Abstract

Kahramanmaraş Earthquake Sequence of 6th of February is the deadliest earthquake that happened in Turkey in the era of instrumental seismology, claiming more than 55 thousand lives and leaving torn down cities and towns behind. More than 450 km long lateral strike-slip fault ruptured during these catastrophic earthquakes. As a result, more than 38 thousand buildings collapsed causing life losses. Considering that the large share of the Turkish building stock consists of RC buildings, the vulnerable RC building stock is the main responsible for this picture. Deficiencies of the Turkish RC building stock are well known since they manifested themselves several times in the past earthquakes. However, considering the improvements in the seismic codes and the seismic hazard maps achieved in the last two decades, the widespread collapse of buildings constructed after year 2000 was rather unexpected. Some of the observed structural damage patterns are similar to those observed also in the pre-2000 buildings in recent earthquakes, however, some other types of damages, such as out-of-plane bending and shear failures or shear-friction capacity failure of RC walls, brittle fracture and bond-slip failure of reinforcement, tension failure of beams and slabs are usually not witnessed. This paper presents a carefully selected set of examples comparing the pre-2000 and post-2000 building damages and collapses, also referring to a detailed summary and comparison of the code developments in Turkey.

Similar content being viewed by others

1 Introduction

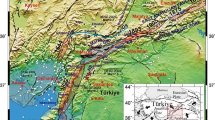

Two consecutive and separate earthquakes hit the Eastern Anatolia region of Turkey on 6th of February 2023, with a 9-hour difference, claiming more than 55 thousand lives and leaving demolished towns and cities behind. The epicentres of the earthquakes were in Pazarcık and Elbistan, with reported moment magnitudes of Mw7.8 and Mw7.5 according to USGS, respectively. AFAD reports these earthquakes as Mw7.7 and 7.6 (AFAD 2023a, b). As a consequence of a complex fracture mechanism on multi fault segments with forward and backward directivity effects, approximately 450 km strike slip fault ruptured.

Considering the widespread effects of this earthquake sequence, affecting 11 provinces and more than 10 million population, the seismic vulnerability of the Turkish building stock, specifically that of the reinforced concrete (RC) buildings, has become one of the central questions that require answer. This is particularly important considering that the rest of the country is seismically very active too. A large earthquake is awaited in the North-Western Turkey where there are densely populated cities with large economic activities, such as Istanbul.

Memories awoke from the devastating Mw7.4 earthquake of 1999 in Gölcük that caused more than 17 thousand life losses and affected Istanbul and other large cities. Construction activities were then paused in most parts of the country for few months, until a new design and construction controlling system was put in place. Year 2000 marked a shift in the awareness of citizens, forced the state to introduce stricter design and construction regulations and is considered a benchmark for the earthquake engineering studies too. Capacity design and ductility concepts were first introduced in the 1998 Turkish seismic code (TSC 1998) (in practice effective after 2000), while even more detailed rules were included in the following seismic codes of 2007 (TSC 2007) and 2018 (TBSC 2018). The distinction between pre- and post-2000 buildings is thus relevant in terms of the evolution of the Turkish seismic codes.

Nevertheless, surprisingly many RC buildings in the earthquake-stricken region, designed and built after year 2000, reached collapse or near-collapse. These structures, most of which are only 10–15 years old, are larger and taller as compared to the pre-2000 buildings, so their collapse inflicted a high death toll. The Kahramanmaraş earthquake sequence brought in the spotlight the actual seismic vulnerability of the post-2000 RC buildings, several of which were supposed to have a ductile response but proved substandard in the most tragic way. Consequently, the need for a decision regarding the remaining building stock, as well as for validation of certain aspects of the current seismic code, becomes urgent.

1.1 Summary of the seismic events and the overall damages

The unprecedent extent of damage in conjunction with the high accelerations in the order of 1 g recorded in several locations led to the obvious question whether the design levels of the most recent Turkish seismic hazard map of 2018 (AFAD 2018) were exceeded.

Ordinary RC buildings are designed for the DD2 level earthquake (475-year return period) but expected not to collapse at the DD1 level earthquake (2475-year return period). Figure 1 shows the spectral accelerations of the recorded motions from both earthquakes compared to the DD1 and DD2 levels for short (0.2 s) and long periods (1.0 s). For short periods, the spectral accelerations of DD1 level are exceeded only in few stations, mostly in Antakya, while for long periods there is exceedance at several stations along and around the fault line. The spectral shape, as well as the spectral ordinates of the hazard maps, may need to be revised after these findings.

Ministry of Environment, Urbanization and Climate Change (MEUCC 2023) is the responsible body in Turkey for officially defining the damage level of each building after an earthquake. The distribution of damage per province, as per most recent data of 3rd of April 2023 (Fig. 2), shows high collapse ratios in Adıyaman, Gaziantep, Hatay and Kahramanmaraş provinces. Zooming in on county level, the largest collapse ratios correspond to Antakya, Nurdağı, Gölbaşı and Doğanşehir along the fault line (Fig. 3), as can be confirmed by reconnaissance observations by the authors themselves. For example, the collapse ratio in Nurdağı reaches almost 15%, unusually high as compared to the known collapse ratios from the past large earthquakes in Turkey (Bal et al. 2008a).

Results of post-earthquake damage assessment per province (MEUCC 2023)

Results of post-earthquake damage assessment per county (see (Reitman et al. 2023) for the fault rupture)

Note that the damages reported by the authorities mostly refer to the damage on RC buildings since most of the Turkish building stock, especially in the urban areas, consists of cast-in-place RC construction. It is extremely important to conclude whether some of the well-known vulnerabilities of the older pre-2000 Turkish building stock persist in the structures designed and built after 2000. The selected cases presented hereinafter constitute a representative sample of the major deficiencies that has been widespread observed in the field.

