Abstract

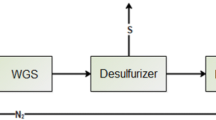

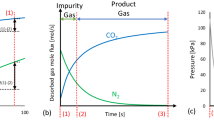

The conventional process employed for the removal of N2 in a natural gas upgrading facility is cryogenic distillation (CD) and entails a significant investment outlay. Operation of the CD unit occurs at approximately 40 bar and − 120 °C, provided by a suitable refrigeration system. At such a low temperature, significant pre-treatment of the feed gas is required to prevent hydrate formation, solidification of CO2 and heat exchanger corrosion damage from mercury. In the current study, the conventional nitrogen removal unit (NRU) using CD is compared to the use of an optimized 9-step pressure vacuum swing adsorption (PVSA) detailed process model employing a Takeda carbon molecular sieve as the adsorbent. The PVSA unit preferentially adsorbs N2 based upon kinetic selectivity of the carbon molecular sieve. Nitrogen rejection by PVSA allows a higher tolerance to the contaminant levels over CD. The impact of this advantage on the overall performance of the entire natural gas upgrading process is evaluated by analysing, in HYSYS, the unit operations upstream and downstream of the CD unit. By employing dimethylethanolamine solvent for acid gas scrubbing and relocating the C2+ fractionation unit upstream of the NRU, the natural gas upgrading process is shown to be more profitable for the production of pipeline gas from raw natural gas at flow rates of up to 40 MMscfd (versus the currently accepted breakeven at 15 MMscfd) using PVSA instead of CD for the NRU.

Similar content being viewed by others

References

Don MacElroy, J.M.: Closing the carbon cycle through rational use of carbon-based fuels. Ambio 45, 5–14 (2016). https://doi.org/10.1007/s13280-015-0728-7

Van Duc Long, N., Lee, M.: Improvement of natural gas liquid recovery energy efficiency through thermally coupled distillation arrangements. Asia-Pacific J. Chem. Eng. 7, S71–S77 (2012). https://doi.org/10.1002/apj.643

Smil, V.: Natural Gas: Fuel for the 21st Century. Wiley, New Jersey (2015)

BP: An Annual Review of the World’s Energy Consumption Pattern; BP Statistical Review of World Energy. (2015)

Mokhatab, S., William, A.: Poe: Handbook of Natural Gas Transmission and Processing. Gulf Professional Publishing, Houston (2012)

Foss, M.M., Ph, D., Land, S.: Interstate Natural Gas — Quality Specifications & Interchangeability. (2004)

Kent, J.A. (ed.): Riegel’s Handbook of Industrial Chemistry. Springer, US, Boston, MA (2003)

Tobin, J., Shambaugh, P., Mastrangelo, E. (2006) Natural Gas Processing The Crucial Link Between Natural Gas Production and Its Transportation to Market. Washington, DC

Kuo, J.C., Wang, K.H., Chen, C.: Pros and cons of different Nitrogen Removal Unit (NRU) technology. J. Nat. Gas Sci. Eng. 7, 52–59 (2012). https://doi.org/10.1016/j.jngse.2012.02.004

Sant Anna, H.R., Barreto, A.G., Tavares, F.W., do Nascimento, J.F. : Methane/nitrogen separation through pressure swing adsorption process from nitrogen-rich streams. Chem. Eng. Process. Process Intensif. 103, 70–79 (2016). https://doi.org/10.1016/j.cep.2015.11.002

Netusil, M., Ditl, P.: Comparison of three methods for natural gas dehydration. J. Nat. Gas Chem. 20, 471–476 (2011). https://doi.org/10.1016/S1003-9953(10)60218-6

Coade, R., Coldham, D.: The interaction of mercury and aluminium in heat exchangers in a natural gas plants. Int. J. Press. Vessel. Pip. 83, 336–342 (2006). https://doi.org/10.1016/j.ijpvp.2006.02.022

