Abstract

This paper presents the effect of particle morphology (grain shape) on the mechanical response of granular materials. Two model systems with extreme differences in morphology were selected (spherical glass ballotini and angular sand) for this experimental programme. A series of hollow cylinder torsion tests were conducted in this programme under monotonic drained conditions on specimens reconstituted to the same relative density. Tests were conducted under different intermediate principal stress ratio (b) on both the model materials. The glass ballotini shows increased dilation at the outset of the test, however, at large strains, the particle rearrangement in the sand and the increased interlocking leads to higher strength at the critical state. The effect of individual particle morphology is manifested in both the increased friction angle and a larger sized failure locus in stress space with increase in angularity. The stresses developed in these two model materials are also accompanied by intriguing volume change behaviour. The glass ballotini despite a lower strength presents a predominantly dilative response immaterial of the ‘b’ value, while the angular sand shows increased strength at large strains, while showing a contractive response. These results allow incorporation of particle morphology effects at the ensemble level in plasticity based constitutive models.

Similar content being viewed by others

References

Rao, K.K., Nott, P.R.: An Introduction to Granular Flow. Cambridge University Press, Cambridge (2008)

Terzaghi, K.: Principles of soil mechanics: V-physical differences between sand and clay. Eng. News Rec. 95(26), 912–915 (1925)

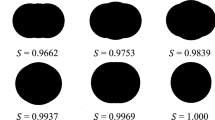

Barrett, P.J.: The shape of rock particles, a critical review. Sedimentology 27(3), 291–303 (1980)

Cox, M.R.B.: The influence of grain shape on dilatancy. Ph.D thesis, The University of Arizona (2008)

Cavaretta, I: The influence of particle characteristics on the engineering behavior of granular materials. PhD thesis, Imperial college London (2009)

Holubec, I., D’Appolonia, E.: Effect of particle slope on the engineering properties of granular soils. In: ASTM Special Technical Publications, vol. 523, pp. 304–318 (1973)

Miura, K., Maeda, K., Furukawa, M., Toki, S.: Physical characteristics of sand with different primary properties. Soils Found. 37(3), 53–64 (1997)

Cho, G.C., Dodds, J., Santamarina, J.C.: Particle shape effects on packing density, stiffness, and strength: natural and crushed sands. J. Geotech. Geo Environ. Eng. 132(5), 591–602 (2006)

Santamarina, J.C., Cho, G.C.: Soil behaviour: the role of particle shape. In: Advances in Geotechnical Engineering. The Skempton Conference, vol. 1. Thomas Telford, London, pp. 604–617 (2004)

Shin, H., Santamarina, J.C.: Role of particle angularity on the mechanical behavior of granular mixtures. J. Geotech Geo Environ. Eng. 139(2), 353–355 (2013)

Abbireddy, C.O.R., Clayton, C.R.I.: The impact of particle form on the packing and shear behaviour of some granular materials: an experimental study. Granular Matter 17(4), 427–438 (2015)

Tsomokos, A., Georgiannou, V.N.: Effect of grain shape and angularity on the undrained response of fine sands. Can. Geotech. J. 47, 539–551 (2010)

Guo, P., Su, X.: Shear strength, interparticle locking and dilatancy of granular materials. Can. Geotech. J. 44, 579–591 (2007)

Casagrande, A., Carillo, N.: Shear failure of anisotropic materials. Proc. Boston Soc. Civ. Eng. 31, 74–87 (1944)

Arthur, J.R.F., Menzies, K.B.: Inherent anisotropy in a sand. Geotechnique 22(1), 115–128 (1972)

Arthur, J.R.F., Chua, K.S., Dunstan, T.: Induced anisotropy in a sand. Geotechnique 27(1), 13–30 (1977)

Oda, M., Koishikawa, I., Higuchi, T.: Experimental study of anisotropic shear strength of sand by plane strain test. Soils Found. 18(1), 25–38 (1978)

Atkinson, J.H., Bransby, P.L.: The Mechanics of Soils—An Introduction to Critical State Soil Mechanics. Mcgraw Hill Book Co. Ltd, Maidenhead (1982)

