Abstract

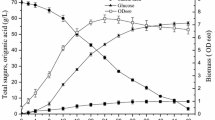

Succinic acid production from the monosaccharides xylose, arabinose, glucose, mannose and galactose was studied using the bacterium Actinobacillus succinogenes. In Duran bottle cultures, containing 10 g/L of each of sugar, succinic acid was produced from all sugars except for galactose. The highest succinate yield, 0.56 g/g, was obtained with glucose, whereas the succinate yield was 0.42, 0.38 and 0.44 g/g for xylose, mannose and arabinose, respectively. The specific succinate productivity was 0.7 g/g h for glucose, but below 0.2 g/g h for the other sugars. Batch bioreactor fermentations were carried out using a sugar mixture of the five sugars giving a total concentration of 50 g/L, mimicking the distribution of sugars in spent sulfite liquor (SSL) from Eucalyptus which is rich in xylose. In this mixture, an almost complete conversion of all sugars (except galactose) was achieved resulting in a final succinate concentration of 21.8–26.8 g/L and a total yield of 0.59–0.68 g/g. There was evidence of co-consumption of glucose and xylose, whereas mannose was consumed after glucose. The main by-products were acetate 0.14–0.20 g/g and formate 0.08–0.13 g/g. NADH balance calculations suggested that NADH required for succinate production was not met solely from formate and acetate production, but other means of NADH production was necessary. Results from mixed sugar fermentations were verified using SSL as substrate resulting in a succinate yield of 0.60 g/g. In addition, it was found that CO2 sparging could replace carbonate supply in the form of MgCO3 without affecting the succinate yield.

Similar content being viewed by others

References

Beauprez JJ, De Mey M, Soetaert WK (2010) Microbial succinic acid production: natural versus metabolic engineered producers. Process Biochem 45:1103–1114. doi:10.1016/j.procbio.2010.03.035

Becker J, Lange A, Fabarius J, Wittmann C (2015) Top value platform chemicals: bio-based production of organic acids. Curr Opin Biotechnol 36:168–175. doi:10.1016/j.copbio.2015.08.022

Borges ER, Pereira N (2011) Succinic acid production from sugarcane bagasse hemicellulose hydrolysate by Actinobacillus succinogenes. J Ind Microbiol Biotechnol 38:1001–1011. doi:10.1007/s10295-010-0874-7

Bozell JJ, Petersen GR (2010) Technology development for the production of biobased products from biorefinery carbohydrates—the US Department of Energy’s “Top 10” revisited. Green Chem 12:539. doi:10.1039/b922014c

Bradfield MFA, Nicol W (2014) Continuous succinic acid production by Actinobacillus succinogenes in a biofilm reactor: steady-state metabolic flux variation. Biochem Eng J 85:1–7. doi:10.1016/j.bej.2014.01.009

Bradfield MFA, Nicol W (2015) Continuous succinic acid production from xylose by Actinobacillus succinogenes. Bioprocess Biosyst Eng 39:1–12. doi:10.1007/s00449-015-1507-3

Cheng K, Zhao X, Zeng J, Zhang J (2012) Biotechnological production of succinic acid: current state. Biofuels Bioprod Biorefin 6:302–318. doi:10.1002/bbb

Cornils B, Lappe P (2012) Dicarboxylic acids, aliphatic. In: Ullmann's Encyclopedia of Industrial Chemistry, vol 11. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, Germany, pp 287–301. doi:10.1002/14356007.a08_523.pub2

Corona-González RI, Bories A, González-Álvarez V, Pelayo-Ortiz C (2008) Kinetic study of succinic acid production by Actinobacillus succinogenes ZT-130. Process Biochem 43:1047–1053. doi:10.1016/j.procbio.2008.05.011

Du C, Lin SKC, Koutinas A, Wang R, Webb C (2007) Succinic acid production from wheat using a biorefining strategy. Appl Microbiol Biotechnol 76:1263–1270. doi:10.1007/s00253-007-1113-7

