Abstract

The energy crisis and environmental pollution have recently fostered research on efficient methods such as environmental catalysis to produce biofuel and to clean water. Environmental catalysis refers to green catalysts used to breakdown pollutants or produce chemicals without generating undesirable by-products. For example, catalysts derived from waste or inexpensive materials are promising for the circular economy. Here we review environmental photocatalysis, biocatalysis, and electrocatalysis, with focus on catalyst synthesis, structure, and applications. Common catalysts include biomass-derived materials, metal–organic frameworks, non-noble metals nanoparticles, nanocomposites and enzymes. Structure characterization is done by Brunauer–Emmett–Teller isotherm, thermogravimetry, X-ray diffraction and photoelectron spectroscopy. We found that water pollutants can be degraded with an efficiency ranging from 71.7 to 100%, notably by heterogeneous Fenton catalysis. Photocatalysis produced dihydrogen (H2) with generation rate higher than 100 μmol h−1. Dihydrogen yields ranged from 27 to 88% by methane cracking. Biodiesel production reached 48.6 to 99%.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Industrialization and urbanization have resulted in a significant increase in the consumption of finite fossil fuel reserves, leading to a cascade of environmental issues that pose a considerable threat to human health, environmental preservation, and energy demand. Recent years have seen a growing emphasis on utilizing environmentally friendly, efficient, and cost-effective technology to eliminate pollutants, produce clean energy, and synthesize valuable compounds. Among many methods, catalysis plays a major role in reducing production costs and boosting reaction efficiency, which will significantly advance the development of human society. Sustainability, on the other hand, is the development that meets the needs of the current generation without compromising the ability of future generations to meet their own needs. Environmental catalysis involves developing catalysts to degrade undesirable substances or enable alternative catalytic synthesis of essential molecules without generating environmentally unacceptable by-products, and their role in achieving sustainability is crucial. Environmental catalysts have made remarkable strides in pollutant elimination as well as energy and material production over the past decades. Novel environmental catalysts derived from waste or cost-effective materials reduce waste and promote a circular economy while improving catalytic performance.

Homogeneous catalysts have high catalytic performance and well-defined structures, but their stability and recyclability are low. Due to the significant potential for separation, reusability, and stability, heterogeneous catalysts are subsequently considered efficient for environmental applications. Although much progress has been achieved in heterogeneous catalysts, producing catalysts with high catalytic selectivity, high atom utilization efficiency, low cost, easy preparation, and well-defined active sites remains a significant challenge. For instance, designing catalytic systems such as single-atom catalysts enhance atom utilization efficiency to reduce catalytic costs and inherit the benefits of heterogeneous and homogeneous catalysts for several environmental applications (Xu et al. 2022). Another example is biochar; due to its porous and functional structure along with superior performance, it has been widely employed in agriculture, composting, gas storage, animal feed, energy storage, construction, and environmental remediation, with the potential to eliminate environmental contaminants, improve soil fertility, and reduce greenhouse gas emissions (Osman et al. 2022a). Adsorption is the most efficient method for decontaminating the environment; however, unsatisfied adsorption capacity, sluggish equilibrium rate, unstable adsorption conditions, and others continue to be obstacles to biochar adsorption applications (Song et al. 2022a).

Herein, we review the advances in photocatalysis, biocatalysis, and electrocatalysis as environmental catalysts and identify their promising and challenging issues. The main commonly used environmental catalysts discussed are biomass- and carbon-based, metal–organic frameworks, nanocomposites, non-noble metal nanoparticles, and enzymes. The advances and challenges in preparation methods for environmental catalysis are also highlighted. In addition, linking the chemical structure of environmental catalysis with their catalytic performance is exhaustively analyzed and discussed. In addition, the applications of environmental catalysis in three major fields, namely recent progress in water and soil remediation, biomass valorization, product upgrading, and biofuel and hydrogen production, are summarized and evaluated, as shown in Fig. 1.

Applications of environmental catalysis, ranging from sustainable applications and technologies to sustainable catalysis approaches. Using catalysts, such as biomass- and carbon-based catalysts, metal–organic frameworks, nanocomposites, non-noble metal nanoparticles, and enzymes for environmental catalysis is a promising area of research. Notably, while some nano-based materials are sustainable, others are not and may be toxic or environmentally damaging. Applying environmental catalysis in three main areas: water and soil remediation, biomass valorization, product upgrading, and biofuel and hydrogen production can provide valuable insights for achieving global environmental protection

Environmental catalysis

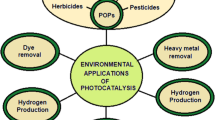

Photocatalysis

Photocatalysis has emerged as the most promising solution for the world’s current energy crisis, environmental pollution, and global warming (Byrne et al. 2018). Since 1972, when Fujishima and Honda discovered the photoelectrochemical properties of titanium oxide (Fujishima and Honda 1972; Byrne et al. 2018; Yap and Lim 2011, 2012), significant effort has been made to develop photocatalysts for efficient photocatalytic processes. Other semiconducting materials, including zinc oxide and cadmium sulfide, have also been proposed as potential photocatalysts due to their similar band gap to titanium oxide. In contrast, their chemical stability and environmental toxicity limit their application in environmental remediation. As a result, titanium oxide remains one of the most researched semiconductor photocatalysts in academia and industry, and its photocatalytic properties have been commercialized in air-purifying (nitrogen oxide and volatile organic compounds conversion) and self-cleaning window film systems (Cha et al. 2019; Lyulyukin et al. 2018). Although their practical application in water and wastewater treatment is still limited, titanium oxide-based photocatalysts have been widely used in persistent pollution-burdened environments, implying that titanium oxide systems may be a viable solution for the removal of widespread emerging pollutants from aquatic environments.

A photocatalytic reaction, in general, consists of three steps. First, photocatalysis is initiated by bombarding a photocatalyst with ultraviolet light photons. Second, suppose the photon energy is greater than the band gap. In that case, these photons cause the generation of electrons (e−) on the surface of the photocatalyst to become ‘excited’ in the valence band (VB), causing them to move to the conduction band (CB). Simultaneously, a positive hole (h+VB) is formed on the valence band. Electrons and holes are excited and migrate to the surface of photocatalysts, where they react with adsorbed electron acceptors and donors, respectively (Fig. 2).

Photocatalytic redox reaction for the degradation of pollutants. Photocatalysis is initiated by bombarding a photocatalyst with ultraviolet light. When the photon energy is greater than the band gap energy, electrons can be generated on the surface of the photocatalyst, where becoming excited in the valence band, which moves to the conduction band. Simultaneously a positive hole is formed on the valence band. Generated electrons and holes further developed superoxide anions and hydroxyl radicals used to remove pollutants. H2O, O2, OH, H+, and H2 refer to water, oxygen, hydroxyl, hydrogen ion, and hydrogen, respectively

In the preceding decades, bare titanium oxide nanomaterials have attracted considerable interest due to their potential applications in environmental pollution removal and photocatalytic hydrogen production (Osman et al. 2020a). Nevertheless, due to its relatively large band gap energy (3.2 eV and 3.0 V for anatase and rutile phases, respectively) (Fig. 3), it can only absorb approximately 6% of the solar energy that reaches the earth at any given time. Thus, significant effort has been devoted to enhancing titanium oxide's absorption properties in the visible spectrum and developing new photocatalytic materials that can capture a broad range, from ultraviolet to visible light and even the near-infrared region. This strategy will lead to the efficient use of solar energy as a clean, abundant, and renewable energy source. The photocatalysts' surface modification, alteration, and structure design can be optimized to increase and broaden light absorption.

Band gaps of non-metal oxide and metal oxide photocatalysts at a pH of 7. Other non-metals and metals have various band gap energies than titanium dioxide. Solar energy can be more effectively adapted to prepare visible-light-driven photocatalysts using their properties, which require narrow band gap energy. Additionally, doping with other non-metal dopants can narrow the band gap energy between the valence and conduction bands. The unit used herein is eV (electron volt), which is a unit of energy commonly used in photocatalysis research to express the energy of photons or electron excitations. It measures the amount of energy gained or lost by an electron when it moves between energy levels in a material. H2O, O2, OH, and H2 refer to water, oxygen, hydroxyl, and hydrogen

Doping titanium oxide with non-metal dopants (such as carbon, nitrogen, sulfur, and fluorine) or metal dopants (such as iron, silver, chromium, and manganese) can narrow the band gap between the valence and conduction bands, thereby enhancing photocatalytic properties (Akpan and Hameed 2011; Elbanna et al. 2016; Luo et al. 2019). There has been a growing interest in the development of novel photocatalysts, such as zinc oxide (Lee et al. 2016; Ani et al. 2018), zinc sulfide (Antoniadou et al. 2011; Hojamberdiev et al. 2020; Zhang et al. 2011), zirconium dioxide (Basahel et al. 2015; Tian et al. 2019; Pirzada et al. 2015), perovskites (Wei et al. 2021a; Bresolin et al. 2020), molybdenum disulfide (Yuan et al. 2019; Li et al. 2018a; Chang et al. 2014), tungsten trioxide (Wang et al. 2012a; Yu et al. 2017; Dutta et al. 2021), cadmium sulfide (Cheng et al. 2018a; Jing and Guo 2006; Zhu et al. 2019), and iron oxide (Hitam and Jalil 2020; Shi et al. 2012; Palanisamy et al. 2013) due to their potential to improve photocatalytic performance and efficiency.

