Abstract

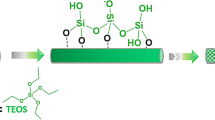

Polypropylene (PP)/sisal fiber (SiF)/cellulose nanocrystals (CNC) hybrid composites were prepared at a variable weight percentage of SiF/CNC loading (29:1, 27:3, 25:5, and 23:7) using melt-blending technique followed by injection molding. The dispersion of the CNCs and SiFs within the nonpolar PP matrix was enhanced by using maleic anhydride grafted PP (MAPP) as a compatibilizer. Furthermore, the mechanical properties like tensile, flexural, and impact properties of the hybrid composites were evaluated. High tensile strength and modulus of 47.02 MPa and 2820.26 MPa, respectively, were observed for the hybrid composite with the incorporation of SiF/CNC (27:3 wt%) in the presence of 5 wt% MAPP. Additionally, an increment of 30.87% and 14.81% was observed for corresponding flexural strength and modulus as compared to their counterparts without MAPP. The elastic moduli obtained experimentally were compared with the theoretical elastic moduli using Cox–Krenchel and Ouali model in combination with the Halpin–Tsai model. Surface morphology by field emission scanning electron microscopy observed that the CNCs and SiFs were well dispersed within the PP matrix in the presence of MAPP. Differential scanning calorimetry thermograms showed no measurable changes in the melting temperature (Tm) of PP in PP hybrid composites; however, an increment in the crystallization temperature (Tc) was observed. The thermogravimetric analysis confirmed the enhancement in the thermal stability of PP hybrid composites due to the synergistic effect of hybridization within the PP matrix. Partial substitution of CNCs along with SiFs within the matrix polymer shows an increment in the stiffness of the hybrid composites as evident by dynamic mechanical analysis.

Graphic abstract

Similar content being viewed by others

References

Dhand V, Mittal G, Rhee KY, Park S-J, Hui D (2015) A short review on basalt fibers reinforced polymer composites. Compos Part B Eng 73:166–180

Czigány T (2006) Special manufacturing and characteristics of basalt fiber reinforced hybrid polypropylene composites: mechanical properties and acoustic emission study. Compos Sci Technol 66(16):3210–3220

Nayak SK, Mohanty S, Samal SK (2009) Influence of short bamboo/glass fibers on the thermal, dynamic mechanical and rheological properties of polypropylene hybrid composites. Mater Sci Eng A 523:32–38

Saba N, Tahir PM, Jawaid M (2014) A review on potentiality of nano filler/natural fiber filled polymer hybrid composites. Polymers (Basel) 6:2247–2273

Kaewkuk S, Sutapun W, Jarukumjorn K (2013) Effects of interfacial modification and fibers content on physical properties of sisal fibers/polypropylene composites. Compos Part B Eng 45:544–549

Joseph K, Thomas S, Pavithran C, Brahmakumar M (1993) Tensile properties of short sisal fiber-reinforced polyethylene composites. J Appl Polym Sci 47(10):1731–1739

Mohanty S, Verma SK, Nayak SK, Tripathy SS (2004) Influence of fibers treatment on the performance of sisal-polypropylene composites. J Appl Polym Sci 94:1336–1345

Fu SY, Lauke B, Mäder E, Yue CY, Hu X (2000) Tensile properties of short-glass-fiber-and short-carbon-fiber-reinforced polypropylene composites. Compos A Appl Sci Manuf 31(10):1117–1125

Kumar S, Doshi H, Srinivasarao M, Park JO, Schiraldi DA (2002) Fibers from polypropylene/nano carbon fiber composites. Polymer 43(5):1701–1703

Samal SK, Mohanty S, Nayak SK (2009) Banana/glass fibers-reinforced polypropylene hybrid composites: fabrication and performance evaluation. Polym Plast Technol Eng 48:397–414

Rahman NA, Hassan A, Yahya R, Lafia-Araga R, Hornsby P (2012) Polypropylene/glass fibers/nanoclay hybrid composites: morphological, thermal, dynamic mechanical and impact behaviours. J Reinf Plast Compos 31:1247–1257

Samal SK, Mohanty S, Nayak SK (2009) Polypropylene—bamboo/glass fiber hybrid composites: fabrication and analysis of mechanical, morphological, thermal, and dynamic mechanical behaviour. J Reinf Plast Compos 28(22):2729–2747

