Abstract

Montmorillonite is a natural clay mineral linked with the smectite group of a dioctahedral 2:1 phyllosilicate formed by two tetrahedral sheets along with one octahedral sheet. In contradiction to other clay nanoparticles, the montmorillonite confers an interlayer spacing on either side of each triple-sheet layer. MMT was fashioned by dissolving rocks and minerals on Earth’s surface. The remarkable qualities responsible for the reinforcing efficiency of MMT include greater surface area and a higher aspect ratio. These qualities confer distinctive thermal, gas barrier, mechanical and rheological properties to MMT-rubber or polymer composites. It is also used as a promoter of rubber particle size reduction in polymer or rubber matrices and has attracted diverse merits for material applications globally. MMT displays potential for use as active agents and as an alternative to other expensive nanoparticles in the fabrication of multi-use and high-quality rubber nanocomposites. Rubber nanocomposites filled with MMT showed superior viscosity, toughness, and rigidity with less tensile strength and elongation at break. This paper reviews current multi-advancements in montmorillonite rubber or polymer nanocomposites (MMT-RCNs/PCNs): applications of MMT-RCNs/PCNs in aerospace, automobile, food additives, antibacterial, polymer, sorbent, catalyst, pharmaceutical, tissue engineering, biosensing, drug release and the utilization of polymer-based hydrogels investigated at both 2D and 3D nanoclay particles for various applications.

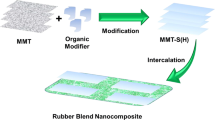

Graphical Abstract

Similar content being viewed by others

References

Nazir MS, Mohamad Kassim M, Mohapatra L, Gilani MA, Raza MR, Majeed K (2016) Characteristic properties of nanoclays and characterization of nanoparticulates and nanocomposites, p 35–55. https://doi.org/10.1007/978-981-10-1953-1_2

Saba N, Tahir PM, Jawaid M (2014) A review on potentiality of nano filler/natural fiber filled polymer hybrid composites. Polymers (Basel) 6:2247–2273. https://doi.org/10.3390/polym6082247

Pires J, de Paula CD, Souza VGL, Fernando AL, Coelhoso I (2021) Understanding the barrier and mechanical behavior of different nanofillers in chitosan films for food packaging. Polymers (Basel) 13:1–29. https://doi.org/10.3390/polym13050721

Alipour A, Naderi G, Bakhshandeh GR, Vali H, Shokoohi S (2011) Elastomer Nanocomposites Based on NR/EPDM/ Organoclay: Morphology and Properties. Intern Polym Process 26:48–55. https://doi.org/10.3139/217.2381

Kong J, Li Z, Cao Z, Han C, Dong L (2017) The excellent gas barrier properties and unique mechanical properties of poly(propylene carbonate)/organo-montmorillonite nanocomposites. Polym Bull 74:5065–5082. https://doi.org/10.1007/s00289-017-2002-6

Abdel-Karim A, El-Naggar ME, Radwan EK, Mohamed IM, Azaam M, Kenawy ER (2021) High-performance mixed-matrix membranes enabled by organically/inorganic modified montmorillonite for the treatment of hazardous textile wastewater. Chem Eng J 405:126964. https://doi.org/10.1016/j.cej.2020.126964

Ogah AO, Afiukwa JN (2014) Characterization, and comparison of mechanical behavior of agro fiber-filled high-density polyethylene bio-composites. J Reinf Plast Compos 33(1):37–46. https://doi.org/10.1177/0731684413509425

Tomer V, Polizos G, Manias E, Randall CA (2010) Epoxy-based nanocomposites for electrical energy storage. I: effects of montmorillonite and barium titanate nanofillers. J Appl Phys 108:1–14. https://doi.org/10.1063/1.3487275

Liu W, Lv L, Yang Z, Zheng Y, Wang H (2020) The effect of OMMT on the properties of vehicle damping carbon black-natural rubber composites. Polymers (Basel) 12:1–11. https://doi.org/10.3390/polym12091983

Jiraskova Y, Bursik J, Seidlerova J, Kutlakova K, Safarik I, Safarikova M, Pospiskova K, Zivotsky O (2018) Microstructural analysis and magnetic characterization of native and magnetically modified montmorillonite and vermiculite. J Nanomater 2018:1–15. https://doi.org/10.1155/2018/3738106

Leporatti S (2019) Polymer clay nano-composites. Polymers (Basel) 11(9):1–27. https://doi.org/10.3390/polym11091445

Wójcik-Bania M, Matusik J (2021) The effect of surfactant-modified montmorillonite on the cross-linking efficiency of polysiloxanes. Materials (Basel) 14(10):1–16. https://doi.org/10.3390/ma14102623

Pumchusak J, Thajina N, Keawsujai W, Chaiwan P (2021) Effect of organo-modified montmorillonite nanoclay on mechanical, thermo-mechanical, and thermal properties of carbon fiber-reinforced phenolic composites. Polymers (Basel) 13(5):1–12. https://doi.org/10.3390/polym13050754

Amari A, Alzahrani FM, Katubi KM, Alsaiari NS, Tahoon MA, Ben Rebah F (2021) Clay-polymer nanocomposites: preparations and utilization for pollutants removal. Materials (Basel) 14:1–21. https://doi.org/10.3390/ma14061365

Khalid M, Walvekar R, Ketabchi M. R, Siddiqui H, Hoque M.E (2016) Rubber/nanoclay composites: towards advanced functional materials. Engineering materials. p 209–224, https://doi.org/10.1007/978-981-10-1953-1_9

Avinash S, Siva I, Yashwant M, Vishal D, Mohamed THS, Ain UMS, Faizal M (2021) Testing of silicon rubber/montmorillonite nanocomposite for mechanical and tribological performance. Nanomaterials 11(11):1–14. https://doi.org/10.3390/nano11113050

Wantat A, Seraypheap K, Rojsitthisak P (2022) Effect of chitosan coatings supplemented with chitosan-montmorillonite nanocomposites on post-harvest quality of ‘Hom Thong’ banana fruit. Food Chem 374:131731. https://doi.org/10.1016/j.foodchem.2021.131731

Caner C, Coşkun BM, Yüceer M (2022) Chitosan coatings and chitosan nanocomposite to enhance the storage stability of fresh eggs during storage. J Food Process Preserv 46(7):e16642. https://doi.org/10.1111/jfpp.16642

Barman KM, Tamang N, Bhattarai A, Saha B (2022) Chapter 8 Montmorillonite-Starch based Nano-Composites and Applications. Mater Res Found 125: 172–209. https://doi.org/10.21741/9781644901915-8

Sadeghianmaryan A, Yazdanpanah Z, Soltani YA, Sardroud HA, Nasirtabrizi MH, Chen X (2020) Curcumin-loaded electrospun polycaprolactone/montmorillonite nanocomposite: wound dressing application with anti-bacterial and low cell toxicity properties. J Biomater Sci Polym Ed 31(2):169–187. https://doi.org/10.1080/09205063.2019.1

Usuki A, Tukigase A, Kato M (2002) Preparation and properties of EPDM-clay hybrids. Polymer (Guildf) 43(8):2185–2189. https://doi.org/10.1016/S0032-3861(02)00013-7

Ahn DU, Jeon JB, Kim SJ (2015) Novel synergistic combinations of amphiphilic fatty acid derivatives for high-performance rubber-organoclay nanocomposites. RSC Adv 5(6):4664–4674. https://doi.org/10.1039/C4RA11452C