In recent years, lightweight and abundant elements such as carbon, phosphorus, binary carbon nitride, hexagonal boron nitride, and boron carbide have given rise to a new class of metal-free materials opens up new photochemical possibilities. In photocatalytic fields, graphene has been extensively studied as an efficient electron acceptor capable of enhancing charge transfer and decreasing electron–hole pair recombination. Polymer graphite carbon nitride (g-C3N4), an analog of graphene, has become a hot material in photocatalysis due to its unique electronic band structure, low cost, and ease of preparation (Cao et al. 2015). The visible light can excite the graphite carbon nitride with a narrow bandgap of 2.7 eV, indicating its potential use in photocatalytic degradation, photocatalytic sterilization, hydrogen generation, and carbon dioxide reduction (Li et al. 2016a; Zheng et al. 2012).

However, a narrower band gap restricts the reduction and oxidation of photogenerated electrons/holes. In addition, the rapid recombination of photogenerated electron–hole pairs in semiconductors with a narrow bandgap diminishes their photocatalytic activity. Thus, significant effort is being put into developing an efficient photocatalyst that uses doping, coupling with other nanomaterials, precipitation with metal particles, crystal growth designs, and heterojunctions. Compared to single-phase semiconductor photocatalysts, hybrids of two or more semiconductor systems, such as heterojunction, appear to be one of the most promising methods for optimizing solar light utilization efficiency. In addition, the design of heterojunctions prevents photogenerated electron–hole pair recombination and permits rapid charge transport. Based on their adjacent band structures, heterojunctions can be classified as conventional type-I and type-II heterojunctions, Z-scheme heterojunctions, p-n heterojunctions, and homojunction band alignments (Wang et al. 2012a; Wang et al. 2012b; Su et al. 2011; Liu et al. 2011). Recent advances in heterojunction-based photocatalysts indicate a promising strategy for boosting photocatalytic activity in environmental pollution degradation, hydrogen production, and carbon dioxide reduction (De Wolf et al. 2012). While significant progress has been made in photocatalysis over the past few decades, its practical application is currently limited due to insufficient activity, poor stability, and high cost. There is still a great deal of work to improve photocatalyst systems.

Electrocatalysis

In recent years, there has been a growing interest in electrochemical processes for treating polluted waters. The ability of electrochemical systems to operate at ambient temperature and pressure, as well as their robust performance and adaptability to changes in the influent composition and flow rate, are a few advantages over alternative methods (Chen 2004). In addition, they typically do not require additional chemicals and produce no waste. Besides, electrochemical processes can be easily integrated with other technologies, such as electrochemical advanced oxidation processes (e.g., anodic oxidation, electro-Fenton, and electrocoagulation) (Sirés et al. 2014). Furthermore, the coupling efficiency with biological technologies (e.g., aerobic, anaerobic, membrane bioreactors, and microbial fuel cells) is also evaluated (Mousset et al. 2021).

In the 1920s, Bowden and Rideal developed electrocatalysis to measure hydrogen evolution reactions (Wu and Hu 2021; Popovski 2004; Boudjemaa 2020). Since then, electrochemistry has been extensively studied for energy conversion devices (such as batteries, fuel cells, and solar cells), electroanalytical sensors, organic synthesis, corrosion science, and wastewater treatment applications (Carlesi Jara et al. 2007; Zhang et al. 2019a; Comninellis 1994). Using palladium dioxide anodes, the degradation of phenolic compounds was studied, creating new opportunities for electrochemical applications in wastewater treatment (Wu and Hu 2021; Nilsson et al. 1973). The ability of electrocatalysis to remove various organic and inorganic contaminants, including dyes, phenols, pesticides, herbicides, and antibiotics, was then investigated (Comninellis 1994; Quiroz et al. 2014; Ansari and Nematollahi 2020; Xing et al. 2018).

Electrocatalysis is responsible for initiating or accelerating redox reactions in the presence of electrodes by supplying an external potential, which an electric field can provide. As depicted in Fig. 4, micropollutant degradation in an electrocatalysis system is primarily accomplished by direct and indirect oxidation processes. Electrocatalytic degradation processes consider several variables, including electrode materials, electrolytes, water matrices' physical and chemical properties (e.g., pH, coexisting ions, and ionic strength), and operating conditions. An electrode conducts electricity, initiates reactions, accelerates electron transfer, and selectively promotes electrochemical reactions. Moreover, catalysts are essential components of the electrodes used in the electrocatalytic degradation of environmental contaminants.

Electrocatalytic system's direct and indirect oxidation mechanisms. The anode surface and the target contaminants undergo direct oxidation, whereas the anions or OH− generated on the anode surface interact with the contaminants via indirect oxidation. e−, OH−, H+, Fe+2, and H2O2 refer to electrons, hydroxide ions, ferrous ions, hydrogen ions, and hydrogen peroxide, respectively

The choice of electrode material affects the efficiency of electrochemical treatment and the possibility of byproduct formation. Electrocatalysts are categorized as either metal oxides such as ruthenium dioxide, iridium dioxide, lead dioxide, or tin dioxide, or carbon, e.g., boron-doped diamonds. Metal-oxide electrodes are categorized as either active anodes, such as iridium dioxide and ruthenium dioxide, or inactive anodes, e.g., ruthenium dioxide, lead dioxide, and tin dioxide. Titanium/lead dioxide is an excellent electrode, for instance, due to its high oxygen evolution potential, excellent electrical conductivity, chemical stability, and low cost. However, the widespread use of titanium/lead dioxide electrodes is limited due to their distinct disadvantages, including relatively high interface resistance, toxic lead ion leaching, film instability, and low current efficiency. To overcome this disadvantage, either a three-dimensional ordered microporous lead dioxide film based on a porous titanium substrate (Liu et al. 2017) or an aluminum-doped lead dioxide electrode via doping was synthesized (Chen et al. 2015). Tin dioxide-based electrodes are commonly used, but their wide band gap (3.6 eV) restricts their applications. Due to its high oxygen evolution potential, stability, and excellent electrocatalytic properties, antimony is the most used dopant. A tin dioxide-antimony/titanium electrode was synthesized using the sol–gel method for the electrochemical oxidation of antibiotics (e.g., ciprofloxacin) (Wang et al. 2016a). Recently, a titanium/carbon nanotube/tin dioxide-antimony-erbium electrode was prepared as the anode, with the carbon nanotube exhibiting a high specific surface area and high oxygen evolution potential in increased hydroxyl radical production at the anode (Lei et al. 2020).

In addition, carbon-based electrodes such as boron-doped diamond, graphite, and carbon nanotubes are commonly used due to their low resistance and high chemical stability. Still, there is a high cost associated with boron-doped diamond electrodes. Boron-doped diamond is the most frequently used carbon-based electrode due to its high oxygen evolution potential, high corrosion resistance, wide electrochemical potential window, excellent electrochemical stability, and low background current, which produces more reactive radicals to achieve a higher mineralization rate of antibiotics (such as sulfamethoxazole and trimethoprim) than other carbon-based electrodes (de Amorim et al. 2013). However, the reported catalysts for electrochemical have been evaluated for environmental remediation applications; limited efforts have been made for the toxic assessment of pollutants that are not efficiently mineralized via electrochemical and electrode materials, which should be considered in future research.

Biocatalysis

Biocatalysis is an integral component of the 'green chemistry' concept pioneered in the 1990s, and its impact on sustainability is now established beyond dispute, as shown in Fig. 5 (Alcalde et al. 2006). Compared to conventional physical and chemical methods, which have several significant drawbacks, such as insufficient purification, low efficiency, high costs, the production of hazardous byproducts, and application to a narrow concentration range for mineralizing organic compounds from wastewater, this method has several significant advantages (Bilal et al. 2019a; Wong et al. 2019). To overcome these obstacles, environmental engineers and biotechnologists are developing an innovative bioremediation technique that is efficient, cost-effective, and environmentally safe. Enzymes provide new options for treating effluent streams containing organic contaminants resistant to treatment (Bilal et al. 2019a). Enzymes are preferred environmental candidates over whole organisms because isolated enzymes are more specific and easier to handle, and their activity can be tailored to the reaction conditions more precisely (Sutherland et al. 2004; Pieper et al. 2004). Numerous biocatalysts, including hydrolases, oxidoreductases, laccases, and peroxidases, are actively involved in biological treatment (Kadri et al. 2017).

