Abstract

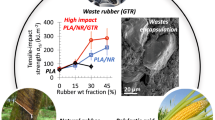

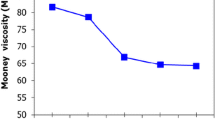

Vulcanized residues of ethylene–propylene–diene monomer rubber (EPDM) from expanded profiles trims, called EPDM-r, were treated to remove the paraffinic oil and then devulcanized by microwaves at different exposure times (0, 2, 3 and 4 min). Elastomeric formulations of EPDM-r compound/raw EPDM compound containing 67 wt% of recycled phase were produced, and the characteristics of the vulcanization process, mechanical and dynamic-mechanical properties, morphology and accelerated aging of the blends were analyzed. The promising results showed that it is possible to obtain new rubber compositions containing 67 wt% of EPDM-r with similar—or even higher—mechanical properties than the Reference sample (without EPDM-r), pointing out to the potential use of devulcanized EPDM-r in several applications, as a possible solution to the destination of these materials, aiming at the sustainable development.

Highlights

-

Production of elastomeric blends containing a high concentration of ethylene–propylene–diene monomer rubber (EPDM), i.e. 67 wt%.

-

Devulcanization of the EPDM residue by microwaves irradiation.

-

Increasing the microwave exposure time improved the efficiency of the devulcanization process.

-

Extraction of the paraffinic oil from the EPDM residue (before devulcanization) improved the efficiency of the devulcanization process.

-

The final material has a potential application of the residues from the automobile industry itself, such as in the manufacture of new products.

Similar content being viewed by others

Data availability

All the data used to support the findings of this study are included in the article.

References

Karaağaç B, Kalkan ME, Deniz V (2017) End of life tyre management: Turkey case. J Mater Cycles Waste Manag 19:577–584. https://doi.org/10.1007/s10163-015-0427-2

Karakurt C (2015) Microstructure properties of waste tire rubber composites: an overview. J Mater Cycles Waste Manag 17:422–433. https://doi.org/10.1007/s10163-014-0263-9

Zanchet A, Carli LN, Giovanela M et al (2012) Use of styrene butadiene rubber industrial waste devulcanized by microwave in rubber composites for automotive application. Mater Des 39:437–443. https://doi.org/10.1016/j.matdes.2012.03.014

Weber T, Zanchet A, Brandalise RN et al (2008) Grinding and characterization of scrap rubbers powders. J Elastom Plast 40:147–159. https://doi.org/10.1177/0095244307082487

Garcia PS, de Sousa FDB, de Lima JA et al (2015) Devulcanization of ground tire rubber: physical and chemical changes after different microwave exposure times. Express Polym Lett 9:1015–1026. https://doi.org/10.3144/expresspolymlett.2015.91

de Sousa FDB, Zanchet A, Scuracchio CH (2017) Influence of reversion in compounds containing recycled natural rubber: in search of sustainable processing. J Appl Polym Sci. https://doi.org/10.1002/app.45325

Zhang X, Saha P, Cao L et al (2018) Devulcanization of waste rubber powder using thiobisphenols as novel reclaiming agent. Waste Manag 78:980–991. https://doi.org/10.1016/J.WASMAN.2018.07.016

Zanchet A, Bandeira Dotta A, de Sousa FDB (2017) Relationship among vulcanization, mechanical properties and morphology of blends containing recycled EPDM. Recycling 2:16. https://doi.org/10.3390/recycling2030016

Asaro L, Gratton M, Seghar S, Aït Hocine N (2018) Recycling of rubber wastes by devulcanization. Resour Conserv Recycl 133:250–262. https://doi.org/10.1016/J.RESCONREC.2018.02.016

Bockstal L, Berchem T, Schmetz Q, Richel A (2019) Devulcanisation and reclaiming of tires and rubber by physical and chemical processes: a review. J Clean Prod 236:117574. https://doi.org/10.1016/J.JCLEPRO.2019.07.049

Zanchet A, Masiero A, de Sousa FDB, Brandalise RN (2019) The influence of UV-accelerated aging process on industrial waste containing EPDM. Recycling 4:25. https://doi.org/10.3390/recycling4020025

Zanchet A, Carli LN, Giovanela M et al (2009) Characterization of microwave-devulcanized composites of ground SBR scraps. J Elastom Plast 41:497–507. https://doi.org/10.1177/0095244309345411

de Sousa FDB, Scuracchio CH, Hu GH, Hoppe S (2017) Devulcanization of waste tire rubber by microwaves. Polym Degrad Stab 138:169–181. https://doi.org/10.1016/j.polymdegradstab.2017.03.008