Yamada H, Tamura K, Yokoyama S (2011) Mixed-layered phyllosilicate and process for producing the same. United States Patent 7959886, 2 (B2), p 1–18

Bergaya F, Lagaly G (2013) General introduction: clays, clay minerals, and clay science, 2nd ed., vol 5, p 1–19. https://doi.org/10.1016/B978-0-08-098258-8.00001-8

Joly S, Garnaud G, Ollitrault R, Bokobza L, Mark JE (2002) Organically modified layered silicates as reinforcing fillers for natural rubber. J Mater Sci 8:4202–4208. https://doi.org/10.1021/cm020093e

Zhou L, He Y, Guo S, Zhang Q, Liu V, Tang L, Zhou X, Duan M (2020) Efficient inhibition of montmorillonite swelling through controlling flexibly piperazine-based structure-based polyether gemini quaternary ammonium salts. Chem Eng J 383:123190. https://doi.org/10.1016/j.cej.2019.123190

Li L, Ma R, Ebina Y, Fukuda K, Takada K, Sasaki T (2007) Layer-by-layer assembly and spontaneous flocculation of oppositely charged oxide and hydroxide nanosheets into inorganic sandwich layered materials. J Am Chem Soc 129(25):8000–8007. https://doi.org/10.1021/ja0719172

Palkowski H, Sokolova OA, Carradò A (2013) Sandwich materials, Encycl Automot Eng p 1–17. https://doi.org/10.1002/9781118354179.auto163

Xu J, Gai S, He F, Niu N, Gao P, Chen Y, Yang P (2014) A sandwich-type three-dimensional layered double hydroxide nanosheet array/graphene composite: fabrication and high supercapacitor performance. Mater Chem A 2(4):1–10. https://doi.org/10.1039/c3ta14048b

Okamoto K, Ray SS, Okamoto M (2003) New poly ( butylene succinate )/layered silicate nanocomposites. II. Effect of organically modified layered silicates on structure and properties. Melt rheology, and biodegradability. J Polym Sci Part B 41(24):3160–3172. https://doi.org/10.1002/polb.10708

Phua YJ, Chow WS, Ishak ZAM (2011) Mechanical properties and structure development in poly ( butylene succinate )/organo-montmorillonite nanocomposites under uniaxial cold rolling. eXPRESS Polym Lett 5(2):93–103. https://doi.org/10.3144/expresspolymlett.2011.11

Bandyopadhyay A, Maiti M, Bhowmick AK (2006) Synthesis, characterization, and properties of clay and silica based rubber nanocomposites. Mater Sci Technol 22(7):818–828. https://doi.org/10.1179/174328406X101265

Mondragón M, Hernández EM, Rivera-Armenta JL, Rodríguez-González FJ (2009) Injection molded thermoplastic starch/natural rubber/clay nanocomposites: morphology and mechanical properties. Carbohydr Polym 77(1):80–86. https://doi.org/10.1016/j.carbpol.2008.12.008

Ismail H, Ramli R (2008) Organoclay filled natural rubber nanocomposites: the effects of filler loading and mixing method. J Reinf Plast Compos 27(16–17):1909–1923. https://doi.org/10.1177/0731684407082541

Jeon MY, Kim D, Kumar P, Lee PS, Rangnekar N, Bai P, Shete M, Elyssai B, Lee HS, Narasimharao K, Basahel SN, Al-Thabaiti S, Xu W, Cho HJ, Fetisov EO, Thyagarajan R, Dejaco RF, Fan W, Mkhoyan AK, Siepmann JI, Tsapatsis M (2017) Ultra-selective high-flux membranes from directly synthesized zeolite nanosheets. Nat Publ Gr 543(7647):690–694. https://doi.org/10.1038/nature21421

Lagaly G, Ogawa M, Dékány I (2006) Chapter 7.3 Clay mineral organic interactions, Dev. Clay Sci. 1, p 309–377 https://doi.org/10.1016/S1572-4352(05)01010-X

Graziano G, Klimeš J, Fernandez-Alonso F, Michaelides A (2012) Improved description of soft layered materials with Van der Waals density functional theory. J Phys Condens Matter 24(42):1–8. https://doi.org/10.1088/0953-8984/24/42/424216

Alexandre M, Dubois P (2000) Polymer-layered silicate nanocomposites: preparation, properties, and uses of a new class of materials. Mater Sci Eng R Rep 28(1):1–63. https://doi.org/10.1016/S0927-796X(00)00012-7

Das A, Costa FR, Wagenknecht U, Heinrich G (2008) Nanocomposites based on chloroprene rubber: effect of chemical nature and organic modification of nanoclay on the vulcanizate properties. Eur Polym J 44(11):3456–3465. https://doi.org/10.1016/j.eurpolymj.2008.08.025

Chiu CW, Lin JJ (2012) Self-assembly behavior of polymer-assisted clays. Prog Polym Sci 37(3):406–444. https://doi.org/10.1016/j.progpolymsci.2011.07.007

Carli LN, Crespo JS, Mauler RS (2011) PHBV nanocomposites based on organomodified montmorillonite and halloysite: the effect of clay type on the morphology and thermal and mechanical properties. Compos Part A 42:1601–1608

Hansora D and Mishra S (2017) Polybutadiene rubber-based nanoblends (PBR-nB): preparation, characterization and applications. In: Markovic GPMV (eds) Rubber nano blends. Springer series on polymer and composite materials. Springer, Cham. https://doi.org/10.1007/978-3-319-48720-5_6

Esmaeili ESA, Rounaghi J, Eckert (2021) Mechanochemical synthesis of rosin-modified montmorillonite: a breakthrough approach to the next generation of ommt/rubber nanocomposites. Nanomaterials 11(8):1–14. https://doi.org/10.3390/nano11081974

Kango S, Kalia S, Celli A, Njuguna J, Habibi Y, Kumar R (2013) Surface modification of inorganic nanoparticles for development of organic-inorganic nanocomposites—a review. Prog Polym Sci 38(8):1232–1261. https://doi.org/10.1016/j.progpolymsci.2013.02.003

Yung KC, Wang J, Yue TM (2006) Modeling young’s modulus of polymer-layered silicate nanocomposites using a modified Halpin—Tsai micromechanical model. J Reinf Plast Compos 25(8):847–861. https://doi.org/10.1177/0731684406065135

Chanra J, Budianto E, Soegijono B (2019) Surface modification of montmorillonite by the use of organic cations via conventional ion exchange method. In: IOP conference series: materials science and engineering, vol 501, no 1, p 1–7, https://doi.org/10.1088/1757-899X/509/1/012057

Das A, Costa FR, Wagenknecht U, Heinrich G (2008) Nanocomposites based on chloroprene rubber: effect of chemical nature and organic modification of nanoclay on the vulcanizate properties. Eur Polymer J 44(11):3456–3465. https://doi.org/10.1016/j.eurpolymj.2008.08.025

Kanny K and Mohan TP (2017) Rubber nanocomposites with nanoclay as the filler. In: Progress in rubber nanocomposites, p 153–177. https://doi.org/10.1016/B978-0-08-100409-8.00005-X

He W, Yao Y, Qin S, Yu J, He M, Xu C, Xu G (2016) Effect of morphology and composition of organic montmorillonite on the structure and properties of poly (butylene terephthalate) nanocomposites. J Macromol Sci Part B 2348:1–32. https://doi.org/10.1080/00222348.2016.1151625