Biocatalytic evaluation and improvement strategies. Biocatalysis involves the application of microbes and biocatalysts (or enzymes). Many biocatalysts have been engineered by rational and directed evolution, contributing to the catalytic activity, enantioselectivity, and stability that are essential for biocatalytic applications. This evolution allows using of biocatalysts for the biosynthesis of value-added pharmaceuticals and fine chemicals. Investigation of the modification of biocatalysts in a short time and recovery of water-soluble enzymes by enzyme immobilization or assistance with solid support attachment greatly enhances the catalytic features of enzymes

In addition, it was determined that other microorganisms, such as fungi, algae, and bacteria, could use a catabolic process to degrade pollutants. Recent interest has centered on microbial lipolytic enzymes because of their ability to catalyze biotransformation reactions involving compounds with ester bonds (e.g., converting waste into biofuel or other value-added products such as fatty acid esters, mono- and diacylglycerols, and others), as listed in Table 1 (Kumar et al. 2020a, b). Since enzyme catalysts are typically water-soluble and difficult to recover from aqueous solutions, using modified and immobilized enzymes is one of the emerging strategies for treating target wastes and lipids today. Enzymes were immobilized using various techniques (Bilal et al. 2017a, b, c, 2018; Zhang et al. 2015) to reuse expensive biocatalysts. It was found that enzyme attachment on solid carriers, either through physical adsorption or covalent bonds, is one of the most practical techniques (Bilal et al. 2018). Therefore, lipolytic enzymes can reduce the massive amount of lipid waste environmentally friendly and address energy security concerns.

Furthermore, various soil-derived enzymes, such as lipases, dehydrogenases, ureases, and catalases, have been proposed as bioindicators for pollution assessments (Margesin et al. 2000). Lipase@ZIF-8 nanoparticle-based biosensor was used to directly detect methyl parathions and organophosphorus pesticides with higher sensitivity and lower cost than laboratory-based methods (Herranz et al. 2018). However, lipase-based biosensors for bioremediation are not yet suitable for commercial use, and additional research is necessary for implementation.

Common environmental catalysts

Fields associated with the environment and energy have adopted the fostered approaches that use benign solvents and mild reaction conditions and produce limited amounts of waste using cost-effective techniques (Chen et al. 2017a). The utilization of environmental catalyst materials contributes to numerous aspects of the United Nations’ seventeen Sustainability Development Goals, particularly Goal 12 (enabling responsible production) and Goal 13 (climate action). Short preparation time, ambient temperature, less hazardous solvents, solvent-free conditions, simple methods, low energy consumption, and fewer by-products are generally considered to be among the most essential characteristics of a green synthesis route (Guesh et al. 2017). Remarkably, environmental catalysts materials have been utilized in various applications, such as electrocatalysis, organic synthesis, biocatalysis, desulfurization, water and soil remediation, biomass valorization, biofuel, and hydrogen production, among others. To reduce environmental pollution and achieve sustainability objectives, numerous materials have been engineered to serve as environmental catalysts instead of traditional catalysts. Metal–organic frameworks, biomass- and carbon-based materials, non-noble metal nanoparticles, nanocomposites, and enzymes are frequently used as environmental catalysts among these materials. A diagrammatic illustration of commonly used environmental catalysts is shown in Fig. 6.

Common environmental catalysts. Metal–organic frameworks are synthesized via metal-linker coordination, forming a uniform porous structure. Carbon-based catalysts are widely used as environmental catalysts in environmental applications. Non-noble metal nanoparticles are considered environmental catalysts under green conditions. Nanocomposites have exhibited remarkable performance in many environmental applications, and enzymes are biological catalysts consisting of protein and active metal sites

Biomass-derived carbon materials

To scale up the technology, scientists must prioritize several essential criteria, such as production cost, efficiency, durability, and environmental impact. Recently, biomass-derived carbon-based materials have been heavily utilized in many applications, including energy storage and conversion, sensing, catalysis, and environmental applications (Park et al. 2022). This was attributed to the outstanding properties of carbonaceous materials in terms of good mechanical stability, unique electronic properties of carbon atoms, electrical conductivity, and structural tenability (Xiao et al. 2022). Notably, researchers have introduced many fabrication strategies to scale carbonaceous materials, such as arc discharge, laser ablation, chemical vapor deposition, pyrolysis, and electrochemical methods, depending on non-renewable petroleum carbon sources such as methane, ethylene, and other petrochemicals (Wang et al. 2021a). However, these strategies unveiled some negative aspects, such as high energy consumption, emission of a large amount of greenhouse gas carbon dioxide, and environmental pollution. For instance, the production of activated carbon consumes large amounts of energy (97 MJ/Kg) with an emission of 6.6 kg/Kg of carbon dioxide. Similarly, graphene production's energy demand was 1100–1640 MJ/Kg with a high carbon dioxide emission (80 kg/Kg) (Boyjoo et al. 2021). On this basis, researchers have attempted to produce novel next generations of carbon materials with desirable characteristics such as affordable cost, facile and sustainable fabrication strategies, low energy consumption, and eco-friendly merit. From an economical and sustainable point of view, researchers have considered biomass an excellent alternative, renewable organic feedstock to crude oil and natural gas (Osman et al. 2022b; Farghali et al. 2022). This is ascribed to the abundance of enormous biomass resources, including plant and animal-derived materials.

The worldwide annual disposal of food waste was found to be equivalent to a third of food production (1300 million tons) (Matharu et al. 2016); also, agricultural practices generate 570 million tons of waste annually (Morrison and Golden 2015). For instance, plant-derived biomass comprises three components: (1) inedible portions (lignin, cellulose, and hemicellulose); (2) edible portions (starch, free sugars, protein, and vegetable oils (triglycerides); and (3) essential oils and other secondary metabolites of high value (Sherwood 2020). Accordingly, the exclusion of unnecessary wastes and the rational upcycling of those wastes guarantee viable, high-quality products, minimize the environmental problems related to unwise waste disposal, i.e., waste management, and achieve the circular economy aspects (Sherwood 2020; Clark et al. 2016; Peng et al. 2023).

Recently, biomass-derived carbon materials were established as the most sustainable and scalable strategy due to the enormous annual production of biomass from agriculture and forestry (104.9 billion tons/year) (Field et al. 1998). Interestingly, there are numerous macrostructures with tunable porosity in biomass-derived carbon materials, including spherical (Xia et al. 2012), reticular (Ubeyitogullari and Ciftci 2016), fibrous (Hu et al. 2016), ribbon-like (Ai et al. 2018), bubble-like (Xie et al. 2018), and plate-like materials (Ling et al. 2015), expanding their applications. Besides, the remarkable characteristics of such materials outperform the noble metals in many aspects, including (1) cost-effectiveness, i.e., carbon price is 0.03$ per gram while gold price is 60$ per gram, silver price is 25$ per gram, and platinum price is 34$ per gram; (2) ease of fabrication due to the abundance of raw materials; (3) tailorable structure due to the presence of heteroatoms, for example nitrogen, oxygen, and sulfur, that facilitate the functionalization and enhance the catalytic activity (Li et al. 2020; Wu and Zhang 2020). However, the synthesis strategy played a crucial role in carbon materials' porosity and surface chemistry. Therefore, a challenging issue is fabricating a uniform porous structure with a well-defined shape of sustainable biomass-derived carbon materials.

The world demand for energy has become a quintessential priority for better and sustainable life for humanity. The massive emissions of carbon dioxide into the atmosphere, which amount to about 30 billion tons annually, have severely threatened the environment with issues like global warming and air pollution as a result of the overuse of fossil fuels as a major source of energy (about 80%) to support the industrial revolution and satisfy population growth (Seh et al. 2017; Zhang et al. 2020; Panwar et al. 2011). According to the international energy agency, atmospheric carbon dioxide concentration increased from 280 to 480 ppm in 2019 (Chu et al. 2017; Swann et al. 2016). As a result, this dangerous environmental crisis has drawn considerable public concern. Therefore, many researchers have devoted their efforts to creating innovative technologies and strategies and generating an alternative, green, and renewable energy source.

