Abstract

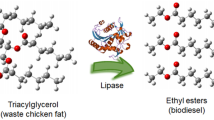

In this work, the combination of different lipases was employed for the production of biodiesel, using the Free Fatty Acids (FFAs) from Residual Chicken Oil (RCO) as a substrate. As biocatalysts, lipases A and B from Candida antarctica (CALA and CALB, respectively) and lipase from Rhizomucor miehei (RML) were used in different combinations; as a result, the best lipase cocktail was composed of 67% CALB and 33% RML, which was used to optimize the esterification reaction parameters (molar ratio (FFAs/ ethyl alcohol), biocatalyst content, temperature and time) by the Taguchi method. Under optimized conditions (1:5, 15% of lipase cocktail, 30 °C and 3 h), it was possible to achieve 89.95 ± 0.3% of conversion.

Graphic Abstract

Similar content being viewed by others

References

Xie Q, Cai L, Xia F et al (2019) High vacuum distillation for low-sulfur biodiesel production: from laboratory to large scale. J Clean Prod 223:379–385. https://doi.org/10.1016/j.jclepro.2019.03.160

Kajaste R (2014) Chemicals from biomass—managing greenhouse gas emissions in biorefinery production chains—a review. J Clean Prod 75:1–10. https://doi.org/10.1016/j.jclepro.2014.03.070

Singh D, Sharma D, Soni SL et al (2019) Chemical compositions, properties, and standards for different generation biodiesels: a review. Fuel 253:60–71. https://doi.org/10.1016/j.fuel.2019.04.174

Yao K, Jo-han N, Tung C et al (2019) Biodiesel process intensification through catalytic enhancement and emerging reactor designs: a critical review. Renew Sustain Energy Rev 116:109399. https://doi.org/10.1016/j.rser.2019.109399

Aguieiras ECG, de Barros DSN, Sousa H et al (2017) Influence of the raw material on the final properties of biodiesel produced using lipase from Rhizomucor miehei grown on babassu cake as biocatalyst of esterification reactions. Renew Energy 113:112–118. https://doi.org/10.1016/j.renene.2017.05.090

Dumont MJ, Narine SS (2007) Soapstock and deodorizer distillates from North American vegetable oils: Review on their characterization, extraction and utilization. Food Res Int 40:957–974. https://doi.org/10.1016/j.foodres.2007.06.006

Predojević ZJ (2008) The production of biodiesel from waste frying oils: a comparison of different purification steps. Fuel 87:3522–3528. https://doi.org/10.1016/j.fuel.2008.07.003

Sabudak T, Yildiz M (2010) Biodiesel production from waste frying oils and its quality control. Waste Manag 30:799–803. https://doi.org/10.1016/j.wasman.2010.01.007

Wyse-Mason RR, Beckles DM (2012) An investigation of restaurant waste oil characteristics for biodiesel production in Trinidad and Tobago. Energy Sustain Dev 16:515–519. https://doi.org/10.1016/j.esd.2012.05.005

Poppe JK, Matte CR, Peralba DCR, M, et al (2015) Optimization of ethyl ester production from olive and palm oils using mixtures of immobilized lipases. Appl Catal A Gen 490:50–56. https://doi.org/10.1016/j.apcata.2014.10.050

Badgujar KC, Bhanage BM (2015) The combine use of ultrasound and lipase immobilized on co-polymer matrix for efficient biocatalytic application studies. J Mol Catal B Enzym 122:255–264. https://doi.org/10.1016/j.molcatb.2015.09.012

Aga SÁ, de Meneses AC, de Araújo PHH, de Oliveira D (2017) A review on enzymatic synthesis of aromatic esters used as flavor ingredients for food, cosmetics and pharmaceuticals industries. Trends Food Sci Technol 69:95–105. https://doi.org/10.1016/j.tifs.2017.09.004

Hoang HN, Matsuda T (2016) Expanding substrate scope of lipase-catalyzed transesterification by the utilization of liquid carbon dioxide. Tetrahedron 72:7229–7234. https://doi.org/10.1016/j.tet.2015.11.052

Lozano P (2010) Enzymes in neoteric solvents: from one-phase to multiphase systems. Green Chem 12:555–569. https://doi.org/10.1039/b919088k

Pourzolfaghar H, Abnisa F, Daud WMAW, Aroua MK (2016) A review of the enzymatic hydroesterification process for biodiesel production. Renew Sustain Energy Rev 61:245–257

Ortiz C, Ferreira ML, Barbosa O et al (2019) Novozym 435: the “perfect” lipase immobilized biocatalyst? Catal Sci Technol 9:2380–2420. https://doi.org/10.1039/c9cy00415g