Davis, R.O., Selvadurai, A.P.S.: Plasticity and Geomechanics. Cambridge University Press, Cambridge (2002)

Pietruszczak, S.: Fundamentals of Plasticity in Geomechanics. CRC Press/Balkema, Boca Raton (2010)

Dakoulas, P., Sun, Y.: Fine Ottawa sand—experimental behaviour and theoretical predictions. J. Geotech. Eng. (ASCE) 118(12), 1906–1923 (1992)

Kandasami, R.K., Murthy, T.G.: Experimental studies on the influence of intermediate principal stress and inclination on the mechanical behaviour of angular sands. Granular Matter 17(2), 217–230 (2015)

Li, X.S., Dafalias, Y.F.: Anisotropic critical state theory: the role of fabric. J. Eng. Mech. (ASCE) 138(3), 263–275 (2012)

Zhao, J., Guo, N.: Unique critical state characteristics in granular media considering fabric anisotropy. Geotechnique 63(8), 695–704 (2013)

Yang, L.: Experimental study of soil anisotropy using hollow cylinder testing. Ph.D thesis, The University of Nottingham (2013)

Yang, Y., Fei, W., Yu, H.S., Ooi, J., Rotter, M.: Experimental study of anisotropy and non-coaxiality of granular solids. Granular Matter 17(2), 189–196 (2015)

O’ Sullivan, C.: Particulate Discrete Element Modelling: A Geomechanics Perspective. Taylor & Francis, Hoboken, NJ (2011)

Rothenburg, L., Bathurst, R.J.: Micromechanical features of granular assemblies with planar elliptical particles. Geotechnique 42(1), 79–95 (1992)

Peña, A.A., Lizcano, A., Alonso-Marroquin, F., Herrmann, H.J.: Biaxial test simulations using a packing of polygonal particles. Int. J. Numer. Anal. Methods Geomech. 32(2), 143–160 (2008)

Estrada, N., Azema, E., Radjai, F., Taboada, A.: Identification of rolling resistance as a shape parameter in sheared granular media. Phys. Rev. E. 84(1), 011306 (2011)

Azema, E., Radjai, F.: Force chains and contact network topology in sheared packings of elongated particles. Rev. E. 85(3), 031303 (2012)

Saint-Cyr, B., et al.: Particle shape dependence in 2D granular media. Europhys. Lett. 98(4), 44008 (2012)

Nouguier-Lehon, C., Cambou, B., Vincens, E.: Influence of particle shape and angularity on the behaviour of granular materials: a numerical analysis. Int. J. Numer. Anal. Methods Geomech. 27, 1207–1226 (2003)

Azema, E., Radjai, F., Dubois, F.: Packings of irregular polyhedral particles: strength, structure, and effects of angularity. Rev. E 87(6), 062203 (2013)

Azema, E., Estrada, N., Radjai, F.: Nonlinear effects of particle shape angularity in sheared granular media. Rev. E. 86(4), 041301 (2012)

Azema, E., Radjai, F., Saussine, G.: Quasistatic rheology, force transmission, and fabric properties of a packing of irregular polyhedral particles. Mech. Mater. 41, 729–741 (2009)

O’ Sullivan, C., Wadee, M.A., Hanley, K.J., Barreto, D.: Use of DEM and elastic stability analysis to explain the influence of the intermediate principal stress on shear strength. Geotechnique 63(15), 1298–1309 (2013)

Abbireddy, C.O.R., Clayton, C.R.I.: Varying initial void ratios for DEM simulations. Géotechnique 60(6), 497–502 (2010)

Kandasami, R.K.: Experimental studies on the mechanical behaviour of cohesive frictional granular materials. Ph.D thesis, Indian Institute of Science (2016)

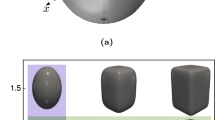

Hight, D.W., Gens, A., Symes, M.J.: The development of a new hollow cylinder apparatus for investigating the effects of principal stress rotation in soils. Geotechnique 33(4), 355–383 (1983)

