Abstract

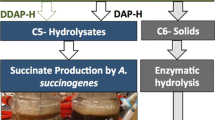

Succinic acid, a four-carbon diacid, has been the focus of many research projects aimed at developing more economically viable methods of fermenting sugar-containing natural materials. Succinic acid fermentation processes also consume CO2, thereby potentially contributing to reductions in CO2 emissions. Succinic acid could also become a commodity used as an intermediate in the chemical synthesis and manufacture of synthetic resins and biodegradable polymers. Much attention has been given recently to the use of microorganisms to produce succinic acid as an alternative to chemical synthesis. We have attempted to maximize succinic acid production by Actinobacillus succinogenes using an experimental design methodology for optimizing the concentrations of the medium components. The first experiment consisted of a 24−1 fractional factorial design, and the second entailed a Central Composite Rotational Design so as to achieve optimal conditions. The optimal concentrations of nutrients predicted by the model were: NaHCO3, 10.0 g l−1; MgSO4, 3.0 g l−1; yeast extract, 2.0 g l−1; KH2PO4. 5.0 g l−1; these were experimentally validated. Under the best conversion conditions, as determined by statistical analysis, the production of succinic acid was carried out in an instrumented bioreactor using sugarcane bagasse hemicellulose hydrolysate, yielding a concentration of 22.5 g l−1.

Similar content being viewed by others

References

Agarwal L, Isar J, Meghwanshi GK, Saxena RK (2006) A cost effective fermentative production of succinic acid from cane molasses and corn steep liquor by Escherichia coli. J Appl Microbiol 100(6):1348–1354

Banik RM, Santhiagu A, Upadhyay SN (2007) Optimization nutrients for gellan gum production by Sphingomonas paucimobilis ATCC-31461 in molasses based medium response surface methodology. Bioresour Technol 98(4):792–797

Bechthold I, Bretz K, Kabasci S, Kopitzky R, Springer A (2008) Succinic acid: a new platform chemical for biobased polymers from renewable resources. Chem Eng Technol 31(5):647–654

Betancur GV, Pereira Jr N (2010) sugarcane bagasse as feedstock for second generation ethanol production. Part I: diluted acid pre-treatment optimization. Electron J Biotechnol. Available at: http://www.ejbiotechnology.info/content/vol13/issue3/full/3/

Box GEP, Hunter WG, Hunter JS (1978) Statistics for experimenters: an introduction to design data analysis and model building. Wiley, New York

Du CY, Carol Lin SK, Koutinas A, Wang RH, Dorado P, Webb C (2008) A wheat biorefining strategy based on solid-state fermentation for fermentative production of succinic acid. Bioresour Technol 99(17):8310–8315

Fogel R, Garcia RR, Oliveira SR, Palacio D, Madeira L, Pereira N (2005) Optimization of acid hydrolysis of sugarcane bagasse and invetigations on its fermetability for production of xylitol by Candida guilliermondii. Appl Biochem Biotechnol 122(1–3):741–752

Gluettler MV, Rumler D, Jain MK (1999) Actinobacillus succinogenes sp. nov., a novel succinic acid producing strain from the bovine rumen. Int J Syst Bacteriol 49:207–216

Huh YS, Jun Y-S, Kong YK, Song H, Lee SY, Hong WH (2006) Effective purification of succinic acid from fermentation broth produced by Mannheimia succiniciproducens. Process Biochem 41(6):1461–1465

Kim DY, Yim SC, Lee PC, Lee WG, Lee SY, Chang HN (2004) Batch and continuous fermentation of succinic acid from wood hydrolyzate by Mannheimia succiniciproducens MBEL55E. Enzyme Microb Technol 34(6–7):648–653

Lavarack BP, Griffin GJ, Rodman D (2002) The acid hydrolysis of sugarcane bagasse hemicellulose to produce xylose, arabinose, glucose and other products. Biomass Bioenergy 23(5):367–380

Lee PC, Lee WG, Kwon S, Lee SY, Chang HN (1999) Succinic acid production by Anaerobiospirillum succiniciproducens: effects of the H2/CO2 supply and glucose concentration. Enzyme Microb Technol 24(8–9):549–554

Lee PC, Lee SY, Hong SH, Chang HN (2002) Isolation and characterization of new succinic acid producing bacterium Manheimia succiniciproducens MBEL 55E, from bovine rumen. Appl Microbiol Biotechnol 21(4):663–668

