Abstract

The core of sustainable mining is the preservation of the ground stability, and in situ stress measurement is crucial as most of the stability issues are directly associated with the in situ and induced stresses. Deformation rate analysis and acoustic emission are reliable and low-cost methods of stress measurement leveraging stress memory in rocks. However, owing to rock heterogeneity and complex geological stress history, the accurate determination of in situ stresses is often challenging. This study proposes a simple, accurate, and improved method for determining the in situ stresses in rocks called the Secant Modulus Method (SMM). The effectiveness of SMM is determined through uniaxial cyclic loading and unloading experiments on different types of soft and hard crystalline rocks. The influence of the loading modes, strain rates, and time delay is also investigated. Additionally, its utility for in situ stress measurement is explored. The SMM method proved effective in determining both applied and in-situ stresses, with no effect from variations in loading conditions, loading rates, and time delays. Moreover, the in situ stresses measured using the SMM were in good agreement with the overcoring method.

Highlights

-

A simple technique based on inelastic deformation in rocks in proposed for in situ stress measurement.

-

The technique is applied on six different types of soft and hard crystalline rocks to validate its application under various conditions.

-

The influence of the loading modes, the strain rates, and the time delay on the stress memory is presented, indicating their minimal influence on both stress memory and SMM.

-

In situ stress measurement using the proposed technique is presented, showing good correlation with the overcoring results in the same location.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Mining remains a crucial driver of industrial and economic growth and plays a substantial role in global development. The core of sustainable mining is the preservation of the ground stability. Unforeseen rock bursts, ground subsidence, and other geotechnical hazards can have catastrophic consequences for both workers and the environment. Stress measurement is a vital tool to minimize negative impacts throughout the mining cycle, from exploration to exploitation and closure. Over the last several decades, considerable efforts have been made to develop viable techniques for stress measurement (Yamamoto et al. 1990; Fairhurst 2003; Karakus, 2014, 2015; Jiang et al. 2016; Ali et al. 2021; Lin et al. 2022). However, only two methods, hydraulic fracturing and overcoring, have achieved scientific acceptance and commercial adoption worldwide. But, these methods have inherent issues in collecting reliable data at greater depths while maintaining reasonable costs (Haimson and Fairhurst 1970; Worotnicki and Walton 1976; Ali et al. 2022a). The studies by Seto et al. (1998), Villaescusa et al. (2002), Windsor et al. (2010), Lehtonen et al. (2012), Karakus et al. (2015), Bai et al. (2018), and Dinmohammadpour et al. (2022) on unconventional non-destructive techniques (NDTs), such as acoustic emission (AE) and deformation rate analysis (DRA), show that these methods are effective and have reliable accuracy. Based on rock stress memory, a phenomenon extensively researched over several decades, these approaches show considerable promise for evolving into alternative, reliable, and economically efficient means of stress measurement. However, like other methods, many researchers have questioned the viability of these methods for stress measurement. In a comprehensive literature review, Lavrov (2003) asserted that stress memory in rock is influenced by various factors, such as the duration of the applied load, the loading rates (Filimonov et al. 2001; Lavrov 2003; Chen and Irfan 2018; Chen et al. 2018), the time delay, (Jin et al. 2009; Fujii et al. 2018; Fu et al. 2021), the water saturation and heating (Yoshikawa and Mogi 1981), the rotation of the principal axis, (Stuart et al. 1993; Lavrov et al. 2002) and the coring process and tensile stresses (Sakaguchi et al. 2002; Chen and Irfan 2018). Contrary to these observations, several studies have proposed a strong correlation between the stress estimates derived from core-based methods and traditional overcoring and hydro-fracturing techniques, which provides strong grounds for further investigation of these methods (Seto et al. 1999; Villaescusa et al. 2002; Dight 2006; Lehtonen et al. 2012; Bai et al. 2018; Dight et al. 2022).