Dantas de Oliveira A and Augusto Gonçalves Beatrice C (2019) Polymer nanocomposites with different types of nanofiller. In: Nanocomposites—recent evolutions, p 103–127, https://doi.org/10.5772/intechopen.81329

Tiemann M, Weinberger C (2021) Selective modification of hierarchical pores and surfaces in nanoporous materials. Adv Mater Interfaces 8(4):1–17. https://doi.org/10.1002/admi.202001153

Nair MV, Kumar AS, Joseph S, Zachariah AK, Maria HJ, Thomas S (2021) Synergistic effect of hybrid fillers on transport behavior of NR/EPDM blends. J Integr Sci Technol 9(1):9–21

Arthi Feiona G, Sabeena T, Sakthi Bagavathy G, Pushpalaksmi M, Jenson Samraj E, Annadurai J (2020) Synthesis and characterization of ZnO-MMT nanocomposite for antibacterial activity studies. J Appl Sc Environ Manag 24(6):1079–1084. https://doi.org/10.4314/jasem.v24i6.21

Chen H, Li Y, Wang S, Li Y, Zhou Y (2018) Highly ordered structured montmorillonite/brominated butyl rubber nanocomposites: dramatic enhancement of the gas barrier properties by an external magnetic field. J Memb Sci 546:22–30. https://doi.org/10.1016/j.memsci.2017.10.013

He H, Ma Y, Zhu J, Yuan P, Qing Y (2010) Organoclays prepared from montmorillonites with different cation exchange capacity and surfactant configuration. Appl Clay Sci 48:67–72. https://doi.org/10.1016/j.clay.2009.11.024

Middea A, Spinelli LS, Souza FG Jr, Neumann R, Fernandes TLAP, Otavio da Gomes FM (2017) Preparation and characterization of an organo-palygorskite-Fe3O4 nanomaterial for removal of anionic dyes from wastewater. Appl Clay Sci 139:45–53. https://doi.org/10.1016/j.clay.2017.01.017

Das A, Werner K, Jurk R, Jehnichen D, Heinrich G (2011) A general approach to rubber——montmorillonite nanocomposites: intercalation of stearic acid. Appl Clay Sci 51(1–2):117–125. https://doi.org/10.1016/j.clay.2010.11.012

Karamia Z, Jazania OM, Navarchiana AH, Saeb MR (2018) State of cure in silicone/clay nanocomposite coatings: the puzzle and the solution. Prog Org Coat 125:222–233. https://doi.org/10.1016/j.porgcoat.2018.09.019

Thuc CNH, Grillet AC, Reinert L, Ohashi F, Thuc HH, Duclaux L (2010) Separation and purification of montmorillonite and polyethylene oxide modified montmorillonite from Vietnamese bentonites. Appl Clay Sci 49(3):229–238. https://doi.org/10.1016/j.clay.2010.05.011

Barakan S, Aghazadeh V (2019) Separation and characterization of montmorillonite from a low-grade natural bentonite: using a non-destructive method. Micro Nano Lett 14(6):688–693. https://doi.org/10.1049/mnl.2018.5364

Qiao Z, Liu Z, Zhang S, Yang Y, Wu Y, Liu L, Liu Q (2020) Purification of montmorillonite and the influence of the puri fi cation method on textural properties. Appl Clay Sci 187:1–8. https://doi.org/10.1016/j.clay.2020.105491

Dill LP, Kochepka DM, Lima LL, Leitão AA, Wypych F, Cordeiro CS (2021) Brazilian mineral clays: classification, acid activation, and application as catalysts for methyl esterification reactions. J Braz Chem Soc 32(1):145–157. https://doi.org/10.21577/0103-5053.20200164

Liu T, Chen J (2021) Extraction and separation of heavy rare earth elements: A review. Sep Purif Technol 276:119263. https://doi.org/10.1016/j.seppur.2021.119263

Vo VS, Mahouche-Chergui S, Nguyen VH, Naili S, Carbonnier B (2019) Crucial role of covalent surface functionalization of clay nanofillers on improvement of the mechanical properties of bioepoxy resin. ACS Sustain Chem Eng 7(18):15211–15220. https://doi.org/10.1021/acssuschemeng.9b02088

Zheng J, Han D, Zhao S, Ye X, Wang Y, Wu Y, Dong D, Liu J, Wu X, Zhang L (2018) Constructing a multiple covalent interface and isolating a dispersed structure in silica/rubber nanocomposites with excellent dynamic performance. ACS Appl Mater Interfaces 10(23):19922–19931. https://doi.org/10.1021/acsami.8b02358

Al-Sabagh AM, Betiha MA, Osman DI, Hashim AI, El-Sukkarya MM, Mahmoud T (2016) A new covalent strategy for functionalized montmorillonite-poly(methyl methacrylate) for improving the flowability of crude oil. RSC Adv 6(111):109460–109472. https://doi.org/10.1039/C6RA21319G

Zha C, Wang W, Lu Y, Zhang L (2014) Constructing covalent interface in rubber/clay nanocomposite by combining structural modification and interlamellar silylation of montmorillonite. ACS Appl Mater Interfaces 6(21):18769–18779. https://doi.org/10.1021/am504426j

Melouki A, Terchi S, Ouali D, Bounab A (2021) Preparation of new copolymer (polystyrene/TMSPM grafted on DDA-fractionated Algerian MMT) hybrid organoclay by radical copolymerization: structural study, thermal stability, and hydrophobicity area. J Therm Anal Calorim 0123456789:1–12. https://doi.org/10.1007/s10973-021-10935-8

Lv M, Mao J, Zhou Y, Zhou R, Zhou J (2021) Adsorption performance and mechanism of mycotoxin on montmorillonite modified by organosilicon grafting. Arab J Chem 14(9):103314. https://doi.org/10.1016/j.arabjc.2021.103314

Park SJ, Kim BJ, Il Seo D, Rhee KY, Lyu YY (2009) Effects of a silane treatment on the mechanical interfacial properties of montmorillonite/epoxy nanocomposites. Mater Sci Eng A 526(1–2):74–78. https://doi.org/10.1016/j.msea.2009.07.023

Karl CW, Rahimi W, Kubowicz S, Lang A, Geisler H, Giese U (2020) Surface modification of ethylene propylene diene terpolymer rubber by plasma polymerization using organosilicon precursors. ACS Appl Polym Mater 2(9):3789–3796. https://doi.org/10.1021/acsapm.0c00401

Tian M, Meng X, Liu Q, Li W, You X, Liu C, Fortner JD (2022) Hydrophilic montmorillonite in tailoring the structure and selectivity of polyamide membrane. J Membr Sci 657:120674. https://doi.org/10.1016/j.memsci.2022.120674

Bunhu T, Chaukuran N, Tichagwa L (2016) Preparation and characterization of polymer-grafted montmorillonite-lignocellulose nanocomposites by in situ intercalative polymerization. J Appl Chem 2016:1–8. https://doi.org/10.1155/2016/4137398

Abdollahi M, Salarizadeh P, Rouhani M, Rekabdar F (2014) Grafting of hydrophilic monomers onto aminopropyl-functionalized sodium montmorillonite via surface-initiated redox polymerization. Polym Int 63(3):576–583. https://doi.org/10.1002/pi.4593