Botev M, Betchev H, Bikiaris D, Panayiotou C (1999) Mechanical properties and viscoelastic behaviour of basalt fibers-reinforced polypropylene. J Appl Polym Sci 74:523–531

Yang HS, Gardner DJ, Nader JW (2011) Characteristic impact resistance model analysis of cellulose nanofibril-filled polypropylene composites. Compos Part A Appl Sci Manuf 42:2028–2035

Bahar E, Ucar N, Onen A, Wang Y, Oksüz M, Ayaz O, Ucar M, Demir A (2012) Thermal and mechanical properties of polypropylene nanocomposite materials reinforced with cellulose nano whiskers. J Appl Polym Sci 125(4):2882–2889

Peng Y, Gallegos SA, Gardner DJ, Han Y, Cai Z (2016) Maleic anhydride polypropylene modified cellulose nanofibril polypropylene nanocomposites with enhanced impact strength. Polym Compos 37(3):782–793

Gwon JG et al (2018) Physicochemical and mechanical properties of polypropylene-cellulose nanocrystal nanocomposites: effects of manufacturing process and chemical grafting. BioResources 13:1619–1636

Foulk JA, Chao WY, Akin DE, Dodd RB, Layton PA (2006) Analysis of flax and cotton fibers fabric blends and recycled polyethylene composites. J Polym Environ 14:15–25

Khan MA, Ganster J, Fink HP (2009) Hybrid composites of jute and man-made cellulose fibers with polypropylene by injection moulding. Compos Part A Appl Sci Manuf 40:846–851

Idicula M, Joseph K, Thomas S (2010) Mechanical performance of short banana/sisal hybrid fibers reinforced polyester composites. J Reinf Plast Compos 29:12–29

Josefsson G, Berthold F, Gamstedt EK (2014) Stiffness contribution of cellulose nanofibrils to composite materials. Int J Solids Struct 51:945–953

Gogoi R, Manik G, Arun B (2019) High specific strength hybrid polypropylene composites using carbon fiber and hollow glass microspheres: development, characterization and comparison with empirical models. Compos Part B Eng 173:106875

Gupta MK, Choudhary N, Agrawal V (2018) Static and dynamic mechanical analysis of hybrid composite reinforced with jute and sisal fibres. J Chin Adv Mater Soc 6(4):666–678

Alshammari BA, Saba N, Alotaibi MD, Alotibi MF, Jawaid M, Alothman OY (2019) Evaluation of mechanical, physical, and morphological properties of epoxy composites reinforced with different date palm fillers. Materials 12(13):2145

Agarwal J, Sahoo S, Mohanty S, Nayak SK (2019) Progress of novel techniques for lightweight automobile applications through innovative eco-friendly composite materials: a review. J Thermoplast Compos Mater 3:12

Hanan F, Jawaid M, Md Tahir P (2020) Mechanical performance of oil palm/kenaf fiber-reinforced epoxy-based bilayer hybrid composites. J Nat Fibers 17(2):155–167

Dhar P, Tarafder D, Kumar A, Katiyar V (2015) Effect of cellulose nanocrystal polymorphs on mechanical, barrier and thermal properties of poly(lactic acid) based bionanocomposites. RSC Adv 5:60426–60440

Thomason JL, Vlug MA (1997) Influence of fiber length and concentration on the properties of glass fiber-reinforced polypropylene: 4. Impact properties. Compos Part A Appl Sci Manuf 28:277–288

Vilaseca F et al (2012) Analysis of the tensile modulus of polypropylene composites reinforced with stone groundwood fiberss. BioResources 7:1310–1323

Nishino T et al (2003) Elastic modulus of the crystalline regions of cellulose triesters. J Polym Sci Part B Polym Phys 33:611–618

Siregar JP, Salit MS, Rahman MZA, Dahlan KZHM (2011) Thermogravimetric analysis (TGA) and differential scanning calometric (DSC) analysis of pineapple leaf fibre (PALF) reinforced high impact polystyrene (HIPS) composites. Pertanika J Sci Technol 19(1):161–170

Kalaprasad G, Joseph K, Thomas S (1997) Influence of short glass fibers addition on the mechanical properties of sisal reinforced low density polyethylene composites. J Compos Mater 31:509–527

