecting the characteristic absorption peaks of functional groups in the evolving gaseous volatiles. In addition, it enables the identification and quantification of volatile compounds released during the thermal degradation of materials. TG-FTIR has proven to be a useful tool in the analysis of thermal degradation of materials and gas evolution, as reported by previous studies [77, 78]. Furthermore, studies have shown the usefulness of TG-FTIR analysis in determining the weight loss of pyrolysis behavior and species of various gas compounds [67, 69, 77].

Typical TG-FTIR analysis system [79]

3.6 TG-MS and GC-MS Methods

Asphalt emissions can be quantified using either gravimetric or gas chromatography methods. TG-MS, a technique that has been used since the 1990s, allows for the investigation of thermal decomposition components and combustion behavior of polymer materials [80,81,82,83]. The combination of different analytical methods can facilitate the analysis of thermal compositions and concentrations of fire effluences released during the burning of asphalt and asphalt mixtures in road tunnels. The typical TG-MS analysis system is shown in Figure 11, and it can calculate the mass change of testing materials during thermal decomposition and combustion while measuring the volatiles released during the heating process [84,85,86].

Typical TG-MS analysis system [87]

Pyrolysis GC-MS analysis is another effective method to characterize the VOC emissions from burning asphalt. The typical GC-MS analysis system, as shown in Figure 12, can provide both quantitative and qualitative identification of VOCs present in asphalt [88].

Typical pyrolysis GC–MS analysis system [79]

This section emphasizes the significance of investigating evaluation methods for measuring the flame retardancy of asphalt materials. The importance lies in ensuring that these methods are suitable and accurate, as their results directly impact the safety of road tunnels. Given the potential risks associated with fires in tunnels, it becomes essential to have reliable techniques that can effectively assess the flame-retardant properties of asphalt materials. This section also highlights the two main categories of evaluation methods currently used for this purpose—equipment methods and analytical methods. By providing a comprehensive overview of these testing methods, the paragraph aims to offer a reference and guideline for future experimental programs in this field. In summary, this section underlines the importance of determining suitable and accurate evaluation methods to enhance the safety of road tunnels, specifically by evaluating the flame retardancy of asphalt materials.

4 Measures to Improve the Fire Resistance of Asphalt Pavement

Existing literature has identified three critical categories of methods to enhance the fire resistance of asphalt pavement in urban road tunnels, by (1) strengthening the fire resistance of the asphalt source, (2) implementing measures to control the source (asphalt in this study) of tunnel fires, and (3) selecting suitable asphalt mixture types.

4.1 Fire-Retardant Mechanism of Asphalt

Mitigating losses and saving lives after a tunnel fire requires reducing the rate of asphalt combustion and the resulting effluences [89, 90]. Asphalt is a highly complex substance composed mainly of Saturates, Aromatics, Resins, and Asphaltenes (SARA), as illustrated in Figure 13a. The combustion of asphalt binder produces numerous combustible gases, and the volatiles released during each burning stage of the SARA fraction consist of different gaseous products and hydrocarbon compounds. Consequently, the fire effluences released from each SARA fraction differ. Nonetheless, CO2 and H2O typically constitute the two primary products of SARA fractions in various combustion sections, as demonstrated in Figure 13b. Due to the complex interplay between endothermic volatilization and exothermic reaction, the morphologies of the burning residues of the SARA fractions are diverse, as illustrated in Figure 13c. Saturates, aromatics, and resins are primarily composed of carbon, oxygen, and a few heteroatoms, while asphaltenes contain less carbon and more oxygen and heteroatoms. The sulfur content of asphalt increases from asphaltenes to saturates [91], emphasizing the importance of studying the fire-retardant mechanism of asphalt. Popular current flame-retarding mechanisms include the free radical mechanism, physical covering mechanism, and thermal barrier mechanism [63, 92, 93].

4.2 Measures to Control the Source (Asphalt in This Study) of Tunnel Fires

4.2.1 Free Radial Mechanism

The free radical mechanism for flame retardation is based on the chain reaction theory of combustion, which requires the presence of free radicals to sustain the combustion process [93]. Materials containing halogens can interrupt the gas-phase combustion zone by capturing free radicals in the combustion reaction, inhibiting the flame from spreading and lowering its density in the combustion zone. This action eventually leads to slowing down the combustion reaction until it comes to a halt. The mechanism relies on a series of chain reactions that happen in the flame, as shown in the following formulas:

At elevated temperatures, the halogen-containing material breaks down and liberates HX (where X represents halogen), which interacts with the free radicals in the fire according to the following equations:

4.2.2 Physical Covering Mechanism

The physical covering mechanism aims to insulate the contact between asphalt and oxygen and can be accomplished by utilizing gas-phase and solid-phase fire retardant materials. Gas-phase fire retardants create non-combustible gases such as CO2, NH3, HCl, and HBr upon heating, which decreases the concentration of combustible gases and oxygen in the combustion zone [95]. Additionally, organic halogen compounds release HX, which is heavier than air, when heated. This forms a protective layer that reduces the burning rate of the material. Conversely, solid-phase fire retardants produce a non-combustible carbonized film or glassy foam when heated. This film or foam covers the surface of the flammable asphalt and blocks the contact between oxygen and combustibles. It also prevents the escape of combustible gases, achieving flame retardancy [96].

4.2.3 Thermal Barrier Mechanism

Additives can help reduce the impact of tunnel fires by absorbing some of the heat generated during combustion. This results in lower temperatures on the asphalt surface, less flammable gases, and fewer toxic emissions. For instance, Mg(OH)2, Al(OH)3, and layered double hydroxide (LDH) can be heated to a specific temperature and decomposed to produce water, which is an endothermic reaction that can absorb heat and slow down the rate of temperature rise. These mechanisms aim to achieve flame retardancy.

The free radical mechanism and physical covering mechanism can work together to prevent combustion during the early stages. Halogen-containing materials can capture free radicals, and solid-phase fire retardants can produce a non-combustible film or foam to block oxygen’s contact with flammable asphalt. As combustion progresses, the thermal barrier mechanism becomes more effective in slowing down the process. Therefore, the three mechanisms can work synergistically to achieve flame retardancy [97, 98].

4.3 Fire-Retardant Asphalt Mixtures

The behavior of volatiles in bituminous mixtures after exposure to fire is influenced by various factors [99]. Table 4 presents the characteristics of typical asphalt mixtures, where hot mix asphalt (HMA) is found to have the worst performance in terms of gas emissions under fire, while grouted macadam (GM) shows better performance compared to HMA [32]. This is mainly due to the higher content of asphalt in HMA, which undergoes incomplete combustion, resulting in a larger amount of CO. In contrast, GM burns without a flame and produces less CO due to the relatively lower content of asphalt and the influence of the cement mortar coating. There is little difference in fire effluence production between open-graded and dense-graded mixtures [51]. In addition, the asphalt mixture plays a significant role in controlling smoke emissions during fire, as observed by Bonati et al. [50, 51]. Figure 14 displays the RSR curves of open-graded and dense-graded asphalt mixtures, revealing that the former exhibits a later and higher peak compared to the latter. The open structure of open-graded mixtures allows for fuel leakage and can contribute to fire propagation. However, Tao [100] proposes a different viewpoint, suggesting that open-graded friction course (OGFC) asphalt can aid in flame retardancy due to its high air void content that provides an escape route for flammable liquids and greases, reducing economic and personnel losses. Similarly, the GM or Combi-layer, which is an open bituminous mixture filled with cement mortar (with a void content of 30%), is utilized on tunnel pavement to prevent fire. By enveloping the aggregates with asphalt, the cement mortar limits the contact of the asphalt with fire, thereby increasing the material’s thermal inertia [32, 101]. Apart from HMA, warm mix asphalt (WMA) has gained popularity in recent years due to its lower compaction temperature than traditional hot mix asphalt (HMA). According to research by Xiao et al. [56] WMA is considered a promising pavement surface material for road tunnels. Furthermore, studies by Li et al. [17] have shown that WMA produces significantly less CO2 and CO under fire conditions compared to HMA. The addition of flame retardant and warm mixing agents in WMA has also been shown to have a synergistic effect on reducing smoke production. These findings highlight the potential benefits of using WMA in tunnel construction to improve safety and reduce environmental impact.