Lee PC, Lee SY, Hong SH, Chang HN, Park SC (2003) Biological conversion of wood hydrolyzate to succinic acid by Anaerobiospirillum succiniciproducens. Biotechnol Lett 25(2):111–114

Lin H, Bennet GN, San KY (2005) Fed-batch culture of a metabolically engineered Escherichia coli strain designed for high-level succinate production and yield under aerobic conditions. Biotechnol Bioeng 90(6):775–779

Liu YP, Zheng P, Sun ZH, Ni Y, Dong JJ, Zhu LL (2008) Economical succinic acid production from cane molasses by Actinobacillus succinogenes. Bioresour Technol 99(6):1736–1742

Lynd LR, Wyman CE, Gerngross TU (1999) Biocommodity engineering. Biotechnol Prog 15(5):777–793

Meynial-Salles I, Dorotyn S, Soucaille P (2008) A new process for the continuous production of succinic acid from glucose at high yield, titer and productivity. Biotechnol Bioeng 99(1):129–135

Okuda N, Ninomiya K, Takao M, Katakura Y, Shioya S (2007) Microaeration enhances productivity of bioethanol from hydrolyzate of waste house wood using ethanologenic Escherichia coli KO11. J Biosci Bioeng 103(4):350–357

Papanikolaou S, Sarantou S, Komaitis M, Aggelis G (2004) Repression of reserve lipid turnover in Cunninghamella echinulata and Mortierella isabellina cultivated in multiple-limited media. J Appl Microbiol 97(4):867–875

Pereira N, Couto MAPG, Santa Anna LM (2008) Series on biotechnology: biomass of lignocellulosic composition for fuel ethanol production within the context of biorefinery. Amigadigital Press, Rio de Janeiro

Rudner MS, Jeremic S, Petterson KA, Kent DR, Brown KA, Drake MD, Goddard WA, Roberts JD (2005) Intramolecular hydrogen bonding in disubstituted ethanes. A comparison of NH…O− and OH…O− hydrogen bonding through conformational analysis of 4-amino-4-oxobutanoate (succinamate) and monohydrogen 1,4-butanoate (monohydrogen succinate) anions. J Phys Chem A 109(40):9076–9082

Sauer M, Porro D, Mattanovich D, Branduardi P (2008) Microbial production of organic acids: expanding the markets. Trends Biotechnol 6(2):100–108

Song H, Lee JW, Choi S, You JK, Hong WH, Lee SY (2007) Effects of dissolved CO2 levels on the growth of Mannheimia succiniciproducens and succinic acid production. Biotechnol Bioeng 98(6):1296–1304

Urbance SE, Pometto AL III, Di Spirito AA, Demirci A (2003) Medium evaluation and plastic composite support ingredient selection for biofilm formation and succinic acid production by Actinobacillus succinogenes. Food Biotechnol 17(1):53–65

van der Werf MJ, Guettler MV, Jain MK, Zeikus JG (1997) Environmental and physiological factors affecting the succinate product ratio during carbohydrate fermentation by Actinobacillus sp. 130Z. Arch Microbiol 167(6):332–342

Vemuri GN, Eiteman MA, Altman E (2002) Succinate production in dual-phase Escherichia coli fermentations depends on the time of transition from aerobic to anaerobic conditions. J Ind Microbiol Biotechnol 28(6):325–332

Wyman CE, Dale BE, Elander RT, Holtzapple M, Ladisch MR, Lee YY (2005) Coordinated development of leading biomass pretreatment technologies. Bioresour Technol 96(18):1959–1966

Zeikus JG, Jain MK, Elankovan P (1999) Biotechnology of succinic acid production and markets for derived industrial products. Appl Microbiol Biotechnol 51(5):545–552

Zheng P, Dong JJ, Sun ZH, Ni Y, Fang L (2009) Fermentative production of succinic acid from straw hydrolysate by Actinobacillus succinogenes. Bioresour Technol 100(8):2425–2429

Acknowledgments

The authors are grateful to the Brazilian Council for Research (CNPq); the Rio de Janeiro Foundation for Science and Technology (FAPERJ) and the Brazilian Oil Company (PETROBRAS) for financial support of this research.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Borges, E.R., Pereira, N. Succinic acid production from sugarcane bagasse hemicellulose hydrolysate by Actinobacillus succinogenes . J Ind Microbiol Biotechnol 38, 1001–1011 (2011). https://doi.org/10.1007/s10295-010-0874-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-010-0874-7