Abstract

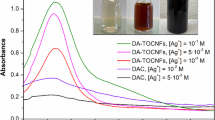

Electro-conductive cellulosic paper has attracted great attention as a promising alternative material in the emerging field of flexible and portable electronic devices. However, the environmentally friendly fabrication of electro-conductive cellulosic paper still remains challenging. Herein, green multi-walled carbon nanotube (MWCNT)/graphene oxide (GO) nanocomposites towards the sustainable development strategy were developed and subsequently used to impart electro-conductivity to cellulosic paper via surface coating process. GO exfoliated from graphite powder was used as a dispersant to improve the dispersion of MWCNTs in water media, and nanocrystalline cellulose (NCC) derived from cotton fibers was employed as a binder for the MWCNT/GO nanocomposites. Effect of NCC amount on the rheological behavior, particle size distribution, sedimentation stability and zeta potential of MWCNT/GO nanocomposites as well as the electro-conductivity and mechanical properties of coated paper was investigated. Results demonstrated that NCC enhanced the dispersion of MWCNT/GO nanocomposites in addition to serving as a binder. Surface coating application of MWCNT/GO nanocomposites was found to impart high electro-conductivity of up to 892 S m−1 to the cellulosic paper while improving its mechanical properties.

Similar content being viewed by others

References

Anderson RE, Guan J, Ricard M, Dubey G, Su J, Lopinski G, Dorris G, Bourne O, Simard B (2010) Multifunctional single-walled carbon nanotube-cellulose composite paper. J Mater Chem 20(12):2400–2407

Arbatan T, Zhang L, Fang X, Shen W (2012) Cellulose nanofibers as binder for fabrication of superhydrophobic paper. Chem Eng J 210:74–79

Ben-Valid S, Botka B, Kamarás K, Zeng A, Yitzchaik S (2010) Spectroscopic and electrochemical study of hybrids containing conductive polymers and carbon nanotubes. Carbon 48(10):2773–2781

Boluk Y, Zhao L, Incani V (2012) Dispersions of nanocrystalline cellulose in aqueous polymer solutions: structure formation of colloidal rods. Langmuir 28(14):6114–6123

Brinchi L, Cotana F, Fortunati E, Kenny JM (2013) Production of nanocrystalline cellulose from lignocellulosic biomass: technology and applications. Carbohydr Polym 94(1):154–169

Dimic-Misic K, Puisto A, Gane P, Nieminen K, Alava M, Paltakari J, Maloney T (2013) The role of MFC/NFC swelling in the rheological behavior and dewatering of high consistency furnishes. Cellulose 20(6):2847–2861

Ding C, Qian X, Yu G, An X (2010) Dopant effect and characterization of polypyrrole-cellulose composites prepared by in situ polymerization process. Cellulose 17(6):1067–1077

Dreyer DR, Park S, Bielawski CW, Ruoff RS (2010) The chemistry of graphene oxide. Chem Soc Rev 39(1):228–240

Enríquez E, Fernández JF, de la Rubia MA (2012) Highly conductive coatings of carbon black/silica composites obtained by a sol–gel process. Carbon 50(12):4409–4417

Fan J, Li Y (2012) Maximizing the yield of nanocrystalline cellulose from cotton pulp fiber. Carbohydr Polym 88(4):1184–1188

Fatehi P (2013) Recent advancements in biorefinery: from biomass to bioproduct and biofuel. Curr Orgc Chem 17(15):1569

Fatehi P, Liu X, Ni Y, Xiao H (2010) Interaction of cationic modified poly vinyl alcohol with high yield pulp. Cellulose 17(5):1021–1031

Fugetsu B, Sano E, Sunada M, Sambongi Y, Shibuya T, Wang X, Hiraki T (2008) Electrical conductivity and electromagnetic interference shielding efficiency of carbon nanotube/cellulose composite paper. Carbon 46(9):1256–1258

Hamada H, Bousfield DW (2010) Nanofibrillated cellulose as a coating agent to improve print quality of synthetic fiber sheets. Tappi J 9(11):25–29

Huang B, Kang GJ, Ni Y (2005) Preparation of conductive paper by in situ polymerization of pyrrole in a pulp fiber system. Pulp Paper Can 107:38–41

Hummers WS Jr, Offeman RE (1958) Preparation of graphitic oxide. J Am Chem Soc 80(6):1339

