Abstract

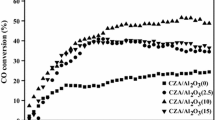

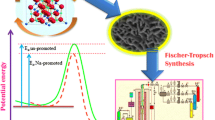

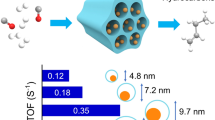

Although alumina-supported copper materials have been widely used as the catalyst in methanol synthesis from CO2 hydrogenation, the effect of calcination temperature of alumina support is not yet fully understood. In this work, hierarchical meso–macroporous alumina material prepared by a sol–gel process was calcined at different temperatures (600, 700, 800 and 900 °C) and used as the supported copper catalysts. XRD, SEM-EDS mapping, XANES and hydrogen temperature-programmed reduction studies suggested that highly dispersed CuO nanoparticles and strong interaction between CuO and alumina support were formed when the alumina support was calcined at 600 °C (Cu/H-600). H2 temperature-programmed desorption and CO2 temperature-programmed desorption results revealed that the strong metal-support interaction of Cu/H-600 created a larger number of active sites for H2 and CO2 adsorption at moderate temperature (100–300 °C), resulting in the maximum yield of methanol. Increasing calcination temperature (700–900 °C) caused an increase of CuO crystallite size and a weakened interaction between CuO and alumina support, resulting in a lower yield of methanol but enhancing the formation of CO. The plot of CO2 conversion to CO against copper surface area indicated that the surface of metallic copper acted as the active site in reverse water–gas shift reaction. The conversion of methanol to dimethyl ether was found to relate with the number of weak acid sites.

Graphical Abstract

Similar content being viewed by others

References

Goeppert A, Czaun M, Jones JP, Prakash GKS, Olah GA (2014) Chem Soc Rev 43:7995–8048

Díez-Ramírez J, Valverde JL, Sánchez P, Dorado F (2016) Catal Lett 146:373–382

Song Y, Liu X, Xiao L, Wu W, Zhang J, Song X (2015) Catal Lett 145:1272–1280

Zhan H, Li F, Xin C, Zhao N, Xiao F, Wei W, Sun Y (2015) Catal Lett 145:1177–1185

Liang XL, Xie JR, Liu ZM (2015) Catal Lett 145:1138–1147

Zhou L, Wang Q, Ma L, Chen J, Ma J, Zi Z (2015) Catal Lett 145:612–619

Witoon T, Kachaban N, Donphai W, Kidkhunthod P, Faungnawakij K, Chareonpanich M, Limtrakul J (2016) Energy Convers Manag 118:21–31

Witoon T, Chalorngtham J, Dumrongbunditkul P, Chareonpanich M, Limtrakul J (2016) Chem Eng J 293:327–336

Witoon T, Permsirivanich T, Kanjanasoontorn N, Akkaraphataworn C, Seubsai A, Faungnawakij K, Warakulwit C, Chareonpanich M, Limtrakul J (2015) Catal Sci Technol 5:2347–2357

Lei H, Hou Z, Xie J (2016) Fuel 164:191–198

Lei H, Nie R, Wu G, Hou Z (2015) Fuel 154:161–166

Sloczyński J, Grabowski R, Olszewski P, Kozlowska A, Stoch J, Lachowska M, Skrzypek J (2006) Appl Catal A Gen 310:127–137

Kanai Y, Watanabe T, Fujitani T, Saito M, Nakamura J, Uchijima T (1994) Catal Lett 27:67–78

Herman RG, Klier K, Simmons GW, Finn BP, Bulko JB, Kobylinski TP (1979) J Catal 56:407–429

Frost JC (1998) Nature 334:577–580

Trueba M, Trasatti SP (2005) Eur J Inorg Chem 17:3393–3403

Hosseininejad S, Afacan A, Hayes RE (2012) Chem Eng Res Des 90:825–833

Zhang L, Zhang H, Ying W, Fang D (2013) Can J Chem Eng 91:1538–1546

Hong UG, Hwang S, Seo JG, Lee J, Song IK (2011) J Ind Eng Chem 17:316–320

Gao J, Jia C, Li J, Zhang M, Gu F, Xu G, Zhong Z, Su F (2013) J Energy Chem 22:919–927

Yahiro H, Nakaya K, Yamamoto T, Saiki K, Yamaura H (2006) Catal Comm 7:228–231

Witoon T, Bumrungsalee S, Chareonpanich M, Limtrakul J (2015) Energy Convers Manag 103:886–894

Tokudome Y, Fujita K, Nakanishi K, Miura K, Hirao K (2007) Chem Mater 19:3393–3398

Arena F, Barbera K, Italiano G, Bonura G, Spadaro L, Frusteri F (2007) J Catal 249:185–194

Mohamed MM, Abu-Zied BM (2000) Thermochim Acta 359:109–117

Chen D, Wu Z (2006) Radiat Phys Chem 75:1921–1925

Wan H, Wang Z, Zhu J, Li X, Liu B, Gao F, Dong L, Chen Y (2008) Appl Catal B Environ 79:254–261

Xia WS, Wan HL, Chen Y (1999) J Mol Catal A Chem 138:185–195

Luo MF, Fang P, He M, Xie YL (2005) J Mol Catal A Chem 239:234–248

Reddy GK, Rao KSR, Rao PK (1999) Catal Lett 59:157–160

Natesakhawat S, Ohodnicki PR Jr, Howard BH, Lekse JW, Baltrus JP, Matranga C (2013) Top Catal 56:1752–1763

Tabatabaei J, Sakakini BH, Watson MJ, Waugh KC (1999) Catal Lett 59:143–149

Dan M, Mihet M, Tasnadi-Asztalos Z, Imre-Lucaci A, Katona G, Lazar MD (2015) Fuel 147:260–268

Guo X, Mao D, Lu G, Wang S, Wu G (2011) J Mol Catal A Chem 345:60–68

Arena F, Italiano G, Barbera K, Bordiga S, Bonura G, Spadaro L, Frusteri F (2008) Appl Catal A Gen 350:16–23

Zhang MH, Liu ZM, Lin GD, Zhang HB (2013) Appl Catal A Gen 451:28–35

Acknowledgments

This research is supported in part by the Graduate Program Scholarship from the Graduate School, Kasetsart University; this work was further financially supported by the Thailand Research Fund (Grant No. RSA5980074), the Center of Excellence on Petrochemical and Materials Technology (PETROMAT), the National Research University Project of Thailand (NRU), the Nanotechnology Center (NANOTEC), NSTDA, Ministry of Science and Technology, Thailand through its program of Center of Excellence Network, and the Kasetsart University Research and Development Institute (KURDI). The authors would like to thank the support from the Synchrotron Light Research Institute (BL5.2: SUT-NANOTEC-SLRI XAS).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kanjanasoontorn, N., Permsirivanich, T., Numpilai, T. et al. Structure–Activity Relationships of Hierarchical Meso–Macroporous Alumina Supported Copper Catalysts for CO2 Hydrogenation: Effects of Calcination Temperature of Alumina Support. Catal Lett 146, 1943–1955 (2016). https://doi.org/10.1007/s10562-016-1849-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-016-1849-8