Altaf F, Batool R, Gill R, Ur Rehman Z, Majeed H, Ahmad A, Shafiq M, Dastan D, Abbas G, Jacob K (2021) Synthesis and electrochemical investigations of ABPBI grafted montmorillonite based polymer electrolyte membranes for PEMFC applications. Renew Energy 164:709–728. https://doi.org/10.1016/j.renene.2020.09.104

Zhu C, Hu T, Tang L, Zeng G, Deng Y, Lu Y, Fang S, Wang J, Liu Y, Yu J (2018) Highly efficient extraction of lead ions from smelting wastewater, slag, and contaminated soil by two-dimensional montmorillonite-based surface ion-imprinted polymer absorbent. Chemosphere 209:246–257. https://doi.org/10.1016/j.chemosphere.2018.06.105

Abu Elella MH, Goda ES, Abdallah HM, Shalan AE, Gamal H, Yoon KR (2021) Innovative bactericidal adsorbents containing modified xanthan gum/montmorillonite nanocomposites for wastewater treatment. Int J Biol Macromol 167:1113–1125. https://doi.org/10.1016/j.ijbiomac.2020.11.065

Lan B, Li P, Luo X, Luo H, Yang Q, Gong P (2021) Hydrogen bonding and topological network effects on optimizing thermoplastic polyurethane/organic montmorillonite nanocomposite foam. Polymer 212:123159. https://doi.org/10.1016/j.polymer.2020.123159

Bokobza L (2019) Natural rubber nanocomposites: a review. Nanomaterials 9(1):1–21. https://doi.org/10.3390/nano9010012

Oliveira M and Machado AV (2013) Preparation of polymer-based nanocomposites by different routes. In: Nanocomposites: synthesis, characterization and applications, p 1–22

Cui L, Paul DR (2011) Polymer nanocomposites from organoclays: structure and properties. Macromol Symp 301(1):9–15. https://doi.org/10.1002/masy.201150302

Uddin F (2018) Montmorillonite: an introduction to properties and utilization. Curr Top Util Clay Ind Med Appl 177:3–24. https://doi.org/10.5772/intechopen.77987

Fu S, Sun Z, Huang P, Li Y, Hu N (2019) Some basic aspects of polymer nanocomposites: a critical review. Nano Mater Sci 1(1):2–30. https://doi.org/10.1016/j.nanoms.2019.02.006

Zheng H, Zhang Y, Peng Z, Zhang Y (2004) Influence of clay modification on the structure and mechanical properties of EPDM/montmorillonite nanocomposites. Polym Test 23(2):217–223. https://doi.org/10.1016/S0142-9418(03)00097-7

Mohomane SM, Djokovic V, Thomas S, Luyt AS (2011) Polychloroprene nanocomposites filled with different organically modified clays: Morphology, thermal degradation, and stress relaxation behavior. Polym Test 30(5):585–593. https://doi.org/10.1016/j.polymertesting.2011.03.002

Fathurrohman MI, Soegijono B, Budianto E, Rohman S, Ramadhan A (2015) The effect of organoclay on curing characteristic, mechanical properties, swelling and morphology of natural rubber/organoclay nanocomposites. Macromol Symp 353(1):62–69. https://doi.org/10.1002/masy.201550308

El-Sabbagh SH, Mahmoud DS, Ahmed NM, Ward AA, Sabaa MW (2017) Composites of styrene butadiene rubber/modified clay: mechanical, dielectric and morphological properties. Pigment Resin Technol 46(3):161–171. https://doi.org/10.1108/PRT-03-2016-0034

Usha Devi KS, Ponnamma D, Causin V, Maria HJ, Thomas S (2015) Enhanced morphology and mechanical characteristics of clay/styrene butadiene rubber nanocomposites. Appl Clay Sci 114:568–576. https://doi.org/10.1016/j.clay.2015.07.009

Esmaeili E, Rounaghi SA, Ecker J (2021) Mechanochemical synthesis of rosin-modified montmorillonite: a breakthrough approach to the next generation of ommt/rubber nanocomposites. Nanomaterials 11(8):1–14. https://doi.org/10.3390/nano11081974

Moustafa H, Lawandy SN, Rabee M, Zahran MAH (2020) Effect of green modification of nanoclay on the adhesion behavior of EPDM rubber to polyester fabric. Int J Adhes Adhes 100:102617. https://doi.org/10.1016/j.ijadhadh.2020.102617

Dilmani MA, Mor Z, Erdoğan A (2017) Preparation and characterization of thermoplastic elastomers/plasticize—compatibilizer/organoclay nanocomposites by reactive extrusion system. Chem Sci J 8(3):1–12. https://doi.org/10.4172/2150-3494.1000166

Archibong FN, Sanusi OM, Mederic P, Ait Hocine N (2021) An overview on recycling waste ground tyre rubbers in thermoplastic matrices: effect of added fillers. Resour Conserv Recycl 175:1–13. https://doi.org/10.1016/j.resconrec.2021.105894

Bhadran B, Vijayan D, George N, Julie Chandra CS, Sabura Begum PM, Joseph R (2018) Reinforcing effect of organoclay in nitrile rubber–effect of mill mixing and latex stage mixing. Appl Clay Sci 165:91–102. https://doi.org/10.1016/j.clay.2018.07.027

Azizli MJ, Khonakdar HA, Mokhtary M, Goodarzi V (2019) Investigating the effect of organoclay montmorillonite and rubber ratio composition on the enhancement compatibility and properties of carboxylated acrylonitrile-butadiene rubber/ethylene-propylene-diene monomer hybrid elastomer nanocomposites. J Polym Res 26(9):1–20. https://doi.org/10.1007/s10965-019-1885-3

Vishvanathperumal S, Gopalakannan S (2019) Effects of the nanoclay and crosslinking systems on the mechanical properties of ethylene-propylene-diene monomer/styrene butadiene rubber blends nanocomposite. SILICON 11(1):117–135. https://doi.org/10.1007/s12633-018-9836-x

Benneghmouche Z, Benachour D (2019) Effect of organophilic clay addition on properties of SAN/EPDM blends. Compos Interfaces 26(8):711–727. https://doi.org/10.1080/09276440.2018.1531655

Jeddi J, Yousefzade O, Babaei A, Ghanbar S, Rostami A (2017) Morphology, microstructure and rheological properties of SAN (styrene-acrylonitrile)/EPDM (ethylene-propylene-diene monomer) nanocomposites: investigating the role of organoclay type and order of mixing. Mater Chem Phys 187:191–202. https://doi.org/10.1016/j.matchemphys.2016.12.001

Durandish M, Alipour A (2013) Investigation into morphology, microstructure, and properties of SBR/EPDM/ORGANO montmorillonite nanocomposites. Chin J Polym Sci (Engl Ed) 31(4):660–669. https://doi.org/10.1007/s10118-013-1262-3

Azizli MJ, Abbasizadeh S, Hoseini M, Rezaeinia S, Azizli E (2017) Influence of blend composition and organic cloisite 15A content in the structure of isobutylene–isoprene rubber/EPDM composites for investigation of the morphology and mechanical properties. J Compos Mater 51(13):1861–1873. https://doi.org/10.1177/0021998316665162

Nematollahi M, Jalali-Arani A, Modarress H (2019) Effect of nanoparticle localization on the rheology, morphology, and toughness of nanocomposites based on poly(lactic acid)/natural rubber/nano-silica. Polym Int 68(4):779–787. https://doi.org/10.1002/pi.5767