Guettler MV, Rumler D, Jain MK (1999) Actinobacillus succinogenes sp. nov., a novel succinic-acid-producing strain from the bovine rumen. Int J Syst Bacteriol 49:207–216

Gunnarsson IB, Alvarado-Morales M, Angelidaki I (2014) Utilization of CO2 fixating bacterium Actinobacillus succinogenes 130Z for simultaneous biogas upgrading and biosuccinic acid production. Env Sci Technol 48:12464–12468. doi:10.1021/es504000h

Ingraham JL, Maaløe O, Neidhardt FC (1983) Growth of the bacterial cell. Sinauer Associates Inc, Sunderland, MA, USA

La Jansen M, van Gulik WM (2014) Towards large scale fermentative production of succinic acid. Curr Opin Biotechnol 30:190–197. doi:10.1016/j.copbio.2014.07.003

Jiang M, Dai W, Xi Y, Wu M, Kong X, Ma J, Zhang M, Chen K, Wei P (2013) Succinic acid production from sucrose by Actinobacillus succinogenes NJ113. Bioresour Technol 153C:327–332. doi:10.1016/j.biortech.2013.11.062

Jiang M, Xu R, Xi YL, Zhang JH, Dai WY, Wan YJ, Chen KQ, Wei P (2013) Succinic acid production from cellobiose by Actinobacillus succinogenes. Bioresour Technol 135:469–474. doi:10.1016/j.biortech.2012.10.019

Lam KF, Leung CCJ, Lei HM, Lin CSK (2014) Economic feasibility of a pilot-scale fermentative succinic acid production from bakery wastes. Food Bioprod Process 92:282–290. doi:10.1016/j.fbp.2013.09.001

Lamed R, Zeikus JG (1980) Glucose fermentation pathway of Thermoanaerobium brockii. J Bacteriol 141:1251–1257

Li J, Jiang M, Chen K-Q, Ye Q, Shang L-A, Wei P, Ying H-J, Chang H-N (2010) Effect of redox potential regulation on succinic acid production by Actinobacillus succinogenes. Bioprocess Biosyst Eng 33:911–920. doi:10.1007/s00449-010-0414-x

Li Q, Yang M, Wang D, Li W, Wu Y, Zhang Y, Xing J, Su Z (2010) Efficient conversion of crop stalk wastes into succinic acid production by Actinobacillus succinogenes. Bioresour Technol 101:3292–3294. doi:10.1016/j.biortech.2009.12.064

Lindemann C, Marose S, Nielsen HO, Scheper T (1998) Two-dimensional fluorescence spectroscopy for on-line bioprocess monitoring. Sens Actuator 51:273–277

Llano T, Rueda C, Quijorna N, Blanco A, Coz A (2012) Study of the delignification of hardwood chips in a pulping process for sugar production. J Biotechnol 162:422–429. doi:10.1016/j.jbiotec.2012.06.030

McKinlay JB, Laivenieks M, Schindler BD, McKinlay A a, Siddaramappa S, Challacombe JF, Lowry SR, Clum A, Lapidus AL, Burkhart KB, Harkins V, Vieille C (2010) A genomic perspective on the potential of Actinobacillus succinogenes for industrial succinate production. BMC Genom 11:680. doi:10.1186/1471-2164-11-680

McKinlay JB, Shachar-Hill Y, Zeikus JG, Vieille C (2007) Determining Actinobacillus succinogenes metabolic pathways and fluxes by NMR and GC-MS analyses of 13C-labeled metabolic product isotopomers. Metab Eng 9:177–192. doi:10.1016/j.ymben.2006.10.006

McKinlay JB, Zeikus JG, Vieille C (2005) Insights into Actinobacillus succinogenes fermentative metabolism in a chemically defined growth medium insights into Actinobacillus succinogenes fermentative metabolism in a chemically defined Growth Medium. Appl Env Microbiol 71:6651–6656. doi:10.1128/AEM.71.11.6651

