Abstract

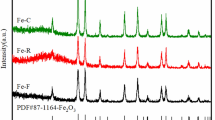

Two series of Fe/Cu/K catalysts were prepared by co-precipitation (CP-xK) and by co-precipitation accompanied with hydrothermal treatment (HY-xK), respectively. The catalysts were investigated by N2 adsorption, X-ray diffraction (XRD), Mössbauer effect spectroscopy (MES), scanning electron microscopy (SEM), high-resolution transmission electron microscopy (HRTEM), H2 temperature-programmed reduction (H2-TPR) and thermogravimetric analysis. N2 adsorption revealed that HY-xK catalysts displayed relatively low surface area, but generated additional macropore. XRD and SEM showed that HY-xK catalysts were well grown crystallite, while the CP-xK catalysts were amorphous. In addition, hydrothermal treatment remarkably influenced the growth orientation of hematite nanocrystals, resulting in the preferential exposure of the (110) plane. HRTEM also indicated that HY-1.32K was dominated by Fe2O3 nanocrystals with (110) plane, and the CP-1.38K primary particle mainly exposed (104) plane. The H2-TPR profiles for the two series of catalysts were similar, though the merged and smooth peak of HY-xK catalysts possibly suggested that the component elements were more uniform. MES and XRD indicated that the catalyst after hydrothermal treatment can be easily reduced into active carbide phases in Fischer–Tropsch synthesis (FTS) reaction. In FTS reaction, the HY-xK catalysts showed higher activity and better stability than the CP-xK catalysts given comparable K content.

Graphical Abstract

Similar content being viewed by others

References

Bukur DB, Lang X (1999) Ind Eng Chem Res 38:3270

Dry ME (1990) Catal Lett 7:241

Dry ME (2002) Catal Today 71:227

Zhang CH, Yang Y, Teng BT, Li TZ, Zheng HY, Xiang HW, Li YW (2006) J Catal 237:405

O’Brien RJ, Davis BH (2004) Catal Lett 94:1

Dry ME, Shingles T, Boshoff LJ, Oosthuizen GJ (1969) J Catal 15:190

Arakawa H, Bell AT (1983) Ind Eng Chem Process Des Dev 22:97

Bukur DB, Mukesh D, Patel SA (1990) Ind Eng Chem Res 29:194

Dry ME, Oosthuizen G (1968) J Catal 11:18

Miller DG, Moskovits M (1988) J Phys Chem 92:6081

O’Brien RJ, Xu L, Spicer RL, Davis BH (1996) Energy Fuels 10:921

Benziger J, Madix R (1980) Surf Sci 94:119

Li S, Li A, Krishnamoorthy S, Iglesia E (2001) Catal Lett 77:197

Yang Y, Xiang HW, Xu YY, Bai L, Li YW (2004) Appl Catal A 266:181

Bukur DB, Lang X, Mukesh D, Zimmerman WH, Rosynek MP, Li C (1990) Ind Eng Chem Res 29:1588

Davis BH, Tungate FL (1991) DOE, Liquefaction contractors meeting, p 275

Shultz JF, Hofer LJE, Karn FS, Anderson RB (1962) J Phys Chem 66:501

Liu KK, Suo HY, Zhang C, Xu J, Yang Y, Xiang HW, Li YW (2010) Catal Commun 12:137

Schwuger M-J, Stickdorn K, Schomaecker R (1995) Chem Rev 95:849

Liu C, Zou B, Rondinone AJ, Zhang ZJ (2000) J Phys Chem B 104:1141

Calderone VR, Shiju NR, Curulla-Ferré D, Chambrey S, Khodakov A, Rose A, Thiessen J, Jess A, Rothenberg G (2013) Angew Chem Int Ed 52:4275

Dong HH, Xie MJ, Xu J, Li MF, Peng LM, Guo XF, Ding WP (2011) Chem Commun 47:4019

Kölbel H, Ralek M (1980) Catal Rev Sci Eng 21:225

Boudart M, McDonald MA (1984) J Phys Chem 88:2185

Feng S, Xu R (2000) Chem. Res 34:239

Mohapatra SK, John SE, Banerjee S, Misra M (2009) Chem Mater 21:3048

Qu J, Yin YX, Wang YQ, Yan Y, Guo YG, Song WG (2013) ACS Appl Mater Interfaces 5:3932

Sun JQ, Zheng SK, Zhang K, Song DC, Liu YT, Sun XD, Chen JG (2014) J Mater Chem 2:13116

Bukur DB, Koranne M, Lang X, Rao KRPM, Huffman GP (1995) Appl Catal A 126:85

Lox ES, Froment GF (1993) Ind Eng Chem Res 32:71

Huang CS, Xu L, Davis BH (1993) Fuel Sci Technol Int 11:639

Shroff MD, Kalakkad DS, Coulter KE, Kohler SD, Harrington MS, Jackson NB, Sault AG, Datye AK (1995) J Catal 156:185

Sirimanothan N, Hamdeh HH, Zhang Y, Davis BH (2002) Catal Lett 82:181

Ning WS, Koizumi N, Chang H, Mochizuki T, Itoh T, Yamada M (2006) Appl Catal A 312:35

Cui XJ, Xu J, Zhang CH, Yang Y, Gao P, Wu BS, Li YW (2011) J Catal 282:35

Cornell RM, Schwertmann U (1996) The iron oxides: structure, properties, reactions, occurences and uses. Second edition. VCH, Weinheim

Liu Z, Lv BL, Wu D, Sun YH, Xu Y (2012) Eur J Inorg Chem 2012:4076

Suo HY, Wang SG, Zhang CH, Xu J, Wu BS, Yang Y, Xiang HW, Li YW (2012) J Catal 286:111

Lohitharn N, Goodwin JG Jr (2008) J Catal 260:7

Rankin JL, Bartholomew CH (1986) J Catal 100:533

Kavitha MK, John H, Gopinath P (2014) Mater Res Bull 49:132

Mahajan D, Gütlich P, Stumm U (2003) Catal Commun 4:101

Herranz T, Rojas S, Perez-Alonso F, Ojeda M, Terreros P, Fierro J (2006) J Appl Catal A 311:66

Acknowledgments

The authors are indebted to the support from the National Natural Science Foundation of China (No. 21373254). This work is also supported by Wuhan Kaidi General Research Institute of Engineering & Technology Co., Ltd.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, C., Chen, J. Effect of Hydrothermal Treatment on Precipitated Iron Catalyst for Fischer–Tropsch Synthesis. Catal Lett 145, 702–711 (2015). https://doi.org/10.1007/s10562-014-1457-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-014-1457-4