Typical RSR curves of the open-graded and dense-graded mixes [104]

5 Development of Fire-Retardants for Urban Road Tunnel Asphalt Pavement

5.1 Development of Asphalt Fire Retardants

To enhance the ability of bituminous pavements in road tunnels to resist fires, one of the most frequently utilized methods is the addition of flame-retardant additives to asphalt binders or mixtures. This approach is preferred due to the high cost of producing fire-resistant materials with high thermal oxygen stability [19, 44]. Flame retardants can be divided into two primary types: additive and reactive flame retardants. Additive flame retardants can be inorganic, halogenated, phosphorus-based, or nitrogen-based, while reactive flame retardants include organophosphorus monomers containing reactive functional groups and organic halides [104]. Table 5 summarizes the main classifications of flame retardants. By adding an appropriate amount of flame retardants, the flammability of asphalt pavements in road tunnels can be reduced, and the spread of fire can be slowed down, thereby minimizing the production of smoke. Flame-retardant asphalt materials were first introduced in the 1950s, and significant advancements in flame-retardant technology for bituminous pavements were made in Europe and the United States during the 1980s [85, 107, 108]. Figure 15 illustrates the development of asphalt fire retardants.

Development of asphalt flame retardants [19]

Road tunnel fires can cause significant casualties, with toxic smoke and effluences from burning asphalt pavements being the main culprits. As a result, the primary goal of using flame-retardant pavement in urban road tunnels is to limit smoke generation from burning asphalt materials and minimize the amount of combustion effluences produced by burning asphalt pavements. The preparation parameters for flame-retarding asphalt are detailed in Table 6.

In the past, halogenated flame retardants were commonly used to enhance the fire resistance of asphalt materials. However, their incomplete combustion often led to increased amounts of CO and smoke, which made them unsuitable for use [117]. Nowadays, the focus is on fire safety and environmental protection, which has led to a shift towards non-toxic and environmentally friendly flame retardants. In China, the majority of flame retardants used for asphalt materials are still low-efficiency and toxic products. However, research and development of green flame retardants for urban tunnel asphalt pavements is gaining momentum. Inorganic halogen-free flame retardants, such as smoke-reducing fillers, are becoming popular [99]. Specifically, for asphalt pavements in urban road tunnels, the emphasis is on resource-rich, cost-efficient, green, and highly thermally stable products.

5.2 Current Development of Fire Retarding Asphalt Materials

The current research status of asphalt flame-retardant technology in urban road tunnels involves ongoing efforts to develop and improve flame-retarding additives for asphalt pavements. Researchers are exploring various chemical compounds and nanomaterials to enhance the flame resistance of road tunnel asphalt pavements. Recently, a polymer flame retardant called brucite, which is halogen-free, has been used to improve the fire resistance of asphalt materials. Brucite is highly effective at suppressing smoke and has excellent thermal stability [118]. Alumina trihydrate (ATH) coupled with LDH has also shown great potential as a fire retardant for asphalt materials. According to experimental results, the combination of ATH and LDH has significantly reduced fire effluences and the release of aldehydes, CO, and methane [116, 119, 120]. Organic-modified montmorillonite (OMMT), which is the primary component of layered silicates, has also been applied to asphalt materials due to its superior ability to control flame effluences and fire retardancy, as demonstrated in Figure 16 [121,122,123,124,125,126,127]. Yang et al. [128] conducted LOI and SEM tests to investigate the flame retardancy and mechanism of the ATH/OMMT composite asphalt mixture, as shown in Figure 17. The results indicate that the combination of ATH and OMMT improves the strength and compactness of the composite-modified asphalt carbon layer and enhances its flame-retardant performance due to the favorable synergistic effect between OMMT and ATH. [66]. Nanoclays have also been validated for their ability to reduce VOC emissions [104].

Flame retardant performance test for ATH/OMMT modified asphalt materials [128]

Tables 5 and 7 compare the flame retardant ability of different compositions and properties, suggesting that there is variability in the effectiveness of various flame retardants [131]. In a study conducted by Sheng et al. [132], four flame retardant components, namely, expandable graphite (EG), magnesium hydroxide (MH), calcium hydroxide (CH), and ammonium polyphosphate (APP), were evaluated for their potential as flame retardants for asphalt pavements in tunnels. The results indicated that a flame-retardant composite with a silane coupling agent (FRC-Si) could effectively reduce the amount of heat and carbon monoxide released during combustion, as well as delay the release of CO, indicating that it has the potential to be used as a flame retardant in asphalt pavements, as shown in Figure 18. Nan and Yu [60] found that LK had good fire effluence suppression ability and reduced the release of CO and CO2 during the combustion of modified asphalt. Zhu et al. [70, 114] compared the smoke emission suppression ability of LS, HL, and MH-modified asphalt materials and found that MH exhibited the best flame-retardant ability, forming a barrier layer that protected the asphalt. However, in the later stages of combustion, the MH-based protection layer was destroyed, and an intensified flame occurred, leading to increasing RSR values. HL, on the other hand, contributed to forming an inert layer of CaCO3 on the asphalt, which delayed its burning and inhibited smoke emissions. The inert layer also isolated the heat transfer from asphalt to the external environment, thereby slowing down and reducing smoke release during asphalt burning. To improve the fire resistance of asphalt pavement during a fire accident in urban road tunnels, metal hydroxides have been used as fire retardants. Camino et al. [133] and Wilkie et al. [134] found that the carbon generated from the breakdown of polymers can be deposited on an oxide formed through the decomposition of metal hydroxides. This process prevents the release of smoke by causing the carbon to evaporate as CO2.

Total (a) heat release rate (b) carbon monoxide curves of BS, FRC, and FRC-Si mixtures [132]

Flame retardants play a critical role in suppressing combustion and reducing the amount of smoke generated during fire incidents. In the future, the development of flame retardants for asphalt pavement in urban road tunnels should focus on the following aspects:

-

(i)

High efficiency in controlling asphalt combustion to prevent or minimize the spread of flames;

-

(ii)

Stable thermal performance and good temperature compatibility with asphalt and mixtures to ensure the effectiveness of the flame retardants during extreme temperatures;

-

(iii)

Long service life and no harmful effluences released to minimize the environmental impact;

-

(iv)

High-cost efficiency and environmentally friendly to ensure sustainability and affordability.

By developing flame retardants that meet these requirements, the fire safety of urban road tunnels can be significantly improved, protecting both human lives and the environment.

