Abstract

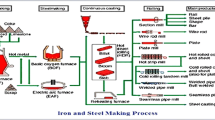

The Linz–Donawitz (LD) slag is an industrial waste generated in Linz–Donawitz process of steel making. It is not gaining importance in construction industry because of its volume instability, and presence of excessive phosphorous and sulphur content. Suitable accelerated ageing and masking of harmful materials can improve the engineering properties of LD slag. The research shows that it is possible to use LD slag in sustainable construction applications including cementitious binders, aggregates in pavement and concretes, building products, soil improvement, etc. However, its use is presently limited to 25% of the total quantity generated and the rest is dumped as landfill. Thus, there is a strong need to review the available literature to explore the gainful utilization of LD slag in various applications. Aim of this paper is to highlight the potential of LD slag for a broad range of applications based on the published research over the past decade along with the recent research and developments. Physico-mechanical properties, microscopic characteristics, and mineralogical composition of LD slag observed in various studies are also reported. Efficacies of LD slag utilization in construction are also presented. This paper also discusses current challenges for its usage.

Similar content being viewed by others

References

Behera M, Bhattacharyya SK, Minocha AK, Deoliya R, Maiti S (2014) Recycled aggregate from C&D waste & its use in concrete—a breakthrough towards sustainability in construction sector: a review. Constr Build Mater 68:501–516

Roy S, Adhikari GR, Gupta RN (2007) Use of gold mill tailings in making bricks: a feasibility study. Waste Manag Res 25:475–482

Menezes RR, Ferreira HS, Neves GA, Lira HDL, Ferreira HC (2005) Use of granite sawing wastes in the production of ceramic bricks and tiles. J Eur Ceram Soc 25:1149–1158

Ye G, Liu X, De Schutter G, Poppe AM, Taerwe L (2007) Influence of limestone powder used as filler in SCC on hydration and microstructure of cement pastes. Cement Concr Compos 29:94–102

Sutcu M, Akkurt S (2009) The use of recycled paper processing residue in making porous brick with reduced thermal conductivity. Ceram Int 35:2625–2631

Demir I, Baspinar MS, Orhan M (2005) Utilization of kraft pulp production residues in clay brick production. Build Environ 40:1533–1537

Demir I (2006) An investigation on the production of construction brick with processed waste tea. Build Environ 41:1274–1278

Rahman MA (1987) Properties of clay–sand–rice husk ash mixed bricks. Int J Cement Compos Lightweight Concr 9:105–108

Kayali O (2005) High performance bricks from fly ash World of coal ash (WOCA). Lexington, Center for Applied Energy Research, pp 1–13

Lin KL (2006) Feasibility study of using brick made from municipal solid waste incinerator fly ash slag. J Hazard Mater 137:1810–1816

Mahllawy MSE (2008) Characteristics of acid resisting bricks made from quarry residues and waste steel slag. Constr Build Mater 22:1887–1896

World Crude Steel Production–summary, world steel association (2017) https://www.worldsteel.org/media-centre/press-releases/2018/World-crude-steel-output-increases-by-5.3--in-2017.html, 24 Jan 2018

Tossavainen M, Engstrom F, Yang Q, Menad N, Larsson ML, Bjorkman B (2007) Characteristics of steel slag under different cooling conditions. Waste Manag 27:1335–1344

Haha MB, Lothenbach B, Saout GL, Winnefeld F (2011) Influence of slag chemistry on the hydration of alkali-activated blast-furnace slag—part I: effect of MgO. Cem Concr Res 41:955–963

Yildirim IZ, Prezzi M (2011) Chemical, mineralogical, and morphological properties of steel slag. Adv Civ Eng 5:1–13

Kim JH, Lee HS (2017) Improvement of early strength of cement mortar containing granulated blast furnace slag using industrial byproducts. Materials 10:1050–1075