2 Observed structural damage patterns in RC buildings

The observed damage was widespread, beyond all expectations, even regarding buildings that are expected to be code-compliant due to their construction period. Such an extensive damage and widespread collapse can only be explained with a chain of systematic errors, both in design and construction phase: deficient implementation and/or limited understanding of the seismic code regulations, lack of engineering knowledge and judgement. Furthermore, in critical issues such as defining the load bearing system and forming continuous frames, the code regulations are not imperative. Thus, despite the fact that rules such as limiting irregularities in plan and elevation, performing strength-based seismic analysis according to the presumed ductility capacity of the structure, and designing RC members with ductile design principles have been fundamental provisions of the seismic codes in force for the past 50 years, numerous structures have been built without following these principles.

2.1 Observed material deficiencies

Much of the extensive damage can be attributed to the poor material quality, known for the pre-2000 structures but not expected in the post-2000 buildings. Bal et al (2008b) discusses the material properties of the Turkish building stock until the end of 90’s and the development since 70’s, but the data regarding the post-2000 construction materials, especially in terms of ductility-related limits, is very scarce. Reconnaissance findings in the aftermath of the earthquakes consistently showed that very often the fine aggregate ratio in granulometry of the concrete mixture is high, and sea sand and round gravels are commonly used (Fig. 4). Smooth reinforcing steel bars with a nominal yield strength of 220 MPa (BÇ I), which were widely used in constructions until the end of 1990’s, present higher ductility but poor bonding behavior as shown in (Fig. 4b). Although substantial improvement has been achieved in construction materials after the 1999 Gölcük earthquake through widespread usage of ready-mix concrete and ribbed reinforcement with larger yield strength capacity, still there are issues observed in the field regarding the use of inappropriate aggregates in terms of shape and granulometry, leading to bonding failure between reinforcement and concrete (Fig. 4c–f). Moreover, the high-strength ribbed reinforcement used in walls and columns of several post-2000 buildings were subjected to brittle facture in shear and in axial tension as shown in Fig. 5. Such failures of reinforcement deserve attention since the design of post-2000 buildings primarily relies on ductility, a significant portion of which is stemming from the ductile behavior of reinforcing steel as a material by itself.

Partially collapsed pre-2000 building in Osmaniye with inappropriate aggregate and mixture of concrete (a), bond failure of corroded smooth reinforcement (b). Heavily damaged post-2000 building in Kahramanmaraş with inappropriate aggregate and mixture of concrete (c and d). Heavily damaged under construction building in Malatya with inappropriate aggregate and mixture of concrete (e) and lap splice of reinforcement (f)

2.2 Collapses due to storey mechanism

As in previous earthquakes in Turkey, the formation of a storey mechanism has been the reason of collapse of many RC buildings after Kahramanmaraş earthquakes. Surprisingly, among them there were many post-2000 buildings, which exhibited the very same weakness (Figs. 6, 7, 8, 9, 10), despite the fact that they were designed in line with the regulations for irregularity in elevation as well as strong column—weak beam concept introduced in the seismic code to eliminate this structural deficiency. Although no hard evidence is available, a plausible explanation for the collapse of the intermediate storey shown in Fig. 6c and d could be the formation of a weak-storey mechanism, attributed to the lack of infill walls (this floor was used as storage of the shoe shop beneath).

Intermediate floors also attract highest drift ratios in wall-frame structures, due to the interaction of the walls with the RC frame, and thus this may be another reason for the collapse. One another possible reason is the abrupt change of column sections. In the Turkish construction practice, the same column dimensions are used in the first few storeys in order to save workmanship from the formwork. This results an abrupt decrease of the column section in certain floors that are above the ground floor. The intermediate floor collapse shown in Fig. 9 may also be the result of this. Furthermore, if combined with lack of infill walls, this abrupt change can also trigger an intermediate storey mechanism.

Indicative of the soft-storey collapse mechanism in post-2000 buildings, two identical buildings in Hatay are presented in Fig. 7. The building on the right collapsed due to a soft-storey mechanism, while the one on the left leaned towards left possibly after pounding with the collapsed one. Considering that the two blocks must have been identical, a construction error or a small difference in design must have caused this result.

Another new building located in Hatay (Fig. 8), still under construction, developed a soft-storey mechanism, despite the fact that it had not received all the design loads yet, such as the permanent loads from finishing of floors and infill walls, as well as the portion of the live loads. Although the pre-collapse picture (Fig. 8) indicates beams inside the structure, the perimeter beams are absent, not allowing to form a frame action. This is a repeated deficiency in many other damaged and collapsed buildings. Additionally, the presence of a higher ground floor can probably be one of the main causes of this collapse. Similarly, the building in Fig. 9, constructed in 2019, had all the perimeter columns oriented perpendicular to the façade, weakness that led to collapse as the building swayed in a direction parallel to the weak direction of these columns.

Missing perimeter beams between the façade columns is a very common practice in Turkey, that was spotted and analytically proven to be problematic for the pre-2000 buildings (Bal and Özdemir 2006). However, the current seismic regulations still allow this application. According to all the Turkish seismic codes from 1975 (TSC 1975) to 2018 (TBSC 2018), an RC structure without proper frame action (i.e., no beams between columns) is possible to be designed and built. Article 4.3.4.5 of the TBSC 2018, as well as equation 4.2 of the same article relate the frame action to the participation of the shear walls in the overall overturning moment, a condition which is satisfied even if the beams are eccentrically connected to the column heads or no continuous beams are connected between columns along major axes of the building. The behaviour factor for design is selected simply based on the contribution of the wall and the frame to the overall overturning moment. In the design the building is still considered to be a ductile frame structure and thus the benefit of a high behaviour factor, up to the level of 8, which decreases the lateral load coefficient significantly, is still possible.

Another characteristic example is the recently constructed building shown in Fig. 10, one of the two blocks of Asur Sitesi, Yeşilyurt, Malatya. Although the building survived the first earthquake of Mw7.8, it did eventually collapse over the ground floor during the second earthquake of Mw7.5. One can argue that the structure received two strong earthquakes, one after the other, which may be beyond what was foreseen in the design, however, poor detailing at the beam-column joints stood out as shown in detail in Fig. 10 and must have certainly contributed to the collapse. Although, design of beam-column joints was regulated in the 1975 code and these regulations have become stricter in the following codes, beam-column joint failures have been most commonly observed damage type due to design and construction errors, showing what the loose design and construction controls can lead to even if the seismic code is proper.

