Abstract

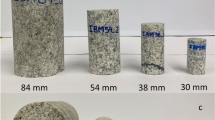

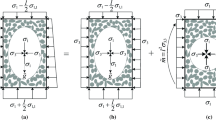

The shape of granular materials is one of the effective parameters in determining mechanical behavior. This property affects the fracture strength, compressibility, maximum friction angle and the distribution of contact stresses. So far, laboratory studies on the effect of shape on the behavior of granular materials have focused mostly on comparing the results of angular and rounded grains. Due to the distribution of different shapes in natural grain materials, experimental studies of the effect of sphericity index are of great importance. On the other hand, it is necessary to investigate the grain shape on the compression model parameters comprehensively. Therefore, based on the energy conservation equation and the use of statistical Weibull and fractal theory, the compressibility model of granular materials under uniaxial loading conditions is obtained by taking into account the quantitative parameters related to the shape of grain. Then, in order to evaluate the analytical model, three stages of laboratory tests are performed. In the first stage, uniaxial loading tests are performed on four different shapes of concrete grains of the same size under the same conditions. In the second stage, similar experiments are performed on angular granite grains to check the applicability of the model to natural materials with different shapes. In the third stage, the sleeper loading modeling is performed on granite grains of real ballast dimensions. The results of large-scale tests are compared with the compressibility model obtained from the results of small-scale tests. Finally, an empirical relationship is proposed to determine the amount of breakage factor based on the energy applied to the grains. The results show that the empirical relationship in combination with the analytical solution can accurately predict the stress-breakage-void ratio behavior of granular materials at each loading step.

Similar content being viewed by others

Abbreviations

- BH :

-

Hardin breakage factor

- c :

-

Convexity coefficient

- D :

-

Fractal dimension

- d :

-

Grain diameter

- dmin :

-

Smallest grain size

- dmax :

-

Largest grain size

- d0 :

-

Average of grain diameters

- ds :

-

Change of surfaces created in grains due to breakage

- e :

-

Void ratio

- E :

-

Applied energy per unit volume

- E 50 :

-

Elasticity modulus

- K 0 :

-

Horizontal stress coefficient due to vertical stress

- M :

-

Coefficient of grain friction

- m :

-

Weibull modulus

- n d :

-

Geometric similarity

- P s :

-

Survival probability

- P’ :

-

Isotropic stress

- q :

-

Deviatoric stress

- S :

-

Sphericity index

- S 0 :

-

Sum of side surfaces of grains

- V s :

-

Volume of grains

- α :

-

Coefficient of grain strength

- β :

-

Coefficient of grain geometry

- \({\beta }_{s}\) :

-

Surface shape factor

- \({\beta }_{v}\) :

-

Volume shape factor

- \(\Gamma\) :

-

Surface-free energy

- \(\delta {\varepsilon }_{q}^{P}\) :

-

Plastic shear strain increment

- \(\delta {\varepsilon }_{v}^{P}\) :

-

Plastic volumetric strain increment

- \(\delta {e}^{P}\) :

-

Plastic void ratio increment

- \(\mu\) :

-

Coefficient of grain friction

- \(\upsigma\) :

-

Induced tensile stress

- \({\sigma }_{y}\) :

-

Stress corresponding to point with the greatest curvature in the e-log σ plot

- \({\sigma }_{0}\) :

-

Characteristic stress

- \({\sigma }_{a}\) :

-

Vertical stress

- \(\phi\) :

-

Angle of internal friction

- \(\Psi\) :

-

State parameter

References

Abedi S, Mirghasemi AA (2011) Particle shape consideration in numerical simulation of assemblies of irregularly shaped particles. Particuology 9(4):387–397. https://doi.org/10.1016/j.partic.2010.11.005

Al-Shayea NA, Khan K, Abduljauwad SN (2000) Effects of confining pressure and temperature on mixed-mode (I–II) fracture toughness of a limestone rock. Int J Rock Mech Min Sci 37(4):629–643. https://doi.org/10.1016/S1365-1609(00)00003-4

Alabbasi Y, Hussein M (2019) Large-scale triaxial and box testing on railroad ballast: a review. SN Applied Sciences 1(12):1592. https://doi.org/10.1007/s42452-019-1459-3

Altuhafi Fatin N, Coop Matthew R, Georgiannou Vasiliki N (2016) Effect of particle shape on the mechanical behavior of natural sands. J Geotech Geoenviron 142(12):04016071. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001569

