Abstract

Residual hemicellulose in dissolving pulp is known as a reason for deterioration of final product quality and processability problems during cellulose derivative production. However, the issue caused by the residual hemicellulose is not fully understood and is primarily based on industrial experience. To better understand the effect of hemicellulose on cellulose derivative process, hemicellulose in prehydrolysis kraft hardwood dissolving pulp was extracted and its glycosidic linkage structure was thoroughly analysed. Two-stage alkaline extraction, consisting of 24 wt% KOH solution and 18 wt% NaOH with 4 wt% H3BO3 solution, was found effective for the sequential extraction of high purity xylan and glucomannan from the dissolving pulp. Considering the purity and yield of extracted xylan, room temperature for Stage-1 KOH extraction condition was preferred, while 1 °C was preferred for Stage-2 NaOH extraction. Mechanical refining treatment at a mild condition improved the extraction yield of hemicellulose, although the molecular weight of the cellulose was reduced with severe refining condition. Glycosidic linkage analysis showed that native 4-O-methylglucuronic acid side groups were removed during pulping process, resulting in a linearized xylan structure, while a high amount of glucuronic acid was detected in commercial beechwood xylan. The extracted hemicellulose from the second stage showed relatively high number of branched backbone unit e.g., 1,4,6-linked mannose and 1,4,6-linked glucose. The protocol developed in this study should be useful for hemicellulose-related applications.

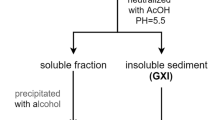

Graphical abstract

Similar content being viewed by others

References

Borrega M, Nieminen K, Sixta H (2011) Degradation kinetics of the main carbohydrates in birch wood during hot water extraction in a batch reactor at elevated temperatures. Bioresour Technol 102:10724–10732

Chareonlimkun A, Champreda V, Shotipruk A, Laosiripojana N (2010) Reactions of C5 and C6-sugars, cellulose, and lignocellulose under hot compressed water (HCW) in the presence of heterogeneous acid catalysts. Fuel 89:2873–2880

Danon B, van der Aa L, de Jong W (2013) Furfural degradation in a dilute acidic and saline solution in the presence of glucose. Carbohydr Res 375:145–152

Davidson GF (1934) The dissolution of chemically modified cotton cellulose in alkaline solutions. Part I: in solutions of NaOH, particularly at temperature below the normal. J Text Inst 25:T174–T196

Duan C, Verma SK, Li J, Ma X, Ni Y (2016) Combination of mechanical, alkaline and enzymatic treatments to upgrade paper-grade pulp to dissolving pulp with high reactivity. Bioresour Technol 200:458–463

Dussan K, Girisuta B, Haverty D, Leahy JJ, Hayes MHB (2013) Kinetics of levulinic acid and furfural production from Miscanthus x giganteus. Bioresour Technol 149:216–224

Gardner PE, Chang MY (1974) The acetylation of native and modified hemicelluloses. Tappi J 57:71–75

Hamilton JK, Quimby GR (1957) The extractive power of lithium, sodium, and potassium hydroxide solutions for the hemicelluloses associated with wood cellulose and holocellulose from western hemlock. Tappi J 40:781–786

Kamide K, Yasuda K, Matsui T, Okajima K, Yamashiki T (1990) Structural change in alkalisoluble cellulose solid during its dissolution into alkaline solutions. Cellul Chem Technol 24:23–31

Kvarnlöf N, Germgård U, Jönsson L, Söderlund CA (2006) Enzymatic treatment to increase the reactivity of a dissolving pulp for viscose production. Appita J 59:242–246

Lamminpää K, Ahola J, Tanskanen J (2012) Kinetics of xylose dehydration into furfural in formic acid. Ind Eng Chem Res 51(18):6297–6303

Lamminpää K, Ahola J, Tanskanen J (2015) Acid-catalysed xylose dehydration into furfural in the presence of kraft lignin. Bioresour Technol 177:94–101