Eckersley, N.: Advanced mercury removal technologies: New technologies can cost-effectively treat “wet” and “dry” natural gas while protecting cryogenic equipment. Hydrocarb. Process. 89, 29–35 (2010)

Gas Processors Association: Engineering data book : SI version. Vol. 2 ; Gas Processors Association. Tulsa, Okla. Gas Processors Suppliers Association (2004)

Gassner, M., Baciocchi, R., Maréchal, F., Mazzotti, M.: Integrated design of a gas separation system for the upgrade of crude SNG with membranes. Chem. Eng. Process. Process Intensif. 48, 1391–1404 (2009). https://doi.org/10.1016/j.cep.2009.07.002

Guild Associates Inc: Nitrogen Rejection and CO2 Removal Made Easy, http://www.moleculargate.com/

Mitariten, M.: Nitrogen removal from natural gas with the molecular gateTM adsorption process. GPA Annu. Conv. Proc. 1, 544–555 (2009)

Maqsood, K.: Synthesis of Energy Efficient Cryogenic Distillation Networks for Maximum Methane Recovery from Natural Gas with Carbon Dioxide and Heavy Hydrocarbons. J. Appl. Sci. 15, 492–499 (2015). https://doi.org/10.3923/jas.2015.492.499

Effendy, S., Xu, C., Farooq, S.: Optimization of a pressure swing adsorption process for nitrogen rejection from natural gas. Ind. Eng. Chem. Res. 56, 5417–5431 (2017). https://doi.org/10.1021/acs.iecr.7b00513

Turton, R., Bailie, R.C., Whiting, W.B., Shaelwitz, J.A.: Analysis. Prentice Hall, Synthesis and Design of Chemical Processes Third Edition (2009)

AspenTech: Aspen HYSYS, https://www.aspentech.com/en/products/engineering/aspen-hysys

Hewitt, G.F., Pugh, S.J.: Approximate Design and Costing Methods for Heat Exchangers. Heat Transf. Eng. 28, 76–86 (2007). https://doi.org/10.1080/01457630601023229

Luyben, W.L.: Estimating refrigeration costs at cryogenic temperatures. Comput. Chem. Eng. 103, 144–150 (2017). https://doi.org/10.1016/j.compchemeng.2017.03.013

Lagorsse, S., Campo, M.C., Magalhães, F.D., Mendes, A.: Water adsorption on carbon molecular sieve membranes: Experimental data and isotherm model. Carbon N. Y. 43, 2769–2779 (2005). https://doi.org/10.1016/j.carbon.2005.05.042

Laroche, C.R., Padilla, G., Dowdle, J.R.: Hybrid solvent formulations for selective h2s removal, (2014)

Willmott, L.F., Batchelder, H.R., Wenzell, L.P., Hirst, L.L.: Performance of a Girbotol Purification Plant at Louisiana. Mo. Department of the Interior, Bureau of Mines (1956)

Siriwardane, R.V., Shen, M.-S., Fisher, E.P., Poston, J.A.: Adsorption of CO2 on Molecular Sieves and Activated Carbon. Energy Fuels 15, 279–284 (2001). https://doi.org/10.1021/ef000241s

Vargas, D.P., Balsamo, M., Giraldo, L., Erto, A., Lancia, A., Moreno-Piraján, J.C.: Equilibrium and Dynamic CO2 Adsorption on Activated Carbon Honeycomb Monoliths. Ind. Eng. Chem. Res. 55, 7898–7905 (2016). https://doi.org/10.1021/acs.iecr.5b03234

Funding

The financial support from the National University of Singapore for CENGas (R-261-508-001-646; R-261-508-001-733) is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Effendy, S., Purdue, M.J. & Farooq, S. Economic assessment of a natural gas upgrading process using pressure vacuum swing adsorption for nitrogen removal. Adsorption 27, 591–602 (2021). https://doi.org/10.1007/s10450-021-00302-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10450-021-00302-2