AREMA (2010) Manual for Railway Engineering The American Railway Engineering and Maintenance-of-Way Association, Lanham, Maryland

ASTM-C1444–00 (2000) Standard Test Method for Measuring the Angle of Repose of Free-Flowing Mold Powders. ASTM International, West Conshohocken, PA

ASTM D2488 (2017) Standard practice for description and identification of soils. ASTM International, West Conshohocken, PA

ASTM D2845–08 (2008) Standard Test Method for Laboratory Determination of Pulse Velocities and Ultrasonic Elastic Constants of Rock. ASTM International, West Conshohocken, PA

ASTM D3967-16 (2016) Standard Test Method for Splitting Tensile Strength of Intact Rock Core Specimens. ASTM International, West Conshohocken, PA

ASTM D7012-14e1 (2014) Standard Test Methods for Compressive Strength and Elastic Moduli of Intact Rock Core Specimens under Varying States of Stress and Temperatures. ASTM International, West Conshohocken, PA

Atkinson J (2007) The Mechanics of Soils and Foundations (2nd ed.). CRC Press. https://doi.org/10.1201/9781315273549

Bareither Christopher A, Edil Tuncer B, Benson Craig H, Mickelson David M (2008) Geological and Physical Factors Affecting the Friction Angle of Compacted Sands. J Geotech Geoenviron 134(10):1476–1489. https://doi.org/10.1061/(ASCE)1090-0241(2008)134:10(1476)

Barrett PJ (1980) The shape of rock particles, a critical review. Sedimentology 27(3):291–303. https://doi.org/10.1111/j.1365-3091.1980.tb01179.x

Bienen B, Byrne BW, Houlsby GT, Cassidy MJ (2006) Investigating six-degree-of-freedom loading of shallow foundations on sand. Géotechnique 56(6):367–379. https://doi.org/10.1680/geot.2006.56.6.367

Bieniawski ZT (1989) Engineering Rock Mass Classifications: A Complete Manual for Engineers and Geologists in Mining, Civil, and Petroleum Engineering. Wiley

Budhu M (2010) Soil Mechanics and Foundations, 3rd edn. Wiley

Chang CS, Hicher PY (2005) An elasto-plastic model for granular materials with microstructural consideration. Int J Solids Struct 42(14):4258–4277. https://doi.org/10.1016/j.ijsolstr.2004.09.021

Cho G-C, Dodds J, Santamarina JC (2006) Particle shape effects on packing density, stiffness, and strength: natural and crushed sands. J Geotech Geoenviron 132(5):591–602. https://doi.org/10.1061/(ASCE)1090-0241(2006)132:5(591)

Coop MR, Sorensen KK, Bodas Freitas T, Georgoutsos G (2004) Particle breakage during shearing of a carbonate sand. Géotechnique 54(3):157–163. https://doi.org/10.1680/geot.2004.54.3.157

Daouadji A, Hicher P-Y (2010) An enhanced constitutive model for crushable granular materials. Int J Numer Anal Meth Geomech 34(6):555–580. https://doi.org/10.1002/nag.815

Daouadji A, Hicher P-Y, Rahma A (2001) An elastoplastic model for granular materials taking into account grain breakage. Eur J Mech A Solids 20(1):113–137. https://doi.org/10.1016/S0997-7538(00)01130-X

DIN-EN-13450 (2002) Aggregates for railway ballast. European Standard, Berlin, Germany

Einav I (2007) Breakage mechanics—Part I: Theory. J Mech Phys Solids 55(6):1274–1297. https://doi.org/10.1016/j.jmps.2006.11.003

Erdoğan ST, Forster AM, Stutzman PE, Garboczi EJ (2017) Particle-based characterization of Ottawa sand: Shape, size, mineralogy, and elastic moduli. Cement Concr Compos 83:36–44. https://doi.org/10.1016/j.cemconcomp.2017.07.003

Gupta AK (2016) Effects of particle size and confining pressure on breakage factor of rockfill materials using medium triaxial test. J Rock Mech Geotech Eng 8(3):378–388. https://doi.org/10.1016/j.jrmge.2015.12.005

Hardin BO (1985) Crushing of soil particles. Journal of Geotechnical Engineering 111(10):1177–1192. https://doi.org/10.1061/(ASCE)0733-9410(1985)111:10(1177)

Holtz RD, Kovacs WD (1981) An Introduction To Geotechnical Engineering. Prentice-Hall. https://books.google.com/books?id=s_ZRAAAAMAAJ

