Abstract

Improving novel and efficient biosensors for determining organic/inorganic compounds is a challenge in analytical chemistry for clinical diagnosis and research in biomedical sciences. Electrochemical enzyme-based biosensors are one of the commercially successful groups of biosensors that make them highly appealing because of their low cost, high selectivity, and sensitivity. Core/shell nanoparticles have emerged as versatile platforms for developing enzyme-based electrochemical biosensors due to their unique physicochemical properties and tunable surface characteristics. This study provides a comprehensive review of recent trends and advancements in the utilization of core/shell nanoparticles for the development of enzyme-based electrochemical biosensors. Moreover, a statistical evaluation of the studies carried out in this field between 2007 and 2023 is made according to the preferred electrochemical techniques. The recent applications of core/shell nanoparticles in enzyme-based electrochemical biosensors were summarized to quantify environmental pollutants, food contaminants, and clinical biomarkers. Additionally, the review highlights recent innovations and strategies to improve the performance of enzyme-based electrochemical biosensors using core/shell nanoparticles. These include the integration of nanomaterials with specific functions such as hydrophilic character, chemical and thermal stability, conductivity, biocompatibility, and catalytic activity, as well as the development of new hybrid nanostructures and multifunctional nanocomposites.

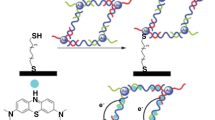

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nowadays, it is well known that nanoscale materials have much more functional, superior, and novel properties than bulk forms. In recent years, nanoparticles became the focus of attention of researchers when it was discovered that the transition from microscale to nanoscale resulted in such drastic changes in material properties. From this point of view, nanotechnology is making tremendous progress in different branches, such as energy storage, sensing, and nanomedicine. The advancement of nanotechnology has led to various nanostructured material forms with different morphology, shape, composition, and surface charge. Nanoparticles consist of a single skeleton, but as the name implies, core/shell materials contain different structures [1].

We know that in recent years, the interest in core/shell materials has increased due to the numerous advantages and various usage areas (Fig. 1).

The most important point that distinguishes these materials from basic nanoparticles is that their functionality increases tremendously because they are multilayered. They are preferred in biomedical and sensor applications due to their hydrophilic character, high surface energies, chemical stability, thermal stability, and bio-compatible nature [2]. These structures may have different shapes (hexagon, cube, disk, tube, rod, wire, prism, and octahedron) depending on the synthesis technique and chemical precursors [1]. The effect of nanoparticles in applications is not only dependent on size but also related to shape. Moreover, the catalytic effect, optical properties, selectivity, and electronic surface properties are directly related to the shape. Therefore, the synthesis design of core/shell nanoparticles seriously determines their role in applications. In this context, it is critical to elucidate the structures of synthesized core/shell nanoparticles through various characterization techniques. In addition, the synergetic interaction of the core and shell material is very important in terms of determining the catalytic/electrocatalytic effect mechanism [3]. There are essential factors that determine the synergetic effect: the ligand effect due to the atomic environment affecting the charge, the surface adsorption properties due to the presence of different atomic groups, and the geometric effect caused by the difference in the reactivity of the surface atoms [4].

In its broadest sense, the term “Biosensor” describes a promising and innovative analytical system that includes a wide range of biological sensing elements such as drug analysis, bio-detection, bioengineering, environmental monitoring, military, and security [5]. Biosensors are classified based on biorecognition elements (enzyme, antibody, oligonucleotide, etc.) and transducer (electrochemical, optical, piezoelectric, thermometric). Biosensors have biological recognition surfaces such as enzymes, proteins, DNA, and cells and are analytical devices that can directly convert a biological response into an electrical signal and monitor this signal [6]. Compared to traditional analytical methods, electrochemical biosensors have important advantages such as portability, simplicity, low cost, and eco-friendliness. Real-time or nearly real-time monitoring can be made possible via biosensors, which eliminates the need for repeated sample and laboratory analysis. In terms of consumables and materials used for sample collection, this may result in less waste being produced. Also, biosensors frequently require little energy inputs to function, especially when compared to typical laboratory approaches. This can lead to decreased overall energy use and less environmental impact. The enzyme-based electrochemical biosensors are the ones that attract the most attention from researchers. The first biosensor was developed by Clark and Lyons (1962) as a glucose oxidase biosensor to detect glucose in biological samples [5]. Glucose oxidase biosensors are widely popular in hospitals and diagnostic clinics, as regular monitoring of their blood sugar is essential for chronic diabetic patients. The main advantage biosensors provide in the medical industry is the ability to perform rapid extended analysis at a significantly lower cost per sample [7]. The immobilization of the enzyme on the electrode surface is critical in enzyme-based biosensors and affects the biosensor’s detection performance. Depending on the type of working electrode and enzyme used, the immobilization technique varies. Apart from all these, some critical parameters limit enzyme-based biosensors. These parameters are low enzyme stability, biocompatibility, selectivity, and reproducibility. Moreover, enzyme stability highly depends on environmental factors such as pH, temperature, and humidity [8]. Therefore, developing surface modification strategies to overcome these limitations has become imperative. Enzyme stability is improved by increasing the sensitivity of the electrode surface, mainly through functional nanoparticles. The sensitivity of an electrode surface refers to its ability to detect and respond to changes in the concentration of analytes or target molecules in a sample. Sensitivity is crucial for accurate detection and quantification of the analyte of interest. Among the core/shell nanoparticle types, the preference for magnetic ones as surface modification material provided the control of the enzyme immobilization process and increased the surface sensitivity [9]. When the modification strategies developed in recent years are examined, it is seen that the use of core/shell nanoparticles has increased, and studies on the development of these materials have accelerated. In addition, other non-negligible advantages of core/shell nanoparticles: (i) Due to the structure of the stable shell, it prevents the core nanomaterials from undergoing chemical/physical changes; (ii) The shell not only effectively improves the surface conductivity and surface activity, stability, and dispersion of core nanomaterials, but also provides special optic, electromagnetic, and electrocatalytic performances to the intrinsic ones through surface coating [10]. However, the role of core/shell nanoparticles in enzyme-based biosensor applications is still not fully elucidated. This situation creates a big gap in the literature and is the biggest challenge in front of future studies. In this context, the structural properties, effects, and functionality of core/shell nanoparticles in terms of both core and shell should be examined in depth.

Therefore, it is important to determine the distribution of the number of studies carried out in this field by year and the trend of research groups. When the distribution of publications on core/shell nanoparticles in enzyme-based biosensor applications between 2007 and 2023 is examined, a tendency to increase in the number of publications in this field has been observed, especially in the last 2 years (Fig. 2). Since 2007, the structures of core/shell materials have been better characterized, and their performance as modification materials has been evaluated in more detail. When the reviews in the literature [11]were evaluated, it was determined that only glucose biosensors were emphasized, and the role of core/shell nanoparticles in the electrochemical detection of different substances was not included. Focusing only on magnetic core/shell nanoparticles in the study is insufficient in terms of elucidating the modification properties of other important core/shell nanoparticles. On the other hand, Liu et al.’s study [11]was conducted in 2015 and does not include current studies. In a study conducted by Zhai et al., they focused only on the detection of mycotoxins found in foods [12]. In another study in the literature[13], only Core–shell structured molecular imprinted materials were focused on, and their effects on all biosensors were discussed in general. In this regard, the main objectives of this review are listed as follows:

-

It is a detailed examination of the performance of core/shell-based enzymatic biosensors developed in recent years, especially in biological samples, regardless of analyte.

-

In-depth examination of the properties of core/shell nanoparticles preferred by researchers in electrochemical enzyme-based biosensor applications and the recommendation of different modification combinations.

-

Suggesting and discussing new modification strategies according to the electrode types used in electrochemical applications.

-

The advantages and limiting factors of core/shell nanoparticles in enzymatic biosensors are discussed.

-

The effect mechanism of core and shell materials on enzymatic biosensors is evaluated separately.

-

Information about the synthesis of core/shell nanoparticles is given.

In this study, we focused on the role of core/shell nanoparticles in enzyme-based biosensor applications, the mechanism of these nanoparticles, and the research carried out in recent years.

