Abstract

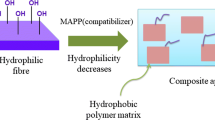

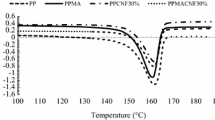

We investigated the rheological and mechanical properties of a polypropylene (PP) composite reinforced by microfibrillated cellulose (MFC) fibers, of which the size was fractionated at ca. 24 µm by removing substances such as lignin or hemicellulose out of natural plants to exert the maximum mechanical performance of cellulose fibers. Due to the poor compatibility of MFC with a non-polar hydrophobic PP matrix, the MFC surface was modified through silylation and acetylation to increase its wetting and dispersion characteristics. The content of silylated-MFC could increase up to 30 wt% in the PP composite through large-volume process such as extrusion and injection molding. In addition, all mechanical properties of the silylated-MFC/PP composite were improved compared to untreated MFC/PP, acetylated MFC/PP composite. It was ensured by a strong shear thinning characteristic of the PP composite with silylated MFC content 30 wt% exhibiting a 69% lower viscosity (337 Pa·s at 4.7 s−1) than the neat PP at 180 °C. The same 30 wt% silylated specimens gave a well-dispersed fibrous MFC in PP, providing a tensile modulus (3.09 GPa) and a flexural modulus (3133 MPa), which were 64 and 81% higher than the neat PP, and 16 and 15% higher than the untreated-MFC composites, respectively. The flexural strength and the heat distortion temperature were also increased by 10 and 22%, compared to neat PP, respectively. In the acetylation reaction, the fibril structure of MFC was damaged due to full substitution by acetyl groups, and the reinforcing effect was insignificant as a filler in PP matrix. The developed silylated-MFC/PP composites provided excellent mechanical properties and high-loading processability that would be difficult to achieve by other eco-friendly composite systems.

Graphical abstract

Similar content being viewed by others

References

Abdelmouleh M, Boufi S, ben Salah A, Belgacem MN, Gandini A (2002) Interaction of silane coupling agents with cellulose. Langmuir 18:3203–3208

Bledzki A, Mamun A, Lucka-Gabor M, Gutowski V (2008) The effects of acetylation on properties of flax fibre and its polypropylene composites. Express Polym Lett 2:413–422

Brochier Salon M-C, Belgacem MN (2011) Hydrolysis-condensation kinetics of different silane coupling agents. Phosphorus Sulfur Silicon 186:240–254

Chandra R, Singh S, Gupta K (1999) Damping studies in fiber-reinforced composites—a review. Compos Struct 46:41–51

Cordin M, Griesser UJ, Bechtold T (2017) Analysis of moisture sorption in lyocell-polypropylene composites. Cellulose 24:1837–1847

Defoirdt N et al (2010) Assessment of the tensile properties of coir, bamboo and jute fibre. Compos A Appl Sci Manuf 41:588–595. https://doi.org/10.1016/j.compositesa.2010.01.005

Eberle AP, Baird DG, Wapperom P (2008) Rheology of non-Newtonian fluids containing glass fibers: a review of experimental literature. Ind Eng Chem Res 47:3470–3488

Eichhorn SJ (2011) Cellulose nanowhiskers: promising materials for advanced applications. Soft Matter 7:303–315

Etcheverry M, Barbosa SE (2012) Glass fiber reinforced polypropylene mechanical properties enhancement by adhesion improvement. Materials 5:1084–1113

Gu SY, Ren J, Wang QF (2004) Rheology of poly (propylene)/clay nanocomposites. J Appl Polym Sci 91:2427–2434

Hameed N, Sreekumar PA, Francis B, Yang W, Thomas S (2007) Morphology, dynamic mechanical and thermal studies on poly(styrene-co-acrylonitrile) modified epoxy resin/glass fibre composites. Compos A Appl Sci Manuf 38:2422–2432. https://doi.org/10.1016/j.compositesa.2007.08.009

Iwamoto S, Yamamoto S, Lee S-H, Endo T (2014) Mechanical properties of polypropylene composites reinforced by surface-coated microfibrillated cellulose. Compos A Appl Sci Manuf 59:26–29. https://doi.org/10.1016/j.compositesa.2013.12.011

Jang K-S (2018) Mechanics and rheology of basalt fiber-reinforced polycarbonate composites. Polymer 147:133–141