Hucka V, Das B (1974) Brittleness determination of rocks by different methods. Int J Rock Mech Min 11(10):389–392. https://doi.org/10.1016/0148-9062(74)91109-7

Indraratna B, Ionescu D, Christie HD (1998) Shear behavior of railway ballast based on large-scale triaxial tests. J Geotech Geoenviron 124(5):439–449. https://doi.org/10.1061/(ASCE)1090-0241(1998)124:5(439)

Jaky J (1948) Pressure in silos. 2nd International Conference on Soil Mechanics and Foundation Engineering, Rotterdam, Netherlands.

Jamiolkowski M, Presti DCFL, Manassero M (2003) Evaluation of Relative Density and Shear Strength of Sands from CPT and DMT. In Soil Behavior and Soft Ground Construction (pp. 201–238). https://doi.org/10.1061/40659(2003)7

Jurtz N, Kraume M, Wehinger GD (2018) Advances in fixed-bed reactor modeling using particle-resolved computational fluid dynamics (CFD). Rev Chem Eng 35(2):139–190. https://doi.org/10.1515/revce-2017-0059

Kaewunruen S, Remennikov A (2008) Dynamic properties of railway track and its components: A state-of-The-art review FoE University of Wollongong. University of Wollongong, Faculty of Engineering https://ro.uow.edu.au/engpapers/493

Karatza Z, Andò E, Papanicolopulos S-A, Viggiani G, Ooi JY (2019) Effect of particle morphology and contacts on particle breakage in a granular assembly studied using X-ray tomography. Granul Matter 21(3):44. https://doi.org/10.1007/s10035-019-0898-2

Koohmishi M, Palassi M (2017) Evaluation of morphological properties of railway ballast particles by image processing method. Transportation Geotechnics 12:15–25. https://doi.org/10.1016/j.trgeo.2017.07.001

Lade PV, Yamamuro JA, Bopp PA (1996) Significance of particle crushing in granular materials. Journal of Geotechnical Engineering 122(4):309–316. https://doi.org/10.1061/(ASCE)0733-9410(1996)122:4(309)

Lee KL, Farhoomand I (1967) Compressibility and crushing of granular soil In anisotropic triaxial compression. Can Geotech J 4(1):68–86. https://doi.org/10.1139/t67-012

Li X, Liu J, Li J (2022) Fractal dimension, particle shape, and particle breakage analysis for calcareous sand. B Eng Geol Environ 81(3):106. https://doi.org/10.1007/s10064-022-02585-3

Li Y (2013) Effects of particle shape and size distribution on the shear strength behavior of composite soils. B Eng Geol Environ 72(3):371–381. https://doi.org/10.1007/s10064-013-0482-7

Liu E (2010) Breakage and deformation mechanisms of crushable granular materials. Comput Geotech 37(5):723–730. https://doi.org/10.1016/j.compgeo.2010.04.009

Liu M, Gao Y, Liu H (2014) An elastoplastic constitutive model for rockfills incorporating energy dissipation of nonlinear friction and particle breakage. Int J Numer Anal Meth Geomech 38(9):935–960. https://doi.org/10.1002/nag.2243

Lu M, McDowell GR (2007) The importance of modelling ballast particle shape in the discrete element method. Granul Matter 9(1):69. https://doi.org/10.1007/s10035-006-0021-3

Marsal R (1967) Large Scale Testing of Rockfill Materials Journal of the Soil Mechanics and Foundations Division 93(2):27–43

McDowell GR (2002) On the yielding and plastic compression of sand. Soils Found 42(1):139–145. https://doi.org/10.3208/sandf.42.1139

McDowell GR, Amon A (2000) The Application of Weibull Statistics to the Fracture of Soil Particles. Soils Found 40(5):133–141. https://doi.org/10.3208/sandf.40.5_133

McDowell GR, Bolton MD (1998) On the micromechanics of crushable aggregates. Géotechnique 48(5):667–679. https://doi.org/10.1680/geot.1998.48.5.667

McDowell GR, Bolton MD, Robertson D (1996) The fractal crushing of granular materials. J Mech Phys Solids 44(12):2079–2101. https://doi.org/10.1016/S0022-5096(96)00058-0

McDowell GR, Daniell CM (2001) Fractal Compression of Soil Géotechnique 51(2):173–176. https://doi.org/10.1680/geot.2001.51.2.173