Enzyme-based electrochemical biosensors and properties

Biosensors can be classified as catalytic or affinity systems, depending on the conferring principle of biological selectivity. The enzymes, any cell organelle, or tissue slice showing catalytic activity can be conducted as a biorecognition part in the class of catalytic biosensors [14]. Enzymes, large protein molecules, are macromolecules that catalyze a chemical reaction and do not undergo any changes at the end of the reaction. Using these highly specific structures as a part of the biosensor system means their properties are transferred to the system. The most important of these properties is their high selectivity towards their substrate. Enzymes are used as a biocomponent element in enzyme-based electrochemical biosensors. An enzyme-based biosensor system immobilized on the transducer surface will only be able to receive a signal in the presence of a suitable substrate. The basic principle of amperometric (A) enzyme biosensors is that the analyte undergoes a catalytic reaction by yielding products. The transducer determines the concentration of these products, which is proportional to the analyte concentration [15]. Enzyme biosensors are classified into three main classes: (i) first-generation biosensors, (ii) second-generation biosensors, and (iii) third-generation biosensors based on the electron transfer method [16]. The first-generation biosensors, also called mediatorless A biosensors, measure the concentration of analytes or products of a reaction. These biosensors rely on oxidases and dehydrogenase enzymes, which need coenzymes such as NADH and FADH throughout the catalysis [16]. For example, the glucose oxidase enzyme oxidizes glucose in the presence of oxygen and converts it to gluconolactone by producing hydrogen peroxide and water as a product. In the continuation of the reaction, gluconic acid is formed. GOx needs a redox cofactor called flavin adenine dinucleotide (FAD+) to carry out the oxidation process is an electron acceptor that is reduced to FADH2 by redox reactions [17]. The reaction that produced H2O2 using oxygen regenerates FAD+ at the anode, which can measure the electron transferred proportionally to the production of H2O2, hence the amount of glucose present in the blood. The corrections for matrix effects related to interference are often necessary for this type of biosensor [17]. In the second-generation biosensors, also called mediator A biosensors, redox mediators such as ferrocene, ferricyanide, and methylene blue are used as an electron acceptor by replacing oxygen [16]. This approach makes this biosensor possible to work at low potentials. However, these biosensor types are less commonly used than the first-generation due to their low stability because of the immobilized mediators.

The third-generation biosensors consist of the enzyme, redox polymer, and electrode. This biosensor can exchange electrons between the enzymes and the electrode without a mediator. The lack of need for mediators in this type of glucose biosensor has increased selectivity [16]. Enzyme biosensors are commercially successful bioanalytical devices that display high sensitivity and selectivity. In the market, approximately 85% of biosensors are enzyme biosensors. Different modification and immobilization approaches are considered in this manuscript to develop the bioanalytical performance of enzyme biosensors, such as sensitivity, selectivity, and stability.

Immobilization techniques in brief

Enzyme immobilization is a critical feature in designing the biorecognition component of enzyme-based biosensors [18]. Enzyme immobilization and modification materials are used to improve parameters such as sensitivity, reproducibility, wide linearity range, selectivity, and short response time. For this reason, most researchers carry out intensive studies on immobilization strategies. The electrode and the preferred enzyme type should be considered in the enzyme immobilization process. Some enzyme immobilization procedures employ a variety of immobilization techniques. An enzyme can be pre-immobilized on beads via affinity, adsorption, or covalent bonding before being retained in a porous polymer [18]. Well-known immobilization techniques include electrostatic interactions, physical adsorption, layer-by-layer deposition, electrochemical doping, pre-immobilization on ion-exchanger beads, cross-linking, covalent immobilization, chemisorption, encapsulation, entrapment, and affinity, respectively [19]. The advantage of immobilization techniques based on adsorption is that they do not contain any steps that disrupt enzyme activity or active site and are straightforward to apply. Therefore, they are more in demand from researchers than other immobilization techniques. However, other proteins or substances can do non-specific adsorption together with enzymes. Therefore, at this point, the selectivity of the modification agent used is of great importance.

On the other hand, one of the drawbacks of this technique is the low stability of enzyme storage. This is because the enzyme binds poorly to the electrode surface depending on environmental conditions (temperature, pH, and humidity). Another popular technique for enzymatic biosensors is covalent immobilization. This immobilization technique is chemical-based and consists of a surface binding procedure by the functional groups contained in biocatalysts. First, the surface is activated with reagents such as carbodiimide or glutaraldehyde so that enzymes can bind to the solid support, followed by enzyme binding to the activated support and removing excess/unbound biomolecules. The most significant advantage of the covalent immobilization technique is that it does not damage the enzyme activity and the active site, as in the adsorption-based technique. However, the drawback of this technique is that it causes the enzyme activity to decrease by changing the conformation of the enzyme and affecting the active site of the enzyme. The enzyme immobilization strategy is a critical process that directly affects biosensor efficiency. In this respect, modification strategies developed through core/shell nanoparticles gain significant importance. For instance, Au shell structures are known to be effective in preventing the loss of enzyme molecules. In addition, when the core is made of Au nanoparticles, it has been discovered that the core material facilitates an electrical connection between the enzyme redox regions and the electrode [15]. At this point, it is thought that the design of core and shell materials, considering their specific properties and their use as a biosensor platform, will contribute significantly.

Overview of core/shell nanomaterials

In recent years, groundbreaking research and rapid advances in nanotechnology have expanded the applications of nanomaterials. With the clarification of the physicochemical properties of these enormous materials, they are now preferred, especially in electrochemical biosensor applications. Moreover, researchers have begun approaching traditional nanomaterials from a new perspective in the last few years. Thus, nanomaterials, including noble metals, which generally act as active catalytic components, can now be synthesized easily and quickly with well-defined sizes, crystal surfaces, shapes, skeletons, and composition [4]. The ability to control the critical properties of nanomaterials to this extent is desirable in many applications in chemistry. Also, it creates a potential for sustainable and green chemical processes. In general terms, core/shell nanoparticles are composites formed with inner layer material (core) and outer layer material (shell), both at the nanoscale [20]. Traditionally, core/shell nanomaterials consist of multilayer and concentric semiconductor materials in connection with the historical development of research. However, the definition of core/shell nanomaterials can be expanded depending on the coating of different boundary materials (either completely or partially) or different inner components. Therefore, core/shell nanostructures can be classified into many classes based on the chemical types and properties of the two components: organic/inorganic, organic/organic, inorganic/inorganic, inorganic/organic, and types [4]. As interest in task-specific core/shell nanostructures increases, component diversity is increasing day by day, and this classification is expanding. For example, in the classification proposed by Gawande et al. [4], materials were classified as hollow core/shell, core-multi shell, and core-porous shell according to their shell structures (Fig. 3).

Classification of core/shell nanoparticles according to different morphologies. A core/shell NPs, B core double-shell particles or core multi-shell NPs, C polyhedral core/shell NPs, D core porous-shell NPs, E hollow-core/shell NPs or single-shell NPs, F hollow-core double-shell NPs, G moveable-core/shell NPs, H multi-core/shell NPs, M irregular shape core/shell NPs, N rod core/shell NPs. Reprinted from Ref [21]. with permission from Wiley

Synthesis of core/shell materials

Core/shell nanoparticle synthesis requires a variety of advanced processes, each precisely intended for producing exact structures with specialized attributes suited for a wide range of applications across multiple disciplines. Seed-mediated growth is currently one of the most preferred important techniques [22]. Within the framework of this technique, nanoparticles that function as seeds or cores offer nucleation sites to control the deposition of shell ingredients [22]. The fabrication of well-defined core nanoparticles is normally the first step in the synthesis process. This is then followed by the introduction of precursor molecules to produce the shell material [23]. Researchers can precisely regulate the growth of the shell layer by carefully altering reaction parameters such as precursor concentrations, reaction temperature, and duration. This allows them to produce core/shell nanoparticles that are homogeneous in size, shape, and composition. This technique provides an outstanding degree of adaptability since it enables the insertion of a wide variety of materials into the core and shell. These materials include metals, metal oxides, semiconductors, and polymers, among others [24]. Furthermore, the sequential layer-by-layer deposition technique offers an alternative method for producing core–shell nanoparticles. This approach involves depositing consecutive layers of complementary functional groups or materials onto the core material using electrostatic interactions, hydrogen bonding, or other specialized chemical interactions. By carefully selecting the materials for each layer and managing the deposition process, researchers may precisely adjust the shell’s thickness, composition, and usefulness. Layer-by-layer deposition enables the creation of multifunctional core/shell nanoparticles for a wide range of applications, including catalysis, sensing, drug administration, and biomedical imaging [24, 25]. Chemical vapor deposition (CVD) is another effective method of creating core/shell nanoparticles. In CVD, precursor gases are injected into a reaction chamber and chemically react to deposit thin films on the surfaces of core nanoparticles scattered over substrates. The primary advantage of CVD is its ability to provide exact control over shell thickness, composition, and crystallinity by altering precursor flow rates, temperature, pressure, and reaction time. This allows for the creation of well-defined core/shell structures with specialized characteristics appropriate for specific applications. Furthermore, CVD is scalable and reproducible, making it a viable option for large-scale synthesis of core/shell nanoparticles for industrial applications[4, 26]. Emulsion polymerization serves as an additional flexible methodology in the synthesis of core/shell nanoparticles. By employing this technique, molecules of an emulsion comprising monomers, surfactants, and initiators are utilized to disperse core nanoparticles [27]. Core/shell nanoparticles are produced when a shell of polymer material envelops the core nanoparticles as polymerization continues. One notable benefit of emulsion polymerization is its capacity to generate core/shell nanoparticles, wherein the shell thickness, composition, and morphology can be precisely manipulated [28]. Moreover, this approach provides adaptability in terms of integrating diverse biomolecules or functional groups into the shell, thereby enabling the fabrication of core/shell nanoparticles with multiple functions for biomedical purposes [29, 30]. The sol–gel technique presents an additional flexible pathway for the synthesis of core/shell nanoparticles. Precursor molecules encounter hydrolysis and condensation reactions in this procedure to generate a sol or gel encircling the core nanoparticles. The sol or gel undergoes further solidification due to thermal treatment or aging, which results in the development of a shell encircling the core nanoparticles. The ability to produce core–shell nanoparticles with a significant degree of control over shell thickness, composition, and porosity is the primary benefit of the sol–gel method. Moreover, this approach provides adaptability in integrating diverse dopants or functional groups into the shell, thereby enabling the fabrication of core–shell nanoparticles that possess customized characteristics to suit applications [31,32,33,34].