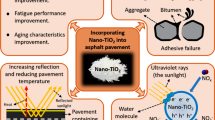

6 Nanotechnology to Strengthen the Fire Retardancy of the Asphalt Pavement in Road Tunnels

The microstructures of asphalt pavement materials, particularly at the micron and nano scales, are crucial to the overall performance of asphalt pavements [135,136,137,138,139,140]. To meet the demands of increasing traffic and rapid urbanization, nanomaterials with a dispersed phase size of less than 100 nm in at least one dimension have been employed to improve the fire resistance of asphalt pavement. Previous studies have classified these nanomaterials into three categories based on their dimensions: zero-dimensional, one-dimensional, and two-dimensional [56, 141,142,143]. Table 8 provides an overview of the typical nanomaterials used to enhance flame retardancy and suppress the smoke release of asphalt materials in asphalt pavements.

The use of zero-dimensional nanomaterials in fire retarding asphalt pavement can be effective due to their small size and large specific surface area, which allows for a good adsorption effect on smoke molecules and light components, leading to fume suppression. For instance, Cui et al. [144] found that the addition of 6 wt% nano calcium carbonate to SBS-modified asphalt binder could achieve a fume suppression effect of 32%. One-dimensional materials, such as CNTs, have also been investigated for their ability to suppress asphalt fumes, with Calooyak et al. [145] reporting an inhibitory effect of over 60%.

In addition, layered nanoclays have been used to improve the fire resistance of asphalt materials. These can be categorized as cationic and anionic types, with OMMT being the most commonly used cationic nanoclay due to its compatibility with asphalt binders. Anionic nanoclays, such as LDHs, have also shown promise for improving the fire resistance of asphalt materials, as shown in Figure 19.

Layered nanoclay can form three different phased structures when combined with bituminous materials: conventional separation composite phase, intercalation composite phase, and exfoliation composite phase, as shown in Figure 19. In the conventional separation composite phase, the compatibility between the asphalt binder and nanoclay is poor, leading to the segregation of the modified asphalt materials. As a result, the nanoclay has little contribution to the performance of the modified asphalt materials during this stage. However, during intercalated and exfoliated stages, the compatibility between the asphalt binder and nanoclay is significantly improved, leading to improved flame resistance of asphalt materials. Previous studies have found intercalated and exfoliated composite structures in organic-modified montmorillonite (OMMT) [148, 149]. Intercalation composites offer interlayer spacing that allows for the lighter components of asphalt materials to occupy while preventing the entry of heavier components such as asphaltene into the matrix. By forming a stripping layer-net structure, the thermal stability of bituminous mixtures can be enhanced, limiting the thermal movement of lighter components and reducing smoke generation. In addition, Kong et al. [150] discovered that OMMT (Organically Modified Montmorillonite) can capture free radicals such as H⋅ and OH⋅ during the pyrolysis process of asphalt materials, thereby preventing the decomposition of chain ends and effectively suppressing the release of VOCs in asphalt fumes.

Studies indicate that the use of nanomaterials can effectively inhibit the emission of asphalt fumes through space restriction, adsorption, and catalytic oxidation mechanisms. However, incorporating nanomaterials into asphalt materials may result in decreased low-temperature performance. Additionally, there are significant challenges related to ensuring the compatibility between asphalt binder and nanomaterials, as well as achieving proper dispersion of the nanomaterials within the asphalt [151].

7 Limitations of Research at the Current Stage

This paper provides a thorough review of the flame retarding asphalt materials and asphalt pavements in urban road tunnels, including the tunnel fire-generation mechanisms, evaluation methods, flame retardants for asphalt pavements, and recent developments in flame retardant technologies. However, several limitations of the research at the current stage need to be addressed:

-

(1)

While different evaluation indexes for asphalt pavement during urban road tunnel fire have been presented in this study, the effective relationships and correlations among different test methods for the fire of asphalt pavements have not been established. Therefore, future studies should focus on developing a comprehensive assessment system that consists of more test parameters to provide a more efficient evaluation experimental framework.

-

(2)

Existing measures to control and reduce the fire effluences of asphalt pavements mainly include controlling from the asphalt source, asphalt mixtures, and tunnel fire source. However, a fire retarding asphalt pavement design guideline in the urban road tunnels has not been studied yet. Establishing an asphalt pavement design guideline is crucial to improving the fire resilience of road tunnels.

-

(3)

Burning asphalt pavements produce complex fumes that contain harmful components, which can threaten human health and damage the ecological environment, particularly in semi-closed road tunnels. However, the specific components of VOCs induced from burned asphalt pavement during a road tunnel fire have not been identified yet.

-

(4)

The compatibility between different fire retardants and asphalt materials has not been thoroughly investigated, which hinders the effects of fire retardants on the asphalt pavements in the road tunnels. Furthermore, some additive fire retardants can impair the performance of asphalt pavements. Therefore, balancing the properties of fire retardants and bituminous materials during the construction stage is necessary to ensure the best combination of engineering performance and flame retardants.

8 Outlook

To further promote research on flame-retarding road tunnel asphalt pavements and reduce their risks to the environment and human health, future research can be carried out in the following areas:

-

(1)

Currently, the relationship between indoor and field tests regarding asphalt fumes is not yet fully understood, and future research should aim to address this gap. One approach could be to integrate indoor test data on asphalt mixtures with field test results in semi-closed environments like tunnels. This could help establish the connection between the two methods from mathematical, organic chemistry, and toxicology perspectives, thus improving fire retarding asphalt research. Additionally, there is a need to develop consistent and appropriate testing standards to guide the construction of low-fume asphalt pavements.

-

(2)

More research is needed to investigate the underlying mechanisms of flame retardancy in road tunnel asphalt pavements, which can help optimize the design and formulation of flame-retarding additives. Research can focus on understanding how these additives interact with the asphalt binder and aggregate, and how they inhibit flame spread and reduce smoke generation. In order to address the issue of asphalt fume emissions at their source, it is important to develop cost-effective and eco-friendly flame retardants and fume suppressants, while maintaining the required road and working performance.

-

(3)

It is crucial to assess the potential environmental impacts associated with the use of flame-retardant additives in road tunnel asphalt pavements. Research can focus on evaluating the leaching behavior of additives into the surrounding environment and their potential effects on air and water quality.

-

(4)

It is essential to study and provide design guidelines and a series of construction standards for urban road tunnels with asphalt pavement. This approach will ensure that more potential dangers are considered during the design and construction stages, lowering the risk of road tunnel fires, strengthening the resilience of road tunnel structures, and increasing the service life of asphalt pavement. In addition, collaboration with international organizations and experts can help develop standardized testing methods, guidelines, and regulations for flame-retardant road tunnel asphalt pavements. This can ensure consistency and compatibility in assessing and implementing flame-retardant technologies worldwide.

-

(5)

Research should also consider the economic viability of using flame-retardant additives in road tunnel asphalt pavements. Cost-effectiveness analyses can help determine the feasibility of implementing flame-retardant technologies and identify potential barriers to their widespread adoption.