Imai M, Akiyama K, Tanaka T, Sano E (2010) Highly strong and conductive carbon nanotube/cellulose composite paper. Compos Sci Technol 70(10):1564–1570

Jang J, Ryu SK (2006) Physical property and electrical conductivity of electroless Ag-plated carbon fiber-reinforced paper. J Mater Proc Technol 180(1):66–73

Jung R, Kim HS, Kim Y, Kwon SM, Lee HS, In HJ (2008) Electrically conductive transparent papers using multiwalled carbon nanotubes. J Polym Sci, Part B: Polym Phys 46(12):1235–1242

Kamyshny A, Steinke J, Magdassi S (2011) Metal-based inkjet inks for printed electronics. Open Appl Phys J 4(1):19–36

Kawashima H, Shinotsuka M, Nakano M, Goto H (2012) Fabrication of conductive paper coated with PEDOT: preparation and characterization. J Coat Technol Res 9(4):467–474

Kharissova OV, Kharisov BI, de Casas Ortiz EG (2013) Dispersion of carbon nanotubes in water and non-aqueous solvents. RSC Adv 3(47):24812–24852

Koga H, Saito T, Kitaoka T, Nogi M, Suganuma K, Isogai A (2013) Transparent, conductive, and printable composites consisting of TEMPO-oxidized nanocellulose and carbon nanotube. Biomacromolecules 14(4):1160–1165

Krishnamoorthy K, Veerapandian M, Yun K, Kim S (2013) The chemical and structural analysis of graphene oxide with different degrees of oxidation. Carbon 53:38–49

Kurihara T, Isogai A (2014) Properties of poly(acrylamide)/TEMPO-oxidized cellulose nanofibril composite films. Cellulose 21(1):291–299

Lee JU, Huh J, Kim KH, Park C, Jo WH (2007) Aqueous suspension of carbon nanotubes via non-covalent functionalization with oligothiophene-terminated poly (ethylene glycol). Carbon 45(5):1051–1057

Lehtinen E (2000) Pigment coating and surface sizing of paper, Papermaking Science and Technology Series Book 11. Helsinki Univ Technol, Fapet Oy

Li S, Zhao W, Wang J, Qian L, Wang K, Pan M (2013) Synthesis and characterization of the thin paper-like graphite oxide and graphene. J Wuhan Univ Technol 35(1):1–6

Mao H, Wu X, Qian X, An X (2014) Conductivity and flame retardancy of polyaniline-deposited functional cellulosic paper doped with organic sulfonic acids. Cellulose 21(1):697–704

Mohtaschemi M, Dimic-Misic K, Puisto A, Korhonen M, Maloney T, Paltakari J, Alava M (2014) Rheological characterization of fibrillated cellulose suspensions via bucket vane viscometer. Cellulose 21(3):1305–1312

Nisogi H, Bousfield DW, Lepoutre PF (2000) Influence of coating rheology on final coating properties. Tappi J 83(2):100–106

Olivier C, Moreau C, Bertoncini P, Bizot H, Chauvet O, Cathala B (2012) Cellulose nanocrystal-assisted dispersion of luminescent single-walled carbon nanotubes for layer-by-layer assembled hybrid thin films. Langmuir 28(34):12463–12471

Oya T, Ogino T (2008) Production of electrically conductive paper by adding carbon nanotubes. Carbon 46(1):169–171

Pan D, Turner JL, Wooley KL (2003) Folic acid-conjugated nanostructured materials designed for cancer cell targeting. Chem Commun 19:2400–2401

Qi H, Mäder E, Liu J (2013) Electrically conductive aerogels composed of cellulose and carbon nanotubes. J Mater Chem A 1(34):9714–9720

Qian X, Chen J, An X (2010) Polypyrrole-coated conductive paper prepared by vapour-phase deposition method. Appita J 63(2):102–107

Richard C, Balavoine F, Schultz P, Ebbesen TW, Mioskowski C (2003) Supramolecular self-assembly of lipid derivatives on carbon nanotubes. Science 300(5620):775–778

Rioux R, Bousfield DW, Triantafillopoulos N (2011) A study of the mechanical properties of coated papers using elastica stiffness and low-load indentation. Tappi J 10(10):41–48

Saravanan C, He Z, Ni Y (2014) Application of polyaniline/clay combination to cellulosic paper as an approach to conductivity development. Bioresources 9(2):1886–1897