Recent developments and applications

In the table showing the electrochemical studies carried out in the last years, there has been an increase in studies conducted with the core/shell. The table shows that the most preferred ones are the A method for enzyme-based electrochemical techniques, GOx for enzymes, glucose for the analyte, iron, gold (Au), and silicon dioxide-containing materials for core/shell modification agent, physical adsorption for immobilization technique, and GCE for working electrode and aqueous solutions in applications. Although many techniques are used within the literature, many other practical methods are used, such as enzymes, core/shell modification materials, immobilization techniques, working electrodes, and applications. Therefore, this method can be applied in many areas easily. Additionally, these methods provide a very low limit of detection. The reason for this and increased electrical conductivity is that surface modification can enhance sensitivity and selectivity.

The biosensor designed by Farshchi et al. [35]for monitoring miRNA-21 that graphene quantum dots (GQD) were prepared on conductive nano-ink using Ag@Au core/shell nanoparticles electrodeposited, and caspase enzyme immobilized on the modified surface. The chronoamperometric (CA) method was preferred as the electrochemical technique for detection. The surface area of this nano-ink is excellent for immobilizing biomarkers. The created paper-based biosensor exhibits excellent stability and sensitivity in addition to being incredibly compact and inexpensive. Moreover, it is a paper-based biosensor; therefore, it is cheap and has high sensitivity and stability. Under optimal conditions, the linearity range was found to be between 5 pM and 5 mM, while the detection limit was found to be 5 pM. It was concluded that the biosensor maintained its performance for 48 h thanks to the Ag@Au core/shell nanoparticles prepared in the study.

In this study, Xie et al. [36] synthesized nanosheet-based titania microspheres with a hollow core/shell structure (Fig. 4) and coupled them to GCE with the help of Nafion to produce a mediator-free biosensor. This material can provide biological compatibility, high conductivity compared to other similar materials, and an eco-friendly and chemically and thermally stable medium for the immobilization of enzymes. The hollow core/shell structure is not found at TiO2-1, TiO2-6, and D-TiO2-48. Despite these, the hollow core/shell structure is found at the TiO2-48-based biosensor, which has a more comprehensive linear range. TiO2 has pores like “trumpet” shaped between the nanolayers, which are found wider outside the shell. This structure directs the adsorbed that can be immobilized enzymes to inside the core of the microsphere. Furthermore, TiO2 increases the strength of the enzyme to leak throughout a reaction with the substrate. The substrate can easily reach the immobilized enzyme inside the hollow core/shell structure. The substrate and enzyme concentration in this narrow region increases the opportunity for interaction. Nanolayer-based TiO2 microspheres with hollow core/shell structures can be available to effectively retain other redox-active proteins. These structures have broad applications such as bioelectronics, biosensors, biomedical devices, and biocatalysis. According to spectroscopic and electrochemical analyses, TiO2 microspheres provide good enzyme stability and bioactivity by acting as an immobilization support that is biocompatible with enzymes. The resulting biosensor demonstrated good performance for the detection of H2O2, with both a low detection limit of 0.05 µM and a large linear range of 0.4–140 µM. This is due to the nanosheet-based hollow core/shell structure of the TiO2 micro-spheres, which facilitates the direct electron transfer of HRP.

SEM and TEM (additions) images of the calcined TiO2 microspheres after observing with different hydrothermal reaction times: 1 h (a), 3 h (b), 6 h (c), 12 h (d), 48 h (e), and 96 h (f). Reprinted from Ref. [36] with permission from Elsevier

In the study of Villalonga et al. [37], a disposable A biosensor was made for quantification and rapid detection of Brettanomyces bruxellensis (Brett) in red wine. The core/shell structure was modified with Fe3O4 and SiO2 superparamagnetic nanoparticles on SPE, and Con A was immobilized to the surface by covalent bonding. These sensors also applied to real wine samples, demonstrated great performance in terms of linear response range, repeatability, selectivity, stability, and detection limit. It has been indicated in this study that proper functionalization of nanoparticles combined with the use of disposable electrodes can be important in preparing disposable, susceptible, reliable, and electrochemical devices for microbial analysis of food. At the end of this study, a linear range of 10–106 CFU/mL, and a limit of detection of 5 CFU/mL was found, respectively.

In the study of Cui et al.[38], GCE was modified to the core/shell structure, which formed with Au nanorods (AuNRs) and mesoporous SiO2 (MS). By combining the suspension of AuNRs@MS core/shell nanoparticles with TiO2 precursor solution immediately before being cast on the electrode for gelation, the nanoparticle suspension was doped in mesoporous TiO2-CS hydrogel. The TiO2-CS hydrogel has a uniform distribution of AuNRs@MS nanoparticles throughout. The electro-conductivity of the TiO2-CS hydrogel and the electrocatalytic activity of the AChE immobilized CS/TiO2-CS matrix is markedly increased upon doping AuNRs@MS nanoparticles. In addition, AChE was immobilized by physical adsorption for the detection of pesticides by the electrochemical impedance spectroscopy (EIS) method. As a result, this biosensor demonstrated high reproducibility and accuracy in detecting pesticide-added vegetable juice samples. Therefore, the developed AChE biosensor can be shown as a method that can be an important application for the detection of pesticides with high reliability, simplicity, and speed. As a result of this study, the linearity range was found to be between 0.018 and 13.6 μM, while the limit of detection was found to be 5.3 nM.

In this study by Li et al.[39], the Fe3O4@SiO2@vmSiO2 microsphere modified on GCE for the detection of dopamine was attached to the surface and stabilized by a covalent bond. The laccase was then immobilized to this modified surface. Detection was made by the EIS method. Fe3O4@SiO2@vmSiO2 microspheres show a well-defined core/shell structure with high magnetization, regular microchannel, and lamellar spacing. This developed sensor exhibited excellent selectivity and detection performance. The results of this method, which was used for the detection of dopamine in an aqueous solution, showed a linearity range between 1.5 and 75 µmol L−1, while the detection limit was found to be 0.177 µmol L−1, which proves that very small-scale measurement could be made.

In the study of Nguyet et al. [40], a new biosensor was made by using diamine oxidase immobilized with the help of covalent binding on CeO2-NR@Ppy nanocomposite with [Fe (CN)6]3−/4− redox probe to be used in Salmonella detection. Measurements were made using the EIS method. It was found that using this prepared DNA biosensor in Salmonella screening saves time and reduces costs and can be widely used as a powerful tool for food analysis and diagnostic application for Salmonella screening. In this study, the linearity range of the DNA biosensor tested in an aqueous solution was between 0.01 and 0.4 nM, while the limit of detection was found as 0.28 nM.

To meet the urgent requirements of practical application in blood sugar, a biosensor with real-time, portable, ultra-high sensitivity and selective biosensing is required. In this study by Yang et al.[41], 3D AgNCs@PB core/shell material was modified on an SPE (Fig. 5). The determination was made by the CA electrochemical method. Glucose is immobilized on this core/shell material by cross-linking. This chip makes glucose measurement approximately four times more sensitive than other SPE electrodes and has great anti-interference features. In this study performed on a rabbit serum sample, the linearity range was found between 0.01 and 1.3 mM, and the detection limit was 0.005 mM.

A Schematic illustration of the flexible chip based on AgNCs@PB nanocomposites fabricated process. B Schematic illustration of the testing mechanism of the flexible chip. Reprinted from Ref [41] with permission from Elsevier

In this study by Ma et al. [42], the core/shell structured PtPd@NCS nanocomposite was modified on 3DGNE, and then AChE was immobilized with covalent binding. This biosensor was tested, and its scale of detection for parathion methyl, chlorpyrifos, and malathion in potato, corn, and grain samples was determined. The electrochemical method used in this study was amperometry. The developed biosensor exhibited high selectivity, reproducibility, and stability. It also exhibited acceptable recovery when applied to real samples and showed excellent potential in creating biosensors to detect organophosphate pesticides and other analytes. Linearity ranged from 1 × 10–14 to 1 × 10−10 M, and 1 × 10−9 to 1 × 10−5 M, and the limit of detection was 7.9 × 10–15 M for malathion; linearity ranged from 1 × 10–13 to 1 × 10−6 M and the limit of detection 7.1 × 10–14 M chlorpyrifos; and for parathion methyl, linearity ranged between 1 × 10–14 and 1 × 10–11 M, and between 1 × 10−10 and 1 × 10−5 M, and detection limits were at 8.6 × 10–15 M.