2.3 Collapses due to deficient structural system

One haunting picture after the Kahramanmaraş earthquakes was that of several large and tall RC buildings on the ground, the collapse of which cost the life of thousands of people. Though most were built according to the post-2000 seismic standards, they did collapse and in a totally different mode than the typical pancake collapse, mainly observed in the past Turkish earthquakes (EERI 1993, 1999; TDV 2003). The vertical load bearing elements were uprooted, many of which remained unbroken, while the structure collapsed as a whole, as if overturned.

Two of those collapsed buildings, located in İskenderun, are presented in Fig. 11. Building #2 had 13-stories and an RC infilled joist-slab system (asmolen), including columns and RC walls. Most likely, because of torsional irregularity, the building twisted while it uprooted. Presumably bond-slip failure took place at the end zone of walls and columns, slipping out of the foundation (Fig. 12).

Two post-2000 buildings collapsed in İskenderun (IHA 2023)

Collapse of a post-2000 building (Building #2 in Fig. 11) in İskenderun (a), focus on the failure of the ground floor columns at the base (b)

One may think the possible effect of the high vertical acceleration component in this type of overall collapse shown in Fig. 11. Incomplete data from the AFAD station #3112, at 2.5 km distance to the location of the collapsed buildings and situated on soft soil deposits, present a maximum vertical acceleration of 0.85 g, which indeed is high. However, it was shown by various researchers earlier (an analytical example can be found in Gazetas et al. 2008) that the vertical component may not play as significant role as believed, for two basic reasons; (1) difference in the frequency content of the horizontal and the vertical components, in combination to the high-frequency behaviour of structures in vertical direction, and (2) extremely low probability of the peaks of horizontal and vertical motions to coincide.

Building #1 (Fig. 13) had 16 stories, was constructed in 2019 and was characteristically narrow and tall in plan. The approximate dimensions obtained from satellite images and street views is 40 m/10 m/45 m (length/width/height). As deduced from available images, the building partially collapsed after the first Mw7.8 earthquake. The right wing of the structure, together with the elevator shaft and the stairwell collapsed, entrapping people in the other half of the building. The remaining half of the building collapsed in the second Mw7.5 earthquake, leading to an estimated death toll of more than 100 persons.

Collapse of the 16-story building in İskenderun, Building #1 (aka MCG Tower) (a), semi-collapsed situation between the two earthquakes (b), source of a and b: (Artıgerçek 2023), cut building and the base of the U-shaped RC wall (c), cut ground floor columns and shear wall (d)

As can be clearly seen in Fig. 13d, its perimeter columns and walls were not connected with beams in the longitudinal direction resulting in reduced moment resisting frame behaviour (see previous discussion). It is possible that the seismic loads could not be transferred to the core wall system at the elevator shaft via the slabs during the first earthquake, causing partial collapse of the right wing. This explanation is supported by the collapsed slab pieces hanging from the remaining part of the building (Fig. 13b). Although there was two opposite facing U-shaped RC walls at the elevator shaft, they were placed only in the one third in plan of the structure causing torsion irregularity.

Furthermore, in a wall-frame structure the presence alone of a core wall does not entail the wall will work as intended under large seismic actions if not properly connected to the frames. The two U-shaped shear walls forming the elevator shaft had flexural cracks at their bottom (Fig. 13c), while the upper part completely disconnected. In other words, while the wall base worked in flexure, the upper portion of the wall, not withheld by frames, could not accommodate the lateral displacements that were further increased by second-order moments. The aspect ratio of the structure (i.e. width / height) did not work favourably. It should be noted that the seismic design is usually done in practice using linear elastic analysis. After the 1998 Turkish seismic code, there are checks in the code regarding the possible second-order effects, as well as the maximum inter-storey drift ratios. However, it is possible that these checks being in fully linear elastic range may not capture the actual response of the structure in the largely nonlinear region.

The case of the collapse buildings in the Altınpark 2 Sitesi apartment complex in Hatay is presented in Fig. 14. The residential complex consisted of four identical RC blocks with moment resisting frames and structural walls in their structural system, as shown in the formwork plan in Fig. 14f. Blocks A and B collapsed. A soft-storey mechanism over the basement led Block A to collapse (Fig. 14e). Block B was uprooted: column and wall failure at foundation level (Fig. 14c) indicated large moments along the strong axis of these elements resulting in fracture of the longitudinal reinforcement.

Blocks of Altınpark 2 Sitesi under construction during the earthquakes (a), collapsed Block B, source: https://agazete.com.tr (b), uprooted columns of Block B above basement level (c), failure of perimeter shear wall of Block B and cut wall base (see the yellow arrow) (d), collapse over the ground floor in Block A (e), and a schematic ground floor formwork plan, without dimensions, of the blocks (Hoca and Çalı 2023) (f)

The buildings had one basement floor and eleven floors above ground, and were not symmetrical in plan in the two directions. In the centre of each building there were two U-shaped walls in the elevator shafts and one L-shaped wall between the two staircase shafts. These U- and L-shaped walls were not coupled with beams, hence they did not constitute a coupled core wall system. There are RC walls perpendicular to the façade in both directions, connected with beams in their weak axis mainly, but in their strong axis the connection between these walls and the ones in the centre is practically ineffective, i.e. few walls are directly connected to each other, instead a column comes in between to which beams are eccentrically connected. Discontinuous beams entail interrupted load paths and extremely weak joints. Such awkward configurations, where columns and walls are placed and connected basically randomly in a grid, are widespread. They are considered code-compliant structures but in fact they behave as substandard, as they do not achieve transfer of loads and do not constitute an appropriate structural system from a structural earthquake engineering point of view.

In the Turkish building stock, infilled joist slab system (asmolen) has been commonly used for decades. Although this slab system may provide some economical and architectural advantages, it presents serious adverse effects in terms of seismic resistance. Primary beams usually have 30-37 cm depth, which do not provide sufficient stiffness to create a proper frame action and to limit lateral displacements. Secondly, a thin layer of 7-10 cm topping does not provide necessary amount of strength and in-plane stiffness for the loads to be transferred to columns and walls. Although stricter rules were introduced in the 2018 seismic code, a significant portion of the RC building, built in the period from 2000 to 2018, possesses this weakness. In Fig. 15, for example, a post-2000 building built with infilled joist slab system has partially collapsed during the 2023 Kahramanmaraş earthquake sequence.