Mesri G, Vardhanabhuti B (2009) Compression of granular materials. Can Geotech J 46(4):369–392. https://doi.org/10.1139/T08-123

Mirghasemi AA, Rothenburg L, Matyas EL (2002) Influence of particle shape on engineering properties of assemblies of two-dimensional polygon-shaped particles. Géotechnique 52(3):209–217. https://doi.org/10.1680/geot.2002.52.3.209

Miura K, Maeda K, Furukawa M, Toki S (1998) Mechanical characteristics of sands with different primary properties. Soils Found 38(4):159–172. https://doi.org/10.3208/sandf.38.4_159

Muir Wood D, Maeda K (2008) Changing grading of soil: Effect on critical states. Acta Geotech 3:3–14. https://doi.org/10.1007/s11440-007-0041-0

Nakata Y, Hyodo M, Hyde AFL, Kato Y, Murata H (2001a) Microscopic Particle Crushing of Sand Subjected to High Pressure One-Dimensional Compression. Soils Found 41(1):69–82. https://doi.org/10.3208/sandf.41.69

Nakata Y, Kato Y, Hyodo M, Hyde AFL, Murata H (2001b) One-dimensional compression behaviour of uniformly graded sand related to single particle crushing strength. Soils Found 41(2):39–51. https://doi.org/10.3208/sandf.41.2_39

Ovalle C, Frossard E, Dano C, Hu W, Maiolino S, Hicher P-Y (2014) The effect of size on the strength of coarse rock aggregates and large rockfill samples through experimental data. Acta Mech 225(8):2199–2216. https://doi.org/10.1007/s00707-014-1127-z

Palmer AC, Sanderson TJO (1991) Fractal crushing of ice and brittle solids. Proceedings: Mathematical and Physical Sciences 433(1889):469–477. https://doi.org/10.1098/rspa.1991.0060

Pestana JM, Whittle AJ (1995) Compression Model for Cohesionless Soils Géotechnique 45(4):611–631. https://doi.org/10.1680/geot.1995.45.4.611

Salim W, Indraratna B (2004) A new elastoplastic constitutive model for coarse granular aggregates incorporating particle breakage. Can Geotech J 41(4):657–671. https://doi.org/10.1139/t04-025

Sammis C, King G, Biegel R (1987) The kinematics of gouge deformation. Pure Appl Geophys 125(5):777–812. https://doi.org/10.1007/BF00878033

Selig ET, Waters JM (1994) Track geotechnology and substructure management [https://doi.org/10.1680/tgasm.20139]. Thomas Telford Publishing. https://doi.org/10.1680/tgasm.20139

Sharma A, Penumadu D (2020) Role of particle shape in determining tensile strength and energy release in diametrical compression of natural silica grains. Soils Found 60(5):1299–1311. https://doi.org/10.1016/j.sandf.2020.08.004

Shin H, Santamarina JC (2013) Role of Particle Angularity on the Mechanical Behavior of Granular Mixtures. J Geotech Geoenviron 139(2):353–355. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000768

Shinohara K, Oida M, Golman B (2000) Effect of particle shape on angle of internal friction by triaxial compression test. Powder Technol 107(1):131–136. https://doi.org/10.1016/S0032-5910(99)00179-5

Stark N, Hay AE, Cheel R, Lake CB (2014) The impact of particle shape on the angle of internal friction and the implications for sediment dynamics at a steep, mixed sand–gravel beach. Earth Surf Dynam 2(2):469–480. https://doi.org/10.5194/esurf-2-469-2014

Sukumaran B, Ashmawy A (2001) Quantitative characterisation of the geometry of discrete particles. Geotechnique 51:619–627. https://doi.org/10.1680/geot.51.7.619.51393

Takei M, Kusakabe O, Hayashi T (2001) Time-dependent behavior of crushable materials in one-dimensional compression tests. Soils Found 41:97–121. https://doi.org/10.3208/sandf.41.97

Tapias M, Alonso EE, Gili J (2016) Compressibility, grain breakage and time-dependent behavior of gap-graded aggregates of sugar cubes. Soils Found 56(5):805–817. https://doi.org/10.1016/j.sandf.2016.08.006

Tong C-X, Zhang K-F, Zhang S, Sheng D (2019) A stochastic particle breakage model for granular soils subjected to one-dimensional compression with emphasis on the evolution of coordination number. Comput Geotech 112:72–80. https://doi.org/10.1016/j.compgeo.2019.04.010