In this study by Butmee et al. [43], for the detection of carcinoembryonic antigen (CEA), SPCE was modified with GNP-MnO2 core/shell Fe3O4@Au nanoparticles on the working electrode (Fig. 6). Upon this modification, anti-CEA was immobilized by covalent bonding. Measurements were taken by LSV and EIS electrochemical methods with the help of a redox probe prepared with 0.1 M phosphate buffer solution containing 5 mM [Fe (CN)6]3−/4−. The applicability of this prepared immunosensor was verified by applying it to a diluted human serum with the electrochemiluminescence (ECL) method. The results proved that accurate results could be obtained in real sample analysis. It can also be a new diagnostic platform with acceptable accuracy and precision, with high sensitivity and portability at low cost. As a result of the measurements, the linearity range was found between 0.001 and 100 ng/mL, while the detection limit was found to be 0.10 pg/mL for LSV and 0.30 pg/mL for EIS.

A The electrode holder set-up and SPCE, (B) schematic demonstration of the electrochemical sensor fabrication steps for detection of CEA.4P. Reprinted from Ref. [43]with permission from Elsevier

In this study by Keerthi et al. [44], a core/shell structure was created by using Mo NPs@f-MWCNTs on SPCE for the detection of dopamine (DA), which was examined by A technique using a redox probe of 5 mM K3[Fe (CN)6]3−/4− and 0.1 M KCl. Designed by combining the advantages of MWCNT and Mo NPs, the DA biosensor platform offers outstanding electron transferability, good electrocatalytic properties, excellent conductivity and selective and rapid reaction to DA, broad linearity range, low limit of detection, and great selectivity. Furthermore, the developed DA sensor shows good reproducibility and stability. The detection of DA has confirmed the real-time application of this developed sensor. Moreover, it was proven that this method has a very low detection scale with a 1.26 nM in the detection limit.

Role of core/shell nanomaterials in enzymatic biosensors

Core/shell materials are primarily used in enzyme-based biosensor applications due to their interesting and superior properties. Core/shell structures can exhibit many new characteristics that single nanoparticles do not have and offer much broader opportunities in electrochemical application than single nanoparticles. Primarily, the presence of the relatively stable shell can hold back internal nanomaterials that suffer from chemical/physical changes. Also, the outer shell effectively increases the conductivity, activity, stability, and differentiation of the core nanomaterial while also imparting very important properties such as electromagnetic, optical, and electrocatalytic properties to the core materials. The use of core/shell nanomaterials to immobilize and adsorb enzymes significantly affects critical parameters such as electron transfer activity and the bio-catalytic performance of enzymes [87].

When the existing studies in the literature were examined, it was determined that the characterization techniques applied for synthesizing core/shell materials were insufficient. Therefore, significant gaps have emerged in explaining the mechanism of action of such functional materials. To overcome these challenges, basic characterization techniques such as TEM/SEM and important techniques such as size distribution, EDX mapping, and core-level XPS should be utilized. It is very important to apply size distribution analysis, especially in materials where the core and shell consist of carbon [88].

For example, in a study conducted by Geng et al. [89], a series of multifunctional shape-controlled non-spherical hollow porous silica nanoparticles (HMSNs) were synthesized as drug carriers using Fe2O3 with four different morphologies such as capsule, cube, rice and rhombus, and multifunctional cap as an encapsulating shell. To elucidate the structure of the materials obtained in the study, high-resolution TEM, BET, XRD, FT-IR, size distribution, 13C NMR, and UV–Vis analyzes were used. Thanks to the high-resolution TEM images, it was determined that the outer silica shell contains a relatively regular vertical porous channel due to the CTAB structure orientation effect.

In a study by Li et al. [90], the illumination of the core/shell structure was performed by X-ray free electron lasers (XFELs) analysis, which is used to determine the structures of non-crystalline single molecules or nanoparticles from coherent diffractive imaging data. In the study, Au–Pd core/shell particle (Fig. 7) was used as a model system to study XFEL scattering patterns.

a Scanning/transmission electron microscopy analysis results for Au–Pd core/shell material, b schematic representation, c image of a single nanoparticle. Reprinted from Ref. [90] with permission from Nature.

It is critical to assess the properties of the core and shell independently to understand the effects of these materials on biosensing processes. Figure 8 shows the statistical grouping of core and shell components preferred in enzyme-based biosensor applications. The results show that Fe3O4, Au, Ag, and Pd are mainly used as core material types, while SiO2, Au, CHIT, and CdS are used as shell material types.

Role of the core in enzymatic biosensors

At this point, it should not be forgotten that the morphology of the carbon material is an element that determines the core function. Hollow carbon spheres are particularly interesting in hollow nano/microstructure materials due to their unique structure, low density, large surface area, thermal resistance, and electronic properties. For example, in a study conducted by He et al. in 2018, hollow carbon spheres coated with needle-like polyaniline (HCS@PANI) were used [91]. Figure 9 shows TEM images of the nanocomposite. The achievement of the HCS@PANI nanostructure, the advantage of the hollow nanostructure, amino efficiency, and improved electrochemical activity endowed it with a strong affinity towards AChE and resulted in a stable electrochemical inhibition biosensor capable of quantitatively detecting malathion [91].

SEM (a, c) and TEM (b, d) images of HCS (a, b) and HCS@PANI (c, d) nanocomposites. Reprinted from Ref. [91] with permission from Elsevier

On the other hand, in the literature, some studies [54] suggest that a hollow carbon core can accelerate enzyme–substrate activation. The main reason for this may be the stability, hydrophilicity, and biocompatibility features of hollow core structures.

In addition, Li et al. [53] examined the advantages of the spherical structure. In general, Au nanoparticle/PANI hybrid composites are mostly prepared by random doping or embedding of Au nanoparticles into conductive polyaniline film. However, this study indicates that Au/polyaniline core/shell materials provide far superior properties and advantages in enzyme-based biosensor research. In particular, it was predicted that the spherical structured Au core component could facilitate the electrical contact of the enzyme redox sites with the electrode [53].

In many studies, it has been concluded that Au nanoparticles should be used together with magnetic nanoparticles. Because the magnetic nanoparticles can be easily separated from the liquid phase by a magnet and immediately redispersed with the removed magnet, this makes it possible to carry out the modification and hybridization process away from the electrode surface, greatly helping to avoid non-specific adsorption in the sensor. In addition, cores formed from Au-magnetic nanoparticles are also effective in reducing surface oxidation [52].

Semiconductor-core/shell nanostructures are considered one of the most suitable methods for charge separation. They are synthesized by combining two or more semiconductors with a suitable lattice pairing between them. Among them, CdTe-CdS is an interesting core/shell quantum dot with ultra-fast charge carrier and charge transfer capability. Especially in glucose detection, the synergetic electrocatalytic effect and electron transfer efficiency of this material draw attention [48].

It should be noted that in enzyme-based biosensor studies, alternative core structures such as graphene or quantum dots are waiting to be discovered. For instance, in a study conducted by Paimard et al. [92], the preference for honey as the core showed an increase in adhesion on the nanofibers on the electrode surface. Honey is preferred for producing electrospinning nanofibers due to its antimicrobial, anti-inflammatory, and antioxidant properties along with various polymers [92].

Role of the shell in enzymatic biosensors

A vital synthesis strategy is to determine shell materials by considering critical parameters for sensor applications such as aggregation, biocompatibility, and conductivity. In addition, shell materials’ properties significantly affect core materials’ functionality. Considering that core materials are generally magnetic particles, bare magnetic particles are prone to aggregation and oxidation [11]. It is an effective way to synthesize magnetic nanoparticles with stable and robust properties and to use shell materials to coat/decorate the magnetic core. In this respect, the tasks of the shell material can be summarized as follows: (i) The shell materials not only prevent the oxidation of O2 of the magnetic cores but also increase the stability of the magnetic core/shell nanocomposites. (ii) Shell materials can embed many functional materials with more active sites, biocompatibility, and specific recognition sites on the surface of magnetic nanoparticles. (iii) Since polymer-based shell materials contain many active groups such as carboxyl, hydroxyl, sulfo, and sulfhydryl group, they offer many active sites to magnetic nanoparticles and can improve the mechanical and optical properties of magnetic nanoparticles [11].

On the other hand, evaluating the shell materials in themselves is necessary. Compared with other shells, carbon-structured shells have higher stability in extreme conditions such as high temperature, pressure, acidic, or basic. Moreover, the outer polysaccharide shell presents various functional groups, such as carboxylic, aldehyde, and hydroxyl. The carbon structure’s high surface area catalyzes the electrochemical charge transfer acceleration in the solution environment [78].

In some studies, it is noteworthy that materials such as Ag, Au, and Pt are used as shells. Nanoparticles with a biocompatible Au shell structure are highly efficient in non-corrosive biological conditions and can be easily functionalized with Au–S chemistry. The Au shell structure is predicted to effectively improve the anti-interference ability and prevent the loss of enzyme molecules [82]. In addition, it is well known that an Ag shell increases electrical conductivity, which is strategically important in electrochemical biosensor applications [78]. Thin Pt (shell) coated on transition metal (core) exhibits significantly improved selectivity, durability, and electrocatalytic activity compared to pure Pt due to structural, electronic, and synergistic interactions between core and Shell [93].