Rodriguez A, Manso JM, Aragon A, Gonzalez JJ (2009) Strength and workability of masonry mortars manufactured with ladle furnace slag. Resour Conserv Recycl 53:645–651

Setien J, Hernandez D, Gonzalez JJ (2009) Characterization of ladle furnace basic slag for use as a construction material. Constr Build Mater 23:1788–1794

Shi C (2002) Characteristics and cementitious properties of ladle slag fines from steel production. Cem Concr Res 32:459–462

Shi C, Hu S (2003) Cementitious properties of ladle slag fines under autoclave curing conditions. Cem Concr Res 33:1851–1856

Luxan MP, Sotolongo R, Dorrego F, Herrero E (2000) Characteristics of the slags produced in the fusion of scrap steel by electric arc furnace. Cem Concr Res 30:517–519

Proctor DM, Fehling KA, Shay EC, Wittenborn JL, Green JJ, Avent C, Bigham RD, Connolly M, Lee B, Shepker TO, Zak MA (2000) Physical and chemical characteristics of blast furnace, basic oxygen furnace, and electric arc furnace steel industry slags. Environ Sci Technol 34:1576–1582

Singh R, Gorai AK, Segaran RG (2013) Characterization of LD slag of Bokaro steel plant and its feasibility study of manufacturing commercial ‘fly ash–LD slag’ bricks. Int J Environ Technol Manag 16:129–145

Ashrit S, Banerjee PK, Ghosh TK, Rayasam V, Nair UG (2015) Characterisation of LD slag fines by X-ray diffraction. Metall Res Technol 112:502–602

Das B, Prakash S, Reddy PSR, Misra VN (2007) An overview of utilization of slag and sludge from steel industries. Resour Conserv Recycl 50:40–57

Yi H, Xu G, Cheng H, Wang J, Wan Y, Chen H (2012) An overview of utilization of steel slag. Proc Environ Sci 16:791–801

Shi C (2004) Steel slag—its production, processing, characteristics, and cementitious properties. J Mater Civ Eng 16:230–236

Huang Y, Lin ZS (2010) Investigation on phosphogypsum–steel slag–granulated blast-furnace slag–limestone cement. Constr Build Mater 24:1296–1301

Pajgade PS, Thakur NB (2013) Utilisation of waste product of steel industry. Int J Eng Res Appl 3:2033–2041

Ozbay E, Erdemir M, Durmus HI (2016) Utilization and efficiency of ground granulated blast furnace slag on concrete properties—a review. Constr Build Mater 105:423–434

Sheshukov OY, Lobanov DA, Mikheenkov MA, Nekrasov IV, Egiazaryan DK (2017) The opportunity of silicate product manufacturing with simultaneous pig iron reduction from slag technogenic formations. AIP Conf Proc 1886:1–5

Manso JM, Losanez M, Polanco JA, Gonzalez JJ (2005) Ladle furnace slag in construction. J Mater Civ Eng 17:513–518

Radenovic A, Malina J, Sofilic T (2013) Characterization of ladle furnace slag from carbon steel production as a potential adsorbent. Adv Mater Sci Eng 2013:1–6

Annual Report 2017–2018, Ministry of steel, Government of India. https://steel.gov.in/annual-reports, 09 Feb 2018

Indian Minerals Yearbook (2015) Slag-iron and steel, 54th edition. Ministry of Mines. 16, 1–10

Pal J, Chaudhary PN, Goswami MC (2003) Utilisation of LD slag–An overview. J Metall Mater Sci 45:61–72

Chand S, Paul B, Kumar M (2016) Sustainable approaches for LD slag waste management in steel industries: a review. Metallurgist 60:116–128

Tiwari MK, Bajpai S, Dewangan UK (2016) Steel slag utilization—overview in Indian perspective. Int J Adv Res 4:2232–2246

Agarwal SK, Vanguri S, Chaturvedi SK, Kumar A, Reddy AS (2017) Performance evaluation of granulated BF slag -steel slag based Portland slag cement. 15th NCB International Seminar on Cement, Concrete and Building Materials. New Delhi, India. TS: VB (A413): 1–11