Pounding or hammering of buildings which can be defined as crashing of two adjacent buildings having stories at same or different elevations, respectively, are also observed in 2023 Kahramanmaraş earthquakes. Figure 16 shows an example where the slabs of adjacent buildings are not at the same level, resulting a severe hammering damage. Despite all the precautions made after 1999 earthquakes, such well-known deficiency still continues due to lack of strict design and construction controls. Several buildings sharing the partition wall of the adjacent one are reported by the authors, confirming that there was no spacing at all between two adjacent buildings.

2.4 Building damage patterns

Due to established poor construction practices prior to year 2000, in combination with limited attention paid to detailing in the previous codes, beam-column joints are usually weak points in the pre-2000 RC buildings in Turkey (see previous discussion). Stirrup spacing along the element and inside the joint was usually larger than 25–30 cm without decreasing the spacing at the column ends, stirrups were most often bent only 90 degrees, ties were not used at all and so on. Some of the observed damages, as expected and known from the previous earthquakes in Turkey, are related to these well-known deficiencies (Figs. 17 and 18). More details will not be given in this work since these critical weaknesses of the pre-2000 Turkish building stock have been widely reported by reconnaissance teams (Aschheim et al. 2000; Scawthorn 2000; Sezen et al. 2000, 2003; EERI 1993; EERI 1999; TDV 2003 among many others). It needs to be stressed, though, that principles of ductility and capacity design are in practice undermined with such bad applications, still seen by practitioners and technicians in Turkey as of secondary importance.

Heavily-damaged building in Osmaniye, buckling of smooth reinforcement, shear failure of column & beam-column joint (a, b and c), Heavily-damaged building in İskenderun, pipeline passing through a column (d), shear failure of column & beam-column joint (e and f), Heavily-damaged building in Hatay, buckling of column reinforcement (g, h and k)

Negligence of the capacity design principles, lack of thorough and strict checks of the design by a third party and bad construction procedures end up in having numerous shear failures in post-2000 RC buildings. In Fig. 19, the two structural RC walls failed in shear. Spacing of the transverse shear reinforcement of the walls in these 9- and 8-storey buildings is about 15 cm and 25 cm, respectively. Though the design specifications of these buildings are not known, the former could reasonably be result of a code-compliant calculation, the wall however still failed and the insufficiency of the stirrups also manifests itself with the buckled vertical reinforcement. The spacing of 25 cm for the transverse reinforcement of such critical U-shaped wall cannot be code-compliant, so the main reason of the failure of the walls in the 8-storey building is either a design mistake and/or a construction error.

A common misconception in the Turkish seismic design practice is that the spacing of confinement reinforcement in the middle zone of columns does not affect much the shear resistance. Hence, structural design engineers determine the minimum amount of confinement reinforcement for the column end zones by means of an empirical formula, taking into account dimensions of columns, characteristic concrete compressive and reinforcement yield strength, and then automatically increase the spacing for the mid-zone of columns to double of that of the end zones, without actually re-checking the shear capacity of the column as a whole. An example of this is shown in Fig. 20, where a column of a 5-storey post-2000 RC building presumably exhibits a shear failure in its mid-height of which inclined compression stress due to shear likely played an important role as observed from the direction of large cracks and splitting. In the same building, narrow spacing of stirrups can be identified in the corner column, probably result of deficient design and/or construction, even flexural failure at the column top end was present (see Fig. 20c).

An RC wall can fail in diagonal shear or in sliding shear. The former, manifested with diagonal cracks along the member, is the dominant mode in pre-2000 buildings, because of lack of capacity design rules and appropriate detailing, while the latter rarely occurs. In the post-2000 buildings, however, the diagonal shear capacity of RC walls is improved because of various detailing rules in the post-2000 seismic design codes. According to the post-2000 codes, after casting concrete at foundation or storey level, the surface shall be roughened up to increase the shear-friction load transfer capacity. Sufficient amount of longitudinal reinforcement shall be placed to transfer shear between adjacent wall segments. According to TBSC-2018, shear-friction capacity between two adjacent wall segments and at wall-foundation interface must be checked. If the capacity is not sufficient, either amount of longitudinal web reinforcement must be increased, or additional reinforcing bars must be replaced to increase the shear-friction capacity.

Seismic loads assumed to be acting at storey levels are also transferred to walls through slabs with shear-friction mechanism. In several RC frame-wall buildings, sliding shear failures (exceedance of the shear-friction capacity) are observed at the contact surface between two adjacent wall segments, wall-foundation or wall-slab interface. Sliding shear failure occurred at the perimeter wall of Block B of Altınpark 2 Sitesi, Hatay, while sliding shear is visible at the wall-basement interface (Fig. 14d). In Fig. 21, out-of-plane sliding shear behavior at the wall-foundation interface and in-plane sliding shear behavior between two adjacent wall segments at construction joint of a 7-story building are also visible.

Out-of-plane shear and bending failure of RC walls causing partial or total collapse have also been reported. In Fig. 22, out-of-plane bending failure of an RC wall of Block C of Altınpark 2 Sitesi, as well as out-of-plane shear failure of perimeter RC walls of Block A are shown. Note that the out-of-plane action has also caused fracture of the longitudinal wall reinforcement. In Fig. 23a–e, an 8-storey building with clear out-of-plane shear and bending failures on the RC walls is presented. Considering that the aforementioned buildings were built after 2000, these failures can be result of a common flaw in the design, i.e., the underestimation of the out-of-plane seismic force demand. Similarly, a heavily damaged building in Hassa, Hatay, where residual storey drifts at the bottom four stories can be readily identified (Fig. 24b), experienced out-of-plane failure of a major perimeter RC wall (Fig. 24a, c, d), indicating a design and/or construction flaw. Torsional failure of L, T, C or other polygonal shape structural walls or columns in which beams generally connected to the end of elements and load path was concentrated in this area is another damage type observed in the earthquakes.