Abbreviations

- ATH:

-

Alumina trihydrate

- APP:

-

Ammonium polyphosphate

- BSG:

-

Bulk specific gravity

- CAHC:

-

Ca–Al hydrotalcite

- CRP:

-

Coated red phosphorus

- CNTs:

-

Carbon nanotubes

- CC:

-

Calcium carbonate

- CH:

-

Calcium hydroxide

- CCA:

-

Cone calorimeter apparatus

- DGM:

-

Dense graded mixture

- EG:

-

Expandable graphite

- EV:

-

Expanded vermiculite

- FR:

-

Flame retardant

- FTIR:

-

Fourier transform infrared spectroscopy

- GM:

-

Grouted macadam

- GC:

-

Gas chromatography

- HMA:

-

Hot mix asphalt

- HL:

-

Hydrated lime

- LOI:

-

Limited oxygen index

- LS:

-

Limestone modified binder

- LDH:

-

Layered double hydroxide

- MS:

-

Mass spectrometry

- MH:

-

Magnesium hydroxide

- OMMT:

-

Organic-modified montmorillonite

- OGM:

-

Open graded mixture

- PA:

-

Porous asphalt

- RSR:

-

Rate of smoke release

- SARA:

-

Saturates, aromatics, resins, and asphaltenes

- SBS:

-

Styrene–butadiene–styrene

- TGA:

-

Thermogravimetric analysis

- VOCs:

-

Volatile organic compounds

- WMA:

-

Warm mix asphalt

References

Xu D, Zhang X, Chen W et al (2019) Utilisation of the deep underground space in Shanghai. Proceed Inst Civil Eng Munic Eng 172:218–223. https://doi.org/10.1680/jmuen.18.00029

Jiang X, Zhang Y, Zhang Z, Bai Y (2021) Study on risks and countermeasures of shallow biogas during construction of metro tunnels by shield boring machine. Transp Res Rec 2675:105–116. https://doi.org/10.1177/0361198121994594/FORMAT/EPUB

Jiang X, Zhang X, Wang S et al (2022) Case study of the largest concrete Earth pressure balance pipe-jacking project in the world. Transp Res Rec 2676:92–105. https://doi.org/10.1177/03611981221076842/FORMAT/EPUB

Cui J, Broere W, Lin D (2021) Underground space utilisation for urban renewal. Tunn Undergr Space Technol 108:103726. https://doi.org/10.1016/j.tust.2020.103726

Xia H, Lin C, Liu X, Liu Z (2022) Urban underground space capacity demand forecasting based on sustainable concept: a review. Energy Build 255:111656. https://doi.org/10.1016/j.enbuild.2021.111656

Jiang X, Zhu H, Yan Z et al (2023) A state-of-art review on development and progress of backfill grouting materials for shield tunneling. Develop Built Environ 16:100250. https://doi.org/10.1016/j.dibe.2023.100250

Jiang X, Gabrielson J, Titi H et al (2022) Field investigation and numerical analysis of an inverted pavement system in Tennessee, USA. Transp Geotech 35:2214–3912. https://doi.org/10.1016/j.trgeo.2022.100759

Khare P, Machesky J, Soto R et al (2020) Asphalt-related emissions are a major missing nontraditional source of secondary organic aerosol precursors. Sci Adv. https://doi.org/10.1126/SCIADV.ABB9785/SUPPL_FILE/ABB9785_SM.PDF

Sultan SA, Guo Z (2016) Evaluating the performance of sustainable perpetual pavements using recycled asphalt pavement in China. Int J Transp Sci Technol 5:200–209. https://doi.org/10.1016/j.ijtst.2017.01.001

Wang S, Jiang X, Bai Y (2019) The influence of hand hole on the ultimate strength and crack pattern of shield tunnel segment joints by scaled model test. Front Struct Civ Eng 13:1200–1213. https://doi.org/10.1007/s11709-019-0546-2

Yang Q, Zhongyin G (2005) Mixture design of fire-retarded ogfc in road tunnel. Road Mater Pavement Des 6:255–268. https://doi.org/10.1080/14680629.2005.9690008

Xu T, Huang X, Zhao Y (2011) Investigation into the properties of asphalt mixtures containing magnesium hydroxide flame retardant. Fire Saf J 46:330–334. https://doi.org/10.1016/j.firesaf.2011.05.001

Zhang Y, Huang X (2022) A review of tunnel fire evacuation strategies and state-of-the-art research in China. Fire Technol. https://doi.org/10.1007/s10694-022-01357-5

Kim YA, Ryoo BY et al (2013) Major accident factors for effective safety management of highway construction projects. J Constr Eng Manag 139:628–640. https://doi.org/10.1061/(ASCE)CO.1943-7862.0000640

Caroly S, Kouabenan DR, Gandit M (2013) Analysis of danger management by highway users confronted with a tunnel fire. Saf Sci 60:35–46. https://doi.org/10.1016/j.ssci.2013.06.006

Jing-Song G (2003) A study on the pyrolysis of asphalt. Fuel 82:49–52. https://doi.org/10.1016/S0016-2361(02)00136-9

Li X, Zhou Z, Deng X et al (2017) Flame resistance of asphalt mixtures with flame retardants through a comprehensive testing program. J Mater Civil Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001788

Qiao R, Shao Z, Wei W, Zhang Y (2019) Theoretical investigation into the thermo-mechanical behaviours of tunnel lining during RABT fire development. Arab J Sci Eng 44:4807–4818. https://doi.org/10.1007/s13369-018-3555-x

Qiu J, Yang T, Wang X et al (2019) Review of the flame retardancy on highway tunnel asphalt pavement. Constr Build Mater 195:468–482. https://doi.org/10.1016/j.conbuildmat.2018.11.034

Wu S, Mo L, Cong P et al (2008) Flammability and rheological behavior of mixed flame retardant modified asphalt binders. Fuel 87:120–124. https://doi.org/10.1016/j.fuel.2007.03.039

Heidarinejad G, Mapar M, Pasdarshahri H (2016) A comprehensive study of two fire sources in a road tunnel: considering different arrangement of obstacles. Tunn Undergr Space Technol 59:91–99. https://doi.org/10.1016/j.tust.2016.06.016

Shen Y, Deng Y, Li T et al (2022) Determining multidimensional diffuse reflection effects in city tunnel lighting environment. Build Environ 212:108796. https://doi.org/10.1016/j.buildenv.2022.108796

Hu LH, Huo R, Li YZ et al (2005) Full-scale burning tests on studying smoke temperature and velocity along a corridor. Tunn Undergr Space Technol 20:223–229. https://doi.org/10.1016/j.tust.2004.08.007

Shen Y, Ling J, Wang W et al (2022) 3D numerical investigation on response of shield tunnel under combined effects of fire and structural loading. Tunn Undergr Space Technol 128:104659. https://doi.org/10.1016/j.tust.2022.104659

Zhang Y, Li W, Rui Y et al (2022) A modified cellular automaton model of pedestrian evacuation in a tunnel fire. Tunn Undergr Space Technol 130:104673. https://doi.org/10.1016/j.tust.2022.104673

Rajabi H, Hadi Mosleh M, Mandal P et al (2020) Emissions of volatile organic compounds from crude oil processing—global emission inventory and environmental release. Sci Total Environ 727:138654. https://doi.org/10.1016/j.scitotenv.2020.138654

Larson RC, Metzger MD, Cahn MF (2006) Responding to emergencies: Lessons learned and the need for analysis. Interfaces (Providence) 36:486–501. https://doi.org/10.1287/INTE.1060.0250