Menad N, Kanari N, Save M (2014) Recovery of high grade iron compounds from LD slag by enhanced magnetic separation techniques. Int J Miner Process 126:1–9

Chand S, Paul B, Kumar M (2016) A comparative study of physicochemical and mineralogical properties of LD slags from some selected steel plants in India. J Environ Sci Technol 9:75–87

Conjeaud M, George CM, Sorrentino FP (1981) A new steel slag for cement manufacture: mineralogy and hydraulicity. Cem Concr Res 11:85–102

Erlin B, Jana D (2003) Forces of hydration that can cause havoc in concrete. Concr Int 25:51–57

Gawwad HAEA, Khater HM, Mohamed SAE (2015) Impact of alkali concentration and metakaolin content on accelerated ageing of Egyptian slag. Am J Chem Eng 3:30–38

Shiomi S, Sano N, Matsushita Y (1977) Removal of phosphorus in BOF slag. Tetsu-to- Hagane 63:1520–1528 (in Japanese)

Sasaki T, Hamazaki T (2015) Development of steam-aging process for steel slag. Nippon Steel Sumitomo Metal Tech Rep 109:23–26

Mahieux PY, Aubert JE, Escadeillas G (2009) Utilization of weathered basic oxygen furnace slag in the production of hydraulic road binders. Constr Build Mater 23:742–747

Pradhan N, Das B, Acharya S, Kar RN, Shukla LB, Misra BN (2005) Removal of phosphorus from LD slag using a heterotrophic bacterium. Miner Metall Process 3:149–152

Panda R, Kar RN, Panda CR (2013) Dephosphorisation of LD slags by penicillium citrinum. Int Q J Environ Sci 3:247–250

Takeuchi S, Sano N, Matsushita Y (1980) Separate recovery of iron and phosphorus from BOF slags using Fe–Si alloys (in Japanese). Tetsu-to-Hagané 66:2050–2057

Morita K, Guo M, Oka N, Sano N (2002) Resurrection of the iron and phosphorus resource in steel-making slag. J Mater Cycles Waste Manag 4:93–101

Marhual NP, Pradhan N, Mohanta NC, Shukla LB, Misra BN (2011) Dephosphorisations of LD slag by phosphorus solubilising bacteria. Int Biodeterior Biodegrad 65:404–409

Shen H, Forssberg E (2003) An overview of recovery of metals from slags. Waste Manag 23:933–949

Chand S, Paul B, Kumar M (2017) Short-term leaching study of heavy metals from LD slags of important steel industries in Eastern India. J Mater Cycles Waste Manag 19:851–862

Mirazimi SMJ, Rashchi F, Saba M (2015) A new approach for direct leaching of vanadium from LD converter slag. Chem Eng Res Des 94:131–140

Mirazimi SMJ, Rashchi F, Saba M (2013) Vanadium removal from roasted LD converter slag: optimization of parameters by response surface methodology (RSM). Sep Purif Technol 116:175–183

Xiang J, Huang Q, Lv X, Bai C (2017) Mechanochemical effects on the roasting behavior of vanadium bearing LD converter slag in the air. Iron Steel Inst Japan Int 57:970–977

Mirazimi SMJ, Abbasalipour Z, Rashchi F (2015) Vanadium removal from LD converter slag using bacteria and fungi. J Environ Manag 153:144–151

Borges AC, Gadioli MCB, Junior LABP, Oliveira JR (2012) Mixture of granite waste and LD steel slag for use in cement production. Mater Sci Forum 727:1535–1540

Chandrasekhar SY (2016) An experimental study on mud concrete using soil as a fine aggregate and LD slag as coarse aggregate. Int J Res Eng Technol 5:264–268

Dongxue L, Xuequan W (1993) Technique methods for increasing early strength of steel slag cement. Jian Shu Build Mater 4:24