Deficiencies are observed also in the beams, beam-slab and beam-column connections and coupling beams of the post-2000 buildings. One of the reasons behind the beam failures is the fact that the in-plane axial tension, compression and shear forces on the slabs are neglected by many structural engineers presuming the presence of a rigid diaphragm. Even if slabs are modelled with 2D shell members, taking into account the in-plane stiffness of the slab, longitudinal reinforcement of RC beams is determined using forces that do not include slab in-plane forces and beam axial forces. Pictures of the beam end-zone failure and beam failure together with the slab (Fig. 25) are good examples of this problem in the post-2000 buildings. In the conventional reinforced concrete design before 2000, bottom reinforcement bars of beams were bent and joined to the top reinforcing bars at about one quarter of the beam span, and then the bent bars were extended through support of the adjacent beam. It is known that, this construction practice continues, as the presence of a crack at the quarter of the beam span demonstrates in Fig. 25c. Typical shear failure of relatively short beams is also shown in Fig. 25d and e. Shear failure mechanism presented in Fig. 25f caused diagonal splitting of the beam into two triangular halves, as described by Paulay (Paulay 1969; Paulay and Binney 1974) for beams that are under-reinforced against shear. Furthermore, It is important to mention that cyclic shear cracks are observed in cantilever beams of several new buildings due to significant vertical component of the earthquakes (Fig. 25g&h).

Bending failure at the beam end zone (a), tension cracks at the beam support continuing through the slab (b), tensile crack at the one quarter of the beam span (c), and shear failures at relatively short beams of Altınpark 2 Sitesi Block C (d, e) in Hatay, shear failure of a coupling beam from a partially collapsed building in Hatay (f), cantilever beam failures (g, h)

3 Summary of the evolution of the seismic design principles in the Turkish seismic codes

In order to better interpret the damages and collapses observed in the field, the evolution of the seismic design regulations in Turkey needs to be studied. The first Turkish building seismic code was published in 1940 and was then revised in 1944, 1947, 1949, 1953, 1961, 1968, 1975, 1998, 2007 and 2018. The seismic design regulations, except the last two versions, are discussed by Sezen et al. (2000, 2003). In this section, a short comparison of the seismic design codes from 1975 (TSC 1975) to 2018 (TBSC 2018) is presented. Note that the 2007 seismic code has very similar provisions to those of the 1998 code (TSC 1998) in terms of reinforced concrete design. This is reason why the 1998 and 2007 codes will be referred to as TSC-1998/2007 in this study. Finally, another important note is that the first probabilistic seismic hazard map of Turkey was published in 1996, and used for the 1998 and 2007 codes, while the 2018 code came with a new generation seismic hazard map (AFAD 2018).

3.1 Material safety factors in RC member design

When TSC-1975 was published, allowable stress design (ASD) approach was being followed for RC sections in respect to the relevant RC design code, TS-500 (1971). According to TS-500 (1971), safety factors applied for concrete and BÇ I reinforcing steel (fy = 220 MPa) were 3.0 and 1.57, respectively, and allowable stress of both concrete and reinforcing steel could be increased by 1.33 for seismic design according to TSC-1975. Hence, when all safety factors are applied, the overall safety factor for RC section design would be calculated as 2.26 for concrete and 1.18 for reinforcing steel. The concrete design standard, TS-500, was revised in 1984 to follow the load and resistance factor design (LRFD), and since then concrete and reinforcing steel strength have been reduced to the factors of safety γc = 1.50 and γs = 1.15, respectively.

Experience in practice shows that concrete compressive strength varied between 8 and 15 MPa for the buildings constructed before mid-90’s, while plain round reinforcing bars were used for almost all of them (Bal et al. 2008b). The minimum limit for the 28-day concrete characteristic compressive strength was given as 18 MPa, 20 MPa, and 25 MPa for high seismicity regions in the TSC-1975, TSC-1998/2007 and TBSC-2018, respectively. However, due to common construction problems such as the lack of enough cement in the composition of the concrete, size distribution of the aggregates, the use of unwashed sea sand, pouring the concrete without considering the ambient temperature, retempering the concrete to increase the workability, short curing and vibration time, the concrete strength is often far below the targeted concrete strength, especially in pre-2000 buildings. It is reported that even ready-mix concrete in the 90’s was below the designated concrete strength (Bal et al. 2008b). As a result of these problems in production of concrete, spalling and degradation also are present, leaving the reinforcement exposed to environmental conditions, resulting in heavy corrosion in most cases. Ready-mix concrete has become widespread at the end of 90’s, as well as the use of ribbed reinforcing steel, having a characteristic yield strength value of 420 MPa. However, the average yield strength of the reinforcement is often higher than expected (Bikçe and Erdem 2021) aggravating adhesion problems already experienced due to the lack of ribs and resulting in poor anchorage conditions.

3.2 Lateral load coefficient and behaviour factors

Even in the 1975 code, frames could be designed with ductile detailing, provided by the code in the form of schematic drawings, such as the 135-degree bent stirrups. In this case the lateral load coefficient would be approximately 50% less than that of the non-ductile frame with unreinforced masonry. In practice, the ductile construction details were not applied, although the design engineers at the time preferred to use the ductile frame coefficient automatically, since the other option would obviously provide larger cross sections. Since there was no check of whether the construction actually followed the ductile design rules, it is standard that those buildings have been design as ductile but actually built non-ductile. The ‘benefit’ of a very high behaviour factor, R = 8, for structures carrying seismic loads by ‘ductile’ frames started with the 1998 seismic code and continued afterwards.

In all three versions of the seismic codes (1998, 2007; 2018), strength-based design approach is followed with slight variations. For the purpose of comparison the lateral load coefficient parameter is used as shown in Eq. (1). In the 1975 code, reduced seismic load, hence the lateral load coefficient, was obtained by multiplying the seismic zone coefficient (C0), the building type coefficient (K), the spectrum coefficient (S) and the importance factor (I) in Eq. (2). Very similarly in the TSC-1998/2007, the lateral load coefficient is obtained by multiplying the seismic zone coefficient (A0)), the spectrum coefficient (Sa) and the importance factor (I), divided by the behaviour factor (R) (Eq. (3). In TBSC-2018, ordinates of elastic acceleration spectrum are divided by a seismic load reduction factor incorporating structural behavior factor as well as building importance factor to obtain reduced spectral accelerations (SaR), hence reduced seismic load is obtained by multiplying SaR and seismic mass, Eq. (4). It is worth noting that, in TBSC-2018, a clarification was made as the structural system behaviour factor includes both structural system ductility (μk) and overstrength factor (D).