Shateri-Khalilabad M, Yazdanshenas ME (2013a) Preparation of superhydrophobic electroconductive graphene-coated cotton cellulose. Cellulose 20(2):963–972

Shateri-Khalilabad M, Yazdanshenas ME (2013b) Fabricating electroconductive cotton textiles using graphene. Carbohydr Polym 96(1):190–195

Sheikholeslam M, Pritzker M, Chen P (2012) Dispersion of multiwalled carbon nanotubes in water using ionic-complementary peptides. Langmuir 28(34):12550–12556

Shen J, Fatehi P (2013) A review on the use of lignocellulose-derived chemicals in wet-end application of papermaking. Curr Org Chem 17(15):1647–1654

Shen J, Song Z, Qian X, Ni Y (2010) A review on use of fillers in cellulosic paper for functional applications. Ind Eng Chem Res 50(2):661–666

Shen XJ, Pei XQ, Liu Y, Fu SY (2014) Tribological performance of carbon nanotube–graphene oxide hybrid/epoxy composites. Compos B 57:120–125

Sun B, Hou Q, Liu Z, He Z, Ni Y (2014) Stability and efficiency improvement of ASA in internal sizing of cellulosic paper by using cationically modified cellulose nanocrystals. Cellulose 21(2):2879–2887

Tagmatarchis N, Zattoni A, Reschiglian P, Prato M (2005) Separation and purification of functionalised water-soluble multi-walled carbon nanotubes by flow field-flow fractionation. Carbon 43(9):1984–1989

Tang Y, Zhou D, Zhang J, Zhu X (2013) Fabrication and properties of paper coatings with the incorporation of nanoparticle pigments: rheological behavior. Dig J Nanomater Biostruct 8(4):1699–1710

Tang Y, Yang S, Zhang N, Zhang J (2014) Preparation and characterization of nanocrystalline cellulose via low-intensity ultrasonic-assisted sulfuric acid hydrolysis. Cellulose 21(1):335–346

Tian L, Meziani MJ, Lu F, Kong CY, Cao L, Thorne TJ, Sun Y (2010) Graphene oxides for homogeneous dispersion of carbon nanotubes. ACS Appl Mater Interfaces 2(11):3217–3222

Veerapandian M, Lee M, Krishnamoorthy K, Yun K (2012) Synthesis, characterization and electrochemical properties of functionalized graphene oxide. Carbon 50(11):4228–4238

Wang H, Leaukosol N, He Z, Fei G, Si C, Ni Y (2013) Microstructure, distribution and properties of conductive polypyrrole/cellulose fiber composites. Cellulose 20(4):1587–1601

Youssef AM, El-Samahy MA, Abdel Rehim MH (2012) Preparation of conductive paper composites based on natural cellulosic fibers for packaging applications. Carbohydr Polym 89(4):1027–1032

Yuan NY, Ma FF, Fan Y, Liu YB, Ding JN (2012) High conductive ethylene vinyl acetate composites filled with reduced graphene oxide and polyaniline. Compos A Appl Sci Manufact 43(12):2183–2188

Zaman M, Liu H, Xiao H, Chibante F, Ni Y (2013) Hydrophilic modification of polyester fabric by applying nanocrystalline cellulose containing surface finish. Carbohydr Polym 91(2):560–567

Zhang C, Ren L, Wang X, Liu T (2010) Graphene oxide-assisted dispersion of pristine multiwalled carbon nanotubes in aqueous media. J Phys Chem C 114(26):11435–11440

Zhao M, Liu X, Zhang Q, Tian G, Huang J, Zhu W, Wei F (2012) Graphene/single-walled carbon nanotube hybrids: one-step catalytic growth and applications for high-rate Li-S batteries. ACS Nano 6(12):10759–10769

Acknowledgments

This work was financially supported by a NSERC CRD grant (CRDPJ 363811-07), Canada Research Chairs programs of the Government of Canada, the National Natural Science Foundation of China (Grant No. 31100442), Zhejiang Provincial Natural Science Foundation of China (Grant No. LY14C160003) and 521 Talent Cultivation Program of Zhejiang Sci-Tech University (Grant No. 11110132521310).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Tang, Y., He, Z., Mosseler, J.A. et al. Production of highly electro-conductive cellulosic paper via surface coating of carbon nanotube/graphene oxide nanocomposites using nanocrystalline cellulose as a binder. Cellulose 21, 4569–4581 (2014). https://doi.org/10.1007/s10570-014-0418-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0418-9