Literature surveys show that SiO2 shell nanoparticles are used more in enzyme-based biosensor applications. For example, in a study conducted by Singh et al. in 2021, SiO2 shell materials were used [65] Furthermore, TEM analysis includes images of Ag@SiO2 composite material at different magnifications (Fig. 10). In general, it has been determined that SiO2 shells are used in enzymatic glucose determination. The main reason for this is the biocompatibility of SiO2 nanoparticles and the increasing stability of magnetic cores [11].

TEM images of the prepared Ag nanoparticles (a, b, and c) and Ag@SiO2 nanoparticles (d, e, and f) are shown in the TEM images at different magnifications. Reprinted from Ref. [65] with permission from the Royal Society of Chemistry

Shell structures can be composed of not only nanoparticle and carbon-like structures but also biological materials. For instance, in a study by He et al., bovine serum albumin was preferred as the shell material [80]. An A glucose sensor was created by immobilizing glucose oxidase (GOx) on poly (methyl methacrylate)-bovine serum albumin (PMMA-BSA) core/shell nanoparticles. The biocompatible BSA protein shell not only immobilized GOx through relatively strong physical interaction but also maintained its bioactivity and native structure, providing thermal stability at room temperature. Thus, with the effect of the shell material, it was observed that the enzyme electrode has a fast response time, low transport barrier, and high affinity for glucose with a wide linear detection range [80].

Advantages, disadvantages, and limitations of core/shell nanoparticle-based enzyme biosensors

Core/shell nanoparticles serve as protective nanocarriers for enzymes, sheltering them from harsh environmental conditions such as pH differences, temperature changes, and enzymatic degradation [94]. Core/shell nanoparticles are also known as core/shell nanocarriers [95]. Both the structural integrity and the activity of the enzyme are protected by the shell layer, which acts as a physical barrier against the interference of external influences. Core/shell nanoparticle-based biosensors have a longer shelf life than non-nanoparticle-encapsulated biosensors because they minimize enzyme degradation. This improved stability assures constant performance over time, reducing the need for regular recalibration or replacement. This explains that core/shell nanoparticles increase the stability of enzymatic biosensors. Also, core/shell nanoparticles have a large surface area relative to their volume, allowing for the immobilization of a larger concentration of enzymes [96]. This enhanced enzyme loading causes amplified signal production in response to target analytes, increasing the biosensor’s sensitivity. Moreover, core/shell nanoparticles include distinctive surface characteristics, including enhanced surface energy and specialized surface structures, that have the potential to facilitate interactions between enzymes and substrates, hence enhancing catalytic activity [97]. The increase in catalytic efficiency results in enhanced reaction kinetics and strengthened signal amplification, resulting in accelerated response times and lower detection limits. Additionally, core/shell nanoparticle production enables meticulous adjustment of their morphology, dimensions, composition, structure, and surface properties [4]. The capacity to adjust the characteristics of nanoparticles allows researchers to customize them according to specific application needs, such as optimizing the immobilization of enzymes, strengthening the affinity of substrates, or improving the selectivity of sensors. Core/shell nanoparticle-based enzymatic biosensors offer several advantages, including improved stability, sensitivity, catalytic activity, and tunability, making them better candidates than other biosensors for a wide variety of analytical and biomedical applications. However, core/shell nanoparticles have some disadvantages that limit their use. Studies aimed at detecting and overcoming these problems are very important. The preparation of core–shell nanoparticles with precise control over size, content, and surface properties can be difficult and necessitate specialized procedures [98]. This level of intricacy can make scaling and replication difficult. On the other hand, synthesis procedures of core/shell materials include equipment (hydrothermal reactors) that provide controlled temperature and pressure parameters. The use of this equipment causes some disadvantages such as high cost and non-portability. Furthermore, the characterization of these nanoparticles to assure consistency and stability can be time-consuming and expensive. In some cases, the diffusion of substrates and products to and from the active sites of enzymes immobilized on core/shell materials may be hindered by the nanoparticle matrix, which may lead to mass transfer limitations and decreased sensitivity [99]. Although core/shell nanoparticles have a high surface area-to-volume ratio, there may be restrictions to the quantity of enzymes that can be immobilized on them. This limited loading capacity can have an impact on the biosensor’s overall sensitivity and effectiveness, especially in applications that require high enzyme concentrations [100, 101]. Moreover, certain nanoparticle materials may not be biocompatible, which calls for cautious selection and surface changes to reduce toxicity hazards, especially in biological and environmental applications. As mentioned before, Au [82] and Silica [11] materials are generally known to be highly biocompatible in core/shell modification applications. However, to expand the role of core/shell materials in biosensor applications, it is important to synthesize different materials with high biocompatibility. In addition, shell nanoparticles in direct contact with the enzyme may create some disadvantages. The overall performance of the biosensor may be impacted by the presence of the nanoparticle shell, which may interfere with the enzyme’s substrate binding site or change its catalytic characteristics. For this reason, shell nanoparticle selection, design, and observation of the enzyme and its mechanism of action are very important. To overcome these constraints, continued research is needed in the areas of mass transfer characteristics, biocompatibility, interference effects mitigation, synthesis method optimization, enzyme immobilization technique improvement, and cost reduction.

Concluding remarks

The electrochemical enzyme-based biosensor with real-time, portable, ultra-high sensitivity and selective biosensing is the requirement for practical application in blood sugar, cancer biomarkers, and other organic/inorganic compounds such as pollutants and contaminants. Therefore, the improvement of electrochemical enzyme biosensors based on newly discovered nanomaterials is still growing. It will remain the significant direction for clinical diagnosis and environmental monitoring in the future. The promising core/shell nanomaterials have some advantages, including the shell materials preventing the core nanomaterials from undergoing chemical/physical changes and improving the surface conductivity, stability, and dispersion of core materials. In this review, the benefits of core/shell nanomaterials used for an enzyme-based biosensor in clinical, food, and environmental analysis were discussed. Table 1 summarizes the core–shell modification materials, immobilization technique, electrode types, electrochemical techniques, enzyme and analyte types, application area, linearity range, and LOD for the determination of H2O2, glucose, and other organic/inorganic compounds. The effects of the properties of the core and shell materials were evaluated together and separately on biosensing processes. The use of core/shell nanomaterials increases the electron transfer between the enzyme and the electrode surface, the development of circumstances of enzyme immobilization and stability, and the catalysis of electrochemical reactions. It is concluded that the GOx enzyme-based electrochemical sensors for determining glucose and iron, Au, and silicon dioxide-containing materials for core/shell modification are commonly studied in biotechnology. The modification of commonly used glassy carbon electrodes with core/shell structure has improved their sensitivity and selectivity. In the future, with the increasing demands for the development of wearable and portable sensors, more attention has been placed on micro/nano-chip devices. For this purpose, the core/shell nanomaterials for biosensors are the best candidates.

Data availability

Data will be available on request.

Abbreviations

- A:

-

Amperometric

- AChE:

-

Acetylcholinesterase

- AuE:

-

Gold electrode

- AuNRs:

-

Au nanorods

- BChE:

-

Butyrylcholinesterase

- BET:

-

Brunauer–Emmett–Teller

- BPA:

-

Bisphenol A

- Brett:

-

Brettanomyces bruxellensis

- BSA:

-

Bovine serum albumin

- C:

-

Carbon

- 13C NMR:

-

Carbon-13 nuclear magnetic resonance

- CA:

-

Chronoamperometry

- CEA:

-

Carcinoembryonic antigen

- CHIT:

-

Chitosan

- ChOx:

-

Cholesterol oxidase

- CPE:

-

Carbon paste electrode

- COF@MWCNTs:

-

Covalent organic framework@multi-walled carbon nanotubes

- Con A:

-

Concanavalin A

- CV:

-

Cyclic voltammetry

- CVD:

-

Chemical vapor deposition

- DA:

-

Dopamine

- DAO:

-

Diamine oxidase

- ECL:

-

Electrochemiluminescence

- EDX:

-

Energy dispersive X-ray

- EIS:

-

Electrochemical impedance spectroscopy

- FADH:

-

Flavin adenine dinucleotide

- FAO:

-

Fructosyl amino-acid oxidase

- FE:

-

Fabricated electrode

- FT-IR:

-

Fourier-transform infrared spectroscopy

- g-PVA:

-

Graft-poly (vinyl alcohol)

- G-AuNP:

-

Graphene-gold nanocomposite

- GCE:

-

Glass carbon electrode

- GQD:

-

Graphene quantum dots

- GOx:

-

Glucose oxidase enzyme

- HA:

-

Hyaluronic Acid

- HbA1c:

-

Glycosylated hemoglobin

- HMSNs:

-

Hollow porous silica nanoparticles

- HRP:

-

Horseradish peroxidase

- ICP:

-

Infinite coordination polymer

- ITO:

-

Indium–tin–oxide

- LOD:

-

Limit of detection

- LSV:

-

Linear sweep voltammetry

- MA:

-

Monoamine oxidase

- MGCE:

-

Magnetic glassy carbon electrode

- MHCS:

-

Mesoporous hollow carbon spheres

- MS:

-

Mesoporous silica

- MWCNTs:

-

Multiwalled carbon nanotubes

- NADH:

-

Nicotinamide adenine dinucleotide

- NCS:

-

N-doped carbon shell

- NMCMs:

-

Nitrogen-doped mesoporous carbon microcapsules

- NR:

-

Nanorod

- PANI:

-

Polyaniline

- PB:

-

Prussian blue

- PDA:

-

Poly-dopamine

- PEC:

-

Photoelectrochemical

- PbE:

-

Paper-based electrode

- PMEs:

-

Platinum microelectrodes

- PMMA:

-

Poly (methyl methacrylate)

- PDE:

-

Platinum disk electrode

- PPy:

-

Polypyrrole

- QD:

-

Quantum dots

- rGONRs:

-

Reduced graphene oxide nanoribbons

- SEM:

-

Scanning electron microscopy

- SPE:

-

Screen-printing electrode

- TB:

-

Thrombin

- TEM:

-

Transmission electron microscopy

- T4 PNK:

-

T4 polynucleotide kinase

- Tyr:

-

Tyrosinase

- XFELs:

-

X-ray free electron lasers

- XRD:

-

X-ray diffraction analysis

- ZIF-8:

-

Zeolitic imidazolate framework

- 3DGNE:

-

3D graphene network electrode

References

Ghosh Chaudhuri R, Paria S (2012) Core/shell nanoparticles: classes, properties, synthesis mechanisms, characterization, and applications. Chem Rev 112:2373–2433

Chatterjee K, Sarkar S, Jagajjanani Rao K, Paria S (2014) Core/shell nanoparticles in biomedical applications. Adv Colloid Interface Sci 209:8–39. https://doi.org/10.1016/j.cis.2013.12.008

Kalambate PK, Dhanjai HZ et al (2019) Core@shell nanomaterials based sensing devices: a review. TrAC - Trends in Analytical Chemistry 115:147–161. https://doi.org/10.1016/j.trac.2019.04.002

Gawande MB, Goswami A, Asefa T et al (2015) Core-shell nanoparticles: synthesis and applications in catalysis and electrocatalysis. Chem Soc Rev 44:7540–7590

Vigneshvar S, Sudhakumari CC, Senthilkumaran B, Prakash H (2016) Recent advances in biosensor technology for potential applications an overview. Front Bioeng Biotechnol 4:1–9. https://doi.org/10.3389/fbioe.2016.00011

Bilge S, DoganTopal B, Caglayan MG et al (2022) Human hair rich in pyridinic nitrogen-base DNA biosensor for direct electrochemical monitoring of palbociclib-DNA interaction. Bioelectrochemistry 148:108264. https://doi.org/10.1016/j.bioelechem.2022.108264

Ispas CR, Crivat G, Andreescu S (2012) Review: recent developments in enzyme-based biosensors for biomedical analysis. Anal Lett 45:168–186. https://doi.org/10.1080/00032719.2011.633188

Wang F, Ding X, Niu X et al (2020) Green preparation of core-shell Cu@Pd nanoparticles with chitosan for glucose detection. Carbohydr Polym 247:116647. https://doi.org/10.1016/j.carbpol.2020.116647

Wu S, Wang H, Tao S et al (2011) Magnetic loading of tyrosinase-Fe3O4/mesoporous silica core/shell microspheres for high sensitive electrochemical biosensing. Anal Chim Acta 686:81–86. https://doi.org/10.1016/j.aca.2010.11.053

Li Y, Huang F, Luo Z et al (2012) A new hydrogen peroxide biosensor based on synergy of Au@Au 2S 2O 3 core-shell nanomaterials and multi-walled carbon nanotubes towards hemoglobin. Electrochim Acta 74:280–286. https://doi.org/10.1016/j.electacta.2012.04.097

Liu L, Lv H, Teng Z et al (2015) Glucose sensors based on Core@Shell magnetic nanomaterials and their application in diabetes management: a review. Curr Pharm Des 21:5359–5368. https://doi.org/10.2174/1381612821666150917092528

Zhai W, Wei D, Cao M et al (2023) Biosensors based on core–shell nanoparticles for detecting mycotoxins in food: a review. Food Chem 136944. https://doi.org/10.1016/j.foodchem.2023.136944

Bhogal S, Kaur K, Malik AK et al (2020) Core-shell structured molecularly imprinted materials for sensing applications. TrAC-Trends in Analytical Chemistry 133:116043. https://doi.org/10.1016/j.trac.2020.116043

Monteiro T, Almeida MG (2019) Electrochemical enzyme biosensors revisited: old solutions for new problems. Crit Rev Anal Chem 49:44–66

Chen H, Simoska O, Lim K et al (2020) Fundamentals, applications, and future directions of bioelectrocatalysis. Chem Rev 120:12903–12993

Rocchitta G, Spanu A, Babudieri S et al (2016) Enzyme biosensors for biomedical applications: Strategies for safeguarding analytical performances in biological fluids. Sensors 16(6):780. https://doi.org/10.3390/s16060780

Sharma A, Agrawal A, Kumar S et al (2021) Zinc oxide nanostructures–based biosensors. Nanostructured Zinc Oxide: Synthesis, Properties and Applications 655–695. https://doi.org/10.1016/B978-0-12-818900-9.00002-4

Sassolas A, Blum LJ, Leca-Bouvier BD (2012) Immobilization strategies to develop enzymatic biosensors. Biotechnol Adv 30:489–511

Bravard C ° sujet : Etude géologique de la région de Saint Laurent du Pont et de la Grande Sûre-Massif de la Chartreuse 2° sujet : le quaternaire des plaines de Biévre-Valloire. 1968. PhD Thesis. Université de Grenoble.

Govender A, Olivier EJ, Haigh SJ et al (2020) Performance of a NiFe2O4@Co core-shell fischer-tropsch catalyst: effect of low-temperature reduction. ACS Omega 5:32975–32983. https://doi.org/10.1021/acsomega.0c04124

Khatami M, Alijani HQ, Sharifi I (2018) Biosynthesis of bimetallic and core-shell nanoparticles: their biomedical applications- a review. IET Nanobiotechnol 12:879–887. https://doi.org/10.1049/iet-nbt.2017.0308

Park JH, Jin S-M, Lee E, Ahn HS (2021) Electrochemical synthesis of core–shell nanoparticles by seed-mediated selective deposition. Chem Sci 12:13557–13563. https://doi.org/10.1039/D1SC03625D

He M, Ai Y, Hu W et al (2023) Recent advances of seed‐mediated growth of metal nanoparticles: from growth to applications. Adv Mater 2211915. https://doi.org/10.1002/adma.202211915

Niu W, Zhang L, Xu G (2013) Seed-mediated growth of noble metal nanocrystals: crystal growth and shape control. Nanoscale 5:3172–3181. https://doi.org/10.1039/c3nr00219e

Shenoy DB, Antipov AA, Sukhorukov GB, Möhwald H (2003) Layer-by-layer engineering of biocompatible, decomposable core−shell structures. Biomacromol 4:265–272. https://doi.org/10.1002/adma.202211915

Chen H, Zhang L, Li M, Xie G (2020) Synthesis of core–shell micro/nanoparticles and their tribological application: a review. Materials 13:4590. https://doi.org/10.3390/ma13204590

Lovell PA, Schork FJ (2020) Fundamentals of emulsion polymerization. Biomacromol 21:4396–4441. https://doi.org/10.1021/acs.biomac.0c00769

Ramli RA, Laftah WA, Hashim S (2013) Core–shell polymers: a review. RSC Adv 3:15543–15565. https://doi.org/10.1039/c3ra41296b

Dhas NL, Raval NJ, Kudarha RR et al (2018) Core–shell nanoparticles as a drug delivery platform for tumor targeting. In: Inorganic frameworks as smart nanomedicines. Elsevier, pp 387–448. https://doi.org/10.1016/b978-0-12-813661-4.00009-2

Gharieh A, Khoee S, Mahdavian AR (2019) Emulsion and miniemulsion techniques in preparation of polymer nanoparticles with versatile characteristics. Adv Colloid Interface Sci 269:152–186. https://doi.org/10.1016/j.cis.2019.04.010

Schileo G (2013) Recent developments in ceramic multiferroic composites based on core/shell and other heterostructures obtained by sol–gel routes. Prog Solid State Chem 41:87–98. https://doi.org/10.1016/j.progsolidstchem.2013.09.001

Zheng K, Boccaccini AR (2017) Sol-gel processing of bioactive glass nanoparticles: a review. Adv Colloid Interface Sci 249:363–373. https://doi.org/10.1016/j.cis.2017.03.008