The exploitation of hydrogen gas as a clean energy source has become a promising approach owing to its non-toxic combustion by-product and the higher caloric value (142 MJ/kg) comparable to fossil and hydrocarbon fuels (Muradov and Veziroğlu 2008; Schlapbach and Züttel 2011). Therefore, great efforts have been exerted to foster an alternative strategy instead of the conventional methods like steam reforming fossil fuel and water electrolysis, which consume a large amount of energy and money (Karayilan et al. 2019; Hosseini and Wahid 2016). Subsequently, photocatalytic water splitting has gained significant interest as a sustainable and green strategy to produce hydrogen (Gopinath and Nalajala 2021). Especially, photocatalytic water splitting has demonstrated an excellent efficiency of solar energy conversion into hydrogen, reaching 5–10%, indicating its proficiency and possible application on a large scale (Arunachalam et al. 2021; Wang et al. 2019a).

Three-dimensional biomass-derived carbon materials revealed an excellent performance in different catalytic applications due to their large specific surface area, high porosity, good conductivity, and propitious thermal and chemical stability, as shown in Table 2. In this perspective, a sustainable and cost-effective three-dimensional carbon aerogel support from seaweed biomass (carrageenan) was prepared to boost the efficiency and photostability of cadmium sulfide photocatalyst (CdS@CAs) (Quan et al. 2018). Carrageenan provided a non-toxic sulfur source, i.e., sulfated galactons, that extended across the double helix structure of carrageenan and was integrated by cadmium cations, resulting in photocatalysts with interconnected macropores and mesopores that accelerated the mass transfer of reactants. The results exhibited an excellent hydrogen evolution rate of 113.5 µmol h−1 with a photocurrent density of 100 µA cm−2. This finding may be attributed to the good electrical conductivity of the photocatalyst that accelerated the photogenerated charge separation and the photocorrosion resistance of cadmium sulfide. A certain carbon coating thickness for cadmium sulfide inhibited the self-oxidation of cadmium-sulfur bonds by the photogenerated holes. Therefore, cadmium sulfide photocatalyst achieved excellent photostability after 4000 s under light illumination.

Further, a sustainable strategy for the catalytic hydrolysis of ammonia borane (ammonia, borane trihydridoboron, ammonia borane) was proposed using magnetically recoverable ruthenium and cobalt (Ru and Co) bimetallic nanoparticles supported on costless cotton-derived carbon fibers (Ru@Co/CCF) (Yang et al. 2018a). Transmission electron microscope and elemental mapping images revealed the uniform dispersion of ruthenium and cobalt bimetallic nanoparticles with an average diameter of 5–15 nm onto helical-shaped carbon fiber support. This was related to the large number of –OH functional groups on the surface of the carbon fibers that uniformly adsorbed Co2+. Interestingly, ruthenium and cobalt on cotton-derived carbon fibers showed a satisfactory turnover frequency (139.59 molH2 molRu−1 min−1) at 30 °C. Due to the cobalt nanoparticles' ferromagnetic properties, ruthenium and cobalt on cotton-derived carbon fibers were involved in several catalytic cycles with good catalytic activity and facile recovery by an external magnet. The chemical storage of hydrogen could be a promising strategy rather than the traditional storage methods such as compression, liquefication, and adsorption due to its high volumetric and gravimetric hydrogen content (i.e., ammonia. borane trihydridoboron has a molecular weight of 30 g mol−1 with a hydrogen content of 19.6 wt%) (Sadhasivam et al. 2017).

Metal–organic frameworks

Metal–organic frameworks are a dominant category of catalysis owing to their unparalleled characteristics that are not wholly exploited, including flexibility, superb reusability, immense surface area, unique physicochemical properties, and intrinsic structures. In addition, metal–organic frameworks are synthesized via metal-linker coordination bonds in three directions, forming a uniform porous structure (Vasanthakumar et al. 2020). Solvothermal is generally the most common method to fabricate metal–organic frameworks; however, it involves dissolving metals and ligands in organic solvents such as dimethyl formamide (Omer et al. 2021; Abd El-Monaem et al. 2022). Notably, dimethyl formamide is a quite detrimental solvent that decomposes to dimethylamine at high temperatures, causing environmental and handling problems (Chen et al. 2017a). Hence, for applying the concept of sustainability and avoiding environmental issues, the preparation of metal–organic frameworks via solvent-free approaches has become a research hotspot. The alternative green synthesis methods of metal–organic frameworks are sorted into two categories according to solvent amount and energy consumption; the first one includes aging (Cliffe et al. 2012; Mottillo et al. 2013), mechanochemical (Užarević et al. 2016; Do and Friščić 2017), and thermochemical (Lanchas et al. 2012). In comparison, the second category contains microwave-assisted (Liang et al. 2013; Klinowski et al. 2011), sonochemical (Song et al. 2016; Yuan et al. 2016), and electrochemical (Liang et al. 2013; Klinowski et al. 2011). Overall, to fabricate metal–organic frameworks in a sustainable and green approach, Julien et al. (2017) summarized the main aspects that should be considered (Fig. 7); (1) utilizing biocompatible building blocks, (2) eschewing bulk solvents, (3) utilizing supercritical liquids or water as a solvent, and (4) rationalizing the energy inputs.

Environmental criteria for metal–organic framework-based catalysts. Green metal–organic can be obtained using green solvents and less toxic metal salts. The linker should be eco-friendly and produces biodegradable products with less hazardous by-products. The process should be energy efficient, and the metal–organic framework-based catalysts should have good recyclability and be applied in green applications

Indeed, metal–organic frameworks' heterogeneous character and porous nature render them outstanding catalysts compared to other catalysts, such as aluminosilicates, zeolites, and others. (Table 3). In addition, the synergistic effect between the Brønsted acid (linker) and Lewis acid (metal node) greatly promotes the strength of catalytic reactions (Jiang et al. 2014). More importantly, the functionality of metal–organic frameworks endows them one more merit than conventional catalysis since it facilitates the modification of metal–organic frameworks with active species, enhancing their catalytic performance (Chen et al. 2017b). The introduction of active species to metal–organic frameworks typically takes place via three strategies: post-synthetic approach, encapsulation of active species into metal–organic frameworks, and functionalization via the unsaturated metal sites or the organic ligand (Dhakshinamoorthy and Garcia 2014; Liu et al. 2014a).

Despite the merits mentioned above of metal–organic framework-based catalysts, they suffer a critical shortcoming: the poor stability of their structure, particularly in organic solvents and water, limiting their applications in water treatment (Tan et al. 2015). The robustness study of metal–organic frameworks in water, acidic and basic media, and water vapor found that the weak coordination bond between metal and linker is the leading cause of oxidative leaching of metal nodes. Thus, the metal-linker coordination bonds' strength has controlled the metal–organic frameworks' stability (Rashid et al. 2020). Nevertheless, few metal–organic frameworks possess high stability in water, especially MIL-family, such as MIL-101 (chromium, iron, aluminum), MIL-100 (chromium, iron), and MIL-53 (chromium, aluminum), as well as zirconium-based metal–organic frameworks (Schoenecker et al. 2012; Lan et al. 2016). Furthermore, porous coordination network-222 and porous coordination network-224 showed relatively high stability in both acidic and basic conditions, while the linker protonation of aluminum- metal–organic frameworks endows excellent stability in the acidic medium (Feng et al. 2013; Feng et al. 2012). The stability of zeolitic imidazolate frameworks was examined in boiling water, sodium hydroxide, and benzene at different temperatures for seven days. The results revealed the superb structural stability of ZIF-8 in boiling benzene and water for seven days and only 24 h in sodium hydroxide solution (Panda et al. 2019). Several studies have focused on enhancing the metal–organic framework's stability, suggesting that the linker's basicity is the key parameter in the robustness of the metal–organic framework since it controls the bond strength between metal and linker (Ali et al. 2021). Owing to these unparalleled advantages, metal–organic frameworks are intensively utilized in diversified applications as follows:

Pascanu et al. (2013) fabricated palladium-loaded MIL-101(Cr)-NH2 composite (Pd@ MIL-101(Cr)-NH2) with different loading ratios of Pd (4, 8, 12, and 16 wt%). It was observed a diminution in the specific surface area (SBET) of MIL-101(Cr)-NH2 from 2869 to 1321 m2/g and pore volume from 1.403 to 0.625 m3/g with the increase in the Pd loading ratios from 4 to 16 wt%, respectively. This finding may be attributed to the particle aggregation of the extra amount of Pd. Furthermore, the catalytic activity of the as-fabricated Pd@ MIL-101(Cr)-NH2 composite was examined in the Suzuki–Miyaura cross-coupling reaction. It was found that the optimal Pb-loading ratio was 8 wt% since aryl and heteroaryl bromides and chlorides were coupled in eco-friendly solvents (H2O and ethanol) within a quite short reaction time and at an ambient temperature of 80 °C. More importantly, the recyclability study depicted the promising catalytic activity of 8 wt% for Pd@MIL-101Cr-NH2 even after the 10th cycle.