Dongxue L, Xinhua F, Xuequan W, Mingshu T (1997) Durability study of steel slag cement. Cem Concr Res 27:983–987

IS 383 (2016) Specification for coarse and fine aggregates from natural sources for concrete. Bureau of Indian Standards, New Delhi

Chand S, Paul B, Kumar M (2015) An overview of use of Linz–Donawitz (LD) steel slag in agriculture. Curr World Environ 10:975–984

Wang K, Qian C, Wang R (2016) The properties and mechanism of microbial mineralized steel slag bricks. Constr Build Mater 113:815–823

Waligora J, Bulteela D, Degrugilliers P, Damidot D, Potdevin JL, Measson M (2010) Chemical and mineralogical characterizations of LD converter steel slags: a multi-analytical techniques approach. Mater Charact 61:39–48

Pati PR, Satapathy A (2015) Development of wear resistant coatings using LD slag premixed with Al2O3. J Mater Cycles Waste Manag 17:135–143

Ashrit S, Banerjee PK, Chatti RV (2015) Characterization of gypsum synthesized from LD slag fines generated at a waste recycling plant of a steel plant. New J Chem 39:4128–4134

Singh SK, Rekha P, Surya M (2017) Utilization of LD slag in newer cementitious binder: A state of art report. CSIR-Central Building Research Institute Roorkee, India, pp 1–48

Ashrit S, Banerjee PK, Nair UG, Rayasam V (2017) Thermogravimetric analysis of LD slag waste fines in the range of 0–6 mm and establishing the correlation between free lime and weight loss of LD slag fines. Metall Res Technol 114:310

Tossavainen M, Forssberg E (1999) The potential leach ability from natural road construction materials. Sci Total Environ 239:31–47

Chand S, Chand SK, Paul B, Kumar M (2018) Long-term leaching assessment of constituent elements from Linz–Donawitz slag of major steel industries in India. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-018-2025-z

Makhija D, Rath RK, Chakravarty K, Patra AS, Mukherjee AK, Dubey AK (2016) Phosphorus partitioning and recovery of low-phosphorus iron-rich compounds through physical separation of Linz–Donawitz slag. Int J Miner Metal Mater 23:751–759

USEPA: SW-846 Test Method 1311 (1992) Toxicity characteristic leaching procedure. United States Environmental Protection Agency, USA

Arsenic AM, Beryllium AM (1996) Method 3050B acid digestion of sediments, sludges, and soils 1.0 scope and application

USEPA: SW-846 Test Method 1312 (1994) Synthetic precipitation leaching procedure. United States Environmental Protection Agency, USA

ASTM D4874–95 (2014) Standard test method for leaching solid material in a column apparatus. American Society for Testing and Materials, USA

Aarabi-Karasgani M, Rashchi F, Mostoufi N, Vahidi E (2010) Leaching of vanadium from LD converter slag using sulfuric acid. Hydrometallurgy 102:14–21

Chinnaraju K, Ramaleumar VR, Lineesh K, Nithya S, Sathish V (2013) Study on concrete using steel slag as coarse aggregate replacement and eco sand as fine aggregate replacement. Int J Res Eng Adv Technol 1:1–6

Gronniger J, Wistuba MP, Falchetto AC (2015) Reuse of Linz-Donawitz (LD) slag in asphalt mixtures for pavement application. Proceedings of the Interantional Conference on Industrial Wasted and Wastewater Treatment & Valorization, 1–17

Dominguez EA, Ullman R (1996) Ecological bricks made with clays and steel dust pollutants. Appl Clay Sci 11:237–249

Duda A (1987) Aspects of the sulphate resistance of steelwork slag cements. Cem Concr Res 17:373–384

Duda A (1989) Hydraulic reactions of LD steelwork slags. Cem Concr Res 19:793–801

Olonade KA, Kadiri MB, Aderemi PO (2015) Performance of steel slag as fine aggregate in structural concrete. Nigerian J Technol 34:452–458