Kelly A, Tyson AW (1965) Tensile properties of fibre-reinforced metals: copper/tungsten and copper/molybdenum. J Mech Phys Solids 13:329–350

Khalil HA, Bhat A, Yusra AI (2012) Green composites from sustainable cellulose nanofibrils: a review. Carbohyd Polym 87:963–979

Kiaei M, Kord B, Vaysi R (2014) Influence of residual lignin content on physical and mechanical properties of kraft pulp/PP composites. Maderas Ciencia y tecnología 16:495–503

Lakes R (2002) High damping composite materials: effect of structural hierarchy. J Compos Mater 36:287–297

Le Baillif M, Oksman K (2009) The effect of processing on fiber dispersion, fiber length, and thermal degradation of bleached sulfite cellulose fiber polypropylene composites. J Thermoplast Compos Mater 22:115–133. https://doi.org/10.1177/0892705708091608

Lepetit A, Drolet R, Tolnai B, Zerrouki R, Montplaisir D (2017) Effect of acetylation on the properties of microfibrillated cellulose-LDPE composites. J Appl Polym Sci 134:44933. https://doi.org/10.1002/app.44933

Lin T, Jia D, He P, Wang M, Liang D (2008) Effects of fiber length on mechanical properties and fracture behavior of short carbon fiber reinforced geopolymer matrix composites. Mater Sci Eng A 497:181–185. https://doi.org/10.1016/j.msea.2008.06.040

Lu J, Drzal LT (2010) Microfibrillated cellulose/cellulose acetate composites: effect of surface treatment. J Polym Sci Part B Polym Phys 48:153–161

Minus M, Kumar S (2005) The processing, properties, and structure of carbon fibers. JOM 57:52–58

Missoum K, Belgacem MN, Bras J (2013) Nanofibrillated cellulose surface modification: a review. Materials (Basel) 6:1745–1766. https://doi.org/10.3390/ma6051745

Mohanty AK, Wibowo A, Misra M, Drzal LT (2004) Effect of process engineering on the performance of natural fiber reinforced cellulose acetate biocomposites. Compos A Appl Sci Manuf 35:363–370. https://doi.org/10.1016/j.compositesa.2003.09.015

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994

Nishiyama N, Horie K, Asakura T (1987) Hydrolysis and condensation mechanisms of a silane coupling agent studied by 13C and 29Si NMR. J Appl Polym Sci 34:1619–1630

Paavilainen S, McWhirter JL, Róg T, Järvinen J, Vattulainen I, Ketoja JA (2012) Mechanical properties of cellulose nanofibrils determined through atomistic molecular dynamics simulations. Nord Pulp Pap Res J 27:282

Pickering KL, Efendy MA, Le TM (2016) A review of recent developments in natural fibre composites and their mechanical performance. Compos A Appl Sci Manuf 83:98–112

Poletto M, Zattera AJ (2017) Mechanical and dynamic mechanical properties of polystyrene composites reinforced with cellulose fibers: coupling agent effect. J Thermoplast Compos Mater 30:1242–1254

Rahman MR, Huque MM, Islam MN, Hasan M (2008) Improvement of physico-mechanical properties of jute fiber reinforced polypropylene composites by post-treatment. Compos A Appl Sci Manuf 39:1739–1747. https://doi.org/10.1016/j.compositesa.2008.08.002

Rogelj J et al (2016) Paris Agreement climate proposals need a boost to keep warming well below 2 degrees C. Nature 534:631–639. https://doi.org/10.1038/nature18307

Rowell RM (2008) Challenges in biomass-thermoplastic composites. J Polym Environ 15:229–235. https://doi.org/10.1007/s10924-007-0069-0

Shi S, Yang C, Nie M (2017) Enhanced interfacial strength of natural fiber/polypropylene composite with mechanical-interlocking interface. ACS Sustain Chem Eng 5:10413–10420. https://doi.org/10.1021/acssuschemeng.7b02448

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494

Sjostrom E (2013) Wood chemistry: fundamentals and applications. Elsevier, Amsterdam

Sohn M-S, Hu X-Z (1994) Mode II delamination toughness of carbon-fibre/epoxy composites with chopped Kevlar fibre reinforcement. Compos Sci Technol 52:439–448