In that context, Nuri et al. (2020) investigated the catalytic activity of Pd-supported amino magnetic MIL-101(Cr) composite (Pd@Fe3O4-NH2@MIL-101(Cr)-NH2) toward Mizoroki–Heck Cross-Coupling reaction of iodobenzene and methyl acrylate. They recorded a decline in the saturation magnetization (Ms) of iron oxide (Fe3O4) after blinding with Pd and MIL-101(Cr). However, the Ms of Pd@Fe3O4-NH2@MIL-101(Cr)-NH2 was still sufficient for the separation by an external magnet instead of the conventional techniques that consumes a long time. Such perfect and easy separation is the prominent role of iron oxide since it does not possess catalytic activity toward Heck cross-coupling reaction. The reusability study displayed the ability of Pd@Fe3O4-NH2@MIL-101(Cr)-NH2 to reuse for seven cycles with no significant decrease in its activity. Furthermore, it was suggested that the reduction of the catalytic activity of the as-fabricated magnetic composite is most likely due to the Pd leaching. Notably, Pd@Fe3O4-NH2@MIL-101(Cr)-NH2 revealed a high catalytic activity and stability toward cross-coupling iodobenzene and methyl acrylate since the turnover frequency reached 2438 h−1 within 30 min at 120 °C.

In one investigation, Alamgholiloo et al. (2021) inspected the catalytic activity of magnetic ZIF-67 composite (Fe3O4/ZIF-67) toward the degradation of ciprofloxacin through peroxymonosulfate activation. The rhombic dodecahedron ZIF-67 was greenly synthesized in a benign solvent (methanol). However, ZIF-67 was successfully synthesized via a green approach in an eco-friendly solvent, and the yield was low (about 57%). Consequently, the green strategies for metal–organic framework preparation need further developments to be applicable in industrial applications.

Notably, Fe3O4/ZIF-67 composite showed high efficiency in degrading ciprofloxacin since the degradation rate reached 98% during 48 h using 0.4 g/L Fe3O4/ZIF-67 and 0.5 g/L peroxymonosulfate. Furthermore, the pure Fe3O4 and ZIF-67 revealed a lower ciprofloxacin degradation efficiency compared to the Fe3O4/ZIF-67 composite, reflecting the synergistic effect between the pristine components. To determine the predominant radical species in the degradation of ciprofloxacin, the scavenger effect was studied in the presence of isopropyl alcohol, benzoquinone, and ethanol. The result clarified that both SO4·− and ·OH are the controlled radicals. Besides, Electron spin resonance confirmed the same result since only the characteristic signals of SO4·− and ·OH appeared in the Fe3O4/ZIF-67/peroxymonosulfate system. These findings indicated that the degradation mechanism of ciprofloxacin most probably occurs via the radical pathway.

In another investigation, Chandra et al. (2019) adopted the green synthesis approach to fabricate another ZIF MOF to photodegrade methylene blue from an aqueous solution. The core–shell tin dioxide (SnO2)-ZIF-8 composite was fabricated with various ratios of tin dioxide, revealing a decrease in the degradation efficiency of methylene blue with the increase in the ratios of tin dioxide due to particle aggregation. It was reported that the photocatalytic degradation mechanism of methylene blue using tin dioxide-ZIF-8 composite occurred as follows: the movement of the generated e− and h+ in the conduction and valance bands of tin dioxide to ZIF-8, reducing the recombination of e− and h+ pair. Then, this e− and h+ pair could form ·OH via the oxygenation of H2O. Thus, ·OH is the responsible radical for the photocatalytic degradation of methylene blue, agreeing with several previous studies (Chandra and Nath 2017; Jing et al. 2014; Kim et al. 2016).

Further, Gong et al. (2019) successfully prepared a magnetic core–shell Fe3O4@GO@MIL-100(Fe) microsphere catalyst using water as a solvent instead of dimethyl formamide in a green and sustainable route. The scanning electron microscope and transmission electron microscope images of the synthesized materials demonstrated that Fe3O4 particles have rough surface spheres with particle sizes ranging from 300 to 350 nm. However, a crinkled surface texture was obtained after being wrapped with graphene oxide (GO) with a 4.5 nm thickness of the GO layer. Upon coating with MIL-100(Fe), the MOF layer was 61 nm thick, confirming the formation of magnetic core–shell Fe3O4@GO@MIL-100(Fe) microspheres. The fabricated catalyst was used for 2,4-dichlorophenol (2,4-DCP) degradation via the photo-Fenton process with almost 100% efficiency in 40 min. The reusability tests revealed that the magnetic core–shell Fe3O4@GO@MIL-100(Fe) catalyst has good stability and recycling ability.

Non-noble metals nanoparticles

Undoubtedly, metal nanoparticles have received immense interest in the last few years in the catalysis field owing to their unique physical and chemical properties (Song et al. 2015). Interestingly, it was deduced that the metal catalysts in a nano-size possess advanced catalytic performances compared to their bulk equivalents since the size and shape play significant roles in the chemical activity of the catalyst (Table 3). The catalyst shape impacts its activity and selectivity toward the catalytic reactions, while the catalyst size controls its specific surface area (Mandić et al. 2017). Nonetheless, the fabrication of shape-controlled metal nanoparticles is still a big challenge and a complicated process. For this purpose, several strategies have been developed to synthesize stable metal nanoparticles with a defined shape, such as the addition of inorganic capping agents, organic ligands, colloids, polymers, or the fabrication of core–shell materials (Campelo et al. 2009).

Among the metals nanoparticles, noble metals have revealed exceptional catalytic performance in various potential applications (Wang and Astruc 2017). However, they could not be classified as sustainable catalysts due to their high price, rare abundance on earth, and detrimental impacts on the biological system. Contrariwise, the availability, premium activity, and selectivity of non-noble metals have acquired considerable fame among the diverse as more favorable catalyst types (Ilies et al. 2020). Therefore, extensive studies have been implemented focusing on preparing non-noble metal nanoparticle-based catalysts under green conditions, considering using nontoxic solvents and consuming low energy. In addition, the utilization of bio-reducing agents such as algal, sugars, glutathione, and mainly plant extract (Fig. 8) instead of the toxic reducing agents such as sodium borohydride or lithium borohydride. For instance, Lohrasbi et al. (2019) fabricated an iron nanocatalyst using Plantago as a bio-reducing agent. The transmission electron microscope image revealed that the particles are uniform spherical with a size range between 4.6 and 30.6 nm.

Synthesis of non-noble metal nanoparticles from plant materials, such as leaves, seeds, flowers, stems, roots, or fruits. The plant extract contains a variety of bioactive agents, such as polyphenols and flavonoids. These bioactive agents can reduce the metal ions to produce metallic nanoparticles. The capping agents in the plant extract act as capping agents for the metallic nanoparticles. These non-noble metal nanoparticles are suitable more preferably-type catalysts. M0 refers to metal nanoparticles

Furthermore, Din et al. (2018) utilized the wild plant Calotropis gigantea as a bio-reducing and stabilizing agent to fabricate nickel nanocatalysts. The various characterization tools inferred the successful fabrication of nickel in a nano-size of 20–40 nm. Thus, such bio-reducing agents could fabricate non-noble metal nanoparticles with controlled particle size and shape in some cases (Murphy 2008).

Unfortunately, there are some flaws in non-noble metal nanoparticles as catalysts, including their rapid deactivation, poor recyclability, and difficult separation. Several previous studies have reported that using supported nanoparticles is the most effective method among the other approaches to overcome these demerits of non-noble metals (Wang et al. 2021b). However, supported metal nanoparticles provoke researchers' anxiety about whether the quite active and dispersed supported metal nanoparticles are harmful to human tissues or not. On the other hand, no cytotoxicity or cellular oxidative stress was inferred for the unsupported metals, although they were retained in human tissues (Campelo et al. 2009). In this perspective, Musa et al. (2017) fabricated copper nanoparticle-supported nanocrystalline cellulose (Cu@NCC) for the catalytic reduction of methylene blue in the presence of sodium borohydride (NaBH4) as a reducing agent. The following equations represent the proposed preparation mechanism of copper nanoparticle-supported nanocrystalline cellulose;

To infer the successful preparation of copper nanoparticle-supported nanocrystalline cellulose, the elemental composition was examined by X-ray fluorescence, clarifying the presence of Cu in nanocrystalline cellulose (NCC). Moreover, the thermogravimetric analysis elucidated an improvement in the thermal behavior of NCC after blinding with Cu nanoparticles, proving the interaction between NCC and Cu nanoparticles. At the same time, a noticeable decline in the surface area of copper nanoparticle-supported nanocrystalline cellulose was recorded compared to that of NCC, most likely due to the dispersion of Cu nanoparticles onto the NCC surface and its pores (Ghosh et al. 2015). Results confirmed the auspicious catalytic activity of copper nanoparticle-supported nanocrystalline cellulose toward reducing methylene blue since the reaction completely terminated within merely 12 min. In comparison, the unsupported Cu nanoparticles reduced methylene blue within 44 min. This finding revealed that the supported nanoparticles possessed higher catalytic activity than the unsupported ones. Contrariwise, Kamal et al. (2019) pointed out that the unsupported carboxymethyl cellulose-stabilized cobalt nanoparticles (CMC-Co) contained higher catalytic activity toward reducing methylene blue than the supported carboxymethyl cellulose-stabilized cobalt bacterial-cellulose nanofibers (CMC-Co-bacterial cellulose nanofibers). This behavior may be explained by the availability of the whole surface area of cobalt nanoparticles of carboxymethyl cellulose-stabilized cobalt nanoparticles to adsorb the methylene blue molecules. In contrast, in carboxymethyl cellulose-stabilized cobalt-bacterial cellulose nanofibers, the cobalt nanoparticles are partly available.