Stress memory in rocks refers to their ability to retain a record of the stress they have experienced in the past. During uniaxial compression of rocks, potential micro-cracks with strengths lower than the applied load initiate and propagate as the stress exceeds their strength (Kuwahara et al. 1990). According to Brace et al. (1966), the generated micro-fractures can be both shear and tensile, which can produce inelastic strains in the specimens in both the axial and lateral directions. Upon reloading the specimen, the generation of new cracks is minimal, and pre-existing cracks initiated in the previous cycles steadily propagate until the previously applied maximum stress is reached. This phenomenon is known as the Kaiser effect and is characterized by a surge in acoustic emission (AE) activity. Yamamoto et al. (1990) observed a change in the strain rate when the stress exceeded the previously applied maximum stress, and proposed the DRA method, which is based on the strain difference function shown in Eq. (1).

where σ is the applied stress and \(\varepsilon_{j} \left( \sigma \right)\) is the strain for the second loading cycle, \(\varepsilon_{i} \left( \sigma \right)\) is the strain for the first loading cycle and \(\Delta \varepsilon_{j,i} \left( \sigma \right)\) is calculated from the gradient of the line. The strain difference function, \(\Delta \varepsilon_{j,i} \left( \sigma \right)\) yields a characteristic curve with a sharp gradient change at the peak values of the previously applied maximum stresses as illustrated in (Fig. 1).

Given that the method relies on the strain difference between two successive cycles, the precision of strain measurement becomes paramount. Accuracy is particularly crucial because the strain difference can potentially increase the relative error. Strain measurement becomes even more critical because of the non-uniform stress/strain distribution within the rock specimen, which is attributable to rock heterogeneity and complex geological stress history. For this reason, identification of the inflection point can be problematic, with multiple bending points commonly observed in most cases. This makes pinpointing the inflection point complex and significantly reduces the precision of stress reconstruction (Hsieh et al. 2014). Therefore, it is imperative to examine these disparities and develop new identification methods for the precise measurement of applied stresses, which can be utilized for in situ stress measurement.

This paper proposes a simple approach, called the Secant Modulus Method (SMM), for measuring in situ stresses in rocks. The approach leverages inelastic strains and evaluates the difference between the loading response of the rock and the secant line derived from the stress–strain relationship. To verify the effectiveness of the proposed method, uniaxial cyclic loading and unloading tests were performed on six types of soft, medium, and hard crystalline rock. The effects of loading modes, strain rates, and time delays on the preloaded rock specimens were also investigated to examine their overall influence on the stress memory and, more specifically, on the SMM. Additionally, the method is utilized for in situ stress measurement in a mine site and the results are compared to the overcoring method applied in the same location.

2 The Proposed Secant Modulus Method

When the number of cycles on a preloaded specimen increased, the inflection point in the DRA curve was observed in the strain difference function of the first two cycles (Fig. 2a). This phenomenon occurs because no new cracks form in the subsequent cycles under the same stress level, thereby resulting in no inflection in the strain difference function of the subsequent cycles. Consequently, the strain difference function of the first cycle and every subsequent cycle exhibited a more distinct inflection point (Fig. 2b). This clearly indicates that the stress memory in the rock is associated with the first application of higher stress only; therefore, cyclic tests may not be required.

The proposed SMM is an efficient way to quantify the applied stress from the inelastic strains generated under uniaxial compression of rocks. The method simply evaluates the difference between the loading response and secant line used in the lateral strain response method (Nicksiar and Martin 2010). Like AE and DRA, the rock specimens were preloaded for a specified period to simulate in situ stresses. This is followed by uniaxial compression at higher stress levels. The strains were measured in both the axial and lateral directions using strain gauges, and the secant modulus was derived from the stress–strain curve. Using the secant modulus, strain values are obtained for the corresponding stress increments, which typically yields a straight line joining the two ends of the stress–strain curve, as demonstrated in Fig. 3. Strain difference is then calculated using the strain difference function, \(\Delta_{\varepsilon j,i} \left( \sigma \right)\) shown in Eq. (1), which results in a characteristic SMM curve with a very clear inflection point precisely at the preload levels which corresponds to the maximum strain difference.

Figure 4 shows an example of a coal and granite sample preloaded at approximately 45% and 60% of their UCS, respectively. The test was conducted at a strain rate of 10−5 s−1 and uniaxial compression was applied after a time delay of 30 min. Despite a seemingly linear stress–strain relationship, a distinct bending point in the strain difference–stress curve can be observed approximately at the applied preload levels in both specimens.