When the Eqs. (2) and (3) are applied for a structure in the highest seismicity zones according to codes of 1975 and 1998/2007, assuming the spectral accelerations are taken from the plateau of the spectrum, and a ductile reinforced concrete frame is used per definition of the code at the time, then the lateral load coefficient would be calculated as 0.10 × 0.80 × 1.0 × 1.0 = 0.08 for the 1975 code, and 0.40 × 2.5 × 1.0/8.0 = 0.125 for the 1998/2007 codes.

The comparison of the seismic design codes is also made via lateral load coefficient spectra, which are similar to the inelastic design spectra in principle. As shown in Figs. 26 and 27, the TSC-1975 lateral coefficient values are smaller than those in the later codes, bearing in mind, however, that the 1975 code, together with the RC design standard, introduced higher safety factors to the concrete and steel materials, as explained above. The exact overstrength caused by these larger safety factors would depend on the section properties, however, the ratio of this extra overstrength applied from 1975 to 1984 fluctuates between 2.26/1.5 = 1.51 and 1.18/1.15 = 1.03, considering safety coefficients of concrete and reinforcing steel, respectively. On the other hand, effective section stiffness coefficients are utilized for modeling of RC members in TBSC-2018 thus leading to higher period values of vibration modes and corresponding lower spectral accelerations.

In order to better understand the effect of different lateral load coefficients from code to code, a simple example is presented here considering an 8-storey RC wall-frame building. Based on the empirical formulae presented in the TSC-1975, dominant natural vibration period of an 8-story wall-frame building with a 15 m × 15 m footprint is estimated as 0.56 s in Tmax = 0.09H/√D or Tmax = 0.07N, where D = 15 m, N = 8 and H = 24 m. The fundamental vibration period of the same structure would be estimated as 0.8 s in the TSC-1998/2007 (Tmax = 0.1N) and 1.06 s in the TBSC-2018 (Tmax = 1.4 × 0.07H0.75). From Fig. 27, where relevant behaviour factors (R) are already implemented, the lateral load coefficients for that structure can be obtained as 0.10, 0.14 and 0.11 for TSC-1975, TSC-1998/2007 and TBSC-2018, respectively. Please note that the response spectrum for the TBSC-2018 is location-dependent, where the parameters for constructing the spectrum are picked from an online interactive map. A location with comparable spectral values is chosen for constructing the TBSC-2018 spectrum.

3.3 Load bearing system selection

One of the most important design issues is the formation of structural system. As explained above, the lateral load coefficient provided by the design codes heavily relies on the fact that the RC frame will behave ductile. In reality these non-ductile structures will not be able to develop the ductility they were designed for. Ductile response is expected under the condition of having ensured frame action and a rigid diaphragm, which is often not valid as have been shown and explained with examples above. In cases where perimeter beams are missing, or the core shear walls are not well connected to the rest of the columns, a robust frame action does not occur, leading to a higher interaction with the slab, which cannot provide the necessary lateral stiffness.

The common system of infilled joist slab systems (asmolen) with shallow beams has been repeatedly criticised for inadequate seismic behaviour. In TSC-1975, for instance, such infilled joist slab system was allowed in high seismicity zones only if RC walls are included in the lateral-load resisting system in buildings taller than 12 m. This strict rule was not incorporated in the 1998 and 2007 codes, although it was replaced with another set of rules in the 2018 code, which does not allow such slab/beam systems in certain areas above a certain building height.

One of the issues a structural engineer faces in the load bearing system selection is the irregularities. Structural irregularities in plan and in elevation were clearly defined in the TSC-1998/2007 code for the first time, although, irregularity concept had been emphasized in some sections of the TSC-1975 but only qualitatively. There are, however, several types of irregularities in the Turkish construction practice, which are not accounted for in the design process. In the TBSC-2018, the irregularities such as torsion, slab discontinuity, projections in plan, weak-storey and soft-storey and supporting of columns on beams constraint at both ends are still allowed with some restrictions and specifications on seismic analysis methods and parameters (Article 3.6.1 of TBSC-2018). Vertical discontinuity of walls and columns supported on cantilever beams are not permitted. Based on the field observations from the collapsed post-2000 buildings, the irregularities such as weak- and soft-storey, as well as high torsion, seem to play a major role in collapse. The post-2000 seismic codes only force the designer to change the seismic analysis method (i.e. from equivalent static to modal combination) if soft-storey mechanism exists, without enforcing any enhancement in the load bearing system. Stricter regulations on irregularities may be needed in the upcoming code revisions.

A common failure mode, specifically observed in tall post-2000 buildings is the uprooting, where the entire structure topples down with the load bearing system of the upper floors mostly intact. It is worth noting that there has been no overturning check in the Turkish codes, although an overall overturning moment is estimated and distributed to the vertical elements without confirming the overall stability of the structure. Few of the most common local RC design software, however, conduct an overturning check although it is not compulsory by the code.

3.4 Ductile design and capacity design rules

As mentioned above, the TSC-1975 included ductile design details, such as the length of the confinement regions, minimum amount of confinement reinforcement, and the 135-degree hooks. A calculation method was provided to determine the maximum amount of shear force at beam-column joints that stirrups should be designed accordingly and the instruction that stirrups must be applied continuously throughout the entire joint region was given. In the RC wall design, the 1975 code defined wall end zones in a length of 10% of the wall width, but there was not any rule to show how the confinement should be in these regions. One of the most important flaws of the TSC-1975 is that there were no rules for RC members to be designed with nominal ductility. It was observed that in many cases, neither the structural designer nor contractor was aware that an RC member shall have at least nominal level of ductility.