Imbernon L, Norvez S (2016) From landfilling to vitrimer chemistry in rubber life cycle. Eur Polym J 82:347–376. https://doi.org/10.1016/j.eurpolymj.2016.03.016

Mandal SK, Alam N, Debnath SC (2012) Reclaiming of ground rubber tire by safe multifunctional rubber additives: I. Tetra benzylthiuram disulfide. Rubber Chem Technol 85:629–644. https://doi.org/10.5254/rct.12.88949

Movahed SO, Ansarifar A, Estagy S (2016) Review of the reclaiming of rubber waste and recent work on the recycling of ethylene–propylene–diene rubber waste. Rubber Chem Technol 89:54–78. https://doi.org/10.5254/rct.15.84850

de Sousa FDB, Gouveia JR, de Camargo Filho PMF et al (2015) Blends of ground tire rubber devulcanized by microwaves/HDPE-Part B: influence of clay addition. Polim E Tecnol 25:382–391. https://doi.org/10.1590/0104-1428.1955

de Sousa FDB, Scuracchio CH (2015) The role of carbon black on devulcanization of natural rubber by microwaves. Mater Res J Mater 18:791–797. https://doi.org/10.1590/1516-1439.004915

de Sousa FDB, Zanchet A (2018) In the search for sustainable processing in compounds containing recycled natural rubber: the role of the reversion process. Recycling 3:47. https://doi.org/10.3390/recycling3040047

Weber T, Zanchet A, Crespo JS et al (2011) Caracterização de artefatos elastoméricos obtidos por revulcanização de resíduo industrial de SBR(copolímero de butadieno e estireno). Polim E Tecnol 21:429–435. https://doi.org/10.1590/S0104-14282011005000066

de Sousa FDB, Gouveia JR, de Camargo Filho PMF et al (2015) Blends of ground tire rubber devulcanized by microwaves/HDPE—Part A: influence of devulcanization process. Polim E Tecnol 25:256–264. https://doi.org/10.1590/0104-1428.1747

de Sousa FDB, Scuracchio CH, Hu GH, Hoppe S (2016) Effects of processing parameters on the properties of microwave-devulcanized ground tire rubber/polyethylene dynamically revulcanized blends. J Appl Polym Sci. https://doi.org/10.1002/app.43503

de Sousa FDB (2017) Devulcanization of elastomers and applications. In: Çankaya N (ed) Elastomers. InTech, Rijeka, pp 209–229

Scuracchio CH, Waki DA, Bretas RES (2006) Caracterização térmica e reológica de borracha de pneu desvulcanizada por microondas. Polim E Tecnol 16:46–52

Scuracchio CH, Waki DA, da Silva MLCP (2007) Thermal analysis of ground tire rubber devulcanized by microwaves. J Therm Anal Calorim 87:893–897. https://doi.org/10.1007/s10973-005-7419-8

Novotny DS, Marsh RI, Masters FC, Tally DN (1978) Microwave devulcanization of rubber. US 4(104):2

Aoudia K, Azem S, Aït Hocine N et al (2017) Recycling of waste tire rubber: microwave devulcanization and incorporation in a thermoset resin. Waste Manag 60:471–481. https://doi.org/10.1016/j.wasman.2016.10.051

Formela K, Hejna A, Zedler Ł et al (2019) Microwave treatment in waste rubber recycling–recent advances and limitations. Express Polym Lett 13:565–588

Pistor V, Ornaghi FG, Fiorio R et al (2010) Devulcanization of ethylene–propylene–diene polymer residues (EPDM-r) by microwaves. Polim E Tecnol 20:165–169. https://doi.org/10.1590/s0104-14282010005000027

de Sousa FDB, Zanchet A, Scuracchio CH (2019) From devulcanization to revulcanization: challenges in getting recycled tire rubber for technical applications. ACS Sustain Chem Eng 7:8755–8765. https://doi.org/10.1021/acssuschemeng.9b00655

de Sousa FDB, Zanchet A, Ornaghi Júnior HL, Ornaghi FG (2019) Revulcanization kinetics of waste tire rubber devulcanized by microwaves: challenges in getting recycled tire rubber for technical application. ACS Sustain Chem Eng. https://doi.org/10.1021/acssuschemeng.9b02904

Khavarnia M, Movahed SO (2016) Butyl rubber reclamation by combined microwave radiation and chemical reagents. J Appl Polym Sci. https://doi.org/10.1002/app.43363

Molanorouzi M, Mohaved SO (2016) Reclaiming waste tire rubber by an irradiation technique. Polym Degrad Stab 128:115–125. https://doi.org/10.1016/j.polymdegradstab.2016.03.009