Park DH, Zeikus JG (1999) Utilization of electrically reduced neutral Red by Actinobacillus succinogenes: physiological function of neutral Red in membrane-driven fumarate reduction and energy conservation utilization of electrically reduced neutral Red by Actinobacillus succinogenes. J Bacteriol 181:2403–2410

Pereira SR, Portugal-Nunes DJ, Evtuguin DV, Serafim LS, Xavier AMRB (2013) Advances in ethanol production from hardwood spent sulphite liquors. Process Biochem 48:272–282. doi:10.1016/j.procbio.2012.12.004

Rødsrud G, Lersch M, Sjöde A (2012) History and future of world’s most advanced biorefinery in operation. Biomass Bioenergy 46:46–59. doi:10.1016/j.biombioe.2012.03.028

Salvachúa D, Mohagheghi A, Smith H, Bradfield MFA, Nicol W, Black B, Biddy M, Dowe N, Beckham GT (2016) Succinic acid production on xylose-enriched biorefinery streams by Actinobacillus succinogenes in batch fermentation. Biotechnol Biofuels 9:28. doi:10.1186/s13068-016-0425-1

Snoep JL, Teixeira de Mattos MJ, Postma PW, Neijssel OM (1990) Involvement of pyruvate dehydrogenase in product formation in pyruvate-limited anaerobic chemostat cultures of Enterococcus faecalis NCTC 775. Arch Microbiol 154:50–55. doi:10.1007/BF00249177

Van der Werf MJ, Guettler MV, Jain MK, Zeikus JG (1997) Environmental and physiological factors affecting the succinate product ratio during carbohydrate fermentation by Actinobacillus sp. 130Z. Arch Microbiol 167:332–342

Villadsen J, Nielsen J, Lidén G (2011) Bioreaction engineering principles, 3rd edn. Springer, New York

Vlysidis A, Binns M, Webb C, Theodoropoulos C (2011) Glycerol utilisation for the production of chemicals: conversion to succinic acid, a combined experimental and computational study. Biochem Eng J 58–59:1–11. doi:10.1016/j.bej.2011.07.004

Werpy T, Petersen G (2004) Top value added chemicals from biomass: volume I—results of screening for potential candidates from sugars and synthesis gas. U.S. Department of Energy, Washington, DC, USA. doi:10.2172/15008859

Yu J, Li Z, Ye Q, Yang Y, Chen S (2010) Development of succinic acid production from corncob hydrolysate by Actinobacillus succinogenes. J Ind Microbiol Biotechnol 37:1033–1040. doi:10.1007/s10295-010-0750-5

Zheng P, Dong J-J, Sun Z-H, Ni Y, Fang L (2009) Fermentative production of succinic acid from straw hydrolysate by Actinobacillus succinogenes. Bioresour Technol 100:2425–2429. doi:10.1016/j.biortech.2008.11.043

Zou W, Zhu L-W, Li H-M, Tang Y-J (2011) Significance of CO2 donor on the production of succinic acid by Actinobacillus succinogenes ATCC 55618. Microb Cell Fact 10:87. doi:10.1186/1475-2859-10-87

Acknowledgments

The EU Commission (FP7 project BRIGIT, Grant Agreement KBBE-2012-6-311935) is acknowledged for its financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

This study was funded by The EU Commission (FP7 project BRIGIT, Grant Agreement KBBE-2012-6-311935) Henrik Almqvist declares that he has no conflict of interest. Chrysanthi Pateraki declares that she has no conflict of interest. Maria Alexandri declares that she has no conflict of interest. Apostolis Koutinas declares that he has no conflict of interest. Gunnar Lidén declares that he has no conflict of interest.

Ethical statement

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Almqvist, H., Pateraki, C., Alexandri, M. et al. Succinic acid production by Actinobacillus succinogenes from batch fermentation of mixed sugars. J Ind Microbiol Biotechnol 43, 1117–1130 (2016). https://doi.org/10.1007/s10295-016-1787-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-016-1787-x