Monteiro RRC, Lima PJM, Pinheiro BB et al (2019) Immobilization of lipase A from Candida antarctica onto chitosan-coated magnetic nanoparticles. Int J Mol Sci 20:4018. https://doi.org/10.3390/ijms20164018

Rodrigues RC, Fernandez-Lafuente R (2010) Lipase from Rhizomucor miehei as a biocatalyst in fats and oils modification. J Mol Catal B Enzym 66:15–32. https://doi.org/10.1016/j.molcatb.2010.03.008

Price J, Nordblad M, Martel HH et al (2016) Scale-up of industrial biodiesel production to 40 m3 using a liquid lipase formulation. Biotechnol Bioeng 113:1719–1728. https://doi.org/10.1002/bit.25936

Amoah J, Ho SH, Hama S et al (2016) Lipase cocktail for efficient conversion of oils containing phospholipids to biodiesel. Bioresour Technol 211:224–230. https://doi.org/10.1016/j.biortech.2016.03.062

Poppe JK, Matte CR, Fernandez-Lafuente R et al (2018) Transesterification of waste frying oil and soybean oil by combi-lipases under ultrasound-assisted reactions. Appl Biochem Biotechnol 186:576–589. https://doi.org/10.1007/s12010-018-2763-x

Alves JS, Vieira NS, Cunha AS et al (2014) Combi-lipase for heterogeneous substrates: a new approach for hydrolysis of soybean oil using mixtures of biocatalysts. RSC Adv 4:6863–6868. https://doi.org/10.1039/c3ra45969a

Fonseca JM, Cardozo-Filho L, Teleken JG, Da SC (2018) Ethyl esters from waste oil: reaction data of non-catalytic hydroesterification at pressurized conditions and purification with sugarcane bagasse ash. J Environ Chem Eng 6:4988–4996. https://doi.org/10.1016/j.jece.2018.07.044

Moecke EHS, Feller R, dos Santos HA et al (2016) Biodiesel production from waste cooking oil for use as fuel in artisanal fishing boats: integrating environmental, economic and social aspects. J Clean Prod 135:679–688. https://doi.org/10.1016/j.jclepro.2016.05.167

Rodrigues RC, Ayub MAZ (2011) Effects of the combined use of Thermomyces lanuginosus and Rhizomucor miehei lipases for the transesterification and hydrolysis of soybean oil. Process Biochem 46:682–688. https://doi.org/10.1016/j.procbio.2010.11.013

Garud SS, Karimi IA, Kraft M (2017) Design of computer experiments: a review. Comput Chem Eng 106:71–95. https://doi.org/10.1016/j.compchemeng.2017.05.010

Dhawane SH, Karmakar B, Ghosh S, Halder G (2018) Parametric optimisation of biodiesel synthesis from waste cooking oil via Taguchi approach. J Environ Chem Eng 6:3971–3980. https://doi.org/10.1016/j.jece.2018.05.053

Rao RS, Kumar CG, Prakasham RS, Hobbs PJ (2008) The Taguchi methodology as a statistical tool for biotechnological applications: a critical appraisal. Biotechnol J 3:510–523

Tacias-Pascacio VG, Torrestiana-Sánchez B, Dal Magro L et al (2019) Comparison of acid, basic and enzymatic catalysis on the production of biodiesel after RSM optimization. Renew Energy 135:1–9. https://doi.org/10.1016/j.renene.2018.11.107

Lima LP, Santos FFP, Costa E, Fernandes FAN (2012) Production of free fatty acids from waste oil by application of ultrasound. Biomass Convers Biorefinery 2:309–315. https://doi.org/10.1007/s13399-012-0056-0

Instituto Adolfo Lutz (2008) 1a Edição digital. In: Métodos físicos-quimicos para análise de Alimentos, 4th ed. São Paulo, pp 589–625. https://doi.org/10.1017/CBO9781107415324.004

EN-14111 (2003) Fat and oil derivatives—fatty acid methyl Esters (FAME)—determination of iodine value, EN Standards. 14214

NBR-14065 (2013) Petroleum distillates and viscous oils —determination of density and specific gravity by digital densimeter, ABNT. 13

NBR-10441 (2014) Petroleum products—transparent and opaque liquids—determination of kinematic viscosity and calculation of dynamic viscosity, ABNT. 22

Cavalcanti EDC, Aguieiras ÉCG, da Silva PR et al (2018) Improved production of biolubricants from soybean oil and different polyols via esterification reaction catalyzed by immobilized lipase from Candida rugosa. Fuel 215:705–713. https://doi.org/10.1016/j.fuel.2017.11.119