Although, details were not provided, there were quite important provisions in the TSC-1975 to improve earthquake response of buildings, with emphasis on the strength of slabs for transferring seismic loads to frames and walls, on the avoidance of partial basement stories, on the limitation of storey-drift ratio, on the arrangement of the infill walls that may affect the dynamic response of the building etc. Another important rule regarding the dimension limits of columns and walls was that width-to-depth ratio could not be larger than 3 for columns and smaller than 5 for walls and the ones remaining within this interval would need to satisfy the minimum requirements for both member types. The limit of the section width-to-depth ratio for columns was increased to 7 (if the ratio is below 7, the vertical RC member is designed as column, otherwise as a wall) in the TSC-1998/2007, and 6 in the TBSC-2018 code, resulting in some of the long column sections observed in the collapsed buildings. Long column sections would have the necessary confinement only if the detailing with ties and stirrups, connecting long stirrup arms at both long edges, was correctly implemented with respect to code provisions, which is not common in the Turkish construction practice. This bad practice resulted in failure of column sections with high section width-to-depth ratio.

One of the main differences between the 1975 code and the newer codes was the capacity design rules. Capacity design came to the earthquake engineering community’s knowledge later than the publication of the 1975 code. The concept of strong column—weak beam was applied in the post-1998 structures, or in effect, in post-2000 buildings. This simple rule aims to prevent the formation of a soft-storey mechanism. The numerous examples of soft-storey collapses presented in Sect. 2 show that it was not successfully implemented in the Turkish building practice.

The presence or lack of infill walls may alter the overall seismic behaviour of an RC structure, especially if the RC load bearing system is weak. The TSC-1975 included a suggestion that the infill walls should be distributed within the building, both in plan and height, in such a way that they will not significantly alter the overall seismic response. The TSC-1998/2007, as well as the TBSC-2018, are more detailed, indicating that infill walls are considered to check for weak-story irregularity, which may result in a lower structural behavior factor for determining seismic loads. However, since the contribution of partition walls to the total effective shear area at each floor is determined as 15%, it is not common to reduce the structural behavior factor due to partition walls of a post-2000 building in practice.

4 Concluding remarks

There is a continuous effort to develop structural design and construction practices in Turkey for designing and building seismically resistant RC structures. Yet, this goal has not been fully accomplished in both structural design and construction phases. The life losses and the widespread collapse, even of the post-2000 buildings, is a manifestation of this failure.

The Turkish seismic code has been revised several times to incorporate state-of-the-art engineering solutions. The implementation of ductile design approach and enforcement of capacity design principles have been major changes in enhancing the seismic behaviour of buildings. In this scope, several rules and conditions have been included for modelling and analysis of structural systems of buildings as well as for design of RC members to prevent collapse or heavy damage. However, a large number of post-2000 buildings collapsed or suffered from unexpectedly heavy damage due to brittle failure modes, such as shear failures of beams, columns, beam-column joints and walls. Some of the structural damage patterns, which are not supposed to commonly occur, including out-of-plane bending and shear failures of walls and columns with large width-to-depth ratio, sliding shear failure of walls, brittle fracture and bond-slip failure of ribbed reinforcement, tension failure of beams and slabs, cantilever beam bending and shear failures, shall be studied in detail.

This also shows that, in addition to all the complex rules for analysis and design, simpler yet more efficient provisions are necessary to control the overall dynamic behavior of the building and to check strength and deformation capacities of structural members. In example; number of structural walls along with their distribution in plan could be correlated with geometrical characteristics of the building, structural systems with effective moment resisting frames having significant contribution to lateral load resisting mechanism could be enforced depending on the irregularities of the structural system and the seismicity of the site location, geometrical conditions could be defined for cross section properties of structural members such as width-to-depth ratio of columns, beam-to-wall and beam-to-column stiffness ratio, providing confinement for a column or wall section through designing wider foundation or basement wall, etc. A performance evaluation step for DD1 level earthquake could be defined for all buildings located in high seismicity regions just to check overturning resistance, shear safety of structural members and residual drifts. Moreover, new policies for inspection of both structural design and construction phases must be developed and urgently implemented by the authorities. As observed through the post-earthquake damage assessment, the level of inspection during the construction phase is insufficient in terms of both quantity and quality.

One of the most striking pictures remaining from the Kahramanmaraş earthquake sequence is the collapsed large RC buildings built in the post-2000 period, sometimes claiming hundreds of lives in one building. Several expensive, tall RC buildings, built in the last 10 to 15 years, uprooted and tilted as a whole, a collapse mechanism that was not quite seen before these earthquakes. It needs to clarified if the ‘uprooting’ problem is revealing of a systematic design or construction issue that causes this kind of deadly collapse mechanism.

As a final remark, the spectral shape in relation to the seismic hazard levels in long period structures needs to be revised. It was found that, although the spectral accelerations at short period (0.2 s) did not exceed the DD1 level earthquake spectra (i.e. 2475 return period), it did so in several locations for the long periods (1.0 s) of the spectrum, especially in the near field zones. This is particularly worrying for the post-2000 structures with low stiffness (i.e., inefficient frame action) and high number of floors, such as 9–10 storeys.

References

AFAD (2018) Seismic hazard Map of Turkey. In: Minist. Inter. Disaster Emerg. Manag. Pres. http://tdth.afad.gov.tr/TDTH

AFAD (2023) 06 Şubat 2023 Pazarcık (Kahramanmaraş) Mw7.7 Elbistan (Kahramanmaraş) Mw7.6 Depremlerine İlişkin Ön Değerlendirme Raporu, AFAD Deprem Dairesi Başkanlığı, available at: https://deprem.afad.gov.tr/assets/pdf/Kahramanmaras%20%20Depremleri_%20On%20Degerlendirme%20Raporu.pdf (last visited 20th of October, 2023).