Lawther JM, Sun R, Banks WB (1996) Effects of extraction conditions and alkali type on yield and composition of wheat straw hemicellulose. J Appl Polym Sci 60:1827–1837

Li J, Liu Y, Duan C, Zhang H, Ni Y (2015) Mechanical pretreatment improving hemicelluloses removal from cellulosic fibers during cold caustic extraction. Bioresour Technol 192:501–506

Morinelly JE, Jensen JR, Browne M, Tomas BC, David RS (2009) Kinetic characterization of xylose monomer and oligomer concentrations during dilute acid pretreatment of lignocellulosic biomass from forests residues and switchgrass. Ind Eng Chem Res 48:9877–9884

Nayeem J, Sarkar M, Quadery AH, Jahan MS (2017) High purity dissolving pulp from jute. NPPRJ 32:623–629

Nimlos MR, Qian X, Davis M, Himmel ME, Johnson DK (2006) Energetics of xylose decomposition as determined using quantum mechanics modeling. J Phys Chem A 110:11824–11838

Oksanen T, Buchert J, Viikari L (1997) The role of hemicelluloses in the hornification of bleached kraft pulps. Holzforschung 51:355–360

Pala H, Mota M, Gama FM (2007) Enzymatic depolymerization of cellulose. Carbohydr Polym 68:101–108

Palmqvist E, Hahn-Hägerdal B (2000) Fermentation of lignocellulosic hydrolysates. II: inhibitors and mechanisms of inhibition. Bioresour Technol 74:25–33

Pettolino FA, Walsh C, Fincher GB, Bacic A (2012) Determining the polysaccharide composition of plant cell walls. Nat Protoc 7:1590–1607

Puls J, Janzon R, Saake B (2006) Comparative removal of hemicelluloses from paper pulps using nitren, cuen, NaOH, and KOH. Lenzing Ber 86:63–70

Roselli A, Hummel M, Monshizadeh A, Maloney T, Sixta H (2014) Ionic liquid extraction method for upgrading eucalyptus kraft pulp to high purity dissolving pulp. Cellulose 21:3655–3666

Sameii N, Mortazavi SM, Rashidi AS, Sheikhzadah-Najar S (2008) An Investigation on the effect of hot mercerization on cotton fabrics made up of open-end yarns. J Appl Polym Sci 8:4204–4209

Schroeder LR, Haigh FC (1979) Gel permeation chromatographic analysis of cellulose and wood pulp polysaccharides. Tappi J 62:103–120

Sixta H (2006) Pulp properties and applications. In: Sixta H (ed) Handbook of Pulp, vol 2. Wiley-VCH, Weinheim, pp 1022–1062

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. National Renewable Energy Laboratory, Golden, CO

Springer EL, Harris JF (1985) Procedures for determining the neutralizing capacity of wood during hydrolysis with mineral acid solutions. Ind Eng Chem Prod Res Dev 24(3):485–489

Teleman A (2009) Hemicellulose and pectins. In: Ek M, Gellerstedt G, Henriksson G (eds) Pulp and paper chemistry and technology, vol 1. Wood chemistry and wood biotechnology. Walter de Gruyter, Berlin, pp 107–111

Tian C, Zheng L, Mia Q, Cao C, Ni Y (2014) Improving the reactivity of kraft-based dissolving pulp for viscose rayon production by mechanical treatments. Cellulose 21:3647–3654

Yemiş O, Mazza G (2011) Acid-catalyzed conversion of xylose, xylan and straw into furfural by microwave-assisted reaction. Bioresour Technol 102:7371–7378

Acknowledgments

This research is generously supported by Eastman Chemical Co., the Grant No: EMN-13-S-E-XX-A-2016-2408.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, C.H., Lee, J., Treasure, T. et al. Alkaline extraction and characterization of residual hemicellulose in dissolving pulp. Cellulose 26, 1323–1333 (2019). https://doi.org/10.1007/s10570-018-2137-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-2137-0