Zhang Y, Zhang X, Huang X (2023) Design a safe firefighting time (SFT) for major fire disaster emergency response. Int J Disaster Risk Reduct 88:2212–4209. https://doi.org/10.1016/j.ijdrr.2023.103606

Hua N, Tessari A, Khorasani NE (2021) Characterizing damage to a concrete liner during a tunnel fire. Tunn Undergr Space Technol 109:103761. https://doi.org/10.1016/j.tust.2020.103761

Hua N, Tessari A, Elhami-Khorasani N (2021) Quantifying uncertainties in the temperature-time evolution of railway tunnel fires. Fire Technol 57:361–392. https://doi.org/10.1007/s10694-020-01007-8

Sheng Y, Ahmed AT, Jia H et al (2022) Preparation and characterization of low flammable asphalt for tunnel pavements. Constr Build Mater 359:129559. https://doi.org/10.1016/j.conbuildmat.2022.129559

Toraldo E (2013) Comparative laboratory investigation into pavement materials for road tunnels. Road Mater Pavement Des 14:310–324. https://doi.org/10.1080/14680629.2013.794366

Chen R, Zhao R, Liu Y et al (2021) Development of eco-friendly fire-retarded warm-mix epoxy asphalt binders using reactive polymeric flame retardants for road tunnel pavements. Constr Build Mater 284:122752. https://doi.org/10.1016/j.conbuildmat.2021.122752

Yang X, Shen A, Liu G et al (2022) Combustion properties and road performance of asphalt mixtures containing alumina trihydrate/organic montmorillonite composites. Constr Build Mater. https://doi.org/10.1016/J.CONBUILDMAT.2021.125981

Ren R, Zhou H, Hu Z et al (2019) Statistical analysis of fire accidents in Chinese highway tunnels 2000–2016. Tunn Undergr Space Technol 83:452–460. https://doi.org/10.1016/j.tust.2018.10.008

Lai J, Zhou H, Cheng F et al (2017) Statistical analysis of fire accidents in highway tunnels and countermeasures for disaster prevention and reduction. Tunn Constr 37:409–415

Lin CL, Chien CF (2021) Lessons learned from critical accidental fires in tunnels. Tunn Undergr Space Technol. https://doi.org/10.1016/j.tust.2021.103944

Ministry of Emergency Management of the People’s Republic of China (2018) Shaanxi Ankang Jingkun Expressway “8·10” Investigation Report on Particularly Serious Road Traffic Accidents

China Emergency Information (2019) Investigation Report on the “8.27” Large Freight Truck Fire Accident in Maoliling Tunnel of G15 Shenhai Expressway

Qiao R, Shao Z, Liu F, Wei W (2019) Damage evolution and safety assessment of tunnel lining subjected to long-duration fire. Tunn Undergr Space Technol 83:354–363. https://doi.org/10.1016/j.tust.2018.09.036

Zhang X, Xiao Y, Long Y et al (2021) VOCs reduction in bitumen binder with optimally designed Ca(OH)2-incorporated zeolite. Constr Build Mater 279:122485. https://doi.org/10.1016/j.conbuildmat.2021.122485

Cui P, Schito G, Cui Q (2020) VOC emissions from asphalt pavement and health risks to construction workers. J Clean Prod 244:118757. https://doi.org/10.1016/j.jclepro.2019.118757

Goh YM, Brown H, Spickett J (2010) Applying systems thinking concepts in the analysis of major incidents and safety culture. Saf Sci 48:302–309. https://doi.org/10.1016/j.ssci.2009.11.006

Wang W, Shen A, Wang L, Liu H (2022) Measurements, emission characteristics, and control methods of fire effluents generated from tunnel asphalt pavement during fire: a review. Environ Sci Pollut Res 29:64267–64297. https://doi.org/10.1007/s11356-022-21512-3

EAGLE NEWS (2022) Six dead in South Korea road tunnel fire. https://www.eaglenews.ph/six-dead-in-south-korea-road-tunnel-fire/. Accessed 6 Apr 2023

Zhang Q, Li Q, Zhang L et al (2014) Experimental and kinetic investigation of the pyrolysis, combustion, and gasification of deoiled asphalt. J Therm Anal Calorim 115:1929–1938. https://doi.org/10.1007/s10973-013-3370-2

Zhang C, Xu T, Shi H, Wang L (2015) Physicochemical and pyrolysis properties of SARA fractions separated from asphalt binder. J Therm Anal Calorim 122:241–249. https://doi.org/10.1007/s10973-015-4700-3

Kummer U, Brauner C From the major fire in the Gotthard Road Tunnel in 2001 to deployment confidence in tunnel fires. International Fire Academy

Ingason H (2003) Proceedings of the International Symposium on Catastrophic Tunnel Fires. In: Ingason H (ed)

Bonati A, Merusi F, Polacco G et al (2012) Ignitability and thermal stability of asphalt binders and mastics for flexible pavements in highway tunnels. Constr Build Mater 37:660–668. https://doi.org/10.1016/j.conbuildmat.2012.07.096

Bonati A, Rainieri S, Bochicchio G et al (2015) Characterization of thermal properties and combustion behaviour of asphalt mixtures in the cone calorimeter. Fire Saf J 74:25–31. https://doi.org/10.1016/j.firesaf.2015.04.003

Zhang T, Zhang M, Shen Y et al (2022) Mitigating the damage of ultra-high performance concrete at elevated temperatures using synergistic flame-retardant polymer fibres. Cem Concr Res. https://doi.org/10.1016/j.cemconres.2022.106835

Yang R, Chen L, Zhang W-Q et al (2011) In situ reinforced and flame-retarded polycarbonate by a novel phosphorus-containing thermotropic liquid crystalline copolyester. Polymer. https://doi.org/10.1016/j.polymer.2011.06.047

Wang Y, Zhang F, Jlao C et al (2010) Convective heat transfer of the bunsen flame in the UL94 vertical burning test for polymers. J Fire Sci 28:337–356. https://doi.org/10.1177/0734904109351484

Wang Y, Zhang J, Jow J, Su K (2009) Analysis and modeling of ignitability of polymers in the UL-94 vertical burning test condition. J Fire Sci 27:561–581. https://doi.org/10.1177/0734904109099999

Xiao F, Guo R, Wang J (2019) Flame retardant and its influence on the performance of asphalt—a review. Constr Build Mater 212:841–861. https://doi.org/10.1016/j.conbuildmat.2019.03.118

Enright PA, Fleischmann CM (1999) Uncertainty of heat release rate calculatiori of the IS056604 cone calorimeter standard test method. Fire Technol 35:153–169

Babrauskas V (1984) Development of the cone calorimeter? A bench-scale heat release rate apparatus based on oxygen consumption. Fire Mater 8:81–95. https://doi.org/10.1002/fam.810080206

Babrauskas V, Peacock RD (1992) Heat release rate: the single most important variable in fire Hazard*. Fire Saf J 18:255–272

Nan X, Yu B (2012) Experimental study on the flame retarding and smoke-suppressing performance of asphalt mixture. CICTP 2012: Multimodal Transportation Systems—Convenient, Safe, Cost-Effective, Efficient—Proceedings of the 12th COTA International Conference of Transportation Professionals. https://doi.org/10.1061/9780784412442.311