Muhmood L, Vitta S, Venkateswaran D (2009) Cementitious and pozzolanic behavior of electric arc furnace steel slags. Cem Concr Res 39:102–109

Mahoutian M, Shao Y, Mucci A, Fournier B (2015) Carbonation and hydration behavior of EAF and BOF steel slag binders. Mater Struct 48:3075–3085

Salman M, Cizer O, Pontikes Y, Vandewalle L, Blanpain B, Balen KV (2014) Effect of curing temperatures on the alkali activation of crystalline continuous casting stainless steel slag. Constr Build Mater 71:308–316

Indian Cement Industry Analysis, https://www.ibef.org/industry/cement-presentation. April 2018

Tufekci M, Demirbas A, Genc H (1997) Evaluation of steel furnace slags as cement additives. Cem Concr Res 27:1713–1717

Tsakiridis PE, Papadimitriou GD, Tsivilis S, Koroneos C (2008) Utilization of steel slag for Portland cement clinker production. J Hazard Mater 152:805–811

Kriskova L, Pontikes Y, Zhang F, Cizer O, Jones PT, Van Balen K, Blanpain B (2014) Influence of mechanical and chemical activation on the hydraulic properties of gamma dicalcium silicate. Cem Concr Res 55:59–68

Kriskova L, Pontikes Y, Cizer O, Mertens G, Veulemans W, Geysen D, Jones PT, Vandewalle L, Van Balen K, Blanpain B (2012) Effect of mechanical activation on the hydraulic properties of stainless steel slags. Cem Concr Res 42:778–788

Kambole C, Paige-Green P, Kupolati WK, Ndambuki JM, Adeboje AO (2017) Basic oxygen furnace slag for road pavements: a review of material characteristics and performance for effective utilisation in southern Africa. Constr Build Mater 148:618–631

Taylor HFW (1997) Cement chemistry, 2nd edn. Telford Publishing, London

Geiseler J (1996) Use of steel works slag in Europe. Waste Manag 16:59–63

Reddy AS, Pradhan RK, Chandra S (2006) Utilization of basic oxygen furnace (BOF) slag in the production of a hydraulic cements binder. Int J Miner Process 79:98–105

Zhang T, Yu Q, Wei J, Li J, Zhang P (2011) Preparation of high performance blended cements and reclamation of iron concentrate from basic oxygen furnace steel slag. Resour Conserv Recycl 56:48–55

Salman M, Cizer O, Pontikes Y, Snellings R, Dijkman J, Sels B, Vandewalle L, Blanpain B, Balen KV (2015) Alkali activation of AOD stainless steel slag under steam curing conditions. J Am Ceram Soc 98:3062–3074

Salman M, Cizer O, Pontikes Y, Snellings R, Vandewalle L, Blanpain B, Balen KV (2015) Cementitious binders from activated stainless steel refining slag and the effect of alkali solutions. J Hazard Mater 286:211–219

IS 12089 (1987) Specification for granulated slag for the manufacture of Portland slag cement. Bureau of Indian Standards, New Delhi

ASTM: C989, C989M (2017) Standard specification for slag cement for use in concrete and mortars. American Society for Testing and Materials, USA

Krivenko P (1994) Progress in alkaline cements. Proceedings of the 1st International. Conference, Alkaline cements and Concretes. (Kiev, Ukraine), 11–129

Glukhovsky V (1994) Ancient, modern and future concretes. First International. Conference. Alkaline Cements and Concretes, (Kiev, Ukraine), 1, 1–8

Motz H, Geiseler J (2001) Products of steel slags—an opportunity to save natural resources. Waste Manag 21:285–293

Kumar DS, Sah R, Prasad G, Prasad SMR, Yadav D, Gupta S, Chaturvedi SK (2020) Use of granulated steel slag in manufacture of cement. JSW Steel Ltd, and NCCB, India, (www.ncbindia.com/pdf_seminar/050-FP.pdf)