Moreira KS, Moura LS, Monteiro RRC et al (2020) Optimization of the production of enzymatic biodiesel from residual babassu oil (Orbignya sp.) via RS. Catalysts. https://doi.org/10.3390/catal10040414

Petersen R, Link R, Rushforth R (2001) Review of design experiments using the Taguchi approach: 16 steps to product and process improvement. J Test Eval 29:588. https://doi.org/10.1520/jte12406j

Chakraborty R, RoyChowdhury D (2013) Fish bone derived natural hydroxyapatite-supported copper acid catalyst: Taguchi optimization of semibatch oleic acid esterification. Chem Eng J 215–216:491–499. https://doi.org/10.1016/j.cej.2012.11.064

Paludo N, Alves JS, Altmann C et al (2015) The combined use of ultrasound and molecular sieves improves the synthesis of ethyl butyrate catalyzed by immobilized Thermomyces lanuginosus lipase. Ultrason Sonochem 22:89–94. https://doi.org/10.1016/j.ultsonch.2014.05.004

Boey PL, Maniam GP, Hamid SA, Ali DMH (2011) Crab and cockle shells as catalysts for the preparation of methyl esters from low free fatty acid chicken fat. JAOCS 88:283–288. https://doi.org/10.1007/s11746-010-1660-4

Alptekin E, Canakci M (2010) Optimization of pretreatment reaction for methyl ester production from chicken fat. Fuel 89:4035–4039. https://doi.org/10.1016/j.fuel.2010.04.031

Barrios CC, Domínguez-Sáez A, Martín C, Álvarez P (2014) Effects of animal fat based biodiesel on a TDI diesel engine performance, combustion characteristics and particle number and size distribution emissions. Fuel 117:618–623. https://doi.org/10.1016/j.fuel.2013.09.037

Mata TM, Mendes AM, Caetano NS, Martins AA (2014) Properties and sustainability of biodiesel from animal fats and fish oil. Chem Eng Trans 38:175–180. https://doi.org/10.3303/CET1438030

Zullaikah S, Lai CC, Vali SR, Ju YH (2005) A two-step acid-catalyzed process for the production of biodiesel from rice bran oil. Bioresour Technol 96:1889–1896. https://doi.org/10.1016/j.biortech.2005.01.028

Mata TM, Cardoso N, Ornelas M et al (2011) Evaluation of two purification methods of biodiesel from beef tallow, pork lard, and chicken fat. Energy Fuels 25:4756–4762. https://doi.org/10.1021/ef2010207

Kulkarni MG, Dalai AK (2006) Waste cooking oil—san economical source for biodiesel: a review. Ind Eng Chem Res 45:2901–2913. https://doi.org/10.1021/ie0510526

Li L, Du W, Liu D et al (2006) Lipase-catalyzed transesterification of rapeseed oils for biodiesel production with a novel organic solvent as the reaction medium. J Mol Catal B Enzym 43:58–62. https://doi.org/10.1016/j.molcatb.2006.06.012

Christopher LP, Kumar H, Zambare VP (2014) Enzymatic biodiesel: challenges and opportunities. Appl Energy 119:497–520. https://doi.org/10.1016/j.apenergy.2014.01.017

Kirubakaran M, Arul Mozhi Selvan V (2018) A comprehensive review of low cost biodiesel production from waste chicken fat. Renew Sustain Energy Rev 82:390–401. https://doi.org/10.1016/j.rser.2017.09.039

Villeneuve P, Turon F, Caro Y et al (2005) Lipase-catalyzed synthesis of canola phytosterols oleate esters as cholesterol lowering agents. Enzyme Microb Technol 37:150–155. https://doi.org/10.1016/j.enzmictec.2005.02.002

Domínguez De María P, Carboni-Oerlemans C, Tuin B et al (2005) Biotechnological applications of Candida antarctica lipase A: State-of-the-art. J Mol Catal B Enzym 37:36–46. https://doi.org/10.1016/j.molcatb.2005.09.001

Anderson EM, Larsson KM, Kirk O (1998) One biocatalyst—many applications: the use of Candida antarctica B-lipase in organic synthesis. Biocatal Biotransform 16:181–204. https://doi.org/10.3109/10242429809003198

Uslu S, Aydın M (2020) Effect of operating parameters on performance and emissions of a diesel engine fueled with ternary blends of palm oil biodiesel/diethyl ether/diesel by Taguchi method. Fuel 275:117978. https://doi.org/10.1016/j.fuel.2020.117978