Dike AS, Yilmazer U (2020) Mechanical, thermal and rheological characterization of polystyrene/organoclay nanocomposites containing aliphatic elastomer modifiers. Mater Res Express 7(1):1–12. https://doi.org/10.1088/2053-1591/ab66ff

Hu B, Li W, Song J, Wang J (2019) Structure and properties of polypropylene/polyolefin elastomer/organic montmorillonite nanocomposites. J Macromol Sci Part B Phys 58(1):73–87. https://doi.org/10.1080/00222348.2018.1541533

Mang JY, Choi DH, Han MJ (2007) Comparison studies on nitrile-butadiene rubber nanocomposites depending on the organically modified montmorillonites. Solid State Phenom 119:83–86. https://doi.org/10.4028/www.scientific.net/SSP.119.83

Okafor KJ, Edelugo SO, Ezema Ike-Eze IC, Chukwunwike SA (2021) Effect of soaking temperature on the tensile and morphological properties of banana stem fiber-reinforced polyester composite. Polym Bull 78(9):5243–5254. https://doi.org/10.1007/s00289-020-03374-2

Zachariah AK, Chandra AK, Mohammed PK, Thomas S (2019) Vulcanization kinetics and mechanical properties of organically modified nanoclay incorporated natural and chlorobutyl rubber nanocomposites. Polym Test 76:154–165. https://doi.org/10.1016/j.polymertesting.2019.02.003

Hull TR, Price D, Liu Y, Wills CL, Brady J (2003) An investigation into the decomposition and burning behavior of ethylene-vinyl acetate copolymer nanocomposite materials. Polym Degrad Stab 82(2):365–371. https://doi.org/10.1016/S0141-3910(03)00214-3

Zhang X, Cui H, Song L, Ren H, Wang R, He A (2018) Elastomer nanocomposites with superior dynamic mechanical properties via trans-1, 4-poly (butadiene-co-isoprene) incorporation. Compos Sci Technol 158:156–163. https://doi.org/10.1016/j.compscitech.2018.02.025

Razavi-Nouri M, Sabet A, Mohebbi M (2020) Thermal, tensile and rheological properties of dynamically cross-linked organoclay filled poly(ethylene-co-vinyl acetate)/acrylonitrile-butadiene rubber nanocomposites: effect of peroxide content. Polymer (Guildf) 190:1–38. https://doi.org/10.1016/j.polymer.2020.122212

Ogah AO, Afiukwa JN, Nduji AA (2014) Characterization and comparison of rheological properties of agro fiber filled high-density polyethylene bio-composites. Open J Polym Chem 04(01):12–19. https://doi.org/10.4236/ojpchem.2014.41002

Bitinis N, Fortunati E, Verdejo R, Rmentano I, Torre L, Kenny JM, López-Manchado MA (2014) Thermal and bio-disintegration properties of poly(lactic acid)/natural rubber/organoclay nanocomposites. Appl Clay Sci 93–94:78–84. https://doi.org/10.1016/j.clay.2014.02.024

Attia NF, Mohamed GG, Ismail MM, Abdou TT (2020) Influence of organic modifier structures of 2D clay layers on thermal stability, flammability and mechanical properties of their rubber nanocomposites. J Nanostructure Chem 10(2):161–168. https://doi.org/10.1007/s40097-020-00338-w

Lu Y, Wang J, Wang L, Song S (2021) Diphenolic acid-modified PAMAM/chlorinated butyl rubber nanocomposites with superior mechanical, damping, and self-healing properties. Sci Technol Adv Mater 22(1):14–25. https://doi.org/10.1080/14686996.2020.1861912

Ivanoska-Dacikj A, Bogoeva-Gaceva G, Rooj S, Wießner S, Heinrich G (2015) Fine tuning of the dynamic mechanical properties of natural rubber/carbon nanotube nanocomposites by organically modified montmorillonite: a first step in obtaining high-performance damping material suitable for seismic application. Appl Clay Sci 118:99–106. https://doi.org/10.1016/j.clay.2015.09.009

Córdova WR, Julve D, Martínez M, Pérez J, Meier JG (2021) Effects of additives of organically modified montmorillonite and octosilicate in a silica reinforced tire tread mixture. Appl Clay Sci 200:1–11. https://doi.org/10.1016/j.clay.2020.105938

Ashok N, Balachandran M, Das NC, Remanan S (2021) Nanoreinforcement mechanism of organomodified layered silicates in EPDM/CIIR blends: experimental analysis and theoretical perspectives of static mechanical and viscoelastic behavior. Compos Interfaces 28(1):35–62. https://doi.org/10.1080/09276440.2020.1736879

Ogah AO (2017) Characterization of sorghum bran/recycled low-density polyethylene for manufacturing polymer composites. J Polym Environ 25(3):533–543. https://doi.org/10.1007/s10924-016-0830-3

Ukeme JT, Ogah AO (2021) Transport properties of toluene through reactive compatibilized polyethylene terephthalate/natural rubber using dikanut shell powder as filler. Eur J Adv Eng Technol 8(5):9–20

Hejazi I, Sharif F, Garmabi H (2011) Effect of material and processing parameters on mechanical properties of polypropylene/ethylene–propylene–diene–monomer/clay nanocomposites. Mater Des 32:3803–3809. https://doi.org/10.1016/j.matdes.2011.03.017

Triantou MI, Gavriel M, Sakellaris P, Tarantil PA (2016) The effect of compatibilizers and organically modified nanoclay on poly’s morphology and performance properties (acrylonitrile–butadiene–styrene)/polypropylene blends. Polym Eng Sci 56:458–468. https://doi.org/10.1002/pen

Wang D, Feng LF, Gu XP, Wang JJ, Zhang CL, He AH (2019) Synergetic effect of a reactive compatibilizer and organo-montmorillonite on the dispersion of polyamide 6 /polydimethylsilicone blend with a high viscosity ratio. Ind Eng Chem Res 58(9):3714–3720. https://doi.org/10.1021/acs.iecr.8b06197

Balakrishnan H, Attaran SA, Imran M, Hassan A, Wahit MU (2014) Epoxidized natural rubber-toughened polypropylene/organically modified montmorillonite nanocomposites. J Thermoplast Compos Mater 27(2):233–250. https://doi.org/10.1177/0892705712443252

Mahdavinia GR, Aghaie H, Sheykhloie H, Vardini MT, Etemadi H (2013) Synthesis of CarAlg/MMT nanocomposite hydrogels and adsorption of cationic crystal violet. Carbohydr Polym 98(1):358–365. https://doi.org/10.1016/j.carbpol.2013.05.096

Nworie FS, Nwabue F, Ikelle II, Ogah AO, Elom N, Illochi NO, Itumoh EJ, Oroke CE (2018) Activated plantain peel biochar as adsorbent for sorption of Zinc(II) ions: Equilibrium and kinetics Studies. J Turk Chem Soc Sec A Chem 5(3):1257–1270. https://doi.org/10.18596/jotcsa.438332

Peighambardoust SJ, Aghamohammadi-Bavil O, Foroutan R, Arsalani N (2020) Removal of malachite green using carboxymethyl cellulose-g-polyacrylamide/montmorillonite nanocomposite hydrogel. Int J Biol Macromol 159:1122–1131. https://doi.org/10.1016/j.ijbiomac.2020.05.093