Španić N (2015) Chemical and thermal properties of cellulose acetate prepared from White Willow (Salix alba) and Black Alder (Alnus glutinosa) as a potential polymeric base of biocomposite materials. Chem Biochem Eng Q 29:357–365. https://doi.org/10.15255/cabeq.2015.2176

Spence KL, Venditti RA, Rojas OJ, Habibi Y, Pawlak JJ (2011) A comparative study of energy consumption and physical properties of microfibrillated cellulose produced by different processing methods. Cellulose 18:1097–1111

Spoljaric S, Genovese A, Shanks RA (2009) Polypropylene–microcrystalline cellulose composites with enhanced compatibility and properties. Compos A Appl Sci Manuf 40:791–799. https://doi.org/10.1016/j.compositesa.2009.03.011

Suzuki K, Okumura H, Kitagawa K, Sato S, Nakagaito AN, Yano H (2013) Development of continuous process enabling nanofibrillation of pulp and melt compounding. Cellulose 20:201–210. https://doi.org/10.1007/s10570-012-9843-9

Tian R, Seitz O, Li M, Hu WW, Chabal YJ, Gao J (2010) Infrared characterization of interfacial Si–O bond formation on silanized flat SiO2/Si surfaces. Langmuir 26:4563–4566. https://doi.org/10.1021/la904597c

van de Ven T, Godbout L (2013) Cellulose—fundamental aspects. InTech, Rijeka

Vlachopoulos J, Strutt D (2003) The role of rheology in polymer extrusion. In: New technology for extrusion conference, Milan, Italy, pp 20–21

Wambua P, Ivens J, Verpoest I (2003) Natural fibres: can they replace glass in fibre reinforced plastics? Compos Sci Technol 63:1259–1264. https://doi.org/10.1016/s0266-3538(03)00096-4

Wu Y, Xia C, Cai L, Garcia AC, Shi SQ (2018) Development of natural fiber-reinforced composite with comparable mechanical properties and reduced energy consumption and environmental impacts for replacing automotive glass-fiber sheet molding compound. J Clean Prod 184:92–100

Xie Y, Hill CAS, Xiao Z, Militz H, Mai C (2010) Silane coupling agents used for natural fiber/polymer composites: a review. Compos A Appl Sci Manuf 41:806–819. https://doi.org/10.1016/j.compositesa.2010.03.005

Yang H-S, Gardner DJ (2011) Mechanical properties of cellulose nanofibril-filled polypropylene composites. Wood Fiber Sci 43:143–152

Zampaloni M et al (2007) Kenaf natural fiber reinforced polypropylene composites: a discussion on manufacturing problems and solutions. Compos A Appl Sci Manuf 38:1569–1580. https://doi.org/10.1016/j.compositesa.2007.01.001

Zepič V, Poljanšek I, Oven P, Škapin AS, Hančič A (2015) Effect of drying pretreatment on the acetylation of nanofibrillated cellulose. BioResources 10:8148–8167

Zhang M, Geng Z, Yu Y (2011) Density functional theory (DFT) study on the dehydration of cellulose. Energy Fuels 25:2664–2670

Zhang D, He M, Qin S, Yu J (2017) Effect of fiber length and dispersion on properties of long glass fiber reinforced thermoplastic composites based on poly(butylene terephthalate). RSC Adv 7:15439–15454. https://doi.org/10.1039/c7ra00686a

Zulkifli NI, Samat N, Anuar H, Zainuddin N (2015) Mechanical properties and failure modes of recycled polypropylene/microcrystalline cellulose composites. Mater Des 69:114–123

Acknowledgments

This work was supported by the National Research Foundation of Korea (NRF), the Ministry of Science, ICT & Future Planning (NRF-2014M3C1B2048175, 2016R1A2B1007134, and 2017R1A2B4006091), and the Ministry of Trade, Industry and Energy (MOTIE) (10067690, 10080545). We also appreciated the project and equipment support from Gyeonggi Province through the GRRC program in Sungkyunkwan University.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kim, SH., Kim, ES., Choi, K. et al. Rheological and mechanical properties of polypropylene composites containing microfibrillated cellulose (MFC) with improved compatibility through surface silylation. Cellulose 26, 1085–1097 (2019). https://doi.org/10.1007/s10570-018-2122-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-2122-7