Liu DL, Yan YZ, Huang YY et al (2013) Study on flame-retardant properties of flame retardant asphalt mixture. Appl Mech Mater. 438–439:387–390

Pavlidou S, Papaspyrides CD (2008) A review on polymer-layered silicate nanocomposites. Prog Polym Sci 33:1119–1198. https://doi.org/10.1016/j.progpolymsci.2008.07.008

Xu T, Wang H, Huang X, Li G (2013) Inhibitory action of flame retardant on the dynamic evolution of asphalt pyrolysis volatiles. Fuel 105:757–763. https://doi.org/10.1016/j.fuel.2012.10.029

Xu T, Shi H, Wang H, Huang X (2014) Dynamic evolution of emitted volatiles from thermal decomposed bituminous materials. Constr Build Mater 64:47–53. https://doi.org/10.1016/j.conbuildmat.2014.04.078

Xu T, Huang X (2010) Study on combustion mechanism of asphalt binder by using TG–FTIR technique. Fuel 89:2185–2190. https://doi.org/10.1016/j.fuel.2010.01.012

Pei J, Wen Y, Li Y et al (2014) Flame-retarding effects and combustion properties of asphalt binder blended with organo montmorillonite and alumina trihydrate. Constr Build Mater 72:41–47. https://doi.org/10.1016/j.conbuildmat.2014.09.013

Shi H, Xu T, Zhou P, Jiang R (2017) Combustion properties of saturates, aromatics, resins, and asphaltenes in asphalt binder. Constr Build Mater 136:515–523. https://doi.org/10.1016/j.conbuildmat.2017.01.064

Xu T, Wang Y, Xia W, Hu Z (2018) Effects of flame retardants on thermal decomposition of SARA fractions separated from asphalt binder. Constr Build Mater 173:209–219. https://doi.org/10.1016/j.conbuildmat.2018.04.052

Hao J, Che Y, Tian Y et al (2017) Thermal cracking characteristics and kinetics of oil sand bitumen and its SARA fractions by TG–FTIR. Energy Fuels 31:1295–1309. https://doi.org/10.1021/acs.energyfuels.6b02598

Zhu K, Wang Y, Zhou Q et al (2018) Investigation on smoke suppression mechanism of hydrated lime in asphalt combustion. J Chem. https://doi.org/10.1155/2018/9585728

Yang X, Shen A, Su Y, Zhao W (2020) Effects of alumina trihydrate (ATH) and organic montmorillonite (OMMT) on asphalt fume emission and flame retardancy properties of SBS-modified asphalt. Constr Build Mater 236:117576. https://doi.org/10.1016/j.conbuildmat.2019.117576

Kang M, Liu Y, Lin W et al (2023) The thermal behavior and flame retardant performance of phase change material microcapsules with halloysite nanotube. J Energy Storage 60:106632. https://doi.org/10.1016/j.est.2023.106632

Wu H, Shen A, He Z et al (2023) Mechanism of a warm-mix agent and its effects on the rheological properties and thermal stability of aluminum hydroxide and organic montmorillonite composite flame-retardant asphalt. J Mater Civil Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0004726

Yang X, Wang G, Liang M et al (2023) Effect of aluminum hydroxide (ATH) on flame retardancy and smoke suppression properties of SBS-modified asphalt. Road Mater Pavement Des 24:173–190. https://doi.org/10.1080/14680629.2021.2012239

Tan Y, Xie J, Wu Y et al (2023) Performance and microstructure characterizations of halloysite nanotubes composite flame retardant-modified asphalt. J Mater Civil Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0004630

Benhammada A, Trache D (2020) Thermal decomposition of energetic materials using TG-FTIR and TG-MS: a state-of-the-art review. Appl Spectrosc Rev 55:724–777. https://doi.org/10.1080/05704928.2019.1679825

Chang X, Xiao Y, Long Y et al (2022) Temperature dependency of VOCs release characteristics of asphalt materials under varying test conditions. J Traffic Transp Eng 9:280–292. https://doi.org/10.1016/j.jtte.2020.12.008. (English Edition)

Zhang T, Zhang M, Chen Q et al (2023) Enhancing the thermo-mechanical properties of calcium aluminate concrete at elevated temperatures using synergistic flame-retardant polymer fibres. Cem Concr Compos 140:105088. https://doi.org/10.1016/j.cemconcomp.2023.105088

Lin S-Y (2016) An overview of advanced hyphenated techniques for simultaneous analysis and characterization of polymeric materials. Crit Rev Solid State Mater Sci 41:482–530. https://doi.org/10.1080/10408436.2016.1186598

Nna-Mvondo D, de la Fuente JL, Ruiz-Bermejo M et al (2013) Thermal characterization of Titan’s tholins by simultaneous TG–MS, DTA, DSC analysis. Planet Space Sci 85:279–288. https://doi.org/10.1016/j.pss.2013.06.025

Otero M, Sánchez ME, Gómez X (2011) Co-firing of coal and manure biomass: A TG–MS approach. Bioresour Technol 102:8304–8309. https://doi.org/10.1016/j.biortech.2011.06.040

Zhang X, Zhu S, Zhu J et al (2022) TG-MS study on co-combustion characteristics and coupling mechanism of coal gasification fly ash and coal gangue by ECSA®. Fuel 314:123086. https://doi.org/10.1016/j.fuel.2021.123086

Knümann R, Bockhorn H (1994) Investigation of the kinetics of pyrolysis of PVC by TG-MS-analysis. Combust Sci Technol 101:285–299. https://doi.org/10.1080/00102209408951877

Zhao J, Huang X, Xu T (2015) Combustion mechanism of asphalt binder with TG–MS technique based on components separation. Constr Build Mater 80:125–131. https://doi.org/10.1016/j.conbuildmat.2014.11.056

Xia W, Xu T, Wang H, Pan Y (2019) Combustion kinetics of asphalt binder components and the release processes of gaseous products. Combust Flame 206:322–333. https://doi.org/10.1016/j.combustflame.2019.05.009

Long Y, Wu S, Xiao Y et al (2018) VOCs reduction and inhibition mechanisms of using active carbon filler in bituminous materials. J Clean Prod 181:784–793. https://doi.org/10.1016/j.jclepro.2018.01.222

Peinado I, Mason M, Biasioli F, Scampicchio M (2018) Hyphenation of proton transfer reaction mass spectrometry with thermal analysis for monitoring the thermal degradation of retinyl acetate. Rapid Commun Mass Spectrom 32:57–62. https://doi.org/10.1002/rcm.7993

Gasthauer E, Mazé M, Marchand JP, Amouroux J (2008) Characterization of asphalt fume composition by GC/MS and effect of temperature. Fuel 87:1428–1434. https://doi.org/10.1016/j.fuel.2007.06.025

Yang X, Shen A, Su Y, Zhao W (2020) Effects of alumina trihydrate (ATH) and organic montmorillonite (OMMT) on asphalt fume emission and flame retardancy properties of SBS-modified asphalt. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2019.117576

Zhang J, Wilkie CA (2003) Preparation and flammability properties of polyethylene–clay nanocomposites. Polym Degrad Stab 80:163–169. https://doi.org/10.1016/S0141-3910(02)00398-1

Shi H, Xu T, Jiang R (2017) Combustion mechanism of four components separated from asphalt binder. Fuel 192:18–26. https://doi.org/10.1016/j.fuel.2016.11.110