3 Experimental Setup and Methodology

3.1 Specimen Description

In this study, we examined concrete and five distinct types of rocks with varying properties ranging from soft and porous limestone, coal, and sandstone to highly crystalline hard rocks, such as Adelaide black granite and bluestone. The coal samples were bituminous and sourced from an underground mine site in NSW, Australia. The specimens were carefully sealed in plastic bags to prevent water evaporation before testing. The second rock type studied was Gosford sandstone, which is medium-grained (0.2–0.3 mm), containing 20–30% feldspar and clay minerals (Sufian and Russell 2013). Tuffeau limestone is a sedimentary rock from the Loire Valley in France. According to Shirani et al. (2021), the predominant minerals identified in limestone were approximately 50% calcite and approximately 30% silica, with mica and clayey minerals constituting approximately 20%. The crystalline rock includes Adelaide black granite, which is a fine-grained rock containing 67% plagioclase, 15% clinopyroxene, 10% orthopyroxene, 5% potassium feldspar, and 3% other minerals. The rock is highly dense with a bulk density of 2.97 tons/m3 (Ali et al. 2022b). Bluestone, another fine-grained foliated, homogeneous metamorphic rock from the Adelaide hills, consists of quartz, feldspar, illite, and chlorite, accounting for 95% of the composition. Additionally, we tested concrete specimens because of their homogeneous nature and lack of loading history. The specimens were cored with 42 mm diameter cores and prepared in accordance with ISRM standards for uniaxial compressive strength tests (Fairhurst and Hudson 1999). The specimen aspect ratio ranged between 2 and 2.5, with the surfaces ground in parallel to minimize end friction effects and ensure a uniform stress state during the experiments. The rock mechanical properties and the prepared specimens are presented in Table 1 and Fig. 5, respectively.

3.2 Experimental Setup and Testing Method

All tests were conducted in an MTS 300 kN servo-controlled testing machine, which consisted of an axial loading frame and a data acquisition system, as shown in Fig. 6. Linear variable differential transformers (LVDTs), strain gauges, and an Acoustic Emission (AE) monitoring system developed by Karakus et al. (2015) were utilized to monitor the deformation process. Strain gauges were applied in both the axial and lateral directions to measure the volumetric change resulting from shear and tensile cracks (Kuwahara et al. 1990; Kusunose et al. 1980).

Schematic of the experimental setup and loaded sandstone specimen in the MTS with instrumentation (Ali et al. 2022c)

To simulate in situ stresses (\(\sigma_{a}\)), the rock samples were prestressed between 30 and 80% of rock’s UCS for 5–30 min. Subsequently, two-cycle compression was applied at approximately 20% higher stress levels to examine the stress level at which the inflection point appears (\(\sigma_{m}\)). The felicity ratio (FR), defined as the ratio of the measured stress to the applied stress, was calculated for each specimen using Eq. (2):

To compare the results with the DRA method, two-cycle compressions were utilized. The impacts of the loading conditions and strain rates were studied by examining three distinct loading modes and five different strain rates. Furthermore, the study explored the effect of time delay by incorporating delays spanning from 30 min to 6 months.

4 Results and Discussion

As previously mentioned, the accuracy of the strain gauges and measured strains during cyclic compression can significantly impact the shape of the DRA curves, which may lead to curves with no inflection points or, in some cases, with multiple inflection points. A good DRA curve was observed when inelastic strains were produced only in the first cycle, with little or no dilatancy occurring during the second cycle. However, achieving this is not always possible because of the heterogeneity of the rock and its unique response during successive cycles. On the other hand, the SMM capitalizes exclusively on the rock’s response in the first cycle, resulting in characteristic curves that exhibit a distinct point of inflection and a consistent trend across all the rock specimens. A comparison of the SMM curves of the DRA and AE methods is illustrated in Fig. 7.

During uniaxial compression, damage accumulates because of both shear and tensile cracks, resulting in volumetric strain (Nicksiar and Martin 2010). In addition, it is well-known that lateral strains are more sensitive to crack growth and can clearly define the onset of cracking (Ali et al. 2022c). For this reason, many studies on crack initiation threshold utilize lateral and volumetric strains as the axial stress–strain curves are typically less sensitive to crack initiation and exhibit a more linear response until the onset of unstable crack growth (Shirani et al. 2021; Diederich 2007). However, interestingly, we found that even when using the axial strains, a very clear point of inflection occurred precisely at the applied stress levels, indicating a dilation in the curve resulting from the inelastic strain. The magnitude of this dilation is so small that it is not easily discernible in the stress–strain relationship and can only be detected using a strain difference function. From the results, it is evident that the method can be effectively applied to the strains measured in each direction as shown in Fig. 8. Hence, it is important to monitor strains in both axial and lateral directions when utilizing these techniques for in situ stress measurements.