Ilgin P, Durak H, Gür A (2015) A novel pH-responsive p(AAm-co-METAC)/MMT composite hydrogel: synthesis, characterization and Its absorption performance on heavy metal ions. Polym Plast Technol Eng 54(6):603–615. https://doi.org/10.1080/03602559.2014.974189

Roufegari-Nejhad E, Sirousazar M, Abbasi-Chiyaneh V, Kheiri F (2019) Removal of methylene blue from aqueous solutions using poly(vinyl alcohol)/montmorillonite nanocomposite hydrogels: taguchi optimization. J Polym Environ 27(10):2239–2249. https://doi.org/10.1007/s10924-019-01514-y

Paritosh Shukla AS, Sharma A (2017) Food additives from an organic chemistry perspective. MOJ Bioorganic Org Chem 1(3):70–79. https://doi.org/10.15406/mojboc.2017.01.00015

Panel E (2016) Safety and efficacy of a natural mixture of illite, montmorillonite, and kaolinite (Argile Verte du Velay) as a feed additive for all animal species. EFSA J 14(1):1–18. https://doi.org/10.2903/j.efsa.2016.4342

Silano V, Barat Baviera JM, Bolognesi C, Brüschweiler BJ, Chesson A, Cocconcelli PS, Crebelli R, Gott DM, Grob K, Lampi E, Mortensen A, Steffensen I, Tlustos C, Loveren HV, Vernis L, Zorn H, Castle L, Cravedi J, Kolf-Clauw M, Milana MR, Pfaff K, Pocas MFT, Svensson K, Wolfle D, Barthelemy D, Riviere G (2019) Safety assessment of the substance, montmorillonite clay modified with hexadecyltrimethylammonium bromide, for use in food contact materials. EFSA J 17(1):1–8. https://doi.org/10.2903/j.efsa.2019.5552

Nadziakiewicza M, Kehoe S, Micek P (2019) Physico-chemical properties of clay minerals and their use as a health-promoting feed additive. Animals 9(10):1–15. https://doi.org/10.3390/ani9100714

Palm HW, Sörensen H, Knaus U (2015) Montmorillonite clay minerals with or without microalgae as a feed additive in larval white leg shrimp (Litopenaeus vannamei). Ann Aquac Res 2(1):1008

Liu H, Wang C, Gu X, Zhao J, Nie C, Zhang W, Ma X (2020) Dietary montmorillonite improves the intestinal mucosal barrier and optimizes the intestinal microbial community of weaned piglets. Front Microbiol 11:1–14. https://doi.org/10.3389/fmicb.2020.593056

Bumbudsanpharoke N, Ko S (2019) Nanoclays in food and beverage packaging. J Nanomater 2019:1–14. https://doi.org/10.1155/2019/8927167

Giannakas A.E and Leontiou AA (2017) Montmorillonite composite materials, and food packaging. 1–71, https://doi.org/10.1002/9781119160243.ch1.

Ahari H, Anvar AA, Ataee M, Naeimabadi M (2021) Employing nanosilver, nanocopper, and nanoclays in food packaging production: a systematic review. Coatings 11(5):1–29. https://doi.org/10.3390/coatings11050509

Salvatore M, Marra A, Duraccio D, Shayanfar S, Pillai SD, Cimmino S, Silvestre C (2016) Effect of electron beam irradiation on the properties of polylactic acid/montmorillonite nanocomposites for food packaging applications. J Appl Polym Sci 13(2):1–12. https://doi.org/10.1002/app.42971

Vilarinho F, Vaz MF, Silva AS (2019) The use of montmorillonite (MMT) in food nanocomposites: methods of incorporation, characterization of MMT/polymer nanocomposites and main consequences in the properties. Recent Pat Food Nutr Agric 11(1):13–26. https://doi.org/10.2174/2212798410666190401160211

Sarfraz J, Gulin-Sarfraz T, Nilsen-Nygaard J, Pettersen MK (2021) Nanocomposites for food packaging applications: an overview. Nanomaterials 11:1–27. https://doi.org/10.3390/nano11010010

Attaran SA, Hassan A, Wahit MU (2017) Materials for food packaging applications based on bio-based polymer nanocomposites. J Thermoplast Compos Mater 30(2):143–173. https://doi.org/10.1177/0892705715588801

Dias MV, de Azevedo VM, Ferreira LF, Carolina A, de Oliveira S, Borges SV, Soares NFF, Medeiros EAA, Carneiro JDS (2021) Chitosan-nanocomposites as a food active packaging: effect of addition of tocopherol and modified montmorillonite. J Food Process Eng 44(11):1–13. https://doi.org/10.1111/jfpe.13843

Tsagkalias IS, Loukidi A, Chatzimichailidou S, Almas CE, Giannakas AE, Achilias DS (2021) Effect of nano and organo-modified montmorillonite/essential oil nanohybrids on the kinetics of the in situ radical polymerizations of styrene. Nanomaterials 11(2):1–25. https://doi.org/10.3390/nano11020474

Lee NY, Ko WC, Hsueh PR (2019) Nanoparticles in the treatment of infections caused by multidrug-resistant organisms. Front Pharmacol 10:1–10. https://doi.org/10.3389/fphar.2019.01153

Peterson E, Kaur P (2018) Antibiotic resistance mechanisms in bacteria: relationships between resistance determinants of antibiotic producers, environmental bacteria, and clinical pathogens. Front Microbiol 9:1–21. https://doi.org/10.3389/fmicb.2018.02928

Crag GM, Newman DJ (2013) Natural products: a continuing source of novel drug leads. Biochim Biophys Acta Gen Subj 1830(6):3670–3695. https://doi.org/10.1016/j.bbagen.2013.02.008

Martin S, Griswold W (2009) Human health effects of heavy metals. Cent Hazard Subst 15:1–6

Mathur P, Jha S, Ramteke S, Jain NK (2018) Pharmaceutical aspects of silver nanoparticles. Arti Cells Nanomed Biotechnol 46(sup1):115–126. https://doi.org/10.1080/21691401.2017.1414825

Zhang XF, Liu ZG, Shen W, Gurunathan S (2016) Silver nanoparticles: synthesis, characterization, properties, applications, and therapeutic approaches. Int J Mol Sci 17(9):1–34. https://doi.org/10.3390/ijms17091534

Noori F, Neree AT, Megoura M, Mateescu MA, Azzouz A (2021) Insights into the metal retention role in the antibacterial behavior of montmorillonite and cellulose tissue-supported copper and silver nanoparticles. RSC Adv 11(39):24156–24171. https://doi.org/10.1039/d1ra02854e

Cui R, Yan J, Cao J, Qin Y, Yuan M, Li L (2021) Release properties of cinnamaldehyde loaded by montmorillonite in chitosan-based antibacterial food packaging. Int J Food Sci Technol 56(8):3670–3681. https://doi.org/10.1111/ijfs.14912

Ma X, Gao L, Ma Y, Zhang X (2021) Antibacterial activity and mechanism of ZnO/Cu2+-chitosan/montmorillonite. J Wuhan Univ Technol Mater Sci Ed 36(4):510–516. https://doi.org/10.1007/s11595-021-2438-2

Seleci M, Ag D, Yalcinkaya EE, Demirkol DO, Guler C, Timur S (2012) Amine-intercalated montmorillonite matrices for enzyme immobilization and biosensing applications. RSC Adv 2:2112–2118. https://doi.org/10.1039/c2ra01225a