Turcotte DL (1986) Fractals and fragmentation. Journal of Geophysical Research: Solid Earth 91(B2):1921–1926. https://doi.org/10.1029/JB091iB02p01921

Varadarajan A, Sharma K, Venkatachalam K, Gupta A (2003) Testing and modeling two rockfill materials. Journal of Geotechnical and Geoenvironmental Engineering. https://doi.org/10.1061/(ASCE)1090-0241(2003)129:3(206)

Wang Y, Shao S, Wang Z (2019) Effect of particle breakage and shape on the mechanical behaviors of granular materials. Adv Civil Eng 2019:7248427. https://doi.org/10.1155/2019/7248427

Weibull W (1939) A statistical theory of the strength of materials. Generalstabens litografiska anstalts förlag.

Wu X, Cai Y, Xu S, Zhuang Y, Wang Q, Wang Z (2021) Effects of size and shape on the crushing strength of coral sand particles under diametral compression test. B Eng Geol Environ 80(2):1829–1839. https://doi.org/10.1007/s10064-020-01972-y

Xiao Y, Liu H, Yang G, Chen Y, Jiang J (2014) A constitutive model for the state-dependent behaviors of rockfill material considering particle breakage. Sci China Tech Sci 57:1636–1646. https://doi.org/10.1007/s11431-014-5601-6

Xiao Y, Meng M, Daouadji A, Chen Q, Wu Z, Jiang X (2020) Effects of particle size on crushing and deformation behaviors of rockfill materials. Geosci Front 11(2):375–388. https://doi.org/10.1016/j.gsf.2018.10.010

Xiao Y, Sun Y, Hanif KF (2015) A particle-breakage critical state model for rockfill material. Sci China Tech Sci 58(7):1125–1136. https://doi.org/10.1007/s11431-015-5831-2

Yamamuro JA, Bopp PA, Lade PV (1996) One-Dimensional Compression of Sands at High Pressures. Journal of Geotechnical Engineering 122(2):147–154. https://doi.org/10.1061/(ASCE)0733-9410(1996)122:2(147)

Yang G, Yan X, Nimbalkar S, Xu J (2019) Effect of Particle Shape and Confining Pressure on Breakage and Deformation of Artificial Rockfill. International Journal of Geosynthetics and Ground Engineering 5(2):15. https://doi.org/10.1007/s40891-019-0164-z

Zhang B-Y, Jie Y-X, Kong D-Z (2013) Particle size distribution and relative breakage for a cement ellipsoid aggregate. Comput Geotech 53:31–39. https://doi.org/10.1016/j.compgeo.2013.04.007

Zhang J, Zhang B (2018) Fractal pattern of particle crushing of granular geomaterials during one-dimensional compression. Adv Civil Eng:2153971. https://doi.org/10.1155/2018/2153971

Zhang S, Tong CX, Li X, Sheng D (2015) A new method for studying the evolution of particle breakage. Géotechnique 65(11):911–922. https://doi.org/10.1680/jgeot.14.P.240

Zhang T, Zhang C, Zou J, Wang B, Song F, Yang W (2020a) DEM exploration of the effect of particle shape on particle breakage in granular assemblies. Comput Geotech 122:103542. https://doi.org/10.1016/j.compgeo.2020.103542

Zhang X, Baudet BA, Yao T (2020b) The influence of particle shape and mineralogy on the particle strength, breakage and compressibility. International Journal of Geo-Engineering 11(1):1–10. https://doi.org/10.1186/s40703-020-0108-4

Zhao B, Wang J, Coop MR, Viggiani G, Jiang M (2015) An investigation of single sand particle fracture using X-ray micro-tomography. Géotechnique 65(8):625–641. https://doi.org/10.1680/geot.4.P.157

Zhu X, Li S, Li Y, Li T, Yin J (2022) Study of the influence of particle breakage on compression properties for carbonate sand. B Eng Geol Environ 81(3):89. https://doi.org/10.1007/s10064-022-02579-1

Acknowledgements

This study was supported by the research grant of the Sahand University of Technology (SUT) (GN. 30.13766).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gorbanpoor, V., Emami Tabrizi, M. & Afshin, H. Experimental investigation of the shape effect on the mechanical behavior of granular materials under uniaxial loading with lateral confinement. Bull Eng Geol Environ 81, 292 (2022). https://doi.org/10.1007/s10064-022-02751-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10064-022-02751-7