4.1 Effect of Cyclic Loading on Rock Stress Memory

During uniaxial compressive loading, cracks generate and propagate under an applied load (Bieniawski 1967; Koerner et al. 1985; Diederichs 2007; Diederichs et al. 2004; Ali et al. 2022c). Upon unloading and reloading of the rock sample, no additional cracks were generated until the previously applied maximum stress exceeded. This resulted in a change in the strain rate in the stress–strain curve after the peak stress exceeded. A negligible change in strain rate was observed with an increase in the number of cycles under the same peak stress levels. A clear manifestation of this was observed in the SMM curves. The inflection point was observed only in the first loading cycle, and no inflection was observed as the number of cycles increased (Fig. 9). This observation is consistent with the DRA results discussed above and the AE method for stress measurements. Therefore, it can be presumed that the rock stress memory is best measured in the first application of higher stress, and subsequent cycles may not be beneficial to understanding the phenomenon.

4.2 The Effect of Loading Conditions and Loading Rates

Rock stress memory is sensitive to several factors; however, the loading conditions/rate of loading is important. Rocks in Earth's crust are subjected to varying numbers of stresses at unknown rates, and the loading rates applied to laboratory core specimens differ from the rates at which the stress memory was originally formed. Additionally, dynamic loadings, such as earthquakes, contribute to the geological stress history of rocks and warrant further investigation. The type of loading rock experience can affect the mechanical behavior manifolds, thus affecting the stress memory (Gao et al. 2021). To comprehensively assess the effects of loading conditions on SMM and stress memory, two separate studies were conducted. The first study employed three different modes of loading on rock samples with varying preloads and subsequent loading/strain rate cycles as illustrated in Fig. 10. In the second study, the Felicity ratio (FR) of rock specimens was observed under five different strain rates.

We found that the SMM and the stress memory were not affected by the loading modes. The Felicity Ratio (FR) measured for all the rock specimens tested lies between 0.9 and 1.1, which according to Lavrov is a good indication of rock stress memory Lavrov (2003). Figure 11 below shows the scatter and box plots of all the specimens tested under three different loading modes.

Further analysis of the results reveals that when cyclic compression is performed at a similar rate (Mode 1) or faster rate (Mode 2) on preloaded specimens, the variance of the Felicity ratio is minimal (Fig. 12) and the characteristic SMM curves are more pronounced with sharper inflection points. Nevertheless, in all three loading modes, the Felicity ratio remained close to 1 although there was relatively greater variability in the soft rocks. Although the loading conditions and rates were deemed insignificant in relation to stress memory and SMM, a faster loading rate is recommended to obtain improved results, as specimens taken from the Earth's crust experience stress at a slow loading rate. Thus, when utilizing this method for in situ stress measurements, a relatively high loading/strain rate should be used.

Likewise, we performed tests under five different loading/displacement rates (0.05 mm/min, 0.1 mm/min, 0.5 mm/min, 1 mm/min, 1.5 mm/min) which corresponds to strain rates ranging 10−6 s−1 and 10−4 s−1. The results of the investigation revealed that the range of strain rates tested had no significant impact on rock stress memory and SMM. The overall FR for all the rock specimens tested remained within the acceptable range discussed above (Fig. 13); however, the loading rates of 0.5 mm/min and 1 mm/min, corresponding to strain rates of 10−5 s−1 and 10−4 s−1 demonstrated much better results.

4.3 The Influence of Time Delay and Preloads

As rock cores recovered in situ may take an extended period, spanning from several days to months, to reach the laboratory, the question of the applicability of the method in light of time delay becomes a pertinent issue. This facet of rock stress memory has received significant attention in previous studies, generating conflicting views on this matter. Initial investigations proposed that stress memory in rock reduces significantly with time delay, potentially leading to its elimination (Lavrov 2002). However, these findings have been disputed by several researchers. Some researchers have observed the Kaiser effect even after a time delay of 300 days (Koerner et al. 1985; Gao et al. 2021), whereas Seto et al. (1998) have reported detecting stress memory after several years of delay. According to Ali et al. (2022c), the methodology employed to study stress memory appears to influence the impact of time delays. Such disparate findings have prompted further investigation into the effect of time delay to assess the suitability and reliability of the SMM for practical applications. In this study, testing was carried out on specimens without any time delay and with delays ranging from 30 min to 1 week, with a selected few being tested after a delay period of 6 months. Figure 14 below shows the FR for the rocks for the different time delays. Because the variation in the results was negligible, the specimens tested without a delay and after delays of 5, 10, and 15 min were all grouped together.