Wu S, Xue Y, Ye Q, Chen Y (2007) Utilization of steel slag as aggregates for stone mastic asphalt (SMA) mixtures. Build Environ 42:2580–2585

Shen DH, Wu C-M, Du J-C (2009) Laboratory investigation of basic oxygen furnace slag for substitution of aggregate in porous asphalt mixture. Constr Build Mater 23:453–461

Asi IM, Qasrawi HY, Shalabi FI (2007) Use of steel slag aggregate in asphalt concrete mixes. Can J Civ Eng 34:902–911

Xie J, Chen Z, Pang L, Wu S (2014) Implementation of modified pull-off test by UTM to investigate bonding characteristics of bitumen and basic oxygen furnace slag (BOF). Constr Build Mater 57:61–68

Pang B, Zhou Z, Xu H (2015) Utilization of carbonated and granulated steel slag aggregate in concrete. Constr Build Mater 84:454–467

Kotresh KM, Kebede YB, Behre S, Gethaun M, Honnappanavar ML (2016) Study focus on concrete replacing LD slag as fine aggregate. Int J Adv Eng Manag Sci 2117–2121

N N, Maheshchandra KV (2014) A study on flexural behaviour of reinforced concrete beams by replacement of Linz–Donawitz (LD) slag as fine aggregate. Int J Civ Struct Eng Res 2:89–96

Suri N, Babu YA (2016) Experimental investigations on partial replacement of steel slag as coarse aggregates and eco sand as fine aggregate. Int J Civ Eng Technol 7:322–328

Brand AS, Roesler JR (2015) Steel furnace slag aggregate expansion and hardened concrete properties. Cem Concr Compos 60:1–9

Sezer GI, Gulderen M (2015) Usage of steel slag in concrete as fine and/or coarse aggregate Indian. J Eng Mater Sci 22:339–344

Bodor M, Santos RM, Cristea G, Salman M, Cizer O, Iacobescu RI, Chiang WY, Balen KV, Vlad M, Gerven TV (2016) Laboratory investigation of carbonated BOF slag used as partial replacement of natural aggregate in cement mortars. Cement Concr Compos 65:55–66

Emery JJ (1982) Slag utilization in pavement construction. Extending Aggregate Resources. ASTM Special Technical Publication 774, ASTM, Washington, DC

Shih PH, Wu ZZ, Chiang HL (2004) Characteristics of bricks made from waste steel slag. Waste Manag 24:1043–1047

Shakir AA, Naganathan SK, Mustapha KNB (2013) Development of bricks from waste material: a review paper. Aust J Basic Appl Sci 7:812–818

Pinto M, Rodrigvez M, Besga G (1995) Effects of Linz–Donawitz (LD) slag as soil properties and pasture production in the Basque country (Northern Spain). N Z J Agric Res 38:143–155

A guide for the use of steel slag in agriculture and for reclamation of acidic lands, https://www.nationalslag.org/sites/nationalslag/files/ag_guide909.pdf, 09 Feb 2018

Poh HY, Ghataora GS, Ghazireh N (2006) Soil stabilization using basic oxygen steel slag fines. J Mater Civ Eng 18:229–240

Lopez Gomez FA, Aldecoa R, Fernandez Prieto MA, Rodrigues JM, Simoes C (1999) Preparation of NPK fertilisers from ferrous-metallurgy. Eur Comm 1

Kumar DS (2015) JSW steel’s granulated LD slag for cement production

Kumar DS, Sah R, Prasad G, Prasad SMR, Yadav D, Gupta S, Chaturvedi SK (2020) Use of granulated steel slag in manufacture of cement. JSW Steel Ltd, and NCCB, India, (www.ncbindia.com/pdf_seminar/050-FP.pdf)

Kumar P, Kumar DS, Marutiram K, Prasad SMR (2017) Pilot-scale steam aging of steel slags. Waste Manag Res pp 1–8