Krumbein, W.C.: Measurement and geological significance of shape and roundness of sedimentary particles. J. Sediment. Petrol. 11(2), 64–72 (1941)

Powers, M.C.: A new roundness scale for sedimentary particles. J. Sediment. Petrol. 23(2), 117–119 (1953)

Krumbein, W.C., Sloss, L.L.: Stratigraphy and Sedimentation, 2nd edn. Freeman and Company, San Francisco (1963)

Okano, J.I., Kikuchi, E., Sasaki, O., Ohi, S.: Geological variation in particle surface roughness preference in the case-bearing caddisflies. Behav. Ecol. Adv. 22(5), 1053–1063 (2011)

ASTM D854: Standard test methods for specific gravity of soil solids by water pycnometer (2010)

ASTM D4253: Standard test methods for maximum index density and unit weight of soils using a vibratory table (2006)

ASTM D4254: Standard test methods for minimum index density and unit weight of soils and calculation of relative density (2006)

Vaid, Y.P., Negussey, D.: Relative density of pluviated sand samples. Soils Found. 24(2), 101–105 (1984)

Cresswell, A., Barton, M.E., Brown, R.: Determining the maximum density of sands by pluviation. Geotech. Test. J. (GTJODJ) 22(4), 324–328 (1999)

Sayao, A., Vaid, Y.P.: A critical assessment of stress non uniformities in hollow cylinder test specimens. Soils Found. 31(1), 60–72 (1991)

Skempton, A.W.: The pore-pressure coefficients A and B. Geotechnique 4(4), 143–147 (1954)

Gutierrez, M., Ishihara, K., Towhata, I.: Flow theory for sand during rotation of principal stress direction. Soils Found. 31(4), 121–132 (1991)

Nakata, Y., Hyodo, M., Murata, H., Yasufuku, N.: Flow deformation of sands subjected to principal stress rotation. Soils Found. 38(2), 115–128 (1998)

Schofield, A., Wroth, C.P.: Critical State Soil Mechanics. McGrow-Hill, London (1968)

Been, K., Jefferies, M.: Stress–dilatancy in very loose sand. Can. Geotech. J. 41, 972–989 (2004)

Alikarami, R., Ando, E., Gkiousas-Kapnisis, M., Torabi, A., Viggiani, G.: Strain localisation and grain breakage in sand under shearing at high mean stress: insights from in situ X-ray tomography. Acta Geotech. 10(1), 15–30 (2015)

Oda, M., Iwashita, K.: Mechanics of Granular Materials—An Introduction. Balkema Publishers, Rotterdam (1999)

Lade, P.V.: Elasto-plastic stress–strain theory for cohesionless soil with curved yield surfaces. Int. J. Solids Struct. 13(11), 1019–1035 (1977)

Pena, A.A., Garcia-Rojo, R., Herrmann, H.J.: Influence of particle shape on sheared dense granular media. Granular Matter 9(3–4), 279–291 (2007)

Azema, E., Radjai, F., Saint-Cyr, B., Delenne, J.Y., Sornay, P.: Rheology of three-dimensional packings of aggregates: microstructure and effects of non-convexity. Phys. Rev. E 87(5), 052205 (2013)

Bolton, M.D.: The strength and dilatancy of sands. Geotechnique 36(1), 65–78 (1986)

Boton, M., Azema, E., Estrada, N., Radjai, F., Lizcano, A.: Quasistatic rheology and microstructural description of sheared granular materials composed of platy particles. Phys. Rev. E 87(3), 032206 (2013)

Oda, M.: Anisotropic strength of cohesionless sands. J. Geotech. Geoenviron. Eng. (ASCE) 107, 1219–1231 (1981)

Cai, Y., Yu, H., Wanatowski, D., Li, X.: Non-coaxial behavior of sand under various stress paths. J. Geotech. Eng. (ASCE) 139(8), 1381–1395 (2013)

Woo, S.I., Salgado, R.: Determination of an image point on a surface based on a \(\pi \) plane-based algorithm. Comput. Mech. 53(5), 1033–1046 (2014)

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

-

\(\hbox {D}_{50}\)—mean grain size/ median obtained from a particle size distribution (plot between cumulative percentage finer and particle size where the particle size corresponding to 50% finer).