In another attempt, Wang et al. (2017) adopted an innovative technique to prepare an electrocatalyst for the oxygen reduction reaction. The platinum-coated cobalt nanoparticles (Co@Pt) were fabricated via in situ seed growth approach. Such a preparation method enables self-nucleation and growth by adjusting the Pt deposition rate to be slower than its diffusion rate on the surface (Park et al. 2016). Besides the generated CO during the Co growth from cobalt carbonyl facilities, the coating of Pt on the Co. Transmission electron microscope image inferred the core–shell-like structure of platinum-coated cobalt with an average diameter of 10 nm, whereas the diameter of the platinum shell was 1 nm. It was found that the catalytic activity of platinum-coated cobalt for oxygen reduction reaction was enhanced 10 times compared to pure platinum.

Furthermore, platinum-coated cobalt exhibited a high stability potential cycling since the non-noble Co nanoparticles were conserved from leaching out by the noble platinum nanoparticles shell. This result was consistent with Park et al. (2016), which enhanced the durability of nickel–platinum (Ni–Pt) electrocatalyst for oxygen reduction reaction by coating it with a thin layer of platinum. It was deduced that Ni–Pt@Pt protected Ni nanoparticles from leaching; however, 11% of Ni was leaching from Ni–Pt. In addition, the activity of Ni–Pt dwindles by about 75% after 10,000 cycles of the oxygen reduction reaction, while the activity of Ni–Pt@Pt decreased by only 25%.

Nanocomposites

Using any pure substance as a catalyst has advantages and disadvantages, so combining two or more to form composites is a superior avenue in modern technology. Such an approach enables the exploitation of the best merits of each substance by overcoming some of its demerits (Ates et al. 2017). Composites are classified into three groups based on their size; micro-composites, macro-composites, and nanocomposites (Paul and Robeson 2008). The extremely high surface area, strong interaction between the matrix, and high stability of nanocomposites have revealed remarkable activity (Yu et al. 2006; Xu et al. 2015a). Notably, it was evinced that the combination of two active components dramatically enhances their catalytic activity (Lin et al. 2019a).

Nonetheless, the rapid growth of nanocomposites during the preparation results in hazardous environmental issues due to their complex decomposition (Ates et al. 2020). One of the most feasible solutions to this problem is utilizing templates to control the size and shape of nanocomposites and protect their surfaces, thereby preventing particle aggregation (Yadav et al. 2019). Diversified commercial temples have been utilized as functionalizing agents to ameliorate nanocomposites' morphology, size, and properties (Table 3). Still, they have revealed a fatal environmental risk due to their difficulty degrading or removing. Hence, synthesizing nanocomposites using bio-renewable resources like starch, chitin, vegetable oils, lignin, natural rubber, and cellulose has drawn vast concern to fabricating catalysts with no harsh synthetic approach (Borah et al. 2017). Such nanocomposite-based sustainable catalysts possess outstanding features, including easy preparation, excellent biocompatibility, low density, good biodegradability, low cost, flexibility, and suitability for modifications (Fig. 9) (Ulu et al. 2018). However, these fabricated nanocomposites from bio-renewable resources still suffer drawbacks limiting their industrial applicability, such as low thermal, chemical, and mechanical stability (Ates et al. 2020).

Characteristics of the nanocomposite-based sustainable catalysts fabricated from renewable resources. Bio-renewable resources such as lignin, starch, and chitin are widely used in nanocomposite-based sustainable catalysts preparation. Nanocomposite-based catalysts should be flexible and suitable for modifications. Biodegradability is the primary condition for nanocomposites to be considered sustainable catalysts. Low density, biocompatibility, and ease of preparation are among the main criteria of nanocomposite-based sustainable catalysts

Nanocomposites derived from bioresources have exhibited remarkable performance in diverse potential applications. For instance, Wang et al. (2019b) fabricated chelated copper onto polydopamine-coated sand composite (Cu-PDA@Sand) for the catalytic degradation of the anionic Congo red and cationic methylene blue as well as reduction of 4-nitrophenol. It was found that 4-nitrophenol was wholly reduced to 4-aminophenol within 13 min. Furthermore, the color of Congo red vanished after only 6 min, while the color of methylene blue dye disappeared after 9 min, suggesting the reduction of methylene blue (Kim et al. 2016; Subair et al. 2016). Moreover, to examine the applicability of copper onto polydopamine-coated sand composite in industrial applications, the long-term catalytic activity was studied after 30 days. It recorded a slight diminution in the apparent reaction rate of 4-nitrophenol, Congo red, and methylene blue (about 6%), inferring the stability of the copper onto polydopamine-coated sand composite. Interestingly, the reusability test showed that the catalytic activity of copper onto polydopamine-coated sand composite toward the reduction of 4-nitrophenol did not decrease yet, even after 20 cycles. These findings confirmed the superb catalytic activity, stability, and reusability of copper onto polydopamine-coated sand composite.

In another study, Hajipour and Malek (2021) inspected the catalytic performance of Co/N-heterocyclic carbene-supported magnetic chitosan composite (Co/NHC@mCs) toward Suzuki and Sonogashira reactions of aryl chlorides. Several key parameters were studied to determine the optimal condition for both reactions, including solvent, base, catalyst dose, and reaction temperature. It was recorded that Suzuki cross-coupling reaction of 1-chloro-4-nitrobenzene with (4-methoxyphenyl) boronic acid achieved a high yield (90%) in polyethylene glycol as a reaction medium and at 70 °C within 8 h using 3 mol% of Co/NHC@mCs. On the other hand, the best yield (84%) in Sonogashira cross-coupling between 1-chloro-4-nitrobenzene and 1-ethynyl-4- methoxybenzene was obtained in polyethylene glycol at 100 °C, using 6 mol% of Co/NHC@mCs. Notably, both reactions proceeded without adding Co/NHC@mCs, and no product was obtained in these cases. Importantly, the recyclability test pointed out the propitious recyclability of Co/NHC@mCs since its catalytic activity dwindled to only 7% after the seven cycles. Furthermore, the used Co/NHC@mCs were characterized by transmission electron microscope, and scanning electron microscope displayed no change in the morphology compared to the fresh Co/NHC@mCs. Additionally, the Co-leaching amount that inductively coupled plasma mass spectrometry recorded was less than 2%. At the same time, X-ray diffraction revealed no change in the peak intensity after using Co/NHC@mCs for 7 cycles. These results suggested the excellent efficiency, stability, and reusability of Co/NHC@mCs. In addition to the sustainability of the earth-abundant Co-based catalyst instead of the high-cost Pt-based catalysts.

In this perspective, Mohammadinezhad and Akhlaghinia (2017) fabricated a costless and efficient nanocatalyst (Fe3O4@Boehmite-NH2-CoII) for both Hecks–Mizoroki and Suzuki–Miyaura reactions. The transmission electron microscope image showed the core–shell structure of Fe3O4@Boehmite-NH2-CoII, where Fe3O4 is the core and Boehmite is the shell. Furthermore, the particle size of Fe3O4@Boehmite-NH2-CoII was found to be in the range of 13–54 nm. Field emission scanning electron microscope revealed an excellent distribution of Fe3O4@Boehmite-NH2-CoII with an average particle size of 20–30 nm. To determine the optimum conditions of the Suzuki–Miyaura coupling reaction between 4-iodobenzene and phenylboronic acid, the effect of solvents was studied in the presence of dimethyl sulfoxide, n-hexane, polyethylene glycol, n-hexane, toluene, tetrahydrofuran, n-hexane, ethanol, acetonitrile, and water. It was found that water could be utilized as a benign, costless, efficient solvent for the reaction. Furthermore, the optimal dose of Fe3O4@Boehmite-NH2-CoII was 0.33 mol%, while the further increase in the catalyst dose (22 mol%) did not change the rate or the yield of the reaction. However, the lower catalyst dose (0.22 mol%) significantly diminished the reaction yield. Moreover, to prove the synergistic effect between the components of the catalyst, the reaction has proceeded in the presence of pristine CoCl2·6H2O, Fe3O4, magnetic Fe3O4@Boehmite, Fe3O4@Boehmite-Pr-Cl, and Fe3O4 @Boehmite-NH2 as catalysts, revealing incomplete coupling between 4-iodobenzene and phenylboronic acid with conversion yields of 40, 20, 20, 5, 5 and 5% after 24 h, respectively.