Movahed SO, Ansarifar A, Zohuri G et al (2016) Devulcanization of ethylene–propylene–diene waste rubber by microwaves and chemical agents. J Elastom Plast 48:122–144. https://doi.org/10.1177/0095244314557975

Hirayama D, Saron C (2012) Chemical modifications in styrene-butadiene rubber after microwave devulcanization. Ind Eng Chem Res 51:3975–3980. https://doi.org/10.1021/ie202077g

Bani A, Polacco G, Gallone G (2011) Microwave-induced devulcanization for poly(ethylene–propylene–diene) recycling. J Appl Polym Sci 120:2904–2911. https://doi.org/10.1002/app.33359

Pistor V, Scuracchio CH, Oliveira PJ et al (2011) Devulcanization of ethylene–propylene–diene polymer residues by microwave-Influence of the presence of paraffinic oil. Polym Eng Sci 51:697–703. https://doi.org/10.1002/pen.21875

Pistor V, Ornaghi FG, Fiorio R, Zattera AJ (2010) Thermal characterization of oil extracted from ethylene–propylene–diene terpolymer residues (EPDM-r). Thermochim Acta 510:93–96. https://doi.org/10.1016/J.TCA.2010.06.028

de Sousa FDB, Scuracchio CH (2012) Vulcanization behavior of NBR with organically modified clay. J Elastomers Plast 44:263–272. https://doi.org/10.1177/0095244311424722

Huibin O, Mohamed S, Thierry B, Jean-claude G (2016) Determination of the activation energy of silicone rubbers using different kinetic analysis methods. EDP Sci. https://doi.org/10.1051/matecconf/201

de Sousa FDB (2016) Vulcanization of natural rubber: Past, present and future perspectives. In: Hamilton JL (ed) Nat. rubber Prop. Behav. Appl. Nova Science Publishers, New York, pp 47–88

Zanchet A, Demori R, de Sousa FDB et al (2019) Sugar cane as an alternative green activator to conventional vulcanization additives in natural rubber compounds: thermal degradation study. J Clean Prod 207:248–260. https://doi.org/10.1016/j.jclepro.2018.09.203

Kumar CR, Fuhrmann I, Karger-Kocsis J (2002) LDPE-based thermoplastic elastomers containing ground tire rubber with and without dynamic curing. Polym Degrad Stab 76:137–144. https://doi.org/10.1016/s0141-3910(02)00007-1

Kumnuantip C, Sombatsompop N (2003) Dynamic mechanical properties and swelling behaviour of NR/reclaimed rubber blends. Mater Lett 57:3167–3174. https://doi.org/10.1016/S0167-577X(03)00019-3

De D, Maiti S, Adhikari B (1999) Reclaiming of rubber by a renewable resource material (RRM). II. Comparative evaluation of reclaiming process of NR vulcanizate by RRM and diallyl disulfide. J Appl Polym Sci 73:2951–2958. https://doi.org/10.1002/(sici)1097-4628(19990929)73:14%3c2951:aid-app19%3e3.0.co;2-b

Cao LM, Cao XD, Jiang XJ et al (2013) In situ reactive compatibilization and reinforcement of peroxide dynamically vulcanized polypropylene/ethylene–propylene–diene monomer tpv by zinc dimethacrylate. Polym Compos 34:1357–1366. https://doi.org/10.1002/pc.22550

Nair TM, Kumaran MG, Unnikrishnan G, Kunchandy S (2008) Ageing studies of ethylene propylene diene monomer rubber/styrene butadiene rubber blends: effects of heat, ozone, gamma radiation, and water. J Appl Polym Sci 107:2923–2929. https://doi.org/10.1002/app.27497

Rattanasom N, Poonsuk A, Makmoon T (2005) Effect of curing system on the mechanical properties and heat aging resistance of natural rubber/tire tread reclaimed rubber blends. Polym Test 24:728–732. https://doi.org/10.1016/j.polymertesting.2005.04.008

Pistor V, Ornaghi FG, Fiorio R, Zattera AJ (2010) Thermal and mechanical characterization of a terpolymer mixture of devulcanized recycled ethylene–propylene–diene and low-density polyethylene. J Elastomers Plast 42:417–431. https://doi.org/10.1177/0095244310379175

Acknowledgements

The authors would like to thank Ciaflex Rubber Industry Ltd. (Caxias do Sul, Rio Grande do Sul, Brazil) for supplying the expanded profiles trims and rubber recipes.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Sousa, F.D.B., Zanchet, A., Marczynski, E.S. et al. Devulcanized EPDM without paraffinic oil in the production of blends as a potential application of the residues from automobile industry. J Mater Cycles Waste Manag 22, 273–284 (2020). https://doi.org/10.1007/s10163-019-00938-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-019-00938-x