The findings of this study indicate that time delay has a minimal impact on the stress memory and SMM, as demonstrated by the consistent FR range of 0.9–1 across all rock specimens. These results contrast with those of numerous studies that have explored the influence of time delay on rock stress memory, as no discernible trend of diminishing FR or fading stress memory was observed. Furthermore, the SMM method was found to be a dependable and effective means of detecting the Kaiser effect for delays of up to 6 months, unlike the tangent modulus method (TMM). The findings suggest that the time dependency of rock stress memory is not an inherent material property but is rather linked to the methodology employed to investigate it.

The rock stress memory is highly influenced by the prestress levels. Previous studies have indicated that the Kaiser effect can be detected in rocks only if the preload is within 30–80% of the rock uniaxial compressive strength (UCS) (Lavrov 2002). This is because preloads below 30% of the rock UCS result in crack closure, preventing inelastic deformation under applied stresses, while preloads above 80% of the rock UCS cause permanent deformation, making it practically impossible to capture the applied stresses in subsequent loading cycles as the rock becomes susceptible to permanent damage. Our findings indicate that the Kaiser effect was detectable at 30% rock UCS in soft rocks and bluestone, whereas in concrete and granite, the inflection was not discernible and occurred at considerably lower stresses. The inflection point was pronounced between 30 and 80% of the rock specimens. The FR values of the rock specimens subjected to different preloads are shown in Fig. 15.

Based on the results presented in, it can be summarized that the SMM method can reliably capture preloads utilizing axial, lateral, and volumetric strain difference functions. It was found to be more effective with the lateral and volumetric strain difference function, and accurate under all test conditions discussed above. A clear inflection point was observed in all rock types examined, and the FR remained in the range of 0.9–1 when the applied preloads were between 40 and 80% of the UCS, below which the FR decreased in some rock types. The stress memory and the SMM remained unaffected by the loading conditions studied although the specimens subjected to slower preloads and faster cycles under mode 2 exhibited more distinct bending points and the FR remained closer to one. Similarly, the strain rate had no significant effect on stress memory and SMM. Our investigation also revealed no time dependency in rock stress memory and SMM. This was evident as a distinct point of inflection observed at the prestress levels in the coal and granite specimens, even after a delay period of 6 months.

4.4 Application and Case Study

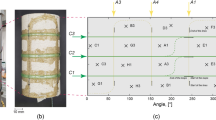

The SMM was used together with the AE method to measure the in situ stress in an underground mine in South Australia. Cyclic tests were performed on sub-cores extracted in six independent directions using a 22 mm diamond drill bit from the oriented main core with a trend and plunge of 285° and 75° respectively in the mine grid. The cores were sourced from a depth of 823 m and 946 m where the overcoring method was applied. A minimum of six independent sub-cores are required to construct the six components of the stress tensor. The actual mine grid of the sub-cores was obtained by rotating the nominal orientation of each sample using Eq. (3).

where \(\theta_{uv}\) is the angle between main core trend/plunge \(\alpha_{u} /\)\(\beta_{u}\) and sub-core trend/plunge \(\alpha_{v}\)/\(\beta_{v}\). Figure 16 shows the sub-core orientations, sample preparation, and loading process in the laboratory.

The specimens were prepared as per the ISRM standards for UCS tests. Subsequently, two compression cycles at stress levels 2.5 times greater than the vertical stress were applied to all the sub-cores. The vertical stress, in turn, was determined through calculations of rock density and the depth at which the rock core was retrieved (823 m and 946 m). The normal stresses (\(\sigma_{n}\)) were calculated in each sub-core direction using both AE and SMM methods. This normal stress (\(\sigma_{n}\)) acting on a surface normal to the unit vector can be given by Eq. (4).

where \(l_{x}\), \(l_{y}\), and \(l_{z}\) are the direction cosines between XYZ and LMN axes. Thus, with the six normal stresses measured using AE and SMM, six simultaneous equations can be established using Eq. (4). By solving the simultaneous equations, the components of the stress tensor can be computed. The principal stresses and their orientations can then be determined using eigenvalue analysis of the stress tensor as described in Villaescusa et al. (2002) and Karakus et al. (2015).