Demir F, Demir B, Yalcinkaya EE, Cevik S, Demirkol D, Anik U, Timu S (2014) Amino acid intercalated montmorillonite: electrochemical biosensing applications. RSC Adv 4(91):50107–50113. https://doi.org/10.1039/C4RA07026G

Unal B, Yalcinkaya EE, Gumustas S, Sonmez B, Ozkan M, Balcan M, Demirkol DO, Timur S (2017) Polyglycolide-montmorillonite as a novel nanocomposite platform for biosensing applications. New J Chem 41(17):9371–9379. https://doi.org/10.1039/c7nj01751k

Giovannini C, Garoli D, Rupper P, Neels A, Rossi RM, Boesel LF (2021) Metal-modified montmorillonite as plasmonic microstructure for direct protein detection. Sensors 21:1–16. https://doi.org/10.3390/s21082655

Zheng H, Liu M, Yan Z, Chen J (2020) Highly selective and stable glucose biosensor based on the incorporation of platinum nanoparticles into polyaniline-montmorillonite hybrid composites. Microchem J 152:104266. https://doi.org/10.1016/j.microc.2019.104266

Yilmaz YY, Yalcinkaya EE, Demirkol DO, Timur S (2020) 4-aminothiophenol-intercalated montmorillonite: organic-inorganic hybrid material as an immobilization support for biosensors. Sens Actuators B Chem 307:127665. https://doi.org/10.1016/j.snb.2020.127665

Altaf F, Batool R, Gill R, Rehman Z, Majeed H, Ahmad A, Shafiq M, Dastan D, Abbas G, Jacob K (2021) Synthesis and electrochemical investigations of ABPBI grafted montmorillonite based polymer electrolyte membranes for PEMFC applications. Renew Energy 164:709–728. https://doi.org/10.1016/j.renene.2020.09.104

Hasani-Sadrabadi MM, Dashtimoghadam E, Majedi FS, Kabiri K (2009) Nafion®/bio-functionalized montmorillonite nanohybrids as novel polyelectrolyte membranes for direct methanol fuel cells. J Power Sources 190(2):318–321. https://doi.org/10.1016/j.jpowsour.2009.01.043

Wilberforce T, Alaswad A, Palumbo A, Dassisti M, Olabi AG (2016) Advances in stationary and portable fuel cell applications. Int J Hydrogen Energy 41(37):16509–16522. https://doi.org/10.1016/j.ijhydene.2016.02.057

Yang W, Li J, Fu Q, Zhang L, Wei Z, Liao Q, Zhu X (2021) Minimizing mass transfer losses in microbial fuel cells: Theories, progresses and prospectives. Renew Sustain Energy Rev 136:110460. https://doi.org/10.1016/j.rser.2020.110460

Charradi K, Ahmed Z, Aranda P, Chtourou R (2019) Silica/montmorillonite nanoarchitectures, and layered double hydroxide-SPEEK based composite membranes for fuel cells applications. Appl Clay Sci 174:77–85. https://doi.org/10.1016/j.clay.2019.03.027

Ahilan V, Wilhelm M, Rezwan K (2018) Porous polymer derived ceramic (PDC)-montmorillonite-H3PMo12O40/SiO2 composite membranes for microbial fuel cell (MFC) application. Ceram Int 44:19191–19199. https://doi.org/10.1016/j.ceramint.2018.07.138

Sheikh-Mohseni MH, Sedaghat S, Derakhshi P, Safekordi A (2019) Electrochemical activity of Ni-montmorillonite/Vulcan XC-72R carbon black nano-catalyst for the oxidation of methanol in acidic medium. J Nanostructure Chem 9:217–224. https://doi.org/10.1007/s40097-019-00312-1

Nikfarjam N, Ghomi M, Agarwal T, Hassanpour M, Sharifi E, Khorsandi D, Ali Khan M, Rossi F, Rossetti A, NazarzadehZare E, Rabiee N, Afshar D, Vosough M, Kumar Maiti T, Mattoli V, Lichtfouse E, Tay FR, Makvandi P (2021) Antimicrobial ionic liquid-based materials for biomedical applications. Adv Funct Mater 31(42):1–27. https://doi.org/10.1002/adfm.202104148

Ul-Islam M, Khan T, Park JK (2012) Nanoreinforced bacterial cellulose-montmorillonite composites for biomedical applications. Carbohydr Polym 89(4):1189–1197. https://doi.org/10.1016/j.carbpol.2012.03.093

Amalraj A, Gopi S, Thomas S, Haponiuk JT (2018) Cellulose nanomaterials in biomedical, food, and nutraceutical applications: a review. Macromol Symp 380(1):1–9. https://doi.org/10.1002/masy.201800115

Sharifzadeh G, Hezaveh H, Muhamad II, Hashim S, Khairuddin N (2020) Montmorillonite-based polyacrylamide hydrogel rings for controlled vaginal drug delivery. Mater Sci Eng C 110:110609. https://doi.org/10.1016/j.msec.2019.110609

Sajjad W, Khan T, Ui Islam M, Khan R, Hussain Z, Khalid A, Wahid F (2019) Development of modified montmorillonite-bacterial cellulose nanocomposites as a novel substitute for burn skin and tissue regeneration. Carbohydr Polym 206:548–556. https://doi.org/10.1016/j.carbpol.2018.11.023

Ng HM, Bee ST, Sin LT, Ratnam CT, Rahmat AR (2020) Interaction effect of Scomberomorus guttatus-derived hydroxyapatite and montmorillonite on the characteristics of polylactic acid blends for biomedical application. J Polym Res 27(8):1–24. https://doi.org/10.1007/s10965-020-02138-w

Sreekanth Reddy O, Subha MC, Jithendra T, Madhavi C, Chowdoji Rao K (2021) Curcumin encapsulated dual cross-linked sodium alginate/montmorillonite polymeric composite beads for controlled drug delivery. J Pharm Anal 11(2):191–199. https://doi.org/10.1016/j.jpha.2020.07.002

Park JH, Shin HJ, Kim MH, Kim JS, Kang N, Lee JY, Kim KT, Lee JI, Kim DD (2016) Application of montmorillonite in bentonite as a pharmaceutical excipient in drug delivery systems. J Pharm Investig 46:363–375. https://doi.org/10.1007/s40005-016-0258-8

Iliescu RI, Andronescu E, Voicu G, Ficai A, Covaliu CI (2011) Applied Clay Science Hybrid materials based on montmorillonite and citostatic drugs: preparation and characterization. Appl Clay Sci 52(1–2):62–68. https://doi.org/10.1016/j.clay.2011.01.031

Del Hoyo C, Rives V, Vicente MA (1996) Thermal studies of pharmaceutical-clay systems Part I Montmorillonite-based systems. Thermochim Acta 286(1):89–103. https://doi.org/10.1016/0040-6031(96)02946-2

Hassani A, Khataee A, Karaca S, Fathinia M (2017) Degradation of mixture of three pharmaceuticals by photocatalytic ozonation in the presence of TiO2/montmorillonite nanocomposite: simultaneous determination and intermediates identification. J Environ Chem Eng 5(2):1964–1976. https://doi.org/10.1016/j.jece.2017.03.032