-

\(\hbox {C}_{\mathrm{u}}\)—uniformity coefficient which is nothing but the ratio between D60 (particle size corresponding to 60% finer obtained from the grain size distribution plot) to D10 (particle size corresponding to 10% finer obtained from the grain size distribution plot). \(C_u=\frac{D_{60}}{D_{10}}\)

-

\(\hbox {C}_{\mathrm{c}}\)—coefficient of curvature. \(C_u=\frac{D_{30}^{2}}{D_{60} D_{10}}\) (D30—particle size corresponding to 30% finer obtained from a grain size distribution plot).

-

Void ratio (e) is the ratio of volume of voids to the volume of solids.

-

Porosity (n) is the ratio of volume of voids to the total volume.

-

Packing fraction \(\chi =\frac{1}{1+e}\).

Sayao and vaid [50]—Criteria put forth to fix the specimen dimensions so as to minimize non-uniformities.

The specimen geometry is fixed such that the stress distribution across the wall is kept as uniform as possible i.e. the stress difference between real and calculated values should be minimized. In order to fix the dimensions of the hollow cylinder specimen, extensive numerical studies have been carried out using both elastic and plastic formulations to arrive at various sample dimensions.

The criterion proposed by Sayao and Vaid [50] in fixing the specimen geometry is given below:

-

1.

Inner radius: \(0.65\le \frac{r_{i}}{r_{o}}\le 0.82\)

-

2.

Height: \(1.8\le \frac{H}{2r_{o}}\le 2.2\)

-

3.

Wall thickness: \(r_{o}-r_{i}\) = 20 to 60 mm

where \(\hbox {r}_{\mathrm{i}}\)—internal radii of the specimen (mm), \(\hbox {r}_{\mathrm{o}}\)—external radii of the specimen (mm), H is the height of the specimen (mm). The above criteria can be used when the sand specimen volume is sufficiently large compared to the volume change during shearing, the density is uniform across the wall and the wall thickness should be large compared to the maximum grain size so that the failure mechanism would not be constrained.

Pressure ratio at the end of each test:

Equations:

\(\hbox {u}_{\mathrm{o}}\) is the external radial displacement, \(\hbox {u}_{\mathrm{i}}\) is the internal radial displacement, \(\upvarepsilon _{\mathrm{z}}\) is the axial strain, \(\upvarepsilon _{\mathrm{r}}\) is the radial strain, \(\upvarepsilon _{\uptheta }\) is the circumferential strain, \(\upgamma _{\uptheta \mathrm{z}}\) is the shear strain, \(\upbeta \) is the rotation angle, H is the initial height of the specimen, \(\Delta \hbox {H}\) is the change in axial displacement, p\(^{\prime }\) is the mean effective stress, q is the three dimensional form of deviatoric stress, \(\hbox {J}_{2}\) is the second deviatoric stress, invariant, \(\hbox {J}_{3}\) is the third deviatoric stress invariant, \(\uptau _{\mathrm{oct}}\) is the octahedral shear stress, \(\upgamma _\mathrm{oct}\) is the octahedral shear strain, \(\hbox {e}_{\max }\)—maximum void ratio the material can achieve, \(\hbox {e}_{\min }\)—minimum void ratio the material can achieve, \(\hbox {e}_{\mathrm{nat}}\)—void ratio at which the specimen is prepared, \(\varepsilon _v\)—volumetric strain and \(\varepsilon _q\)—deviatoric strain.

Rights and permissions

About this article

Cite this article

Kandasami, R.K., Murthy, T.G. Manifestation of particle morphology on the mechanical behaviour of granular ensembles. Granular Matter 19, 21 (2017). https://doi.org/10.1007/s10035-017-0703-z

Received:

Published:

DOI: https://doi.org/10.1007/s10035-017-0703-z