4.4.1 Principal Stress Magnitudes

A minimum of two specimens were tested in each sub-core direction, and the average values of the AE and SMM analyses were used to construct the stress tensor using the procedure described earlier. The principal stress magnitudes and their orientations based on the mean values of AE and SMM are shown in Fig. 17. The range shows the variation in the stress magnitudes based on the 10% margin of error applied to the measured values based on the felicity ratio of 0.9–1.1 (Ali et al. 2021, 2023). The measured results show a thrust-faulting regime in the area with SH > Sh > Sv, which is in good correlation with OC and other similar measurements in the basin (Klee et al. 2011). The measurements of the intermediate and minor principal stresses obtained using both methods were in reasonable agreement. However, the OC method tends to yield higher values for the major principal stress. This variation is acceptable given the differences in the measurement techniques and algorithms used to solve the system of equations. When comparing the results of the first stress variants, it can be observed that the margin of error was quite low. This is because solutions that result in a higher maximum principal stress also tend to result in lower intermediate and minor principal stresses.

Comparison of Principal stresses measured using AE, SMM, and OC methods (Ali et al. 2023)

4.4.2 Principal Stress Orientations

Our measurements indicate that the major principal stress is horizontal and oriented at approximately 280° ± 10° which is like the tectonic regimes and other measurements in the basin, suggesting an East–West orientation (Klee et al. 2011; Rajabi et al. 2017) as shown in Fig. 18b. The measurement from the OC shows a northwest–southeast orientation, which has also been recorded in some other mines in the region (Klee et al. 2011). The orientations can vary with the locations, and these variations in the lateral stress direction are primarily caused by the in situ geological structures that can change the direction of the stress flow in the mine. Additionally, variations or errors in the measured normal stresses can significantly affect the direction of the horizontal stresses.

a Principal stress orientation from AE and SMM methods. b Principal stress orientation in Australia showing the region in question (Rajabi et al. 2017)

5 Conclusion

A new method called the Secant Modulus Method (SMM) is proposed for in situ stress measurements from oriented cored rocks. This method is both simple and accurate, leveraging the inelastic strains generated during the uniaxial cyclic compression of the rock. A combination of six different rocks was used to validate the method and determine its effectiveness under various loading conditions, loading rates, and time delays. The method was found effective with the axial, lateral, and volumetric strains and exhibited a clear point of inflection precisely at the prestress levels. Unlike the DRA method, only one cycle of compression is required and prestress levels between 30 and 80% of rock UCS were easily determined. We found that loading conditions, loading rates, and time delays did not affect the stress memory and the SMM. Under three different modes of loading and five different strain rates, the stresses were measured with an error of less than 10%. Likewise, no effect of time delay was observed for delays ranging between 30 min and 6 months. Lastly, the SMM was applied together with the AE methods for in situ stress measurement from oriented cored rock retrieved in a mine site in South Australia. The magnitude and the orientation of the principal stresses were found to be in good correlation with the OC method applied in the same location and other stress measurements in the basin.

Availability of Data and Materials

The raw data for this research can be provided on request through the corresponding author.

References

Ali Z, Karakus M, Nguyen GD, Amrouch K (2021) Understanding the Kaiser effect in concrete using deformation rate analysis and acoustic emission. In: Proceedings of the 10th Australasian conference on applied mechanics. Adelaide. EA.