AFAD (2023) Ministry of Interior, Disaster and Emergency Management Presidency. https://tadas.afad.gov.tr/. Accessed October 20, 2023

Artıgerçek (2023) MCG Tower’ın iki kulesi de çöktü. https://artigercek.com/guncel/mcg-towerin-iki-kulesi-de-coktu-muteahhiti-2-yil-once-drone-destekli-operasyonla-240982h. Accessed 17 Jul 2023

Aschheim M, Gulkan P, Sezen H (2000) Chapter 11: performance of buildings, in Kocaeli, Turkey earthquake of August 17, 1999 Reconnaissance Report. Earthquake Spectra, Supplement A to Volume 16

Bal İE, Crowley H, Pinho R (2008a) Displacement-based earthquake loss assessment for an earthquake scenario in Istanbul. J Earthq Eng 12:12–22. https://doi.org/10.1080/13632460802013388

Bal İE, Crowley H, Pinho R, Gülay FG (2008b) Detailed assessment of structural characteristics of Turkish RC building stock for loss assessment models. Soil Dyn Earthq Eng 28:914–932. https://doi.org/10.1016/j.soildyn.2007.10.005

Bal İE, Özdemir Z (2006) The adverse effects of perimeter frame discontinuity on earthquake response of RC buildings. In: Seventh International Congress on Advances in Civil Engineering. October 11–13, Yıldız Technical University, Istanbul, Turkey

Bikçe M, Erdem MM (2021) Investigation of construction material quality and workmanship defects of RC buildings collapsed and severely damaged in the 6.8 Mw Sivrice, Elazığ, Turkey earthquake, January 2020. Bull New Zeal Soc Earthq Eng 54(3):184–196. https://doi.org/10.5459/bnzsee.54.3.184-196

EERI (1993) Erzincan, Turkey Earthquake Reconnaissance Report, Earthquake Spectra, Supplement to Volume 9, July 1993.

EERI (1999) 1999 Kocaeli, Turkey, Earthquake Reconnaissance Report (CD ROM), Supplement 1 to Earthquake Spectra, Volume 16

Gazetas G, Garini E, Anastasopoulos I, Georgarakos T (2008) Effects of near-fault ground shaking on sliding systems. J Geotech Geoenviron Eng. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000174

Hoca A, Çalı İ (2023) Panel discussion:06 February 2023 earthquakes in terms of structure - earthquake engineering (in Turkish). https://www.youtube.com/watch?v=NaeUsiSFNG4&t=10676s. Accessed 17 Jul 2023

IHA (2023) İskenderun’da tahribat havadan görüntülendi. https://www.iha.com.tr/hatay-haberleri/-4175989. Accessed 17 Jul 2023

Google Maps. (n.d.)., Figure8, [İsmet İnönü Cad., Antakya, Hatay]. Retrieved October 20, 2023, from https://www.google.com/maps/@36.2293656,36.1678205,3a,75y,332.31h,69.17t/data=!3m6!1e1!3m4!1sxouS8MRTm3Uf50ci3U9fbQ!2e0!7i16384!8i8192?entry=ttu

MEUCC (2023) 06.02.2023 7.7 Mw Kahramanmaraş-Pazarcık earthquake. Republic of Turkey Ministry of Environment, Urbanization and Climate Change, General Directorate of Conctruction Works

Paulay T, Binney JR (1974) Diagonally reinforced coupling beams of shear walls. Am Concr Inst 42:579–598

Paulay T (1969) The coupling of shear walls. Ph.D. Thesis, University of Canterbury

Reitman NG, Briggs RW, Barnhart WD et al (2023) Fault rupture mapping of the 6 February 2023 Kahramanmaraş, Türkiye, earthquake sequence from satellite data. US Geol Surv Data Release. https://doi.org/10.5066/P985I7U2

Scawthorn C (2000) The Marmara, Turkey earthquake of August 17, 1999 : Reconnaissance report. U.S. Multidisciplinary Center for Earthquake Engineering Research (MCEER), Buffalo, New York

Sezen H, Whittaker A, Elwood K, Mosalam K (2003) Performance of reinforced concrete buildings during the August 17, 1999 Kocaeli, Turkey earthquake, and seismic design and construction practise in Turkey. Eng Struct 25:103–114. https://doi.org/10.1016/S0141-0296(02)00121-9

Sezen H, Elwood KJ, Whittaker AS, et al (2000) Structural engineering reconnaissance of the August 17, 1999, Kocaeli (Izmit), Turkey, earthquake. Pacific Earthquake Engineering Research Center-PEER Report 2000/09

TBSC (2018) Principles for the design of buildings under the impact of earthquakes (in Turkish). Ministry of Interior, Disaster and Emergency Management Presidency, Ankara, Turkey

TDV (2003) 1 Mayıs 2003 Bingöl Depremi Ön İnceleme Raporu, Tezcan S.S. and Bal. İ.E., Turkish Earthquake Foundation, Report TDV/DR 012–84, Hurriyet Publications.

TS-500 (1971) Turkish standards for requirements for design and construction of reinforced concrete structures. Turkish Standard Institute, Ankara

TSC (1998) Regulation on buildings to be constructed in disaster areas (in Turkish). Ministry of public works and settlements, Ankara

TSC (2007) Specification for buildings to be built in seismic zones. Ministry of Public Works and Settlement Government of Republic of Turkey, Ankara

TSC (1975) Specifications for structures to be built in disaster areas. Turkish Government Ministry of Recontruction and Resettlement-Earthquake Research Institute, Ankara, Turkey

Acknowledgements

The Authors would like to thank to Mehmet Atmaca, M.Sc. structural engineer, for his exceptional photographs required special effort to be taken. Authors are also grateful to Prof. M. Nuray Aydınoğlu for his valuable comments and guidance during the preparation of this article.

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK). The authors declare that no funds, grants, or other support were received during the preparation of this manuscript. The authors have no relevant financial or non-financial interests to disclose.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Eren Vuran, Cavit Serhatoğlu, M. Ömer Timurağaoğlu, Eleni Smyrou, İhsan E. Bal and Ramazan Livaoğlu. The first draft of the manuscript was written by Eren Vuran and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript. The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Corresponding author

Ethics declarations

Competing interests

The authors have not disclosed any competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Vuran, E., Serhatoğlu, C., Timurağaoğlu, M. et al. Damage observations of RC buildings from 2023 Kahramanmaraş earthquake sequence and discussion on the seismic code regulations. Bull Earthquake Eng (2024). https://doi.org/10.1007/s10518-023-01843-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10518-023-01843-3