Mélinon P, Begin-Colin S, Duvail JL et al (2014) Engineered inorganic core/shell nanoparticles. Phys Rep 543:163–197. https://doi.org/10.1016/j.physrep.2014.05.003

Schmidt H, Jonschker G, Goedicke S, Mennig M (2000) The sol-gel process as a basic technology for nanoparticle-dispersed inorganic-organic composites. J Solgel Sci Technol 19:39–51. https://doi.org/10.1023/A:1008706003996

Farshchi F, Saadati A, Fathi N et al (2021) Flexible paper-based label-free electrochemical biosensor for the monitoring of miRNA-21 using core-shell Ag@Au/GQD nano-ink: a new platform for the accurate and rapid analysis by low cost lab-on-paper technology. Anal Methods 13:1286–1294. https://doi.org/10.1039/d1ay00142f

Xie Q, Zhao Y, Chen X et al (2011) Nanosheet-based titania microspheres with hollow core-shell structure encapsulating horseradish peroxidase for a mediator-free biosensor. Biomaterials 32:6588–6594. https://doi.org/10.1016/j.biomaterials.2011.05.055

Villalonga ML, Borisova B, Arenas CB et al (2019) Disposable electrochemical biosensors for Brettanomyces bruxellensis and total yeast content in wine based on core-shell magnetic nanoparticles. Sens Actuators B Chem 279:15–21. https://doi.org/10.1016/j.snb.2018.09.092

Cui HF, Zhang TT, Lv QY et al (2019) An acetylcholinesterase biosensor based on doping Au nanorod@SiO2 nanoparticles into TiO2-chitosan hydrogel for detection of organophosphate pesticides. Biosens Bioelectron 141:111452. https://doi.org/10.1016/j.bios.2019.111452

Li Z, Zheng Y, Gao T et al (2018) Fabrication of biosensor based on core–shell and large void structured magnetic mesoporous microspheres immobilized with laccase for dopamine detection. J Mater Sci 53:7996–8008. https://doi.org/10.1007/s10853-018-2165-z

Nguyet NT, Yen LTH, Doan VY et al (2019) A label-free and highly sensitive DNA biosensor based on the core-shell structured CeO 2 -NR@Ppy nanocomposite for Salmonella detection. Mater Sci Eng, C 96:790–797. https://doi.org/10.1016/j.msec.2018.11.059

Yang Z, Zhang C, Zhang J, Bai W (2014) Potentiometric glucose biosensor based on core-shell Fe3O4-enzyme-polypyrrole nanoparticles. Biosens Bioelectron 51:268–273. https://doi.org/10.1016/j.bios.2013.07.054

Ma L, Zhou L, He Y et al (2018) Hierarchical nanocomposites with an N-doped carbon shell and bimetal core: novel enzyme nanocarriers for electrochemical pesticide detection. Biosens Bioelectron 121:166–173. https://doi.org/10.1016/j.bios.2018.08.038

Butmee P, Tumcharern G, Thouand G et al (2020) An ultrasensitive immunosensor based on manganese dioxide-graphene nanoplatelets and core shell Fe3O4@Au nanoparticles for label-free detection of carcinoembryonic antigen. Bioelectrochemistry 132:107452. https://doi.org/10.1016/j.bioelechem.2019.107452

Keerthi M, Boopathy G, Chen SM et al (2019) A core-shell molybdenum nanoparticles entrapped f-MWCNTs hybrid nanostructured material based non-enzymatic biosensor for electrochemical detection of dopamine neurotransmitter in biological samples. Sci Rep 9:1–12. https://doi.org/10.1038/s41598-019-48999-0

Abd El-Haleem HS, Hefnawy A, Hassan RYA et al (2016) Manganese dioxide-core-shell hyperbranched chitosan (MnO2-HBCs) nano-structured screen printed electrode for enzymatic glucose biosensors. RSC Adv 6:109185–109191. https://doi.org/10.1039/c6ra24419j

Chawla S, Pundir CS (2011) An electrochemical biosensor for fructosyl valine for glycosylated hemoglobin detection based on core-shell magnetic bionanoparticles modified gold electrode. Biosens Bioelectron 26:3438–3443. https://doi.org/10.1016/j.bios.2011.01.021

Chen S, Yuan R, Chai Y et al (2009) Amperometric hydrogen peroxide biosensor based on the immobilization of horseradish peroxidase on core-shell organosilica@chitosan nanospheres and multiwall carbon nanotubes composite. Electrochim Acta 54:3039–3046. https://doi.org/10.1016/j.electacta.2008.12.009

Gu Z, Yang S, Li Z et al (2011) An ultrasensitive electrochemical biosensor for glucose using CdTe-CdS core-shell quantum dot as ultrafast electron transfer relay between graphene-gold nanocomposite and gold nanoparticle. Electrochim Acta 56:9162–9167. https://doi.org/10.1016/j.electacta.2011.07.117

Gumpu MB, Nesakumar N, Sethuraman S et al (2014) Development of electrochemical biosensor with ceria-PANI core-shell nano-interface for the detection of histamine. Sens Actuators B Chem 199:330–338. https://doi.org/10.1016/j.snb.2014.04.009

Hu F, Chen S, Yuan R (2013) Application of magnetic core-shell microspheres on reagentless immunosensor based on direct electrochemistry of glucose oxidase for detection of carbohydrate antigen 19–9. Sens Actuators B Chem 176:713–722. https://doi.org/10.1016/j.snb.2012.08.072

Krishnan SK, Prokhorov E, Bahena D et al (2017) Chitosan-covered Pd@Pt core-shell nanocubes for direct electron transfer in electrochemical enzymatic glucose biosensor. ACS Omega 2:1896–1904. https://doi.org/10.1021/acsomega.7b00060

Li K, Lai Y, Zhang W, Jin L (2011) Fe2O3@Au core/shell nanoparticle-based electrochemical DNA biosensor for Escherichia coli detection. Talanta 84:607–613. https://doi.org/10.1016/j.talanta.2010.12.042

Li NF, Lei T, Ouyang C et al (2009) An amperometric enzyme biosensor based on in situ electrosynthesized core-shell nanoparticles. Synth Met 159:1608–1611. https://doi.org/10.1016/j.synthmet.2009.04.027

Luo R, Feng Z, Shen G et al (2018) Acetylcholinesterase biosensor based on mesoporous hollow carbon spheres/core-shell magnetic nanoparticles-modified electrode for the detection of organophosphorus pesticides. Sensors (Switzerland) 18(12):4429. https://doi.org/10.3390/s18124429

Luo X, Killard AJ, Morrin A, Smyth MR (2007) In situ electropolymerised silica-polyaniline core-shell structures: electrode modification and enzyme biosensor enhancement. Electrochim Acta 52:1865–1870. https://doi.org/10.1016/j.electacta.2006.07.051

Mani V, Govindasamy M, Chen SM et al (2017) Core-shell heterostructured multiwalled carbon nanotubes@reduced graphene oxide nanoribbons/chitosan, a robust nanobiocomposite for enzymatic biosensing of hydrogen peroxide and nitrite. Sci Rep 7:1–10. https://doi.org/10.1038/s41598-017-12050-x

Mao S, Long Y, Li W et al (2013) Core-shell structured Ag@C for direct electrochemistry and hydrogen peroxide biosensor applications. Biosens Bioelectron 48:258–262. https://doi.org/10.1016/j.bios.2013.04.026

Martín M, Salazar P, Villalonga R et al (2014) Preparation of core-shell Fe3O4@poly(dopamine) magnetic nanoparticles for biosensor construction. J Mater Chem B 2:739–746. https://doi.org/10.1039/c3tb21171a

Ming-Ju Chen, Kreuter JY-TK (1996) Nanoparticles and microparticles for drug and vaccine delivery. J Anat 189(3):503–505. https://doi.org/10.1002/bit

Ozdemir C, Akca O, Medine EI et al (2012) Biosensing applications of modified core-shell magnetic nanoparticles. Food Anal Methods 5:731–736. https://doi.org/10.1007/s12161-011-9308-z

Peng HP, Liang RP, Zhang L, Qiu JD (2013) Facile preparation of novel core-shell enzyme-Au-polydopamine-Fe3O4 magnetic bionanoparticles for glucose sensor. Biosens Bioelectron 42:293–299. https://doi.org/10.1016/j.bios.2012.10.074

Qin Z, Zhao Y, Lin L et al (2017) Core/shell microcapsules consisting of Fe3O4 microparticles coated with nitrogen-doped mesoporous carbon for voltammetric sensing of hydrogen peroxide. Microchim Acta 184:4513–4520. https://doi.org/10.1007/s00604-017-2497-4

Sanko V, Şenocak A, Oğuz Tümay S et al (2021) Core-shell hierarchical enzymatic biosensor based on hyaluronic acid capped copper ferrite nanoparticles for determination of endocrine-disrupting bisphenol A. Electroanalysis 1–13. https://doi.org/10.1002/elan.202100386

Shukla SK, Deshpande SR, Shukla SK, Tiwari A (2012) Fabrication of a tunable glucose biosensor based on zinc oxide/chitosan-graft-poly(vinyl alcohol) core-shell nanocomposite. Talanta 99:283–287. https://doi.org/10.1016/j.talanta.2012.05.052