Ali Z, Karakus M, Nguyen GD, Amrouch K (2022a) Application of full-field strain measurement to study Kaiser effect in granite under indirect tensile loading. In: Proceedings of the 56th US rock mechanics/geomechanics symposium. ARMA, Santa Fe

Ali Z, Karakus M, Nguyen GD, Amrouch K (2022b) Experimental investigation of hydraulic fracturing in granite under hydrostatic stress conditions. In: Proceedings of the 5th international conference on sub level and block caving. ACG, Adelaide

Ali Z, Karakus M, Nguyen GD, Amrouch K (2022c) Effect of time delay and strain rate on tangent modulus method (TMM) in coal and coal measured rocks. Int J Coal Sci Technol. https://doi.org/10.1007/s40789-022-00552-7

Ali Z, Karakus M, Nguyen GD, Amrouch K (2023) In-situ stress measurement using non-destructive and relief methods. In: Proceedings of 15th international ISRM congress, Salzburg. ISRM

Bai X, Zhang D, Wang H, Li S, Rao Z (2018) A novel in situ stress measurement method based on acoustic emission Kaiser effect: a theoretical and experimental study. R Soc Open Sci. https://doi.org/10.1098/rsos.181263

Bieniawski ZT (1967) Mechanism of brittle fracture of rock, part II: experimental studies. Int J Rock Mech Min Sci 4:407–423

Brace WF, Paulding JBW, Scholz C (1966) Dilatancy in the fracture of crystalline rocks. J Geophy Res 71:3939–3953

Chen Y, Irfan M (2018) Experimental study of Kaiser effect under cyclic compression and tension tests. Geomech Eng 14(2):203–209. https://doi.org/10.12989/gae.2018.14.2.203

Chen Y, Irfan M, Song C (2018) Verification of Kaiser effect in rocks under tensile stress: experiment using Brazilian test. Int J Geomech. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001181

Diederichs MS (2007) The 2003 Canadian Geotechnical Colloquium: mechanistic interpretation and practical application of damage and spalling prediction criteria for deep tunnelling. Can Geotech J 44:1082–1116

Diederichs MS, Kaiser PK, Eberhardt E (2004) Damage initiation and propagation in hard rock during tunnelling and the influence of near-face stress rotation. Int J Rock Mech Min Sci 41(5):785–812. https://doi.org/10.1016/j.ijrmms.2004.02.003

Dight P (2006) Determination of in-situ stress from oriented core. In: ISRM conference on in-situ stress. Norway, pp 167–175.

Dight P, Dyskin A, Wang H, Jeffcoat-Sacco B, Hsieh A, Akdag S (2022) rock properties to predict rockburst vulnerability in three dimensions (Strainburst). Results of research carried out as MRIWA Project M0464 at the Australian Centre for Geomechanics, UWA

Dinmohammadpour M, Nikkhah M, Goshtasbi K, Ahangari K (2022) Application of the Kaiser effect in in-situ stress measurement in rocks—an overview. Rudarsko-Geološko-Naftni Zbornik 37(4):1–16. https://doi.org/10.17794/rgn.2022.4.1

Fairhurst C (2003) Stress estimation in rock: a brief history and review. Int J Rock Mech Min Sci 40(7):957–973. https://doi.org/10.1016/j.ijrmms.2003.07.002

Fairhurst CE, Hudson JA (1999) Draft ISRM suggested method for the complete stress-strain curve for intact rock in uniaxial compression. Int J Rock Mech Min Sci 36:281–289

Filimonov Y, Lavrov A, Shafarenko Y, Shkuratnik V (2001) Memory effects in rock salt under triaxial stress state and their use for stress measurement in a rock mass. Rock Mech Rock Eng 34(4):275–291. https://doi.org/10.1007/s006030170002

Fu X, Ban Y, Xie Q, Abdullah R, Duan J (2021) Time delay mechanism of the Kaiser effect in sandstone under uniaxial compressive stress conditions. Rock Mech and Rock Eng 54(3):1091–1108. https://doi.org/10.1007/s00603-020-02310-0

Fujii Y, Makasib M, Kodamaa J, Fukudaa D, Gotoc K, Kumakurac S, Kanaokad M (2018) Tangent modulus method—an original method to measure in-situ rock stress. Tunn Undergr Space Technol 82:148–155. https://doi.org/10.1016/j.tust.2018.08.005

Gao M, Xie J, Gao X, Wang W, Li C, Yang B, Liu J, Xie H (2021) Mechanical behaviour of coal under different mining rates: a case study from laboratory experiments to field testing. Int J Min Sci Technol 31(5):825–841. https://doi.org/10.1016/j.ijmst.2021.06.007

Haimson BC, Fairhurst C (1970) In situ stress determination at great depth by means of hydraulic fracturing. In: Proceedings of the 11th US National symposium on rock mechanics—theory and practice. New York, pp 559–589