Xie W, Ma N (2010) Enzymatic transesterification of soybean oil by using immobilized lipase on magnetic nano-particles. Biomass Bioenerg 34:890–896. https://doi.org/10.1016/j.biombioe.2010.01.034

Martins AB, Da Silva AM, Schein MF et al (2014) Comparison of the performance of commercial immobilized lipases in the synthesis of different flavor esters. J Mol Catal B Enzym 105:18–25. https://doi.org/10.1016/j.molcatb.2014.03.021

Waghmare GV, Rathod VK (2016) Ultrasound assisted enzyme catalyzed hydrolysis of waste cooking oil under solvent free condition. Ultrason Sonochem 32:60–67. https://doi.org/10.1016/j.ultsonch.2016.01.033

Ramos EZ, Júnior RHM, De Castro PF et al (2015) Production and immobilization of Geotrichum candidum lipase via physical adsorption on eco-friendly support: characterization of the catalytic properties in hydrolysis and esterification reactions. J Mol Catal B Enzym 118:43–51. https://doi.org/10.1016/j.molcatb.2015.05.009

Hari Krishna S, Manohar B, Divakar S et al (2000) Optimization of isoamyl acetate production by using immobilized lipase from Mucor miehei by response surface methodology. Enzyme Microb Technol 26:131–136. https://doi.org/10.1016/S0141-0229(99)00149-0

Szczesna Antczak M, Kubiak A, Antczak T, Bielecki S (2009) Enzymatic biodiesel synthesis—key factors affecting efficiency of the process. Renew Energy 34:1185–1194. https://doi.org/10.1016/j.renene.2008.11.013

Guan F, Peng P, Wang G et al (2010) Combination of two lipases more efficiently catalyzes methanolysis of soybean oil for biodiesel production in aqueous medium. Process Biochem 45:1677–1682. https://doi.org/10.1016/j.procbio.2010.06.021

Wu H, Zong MH, Luo Q, Wu HC (2003) Enzymatic conversion of waste oil to biodiesel in a solvent-free system. ACS Div Fuel Chem Prepr 48:533–534

Du W, Xu Y, Liu D (2003) Lipase-catalysed transesterification of soya bean oil for biodiesel production during continuous batch operation. Biotechnol Appl Biochem 38:103. https://doi.org/10.1042/ba20030032

Fallavena LP, Antunes FHF, Alves JS et al (2014) Ultrasound technology and molecular sieves improve the thermodynamically controlled esterification of butyric acid mediated by immobilized lipase from Rhizomucor miehei. RSC Adv 4:8675–8681. https://doi.org/10.1039/c3ra47315e

Zhu X, Zhou T, Wu X et al (2011) Covalent immobilization of enzymes within micro-aqueous organic media. J Mol Catal B Enzym 72:145–149. https://doi.org/10.1016/j.molcatb.2011.05.012

Wang L, Chen Y (2009) Enzymatic catalysis in non-aqueous solvents. Shengwu Gongcheng Xuebao/Chinese J Biotechnol 25:1789–1794

Acknowledgments

We gratefully acknowledge the financial support of Brazilian Agencies for Scientific and Technological Development, Fundação Cearense de Apoio ao Desenvolvimento Científico e Tecnológico (FUNCAP), Project Number BP3-0139-00005.01.00/18, Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq), Project Numbers 422942/2016-2, 408790/2016-4 and 311062/2019-9. Coordenação de Aperfeiçoamento de Ensino Superior (CAPES). In addition, we gratefully acknowledge the supply of Lipases by Mr. Martinez (Novozymes, Spain).

Funding

Fundação Cearense de Apoio ao Desenvolvimento Científico e Tecnológico (FUNCAP), Project Number BP3-0139-00005.01.00/18, Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq), Project Numbers 422942/2016-2 and 408790/2016-4, Coordenação de Aperfeiçoamento de Ensino Superior (CAPES).

Author information

Authors and Affiliations

Contributions

Conceptualization, TGR, PHDLG; Formal analysis, TGR, PHDLG, and RRCM; Methodology, MCMS and JCSDS; Project administration, JCSDS; Resources, TGR, PHDLG and MCMDS; Supervision, MCMDS and JCSDS; Writing–original draft, JCSDS; Writing–review & editing, TGR, PHDLG, RRCM, MCMDS and JCSDS.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rocha, T.G., de L. Gomes, P.H., de Souza, M.C.M. et al. Lipase Cocktail for Optimized Biodiesel Production of Free Fatty Acids from Residual Chicken Oil. Catal Lett 151, 1155–1166 (2021). https://doi.org/10.1007/s10562-020-03367-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-020-03367-w