In another study, Basaveni et al. (2019) fabricated nickel (Ni) nanoparticle-based catalyst encapsulated in a supporting and stabilizing matrix hyperbranched poly-aromatic polymer anched poly-aromatic polymer for the catalytic transfer hydrogenation of alkenes and nitroarenes. The hyperbranched poly-aromatic polymer matrix acted as a control matrix for the nickel nanoparticles' particle size. The nickel nanoparticles' size was controlled by encapsulation into the cavities of hyperbranched poly-aromatic polymer that prevent their aggregations. The ni-hyperbranched poly-aromatic polymer had high activity and good air stability. The catalytic transfer hydrogenation was carried out under base-free conditions without the need for high pressure, highly acidic conditions, or a strongly flammable hydrogen source. The Ni-hyperbranched poly-aromatic polymer catalytic system showed good tolerance toward alkyne, hydroxyl, or halogen substituents.

Enzymes

Enzyme biocatalysis has drawn vast attention in industrial applications, such as producing antibiotic precursors and synthesizing valuable chemical products such as acrylamide, detergents, and others (Ottone et al. 2021; Madhavan et al. 2021). Enzymes are biological catalysts that constitute a complex protein chain connected to active metal sites offering unique selectivity toward the substrate molecules and good catalytic activity (Yi et al. 2021; Nazor et al. 2021). Besides, enzymes have demonstrated excellent catalytic activity in various chemical conversions from simple hydrolysis to reaction syntheses, outperforming other traditional chemical processes (Bell et al. 2021). Therefore, enzymes have been involved in many applications, as listed in Table 4. Thanks to their intrinsic properties, high selectivity and turnover number, cost-effectiveness, sustainability, and eco-friendly advantage (Zhang et al. 2021a). Owing to the biodegradability and sustainability of enzymes, they have been extensively utilized in environmental applications such as the bioremediation of water and soil pollution (Singh et al. 2021; Sellami et al. 2022). Additionally, enzymes have exhibited an auspicious catalytic performance in the biorefinery of waste polysaccharides and agro-industrial residues into valuable products such as bioplastics, biofuels, and sweeteners (Shiva et al. 2022; Mirpoor et al. 2021; Baptista et al. 2021) as well as the revalorization of lignocellulose or cellulose wastes into costless biofuels (Fig. 10) (Mathew et al. 2021; Li et al. 2021). Notably, the high reaction kinetics, selectivity, cost-effectiveness, recyclability, and non-toxicity of enzymes render them promising candidates in wastewater remediation.

Applications of enzymatic biocatalysis for sustainability. Enzymes are utilized in the bioremediation of industrial wastewater and biofuel production from lignin residues and waste oil. Many enzymes are used in the biorefinery field. Enzymes have shown excellent activity in chemical conversion processes

Due to the extensive production of oils, greases, and fats over the past few years, estimated as 20–3.8 million metric tons of edible vegetable oils in 2018 (Luo et al. 2020), large amounts of waste oil containing organic and inorganic loads have been disposed into the aquatic environment, producing filamentous microorganism blooms onto the water’s surface (Feng et al. 2021). Activated sludge was involved in mitigating such aquatic problems, but the floating oil effluent limited performance, causing poor sedimentation and reduced sludge biomass (Cammarota and Freire 2006). Lipases exhibited efficient biodegradation of triglycerides (i.e., vegetable oils, fats, greases) rather than traditional activated sludge. For example, Meng and co-workers investigated the anaerobic degradation of three different types of triglycerides (animal fat, vegetable oil, and floatable grease) involving lipase derived from three different sources, namely Aspergillus (lipase I), Candida (lipase II), and Porcine pancreatic (lipase III) (Meng et al. 2017). Lipase I and II showed an efficient biodegradation rate under appropriate hydrolysis conditions (24 h, 1000–1500 µL of lipase volume, and 40–50 °C), producing byproducts of long chains of fatty acids.

In contrast, lipase III showed a modest biodegradation performance. These findings confirmed the influence of the enzyme’s source on their activity. In another attempt, Theerachat et al. (2017) exhibited excellent degradation efficiency (93%) of palm oil mill effluent with a high oil concentration (7762 mg L−1) using lipase derived from candida rugosa-cultured yeast cells. However, these enzymatic treatments were considered primary processes and needed to be accompanied by another treatment process, such as activated sludge or anaerobic fermentation, to attain complete treatment of the fatty acids and glycerol byproducts.

Despite the harsh removal of many micropollutants due to their resistance to natural biodegradation, toxicity, and presence in nanogram or microgram concentrations in the aquatic medium, enzymes demonstrated proficient catalytic degradation performance against a diverse range of micropollutants such as pharmaceuticals, pesticides, phenolic compounds, and organic dyes. However, their vulnerable stability under extreme pH and temperature conditions and their poor reusability due to the difficult separation of enzymes from reaction media remain challenging. Accordingly, directed evolution and genetic engineering techniques (i.e., tuning the sequential structure of genes) have been conducted to boost enzymes' stability and catalytic performance (Saravanan et al. 2021; Palomo 2021). Recently, researchers found that immobilization of enzymes into solid support such as organics (natural or synthetic polymers), inorganics (silica, zeolites, graphene, titania, alumina), or organic–inorganic hybrid materials improves the catalytic performance of enzymes, the biocompatibility as well as the stability and the reusability considering the economic point of view (Ashkan et al. 2021; Zahirinejad et al. 2021). Notably, the immobilization strategy and the type of enzyme carrier represent crucial factors that directly affect the stability of the enzymes due to the possible undesired interactions with the solid support and the sluggish mass transfer of the target molecules retarding the catalytic interaction with enzymes (Nunes et al. 2021). In this context, Mahmoodi and Saffar-Dastgerdi (2020) developed a novel biocatalyst of laccase covalently immobilized onto zeolite (NZ)-graphene oxide (GO) for the effective removal of Direct red 23 organic pollutants. Covalent immobilization of laccase through salinization and crosslinking of the surface support via (3-aminopropyl) trimethoxy and glutaraldehyde, respectively, provided super stability and higher loading of the enzyme. Laccase covalently immobilized onto zeolite (NZ)-graphene oxide (GO) exhibited higher degradation efficiency by increasing the graphene oxide content from 3 to 7% due to the accelerated electron transfer from the enzyme to the support. Besides, graphene oxide content the loading amount of enzyme (350 mg/g) compared to bare zeolite support (180 mg/g) (i.e., 1.7 times higher than zeolite). This was attributed to the increased surface area of the NZ-GO nanocomposite support concerning bare zeolite, enabling a greater loading amount of enzyme.

Interestingly, Laccase covalently immobilized onto zeolite (NZ)-graphene oxide (GO) demonstrated remarkable retained efficiency of 95% over 5 cycles, verifying the outstanding stability of the immobilized laccase. Additionally, the immobilized enzyme revealed its superior storage stability than the free enzyme, achieving higher catalytic activity of 83% after 8 days of incubation comparable to the latter (60%). It is worth noting that covalent immobilization passively affects the catalytic activity of enzymes due to the conformational distortion and change in the chemical structure of enzymes after covalent attachment.

In this stream, Ahmed et al. (2018) exhibited an innovative strategy to immobilize cellulase for sustainable cellulose biorefinery into valuable products. Considering the advantage of enzyme immobilization via physical adsorption, retaining the structured entity, and catalytic activity of enzymes, cellulase was successfully immobilized onto UiO-66-NH2 (cellulase@UiO-66-NH2) under mild conditions. Brunauer–Emmett–Teller (BET) measurements declared cellulase@UiO-66-NH2 possessed a lower specific surface area (269.3 m2 g−1) than pristine UiO-66-NH2 (593 m2 g−1), attributed to the pore-clogging by the loaded enzymes, confirming the successful immobilization approach. In fact, UiO-66-NH2 offered large numbers of -NH2 adsorptive sites compared with UiO-66 and achieved a greater cellulase loading capacity (350 mg/g) than UiO-66 (102 mg/g). Cellulase@UiO-66-NH2 accomplished outstanding hydrolysis of cellulose (85%) rather than free cellulase (60%) under conditions of 80 °C and pH = 3–6 in 30 min due to the extra stability of the immobilized cellulase. Besides, cellulase@UiO-66-NH2 demonstrated 72% conversion efficiency after 10 cycles, outperforming covalently loaded cellulase onto Fe3O4@ UiO-66-NH2 via precipitation and glutaraldehyde crosslinking that attained 70% after only 5 cycles. These findings established that physical adsorption is a decent strategy for improving the catalytic performance of immobilized enzymes.