Kryuchkova M, Batasheva S, Akhatova F, Babaev V, Buzyurova D, Vikulina A, Volodkin D, Fakhrullin R, Rozhina E (2021) Pharmaceuticals removal by adsorption with montmorillonite nanoclay. Int J Mol Sci 22(18):1–15. https://doi.org/10.3390/ijms22189670

Chauhan M, Saini VK, Suthar S (2020) Ti-pillared montmorillonite clay for adsorptive removal of amoxicillin, imipramine, diclofenac-sodium, and paracetamol from water. J Hazard Mater 399:122832. https://doi.org/10.1016/j.jhazmat.2020.122832

Zakuwan SZ, Ahmad I (2018) Synergistic effect of hybridized cellulose nanocrystals and organically modified montmorillonite on κ-carrageenan bionanocomposites. Nanomaterials 8(11):1–14. https://doi.org/10.3390/nano8110874

Sandri G, Faccendini A, Longo M, Ruggeri M, Rossi S, Bonferroni MC, Miele D, Prina-Mello A, Aguzzi C, Viseras C, Ferrari F (2020) Halloysite-and montmorillonite-loaded scaffolds as enhancers of chronic wound healing. Pharmaceutics 12(2):1–19. https://doi.org/10.3390/pharmaceutics12020179

Vallova S, Plevova E, Smutna K, Sokolova B, Vaculikova L, Valovicova V, Hundakova M, Praus P (2021) Removal of analgesics from aqueous solutions onto montmorillonite KSF. J Therm Anal Calorim 147:1–9. https://doi.org/10.1007/s10973-021-10591-y

Olad A, Farshi Azhar F (2014) The synergetic effect of bioactive ceramic and nanoclay on the properties of chitosan-gelatin/nanohydroxyapatite-montmorillonite scaffold for bone tissue engineering. Ceram Int 40:10061–10072. https://doi.org/10.1016/j.ceramint.2014.04.010

Wong LW, Goh CBS, Pasbakhsh P, Tan JBL (2022) Natural hollow clay nanotubes and their applications as polymer nanocomposites in tissue engineering. J Sci Adv Mater Devices 7(2):100431. https://doi.org/10.1016/j.jsamd.2022.1004

Koç Demir A, Elçin AE, Elçin YM (2018) Strontium-modified chitosan/montmorillonite composites as bone tissue engineering scaffold. Mater Sci Eng C 89:8–14. https://doi.org/10.1016/j.msec.2018.03.021

Zheng JP, Wang CZ, Wang XX, Wang HY, Zhuang H, De Yao K (2007) Preparation of biomimetic three-dimensional gelatin/montmorillonite-chitosan scaffold for tissue engineering. React Funct Polym 67:780–788. https://doi.org/10.1016/j.reactfunctpolym.2006.12.002

Cui ZK, Kim S, Baljon JJ, Wu BM, Aghaloo T, Lee M (2019) Microporous methacrylated glycol chitosan-montmorillonite nanocomposite hydrogel for bone tissue engineering. Nat Commun 10:1–10. https://doi.org/10.1038/s41467-019-11511-3

Olad A, Bakht Khosh Hagh H, Mirmohseni A, Farshi Azhar F (2019) Graphene oxide and montmorillonite enriched natural polymeric scaffold for bone tissue engineering. Ceram Int 45(12):15609–15619. https://doi.org/10.1016/j.ceramint.2019.05.071

Yu K, Zhu T, Wu Y, Zhou X, Yang X, Wang J, Fang J, El-Hamshary H, Al-Deyab SS, Mo X (2017) Incorporation of amoxicillin-loaded organic montmorillonite into poly(ester-urethane) urea nanofibers as a functional tissue engineering scaffold. Colloids Surf. B Biointerfaces 151:314–323. https://doi.org/10.1016/j.colsurfb.2016.12.034

Batra R, Purwar R, Kulanthaivel S, Mishra P (2021) Cetyl trimethyl ammonium bromide modified montmorillonite-doped tasar silk fibroin/polyvinyl alcohol blend 3D nanowebs for tissue engineering applications. Macromol Mater Eng 2100450:1–12. https://doi.org/10.1002/mame.202100450

Demirdögen B, Plazas Bonilla CE, Trujillo S, Perilla JE, Elcin AE, Elcin YM, Gómez Ribelles JL (2014) Silica coating of the pore walls of a microporous polycaprolactone membrane to be used in bone tissue engineering. J Biomed Mater Res Part A 102(9):3229–3236. https://doi.org/10.1002/jbm.a.34999

Akbari N, Khorshidi S, Karkhaneh A (2022) Effect of piezoelectricity of nanocomposite electrospun scaffold on cell behavior in bone tissue engineering. Iran Polym J. https://doi.org/10.1007/s13726-022-01047-7

Kundu K, Afshar A, Katti DR, Edirisinghe M, Katti KS (2021) Composite nanoclay-hydroxyapatite-polymer fiber scaffolds for bone tissue engineering manufactured using pressurized gyration. Compos Sci Technol 202:108598. https://doi.org/10.1016/j.compscitech.2020.108598

Chellapandi T, Madhumitha G (2021) Montmorillonite clay—based heterogeneous catalyst for the synthesis of nitrogen heterocycle organic moieties: a review. Mol Divers 26:1–29. https://doi.org/10.1007/s11030-021-10322-3

Dasgupta S, Török B (2008) Application of clay catalysts in organic synthesis a review. Org Prep Proced Int 40(1):1–65. https://doi.org/10.1080/00304940809356640

Li M, Li Y, Yu P, Zhao H, Xiang L, Feng N, Li Q, He K, Luo X, Cai Q, Zhou S, Moa C, Yeung K (2022) Exploring degradation mechanism of tetracycline via high-effective peroxymonosulfate catalysts of montmorillonite hybridized CoFe composites and safety assessment. Chem Eng J 427:130930. https://doi.org/10.1016/j.cej.2021.130930

Bonacci S, Iriti G, Mancuso S, Novelli P, Paonessa R, Tallarico S, Nardi M (2020) Montmorillonite K10: an efficient organo-heterogeneous catalyst for synthesis of benzimidazole derivatives. Catalysts 10:1–12. https://doi.org/10.3390/catal10080845

Vaculíková L, Valovičová V, Plevová P, Napruszewska BD, Duraczyńska D, Karcz R, Serwicka EM (2021) Synthesis, characterization and catalytic activity of cryptomelane/montmorillonite composites. Appl Clay Sci 202:1–9. https://doi.org/10.1016/j.clay.2021.105977

Munir M, Ahmad M, Rehan M, Saeed M, Shiung Lam Su, Nizami AS, Waseem A, Sultana S, Zafar M (2021) Production of high-quality biodiesel from novel non-edible Raphnus raphanistrum L. seed oil using copper modified montmorillonite clay catalyst. Environ Res 193:110398. https://doi.org/10.1016/j.envres.2020.110398

Zhang L, Xu J, Shen H, Xu J, Cao J (2021) Montmorillonite-catalyzed furfurylated wood for flame retardancy. Fire Saf J 121:03297. https://doi.org/10.1016/j.firesaf.2021.103297

Acknowledgements

The authors are grateful to our respective universities for creating the enabling environment for this work.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Dale Huber.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Archibong, F.N., Orakwe, L.C., Ogah, O.A. et al. Emerging progress in montmorillonite rubber/polymer nanocomposites: a review. J Mater Sci 58, 2396–2429 (2023). https://doi.org/10.1007/s10853-023-08173-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08173-4