Qin X, Zhu S, Chen S, Deng K (2013) The mechanism of flame and smoke retardancy of asphalt mortar containing composite flame retardant material. Constr Build Mater 41:852–856. https://doi.org/10.1016/j.conbuildmat.2012.12.048

Li Z, Kong B, Wei A et al (2016) Free radical reaction characteristics of coal low-temperature oxidation and its inhibition method. Environ Sci Pollut Res 23:23593–23605. https://doi.org/10.1007/S11356-016-7589-X/FIGURES/10

Xia W, Wang S, Wang H, Xu T (2021) Inhibitory effects of developed composite flame retardant on bituminous combustion and volatile emissions. J Clean Prod 279:123538. https://doi.org/10.1016/j.jclepro.2020.123538

Lu S-Y, Hamerton I (2002) Recent developments in the chemistry of halogen-free flame retardant polymers. Prog Polym Sci 27:1661–1712. https://doi.org/10.1016/S0079-6700(02)00018-7

Perez RM, Sandler JKW, Altstädt V et al (2007) Novel phosphorus-modified polysulfone as a combined flame retardant and toughness modifier for epoxy resins. Polymer 48:778–790. https://doi.org/10.1016/j.polymer.2006.12.011. (Guildf)

Lei Y, Wang H, Chen X et al (2018) Shear property, high-temperature rheological performance and low-temperature flexibility of asphalt mastics modified with bio-oil. Constr Build Mater 174:30–37. https://doi.org/10.1016/j.conbuildmat.2018.04.094

Bautista EG, Flickinger J, Saha R et al (2015) Effect of Coal Combustion Products on high temperature performance of asphalt mastics. Constr Build Mater 94:572–578. https://doi.org/10.1016/j.conbuildmat.2015.07.022

Puente E, Lázaro D, Alvear D (2016) Study of tunnel pavements behaviour in fire by using coupled cone calorimeter—FTIR analysis. Fire Saf J 81:1–7. https://doi.org/10.1016/j.firesaf.2016.01.010

Tao P (2013) The study on flame retardant asphalt and asphalt mixture. Appl Mech Mater 361–363:1829–1832. https://doi.org/10.4028/www.scientific.net/AMM.361-363.1829

Zhang T, Chen M, Wang Y, Zhang M (2023) Roles of carbonated recycled fines and aggregates in hydration, microstructure and mechanical properties of concrete: a critical review. Cem Concr Compos 138:104994. https://doi.org/10.1016/j.cemconcomp.2023.104994

Jiang X, Titi H, Ma Y et al (2022) Evaluating the performance of inverted pavement structure using the accelerated pavement test (APT). Constr Build Mater 346:128489. https://doi.org/10.1016/j.conbuildmat.2022.128489

Jiang X, Gabrielson J, Titi H et al (2022) Field investigation and numerical analysis of an inverted pavement system in Tennessee, USA. Transp Geotech 35:100759. https://doi.org/10.1016/j.trgeo.2022.100759

Bonati A, Merusi F, Bochicchio G et al (2013) Effect of nanoclay and conventional flame retardants on asphalt mixtures fire reaction. Constr Build Mater 47:990–1000. https://doi.org/10.1016/j.conbuildmat.2013.06.002

Jiang J, Leng Z, Yang B et al (2022) Penetration mechanism of the emulsion-based rejuvenator in damaged porous asphalt mixture: microstructure characterization and 3D reconstruction. Mater Des 221:111014. https://doi.org/10.1016/j.matdes.2022.111014

Jiang J, Ni F, Gu X et al (2019) Evaluation of aggregate packing based on thickness distribution of asphalt binder, mastic and mortar within asphalt mixtures using multiscale methods. Constr Build Mater 222:717–730. https://doi.org/10.1016/j.conbuildmat.2019.06.083

Zhao H, Li HP, Liao KJ (2010) Study on properties of flame retardant asphalt for tunnel. Pet Sci Technol 28:1096–1107. https://doi.org/10.1080/10916460802611465

Bourbigot S, Cerin O, Duquesne S, Clavel N (2013) Flame retardancy of bitumen: a calorimetry study. J Fire Sci 31:112–130. https://doi.org/10.1177/0734904112458240/FORMAT/EPUB

Cong P, Yu J, Wu S, Luo X (2008) Laboratory investigation of the properties of asphalt and its mixtures modified with flame retardant. Constr Build Mater 22:1037–1042. https://doi.org/10.1016/j.conbuildmat.2007.03.012

Wu S, Cong P, Yu J et al (2006) Experimental investigation of related properties of asphalt binders containing various flame retardants. Fuel 85:1298–1304. https://doi.org/10.1016/j.fuel.2005.10.014

Hornsby PR, Watson CL (1990) A study of the mechanism of flame retardance and smoke suppression in polymers filled with magnesium hydroxide*. Polym Degrad Stab 30:73–87

Kim S (2003) Flame retardancy and smoke suppression of magnesium hydroxide filled polyethylene. J Polym Sci B Polym Phys 41:936–944. https://doi.org/10.1002/POLB.10453

Wu K, Zhu K, Kang C et al (2016) An experimental investigation of flame retardant mechanism of hydrated lime in asphalt mastics. Mater Des 103:223–229. https://doi.org/10.1016/j.matdes.2016.04.057

Zhu K, Wang Y, Tang D et al (2019) Flame-retardant mechanism of layered double hydroxides in asphalt binder. Materials. https://doi.org/10.3390/MA12050801

Gao Y, Wu J, Wang Q et al (2014) Flame retardant polymer/layered double hydroxide nanocomposites. J Mater Chem A Mater 2:10996. https://doi.org/10.1039/c4ta01030b

Li M, Pang L, Chen M et al (2018) Effects of aluminum hydroxide and layered double hydroxide on asphalt fire resistance. Materials. https://doi.org/10.3390/ma11101939

Lindemann RF (1969) Flame-retardants for polystyrenes. Ind Eng Chem 61:70–75. https://doi.org/10.1021/ie50713a007

Wang X, Pang H, Chen W et al (2013) Nanoengineering core/shell structured brucite@polyphosphate@amine hybrid system for enhanced flame retardant properties. Polym Degrad Stab 98:2609–2616. https://doi.org/10.1016/j.polymdegradstab.2013.09.021

Barral M, Garmendia P, Muñoz ME et al (2012) Novel bituminous mastics for pavements with improved fire performance. Constr Build Mater 30:650–656. https://doi.org/10.1016/j.conbuildmat.2011.12.055

Kiliaris P, Papaspyrides CD (2010) Polymer/layered silicate (clay) nanocomposites: an overview of flame retardancy. Prog Polym Sci 35:902–958. https://doi.org/10.1016/j.progpolymsci.2010.03.001

Liu S, Zhou SB, Xu Y (2018) Evaluation of cracking properties of SBS-modified binders containing organic montmorillonite. Constr Build Mater 175:196–205. https://doi.org/10.1016/j.conbuildmat.2018.04.185

Feldman D (2014) Polymer nanocomposites in building, construction. J Macromol Sci Part A Pure Appl Chem 51:203–209. https://doi.org/10.1080/10601325.2014.871948

Zhang C, Yu J, Feng K et al (2016) Synthesis and characterization of triethoxyvinylsilane surface modified layered double hydroxides and application in improving UV aging resistance of bitumen. Appl Clay Sci 120:1–8. https://doi.org/10.1016/j.clay.2015.11.013