Yang HS et al (2004) Rice-husk flour filled polypropylene composites; mechanical and morphological study. Compos Struct 63:305–312

Tarrés Q et al (2019) Interface and micromechanical characterization of tensile strength of bio-based composites from polypropylene and henequen strands. Ind Crops Prod 132:319–326

Keener T, Stuart R, Brown T (2004) Maleated coupling agents for natural fiber composites. Compos Part A Appl Sci Manuf 35:357–362

Rezaei F, Yunus R, Ibrahim NA, Mahdi ES (2008) Development of short-carbon-fibers-reinforced polypropylene composite for car bonnet. Polym. Plast Technol Eng 47:351–357

Weiss RA (1981) Mechanical properties of polypropylene reinforced with short graphite fibers. Polym Compos 2(3):95–101

Fu SY, Xu G, Mai YW (2002) On the elastic modulus of hybrid particle/short-fibers/polymer composites. Compos Part B Eng 33:291–299

Biswal M, Mohanty S, Nayak SK (2009) Influence of organically modified nanoclay on the performance of pineapple leaf fibers-reinforced polypropylene nanocomposites. J Appl Polym Sci 114(6):4091–4103

Xu N, Ding E, Xue F (2017) Influence of particle size of isotactic polypropylene (iPP) on barrier property against agglomeration of homogenized microcrystalline cellulose (HMCC). iPP HMCC Compos 38(3):213–222. https://doi.org/10.1515/polyeng-2017-0004

Azeredo HM, Mattoso LHC, Wood D, Williams TG, Avena-Bustillos RJ, McHugh TH (2009) anocomposite edible films from mango puree reinforced with cellulose nanofibers. J Food Sci 74(5):N31–N35

Johari AP, Mohanty S, Kurmvanshi SK, Nayak SK (2016) Influence of different treated cellulose fiberss on the mechanical and thermal properties of poly(lactic acid). ACS Sustain Chem Eng 4:1619–1629

Heux L (2006) Nanocomposites of isotactic polypropylene reinforced with rod-like cellulose whiskers. Polymer 47:6285

Matei E et al (2017) Recycled polypropylene improved with thermoplastic elastomers. Int J Polym Sci 2017:17

Espert A, Camacho W, Karlson S (2003) Thermal and thermomechanical properties of biocomposites made from modified recycled cellulose and recycled polypropylene. J Appl Polym Sci 89:2353–2360

Kim SH et al (2019) Rheological and mechanical properties of polypropylene composites containing microfibrillated cellulose (MFC) with improved compatibility through surface silylation. Cellulose 26:1085–1097

Unterweger C, Brüggemann O, Fürst C (2014) Effects of different fiberss on the properties of short-fibers-reinforced polypropylene composites. Compos Sci Technol 103:49–55

Kotzev G, Djoumaliisky S, Natova M, Benavente R (2012) Vibration-assisted melt compounding of polypropylene/carbon black composites: processability, filler dispersion and mechanical properties. J Reinf Plast Compos 31:1353–1363

Cichosz S, Masek A, Wolski K, Zaborski M (2019) Universal approach of cellulose fibers chemical modification result analysis via commonly used techniques. Polym Bull 76:2147–2162

Hassan ML, Mathew AP, Hassan EA, Fadel SM, Oksman K (2014) Improving cellulose/polypropylene nanocomposites properties with chemical modified bagasse nanofiberss and maleated polypropylene. J Reinf Plast Compos 33:26–36

Kitano T, Hashmi SAR, Chand N (2004) Influence of steady shear flow on dynamic viscoelastic properties of un-reinforced and Kevlar, glass fiber reinforced LLDPE. Bull Mater Sci 27:409–415

Amash A, Zugenmaier P (1997) Thermal and dynamic mechanical investigations on fibers-reinforced polypropylene composites. J Appl Polym Sci 63(9):1143–1154

Younis AA (2017) Flammability properties of polypropylene containing montmorillonite and some of silicon compounds. Egypt J Pet 26:1–7

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Agarwal, J., Mohanty, S. & Nayak, S.K. Influence of cellulose nanocrystal/sisal fiber on the mechanical, thermal, and morphological performance of polypropylene hybrid composites. Polym. Bull. 78, 1609–1635 (2021). https://doi.org/10.1007/s00289-020-03178-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03178-4