Synthesis of environmental catalysts

The methods to prepare environmental catalysts are essential determinants of their catalytic behavior. Integrating green chemistry principles during large-scale syntheses, such as moderating energy input, organic solvent issues, and problematic wastes, is a significant challenge (Rodríguez-Padrón et al. 2019a). Jahangiri et al. (2014) defined a triangular concept to be tailored in catalyst design to achieve optimal performance, which included: (1) chemical-physical properties (i.e., surface area, porosity, dimension, acidity, composition, density), (2) catalytic properties (i.e., activity, selectivity, stability), and (3) mechanical properties (i.e., strength, attrition).

Furthermore, these materials' electronic and optical properties can be crucial in catalyst optimization (Rodríguez-Padrón et al. 2019a). Each catalyst's synthesis may involve a series of complex processes, some of which may be unknown (Schwarz et al. 1995). A minor alteration in the preparation details can result in a significant change in the final catalyst properties. Typically, the trial-and-error method was determined to be a viable solution. The conventional procedures for environmental catalyst preparation are precipitation (Geus and Van Dillen 2008; Wang et al. 2021c; Munnik et al. 2015), impregnation (via deposition, grafting, ion exchange, and others) (Munnik et al. 2015; Hafdi et al. 2021; Baeza et al. 2016), precipitation-impregnation (Ayati et al. 2014; Orooji et al. 2021), sol–gel (Mahy et al. 2021; Esposito 2019), chemical deposition (Tuna et al. 2022), hydrothermal (Mamaghani et al. 2019; Ayati et al. 2015), microwave-assisted (Ahmad and Hossain 2022), along with other methods (Zhang 2020; Yin et al. 2022). Because of its ease of use and low cost, precipitation is the most commonly used in preparing environmental catalysts (Rajput et al. 2022), where anions and cations combine in solution and form insoluble solids or supersaturated forms. Reagent addition, precipitate formation by pH, temperature and/or concentration adjustment, flocculation, sedimentation, and solid–liquid separation are all steps involved (Rajput et al. 2022; Wang et al. 2005), as shown in Fig. 11. It typically suffered from the separation of the product after precipitation and large volumes of salt-containing solutions (Hutchings and Védrine 2004). It has been extensively used to synthesize single-component, supported, and mixed catalysts (Perego and Villa 1997). For example, Chetri et al. (2014) successfully used this method to fabricate core–shell TiO2/SnO2 and SnO2/TiO2 nanocomposites with high potential for dye degradation under visible light irradiation. Magdalane et al. (2019) prepared the tin (IV) oxide/titanium dioxide nanostructure via a low-temperature precipitation method using tin chloride and titanium isopropoxide as main precursors and starch as a template.

Parameters affecting the catalyst characteristics using the precipitation method. All these parameters must be optimized to obtain the catalyst-specific features. They can impact the nucleation and/or crystal growth of structures. So, the size and porosity of catalysts can be tuned by the variation of these parameters. Amongst, the solution composition and precipitating agent play the central role. For instance, the type of precipitation agent, such as sodium carbonate, sodium bicarbonate, sodium hydroxide, and ammonium carbonate, significantly impacts the final catalyst's characteristics

Coprecipitation is one of the most practical approaches for fabricating bi-metallic catalysts (Munnik et al. 2015; Yao et al. 2018). The coprecipitation technique and deposition–precipitation for the fabrication of supported bimetallic catalysts are illustrated in Fig. 12. In this approach, the nucleation and growth of combined active metal and support are obtained in a single step in the solutions containing both active metal and support salts (Benhiti et al. 2020; Chen et al. 2016).

Synthesis of a supported bimetallic catalyst via a coprecipitation and b deposition precipitation. The support precursor is added to precipitated metal precursors in the coprecipitation approach. In contrast, the support material is added to the pH-adjusted metal precursor and urea solution in the deposition precipitation technique. After drying, the second metal is deposited by deposition precipitation with urea

Impregnation is another method for improving the dispersion of an active phase on either inert or active support that already possesses desired porous texture and mechanical toughness (Hutchings and Védrine 2004). It involves three steps (1) contacting the support with the solution containing a precursor, (2) drying, and (3) activating by calcination, reduction, or other suitable treatment (Hutchings and Védrine 2004; Perego and Villa 1997). The impregnation method can be divided into equivalent impregnation, using a particular carrier quality, and excessive impregnation, employing more than the amount of impregnation liquid metal salt solution volume. The impregnation method produces a catalyst with large particle size, easy recovery, and reagent-saving advantages. Alumina is commonly used support (Kim et al. 2022; Lerici et al. 2022), and silica (Xu et al. 2016; Gai et al. 2022), titania (Huang et al. 2022; Lincho et al. 2021; Martín-Hernández et al. 2012), carbon nanotubes (Afifeh et al. 2019; Li et al. 2022), metal–organic frameworks (Beni et al. 2020), cerium(III) oxide (Liu et al. 2015; Wang et al. 2016b), are some other employed supports in the synthesis of environmental catalysts via the impregnation way.

Actual ion exchange reactions between the precursor ions and those of the support surface are required for effective interaction in the impregnation process. By adding other competitive adsorption and exchange ions, the exchange process can be delayed to improve dispersion on the support. In preparing supported Pt° particles, for example, Cl− or NH4+ ions are commonly added to the precursor solutions to improve particle dispersion (Hutchings and Védrine 2004). The literature (Schwarz et al. 1995; Hutchings and Védrine 2004; Quiton et al. 2021) examines the impact of several effective parameters in the impregnation approach.

The mechanochemistry synthesis of catalysts for environmental applications has also gained the scientific community's interest as a promising strategy (He et al. 2020a; Muñoz-Batista et al. 2018). This alternative solvent-free route has the advantages of high versatility, simplicity, and reproducibility (Rodríguez et al. 2007). It relies on directly absorbing mechanical energy by reagents, usually solids, during milling or grinding (Głowniak et al. 2021). Several mechanochemical methodologies, including top-down and bottom-up, have been developed based on milling equipment to transform precursors into the desired structures.

The commonly laboratory-level mechanochemistry synthesis are planetary ball mills, shaker mills, and attritor mills (Yin et al. 2022). Each mill possesses its advantages and disadvantages, which are extensively compared in the review articles (Yin et al. 2022; Espro and Rodríguez-Padrón 2021). Various mechanochemical synthesis techniques have recently progressed, such as solid-state grinding and liquid-assisted grinding (Xu et al. 2015b).

The mechanochemical routes have been employed to fabricate various environmental catalysts (Ralphs et al. 2013; Szczęśniak et al. 2020). High efforts have been made in the mechanochemical approach to narrow titanium oxide and zinc oxide bandgap and improve its photocatalytic behavior through its anionic and cationic doping through a ball mill (Pillai et al. 2020; Wu et al. 2019a; Reddy et al. 2019), or it's incorporated with various semiconductors, such as iron(III) oxide/titanium oxide (Subramonian et al. 2017), hexagonal boron nitride/titanium oxide (Fu et al. 2013), vanadium(V) oxide/titanium oxide (Mondal et al. 2020), and silver phosphate/zinc oxide (Liu et al. 2013a) hybrid composite. This considerable enhancement could be due to the decrease in particle size and therefore increase in surface area and enhancement of charge separation associated with the two components.

Similarly, by high-energy ball milling (8 days) and wet milling (1 h) to exfoliate graphite carbon nitride, higher photocatalytic efficiencies were achieved compared to that of pristine bulk (Ma et al. 2021). The different graphite carbon nitride heterojunctions could form under ball millings, such as ultrathin layer sheets (Wei et al. 2021b), sandwich-like three-dimensional structures (Ni et al. 2021), and multi-layer core–shell structures (Zhou et al. 2015). Also, the synthesis or decoration of carbonaceous material [e.g., graphite oxide (Ahmad et al. 2018), biochar (Yu et al. 2021a; Fawzy et al. 2021), and carbon nanotubes (Panahian and Arsalani 2017)] using high-energy ball milling provides a rapid and solventless process to intensify their environmental catalytic activity. Ball milling or liquid-assisted grinding was remarkably used as a promising alternative for metal–organic framework synthesis and modifications (Głowniak et al. 2021; Chen et al. 2019a; Stolar and Užarević 2020). Yin et al. (2022) well-reviewed the mechanochemical synthesis of various catalysts and reagents for water decontamination.