Xuequan W, Hong Z, Xinkai H, Husen L (1999) Study on steel slag and fly ash composite Portland cement. Cem Concr Res 29:1103–1106

Xue Y, Wu S, Hou H, Zha J (2006) Experimental investigation of basic oxygen furnace slag used as aggregate in asphalt mixture. J Hazard Mater B 138:261–268

Murphy JN, Meadowcroft TR, Barr PV (1997) Enhancement of the cementitious properties of steelmaking slag. Can Metall Q 36:315–331

Monshi A, Asgarani MK (1999) Producing Portland cement from iron and steel slags and limestone. Cem Concr Res 29:1373–1377

Li YS (1999) The use of waste basic oxygen furnace slag and hydrogen peroxide to degrade 4-chlorophenol. Waste Manag 19:495–502

Belhadj E, Diliberto C, Lecomte A (2012) Characterization and activation of basic oxygen furnace slag. Cem Concr Compos 34:34–40

Chen Z, Wu S, Xiao Y, Zeng W, Yi M, Wan J (2016) Effect of hydration and silicone resin on basic oxygen furnace slag and its asphalt mixture. J Clean Prod 112:392–400

Yildirim IZ, Prezzi M (2009) Use of steel slag in subgrade applications, in: joint transportation research program: Final Report—FHWA/IN/JTRP-2009/32, SPR-3129, Indiana Department of Transportation—Office of Research and Development, West Lafayette, USA, 2009, 1–274

Lun Y, Zhou M, Cai X, Xu F (2008) Methods for improving volume stability of steel slag as fine aggregate. J Wuhan Univ Technol 23:737–742

Miraoui M, Zentar R, Abriak N-E (2012) Road material basis in dredged sediment and basic oxygen asphalt mixture, furnace steel slag. Constr Build Mater 30:309–319

Björkman B, Eriksson J, Nedar L, Samuelsson C (1996) Waste reduction through process optimization and development. JOM 48:45–49

Wang Q, Yan P, Han S (2011) The influence of steel slag on the hydration of cement during the hydration process of complex binder. Sci China Technol Sci 54:388–394

Alanyali H, Col M, Yilmaz M, Karagoz S (2009) Concrete produced by steel-making slag (basic oxygen furnace) addition in Portland cement. Int J Appl Ceram Technol 6:736–748

Reddy AS, Pradhan RK, Chandra S (2006) Utilization of Basic Oxygen Furnace (BOF) slag in the production of a hydraulic cement binder. Int J Miner Process 79:98–105

Vlcek J, Tomkova V, Ovcacikova H, Ovcacik F, Topinkova M, Matejka V (2013) Slags from steel production: properties and their utilization. Metalurgija 52:329–333

Altun IA, Yılmaz I (2002) Study on steel furnace slags with high MgO as additive in Portland cement. Cem Concr Res 32:1247–1249

Ahmedzadea P, Sengoz B (2009) Evaluation of steel slag coarse aggregate in hot mix asphalt concrete. J Hazard Mater 165:300–305

Devi VS, Gnanavel BK (2014) Properties of concrete manufactured using steel slag. 12th Global congress on manufacturing and management (GCMM). Proc Eng 97:95–104

IS 1077 (1992) Common burnt clay building bricks specifications. Bureau of Indian Standards, New Delhi, India

IS 12894 (2002) Pulverized fuel ash-lime bricks-specification. Bureau of Indian Standards, New Delhi, India

Acknowledgements

The paper forms part of research and development project at CSIR-Central Building Research Institute, Roorkee under financial assistance from Ministry of Steel, Government of India (Grant No. 11(24)/GBS/2017-TD).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singh, S.K., Rekha, P. & Surya, M. Utilization of Linz–Donawitz slag from steel industry for waste minimization. J Mater Cycles Waste Manag 22, 611–627 (2020). https://doi.org/10.1007/s10163-020-00981-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-020-00981-z