Singh P, Katkar PK, Patil UM, Bohara RA (2021) A robust electrochemical immunosensor based on core-shell nanostructured silica-coated silver for cancer (carcinoembryonic-antigen-CEA) diagnosis. RSC Adv 11:10130–10143. https://doi.org/10.1039/d0ra09015h

Tan XC, Zhang JL, Tan SW et al (2009) Amperometric hydrogen peroxide biosensor based on immobilization of hemoglobin on a glassy carbon electrode modified with Fe3O4/chitosan core-shell microspheres. Sensors 9:6185–6199. https://doi.org/10.3390/s90806185

Tang J, Li J, Xiong P et al (2020) Rolling circle amplification promoted magneto-controlled photoelectrochemical biosensor for organophosphorus pesticides based on dissolution of core-shell MnO2 nanoflower@CdS mediated by butyrylcholinesterase. Microchim Acta 187:1–9. https://doi.org/10.1007/s00604-020-04434-0

Tarish S, Xu Y, Wang Z et al (2017) Highly ef fi cient biosensors by using well- ordered ZnO / ZnS core / shell nanotube arrays. Nanotechnology 28(40):405501. https://doi.org/10.1088/1361-6528/aa82b0

Wang AJ, Li YF, Li ZH et al (2012) Amperometric glucose sensor based on enhanced catalytic reduction of oxygen using glucose oxidase adsorbed onto core-shell Fe 3O 4@silica@Au magnetic nanoparticles. Mater Sci Eng, C 32:1640–1647. https://doi.org/10.1016/j.msec.2012.04.055

Wang L, Zeng Y, Shen A et al (2016) Facile and controllable synthesis of triplex Au@Ag-Pt@infinite coordination polymer core-shell nanoparticles for highly efficient immobilization of enzymes and enhanced electrochemical biosensing activity. RSC Adv 6:86025–86033. https://doi.org/10.1039/c6ra15293g

Xu W, Yang W, Guo H et al (2020) Constructing a TiO2/PDA core/shell nanorod array electrode as a highly sensitive and stable photoelectrochemical glucose biosensor. RSC Adv 10:10017–10022. https://doi.org/10.1039/c9ra10445c

Yan W, Feng X, Chen X et al (2008) A super highly sensitive glucose biosensor based on Au nanoparticles-AgCl@polyaniline hybrid material. Biosens Bioelectron 23:925–931. https://doi.org/10.1016/j.bios.2007.09.002

Yang P, Pang J, Hu F et al (2018) An ultrasensitive biosensing flexible chip using a novel silver@Prussian blue core-shell nanocube composite. Sens Actuators B Chem 276:31–41. https://doi.org/10.1016/j.snb.2018.08.070

Yang X, Wang Y, Liu Y, Jiang X (2013) A sensitive hydrogen peroxide and glucose biosensor based on gold/silver core-shell nanorods. Electrochim Acta 108:39–44. https://doi.org/10.1016/j.electacta.2013.06.017

Zhang Y, Zeng GM, Tang L et al (2007) A hydroquinone biosensor using modified core-shell magnetic nanoparticles supported on carbon paste electrode. Biosens Bioelectron 22:2121–2126. https://doi.org/10.1016/j.bios.2006.09.030

Zhiguo G, Shuping Y, Zaijun L et al (2011) An ultrasensitive hydrogen peroxide biosensor based on electrocatalytic synergy of graphene-gold nanocomposite, CdTe-CdS core-shell quantum dots and gold nanoparticles. Anal Chim Acta 701:75–80. https://doi.org/10.1016/j.aca.2011.06.015

Zhou X, Dai X, Li J et al (2015) A sensitive glucose biosensor based on Ag@C core-shell matrix. Mater Sci Eng, C 49:579–587. https://doi.org/10.1016/j.msec.2015.01.063

Satvekar RK, Pawar SH (2018) Multienzymatic cholesterol nanobiosensor using core–shell nanoparticles ıncorporated silica nanocomposite. J Med Biol Eng 38:735–743. https://doi.org/10.1007/s40846-017-0345-y

Lu X, Tao L, Song D et al (2018) Bimetallic Pd@Au nanorods based ultrasensitive acetylcholinesterase biosensor for determination of organophosphate pesticides. Sens Actuators B Chem 255:2575–2581. https://doi.org/10.1016/j.snb.2017.09.063

He C, Liu J, Zhang Q, Wu C (2012) A novel stable amperometric glucose biosensor based on the adsorption of glucose oxidase on poly(methyl methacrylate)-bovine serum albumin core-shell nanoparticles. Sens Actuators B Chem 166–167:802–808. https://doi.org/10.1016/j.snb.2012.03.081

Xu W, Yi H, Yuan Y et al (2015) An electrochemical aptasensor for thrombin using synergetic catalysis of enzyme and porous Au@Pd core-shell nanostructures for signal amplification. Biosens Bioelectron 64:423–428. https://doi.org/10.1016/j.bios.2014.08.091

Chen X, Zhu J, Chen Z et al (2011) A novel bienzyme glucose biosensor based on three-layer Au-Fe 3O4@SiO2 magnetic nanocomposite. Sens Actuators B Chem 159:220–228. https://doi.org/10.1016/j.snb.2011.06.076

Asadian E, Shahrokhian S, Zad AI (2016) Hierarchical core-shell structure of ZnO nanotube/MnO2 nanosheet arrays on a 3D graphene network as a high performance biosensing platform. RSC Adv 6:61190–61199. https://doi.org/10.1039/c6ra07197j

Wang X, Yang S, Shan J, Bai X (2022) Novel electrochemical acetylcholinesterase biosensor based on core-shell covalent organic framework@ multi-walled carbon nanotubes (COF@ MWCNTs) composite for detection of malathion. Int J Electrochem Sci 17:220543. https://doi.org/10.20964/2022.05.24

Beatto TG, Gomes WE, Etchegaray A et al (2023) Dopamine levels determined in synthetic urine using an electrochemical tyrosinase biosensor based on ZnO@ Au core–shell. RSC Adv 13:33424–33429. https://doi.org/10.1039/d3ra06277e

Liu Z, Tao J, Zhu Z et al (2022) A sensitive electrochemical assay for T4 polynucleotide kinase activity based on Fe3O4@ TiO2 and gold nanoparticles hybrid probe modified magnetic electrode. J Electrochem Soc 169:027504. https://doi.org/10.1149/1945-7111/ac4f6c

Shi EY, She Y, Yao JP et al (2018) Nitrogen doped graphene-core/shell CdS@TiO2 for direct electrochemistry of hemoglobin and hydrogen peroxide biosensor application. Int J Electrochem Sci 13:11225–11237. https://doi.org/10.20964/2018.11.100

Bilge S, Sınağ A (2022) TiO2/core-shell structured carbon support materials derived from hydrothermal carbonization of waste masks biomass: a green photocatalyst. Inorg Chem Commun 144:109911. https://doi.org/10.1016/j.inoche.2022.109911

Geng H, Chen W, Xu ZP et al (2017) Shape-controlled hollow mesoporous silica nanoparticles with multifunctional capping for ın vitro cancer treatment. Chem Eur J 23:10878–10885. https://doi.org/10.1002/chem.201701806

Li X, Chiu CY, Wang HJ et al (2017) Diffraction data of core-shell nanoparticles from an X-ray free electron laser. Sci Data 4(1):1–8. https://doi.org/10.1038/sdata.2017.48

He L, Cui B, Liu J et al (2018) Novel electrochemical biosensor based on core-shell nanostructured composite of hollow carbon spheres and polyaniline for sensitively detecting malathion. Sens Actuators B Chem 258:813–821. https://doi.org/10.1016/j.snb.2017.11.161

Paimard G, Shahlaei M, Moradipour P et al (2020) Impedimetric aptamer based determination of the tumor marker MUC1 by using electrospun core-shell nanofibers. Microchim Acta 187:1–10. https://doi.org/10.1007/s00604-019-3955-y

Zhao W, Jin J, Wu H et al (2017) Electrochemical hydrogen peroxide sensor based on carbon supported Cu@Pt core-shell nanoparticles. Mater Sci Eng, C 78:185–190. https://doi.org/10.1016/j.msec.2017.04.072

Ho KM, Mao X, Gu L, Li P (2008) Facile route to enzyme immobilization: core− shell nanoenzyme particles consisting of well-defined poly (methyl methacrylate) cores and cellulase shells. Langmuir 24:11036–11042. https://doi.org/10.1007/s00604-019-3955-y

Kumar R, Mondal K, Panda PK et al (2020) Core–shell nanostructures: perspectives towards drug delivery applications. J Mater Chem B 8:8992–9027

Wang J, Zhao G, Yu F (2016) Facile preparation of Fe3O4@ MOF core-shell microspheres for lipase immobilization. J Taiwan Inst Chem Eng 69:139–145. https://doi.org/10.1016/j.jtice.2016.10.004