Archibong FN, Orakwe LC, Ogah OA et al (2023) Emerging progress in montmorillonite rubber/polymer nanocomposites: a review. J Mater Sci. https://doi.org/10.1007/s10853-023-08173-4

Ashish PK, Singh D, Bohm S (2016) Evaluation of rutting, fatigue and moisture damage performance of nanoclay modified asphalt binder. Constr Build Mater 113:341–350. https://doi.org/10.1016/j.conbuildmat.2016.03.057

Ashish PK, Singh D, Bohm S (2017) Investigation on influence of nanoclay addition on rheological performance of asphalt binder. Road Mater Pavement Des 18:1007–1026. https://doi.org/10.1080/14680629.2016.1201522

Iskender E (2016) Evaluation of mechanical properties of nano-clay modified asphalt mixtures. Measurement 93:359–371. https://doi.org/10.1016/j.measurement.2016.07.045

Yang X, Shen A, Liang M et al (2021) Dynamic flame retardancy and flame mechanism of SBS- modified asphalt containing alumina trihydrate and organic montmorillonite. Constr Build Mater 309:125077. https://doi.org/10.1016/j.conbuildmat.2021.125077

Alexandre M, Dubois P (2000) Polymer-layered silicate nanocomposites: preparation, properties and uses of a new class of materials. Mater Sci Eng R Rep 28:1–63. https://doi.org/10.1016/S0927-796X(00)00012-7

Golestani B, Nam BH, Moghadas Nejad F, Fallah S (2015) Nanoclay application to asphalt concrete: characterization of polymer and linear nanocomposite-modified asphalt binder and mixture. Constr Build Mater 91:32–38. https://doi.org/10.1016/j.conbuildmat.2015.05.019

Yang X, Wang G, Rong H et al (2022) Review of fume-generation mechanism, test methods, and fume suppressants of asphalt materials. J Clean Prod 347:131240. https://doi.org/10.1016/j.jclepro.2022.131240

Sheng Y, Wu Y, Yan Y et al (2020) Development of environmentally friendly flame retardant to achieve low flammability for asphalt binder used in tunnel pavements. J Clean Prod 257:120487. https://doi.org/10.1016/j.jclepro.2020.120487

Camino G, Costa L, Luda Di Cortemiglia MP (1991) Overview of fire retardant mechanisms. Polym Degrad Stab 33:131–154

Hornsby PR, Rothon RN, Takeda K et al (2005) General considerations on the use of fillers and nanocomposites. an introduction to the use of fillers and nanocomposites in fire retardancy. In: Le Bras M, Wilkie CA, Bourbigot S (eds) Fire Retardancy of Polymers. The Royal Society of Chemistry, London, pp 1–14

Segundo IR, Freitas E, Branco VTFC et al (2021) Review and analysis of advances in functionalized, smart, and multifunctional asphalt mixtures. Renew Sustain Energy Rev 151:111552. https://doi.org/10.1016/j.rser.2021.111552

Yang X, Shen A, Guo Y et al (2021) A review of nano layered silicate technologies applied to asphalt materials. Road Mater Pavement Des 22:1708–1733. https://doi.org/10.1080/14680629.2020.1713199

Shah PM, Mir MS (2020) Application of nanotechnology in pavement engineering: a review. Can J Civ Eng 47:1037–1045. https://doi.org/10.1139/cjce-2019-0395

Debbarma K, Debnath B, Sarkar PP (2022) A comprehensive review on the usage of nanomaterials in asphalt mixes. Constr Build Mater 361:129634. https://doi.org/10.1016/j.conbuildmat.2022.129634

Lu D, Jiang X, Tan Z et al (2023) Enhancing sustainability in pavement engineering: a-state-of-the-art review of cement asphalt emulsion mixtures. Clean Mater. https://doi.org/10.1016/j.clema.2023.100204

Lu D, Jiang X, Leng Z (2024) Sustainable microwave-heating healing asphalt concrete fabricated with waste microwave-sensitive fillers. J Clean Prod 434:140343. https://doi.org/10.1016/j.jclepro.2023.140343

Zhang H, Duan H, Zhu C et al (2021) Mini-review on the application of nanomaterials in improving anti-aging properties of asphalt. Energy Fuels 35:11017–11036. https://doi.org/10.1021/acs.energyfuels.1c01035

Zhang D, Zhang H, Zhu C, Shi C (2017) Synergetic effect of multi-dimensional nanomaterials for anti-aging properties of SBS modified bitumen. Constr Build Mater 144:423–431. https://doi.org/10.1016/j.conbuildmat.2017.03.205

Zhang D, Huang Z, Yuan G et al (2022) Research on the anti-aging mechanism of SBS-modified asphalt compounded with multidimensional nanomaterials based on atomic force microscopy. Constr Build Mater 317:125808. https://doi.org/10.1016/j.conbuildmat.2021.125808

Cui PQ, Wu SP, Xiao Y, Zhang HH (2015) Experimental study on the reduction of fumes emissions in asphalt by different additives. Mater Res Innovations 19:S1158–S1161. https://doi.org/10.1179/1432891715Z.0000000001395

Galooyak SS, Palassi M, Farahani HZ, Goli A (2015) Effect of carbon nanotube on the rheological properties of Bitumen. Petrol Coal 57:556–564

Peng C, Yu J, Dai J, Yin J (2015) Effect of Zn/Al layered double hydroxide containing 2-hydroxy-4-n-octoxy-benzophenone on UV aging resistance of asphalt. Adv Mater Sci Eng 2015:1–13. https://doi.org/10.1155/2015/739831

Zhang H, Zhang D, Zhu C (2015) Properties of Bitumen containing various amounts of organic Montmorillonite. J Mater Civil Eng. https://doi.org/10.1061/(asce)mt.1943-5533.0001261

Xiu M, Wang X, Morawska L et al (2020) Emissions of particulate matters, volatile organic compounds and polycyclic aromatic hydrocarbons from warm and hot asphalt mixes. J Clean Prod 275:123094. https://doi.org/10.1016/j.jclepro.2020.123094

Li L, Wu S, Liu G et al (2017) Effect of organo-montmorillonite nanoclay on VOCs inhibition of bitumen. Constr Build Mater 146:429–435. https://doi.org/10.1016/j.conbuildmat.2017.04.040

Kong Q, Hu Y, Song L, Yi C (2009) Synergistic flammability and thermal stability of polypropylene/aluminum trihydroxide/Fe-montmorillonite nanocomposites. Polym Adv Technol 20:404–409. https://doi.org/10.1002/PAT.1285

Wang M, Li P, Nian T, Mao Y (2021) An overview of studies on the hazards, component analysis and suppression of fumes in asphalt and asphalt mixtures. Constr Build Mater 289:123185. https://doi.org/10.1016/j.conbuildmat.2021.123185

Acknowledgements

We sincerely appreciate the insightful input provided by experts in the tunnel and pavement industries.

Funding

Open access funding provided by The Hong Kong Polytechnic University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jiang, X., Zhu, H., Yan, Z. et al. Fire-Retarding Asphalt Pavement for Urban Road Tunnels: A State-of-the-Art Review and Beyond. Fire Technol (2024). https://doi.org/10.1007/s10694-024-01556-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10694-024-01556-2