Hsieh A, Dight P, Dyskin AV (2014) Ghost KE at low stress. Int J Rock Mech Min Sci 68:15–21. https://doi.org/10.1016/j.ijrmms.2014.02.005

Jiang J, Liu Q, Xu J (2016) Analytical investigation for stress measurement with the rheological stress recovery method in deep soft rock. Int J Min Sci Technol 26(6):1003–1009. https://doi.org/10.1016/j.ijmst.2016.09.007

Jin Y, Qi Z, Chen M, Zhang G, Xu G (2009) Time-sensitivity of the Kaiser effect of acoustic emission in limestone and its application to measurements of in situ stress. Pet Sci 6(2):176–180. https://doi.org/10.1007/s12182-009-0028-6

Karakus M (2014) Quantifying the discrepancy in preloads estimated by acoustic emission and deformation rate analysis. In: Proceedings of the European Rock Mechanics Symposium. ISRM, Vigo

Karakus M, Perez S, Goodchild D (2015) In-situ stress measurement from oriented sub-cores using Kaiser effect. In: Proceedings of the 24th international mining congress and exhibition of Turkey. Chamber of Mining Engineers of Turkey, Antalya

Klee G, Bunger A, Meyer G, Rummel F, Shen B (2011) In situ stresses in borehole blanche-1/South Australia derived from breakouts, core discing and hydraulic fracturing to 2 km depth. Rock Mech Rock Eng 44:531–540

Koerner RM, Lord AE, Deutsch WL (1985) Field determination of prestress (existing stress) in soil and rock masses using acoustic emission. J Acoust Emiss 4(2):22–25

Kusunose K, Yamamoto K, Hirasawa T (1980) Source process of microfracture in granite with reference to earthquake prediction. Tohoku Geophy J 26:111–121

Kuwahara Y, Yamamoto K, Hirasawa T (1990) An experimental and theoretical study of inelastic deformation of brittle rocks under cyclic uniaxial loading. Tohoku Geophy J 33:1–21

Lavrov A, Vervoort A, Wevers M, Napier AL (2002) Experimental and numerical study of Kaiser effect in cyclic Brazilian tests with disk rotation. Int J Rock Mech Mining Sci 39:287–302. https://doi.org/10.1016/S1365-1609(02)00038-2.

Lavrov A (2003) The KE in rocks: principles and stress estimation techniques. Int J Rock Mech Min Sci 40(2):151–171. https://doi.org/10.1016/S1365-1609(02)00138-7

Lehtonen A, Cosgrove J, Hudson J, Johansson E (2012) An examination of in-situ rock stress estimation using KE. Eng Geol 124:24–37. https://doi.org/10.1016/j.enggeo.2011.09.012

Lin U, Singh SK, Xiang Z, Kang WH, Raval S, Oh J, Canbulat I (2022) An investigation of machine learning techniques to estimate minimum horizontal stress magnitude from borehole breakout. Int J Min Sci 32(5):2095–2686. https://doi.org/10.1016/j.ijmst.2022.06.005

Nicksiar M, Martin CD (2010) Evaluation of methods for determining crack initiation in compression tests on low porosity rocks. Rock Mech Rock Eng 45(4):607–617. https://doi.org/10.1007/s00603-012-0221-6

Rajabi M, Tingay M, Heidbach O, Hillis R, Reynolds S (2017) The present-day stress field of Australia. Earth Sci Rev 168:165–189

Sakaguchi K, Lino W, Matsuki K (2002) Damage in a rock core caused by induced tensile stress and its relation to differential strain curve analysis. Int J Rock Mech Min Sci 39(3):367–380. https://doi.org/10.1016/S1365-1609(02)00039-4

Seto M, Utagawa M, Katsuyama K, Kiyama T (1998) In Situ Stress determination using AE and DRA techniques. Int J Rock Mech Min Sci 35(4–5):458–459

Seto M, Nag D, Vutukuri VS (1999) In-situ rock stress measurement from rock cores using the acoustic emission method and deformation rate analysis. Geotech Geol Eng 17:41–266

Shirani FR, Taheri A, Karakus M (2021) Post-peak behaviour of rocks under cyclic loading using a double criteria damage-controlled test method. Bull Eng Geol Environ 80:1713–1727. https://doi.org/10.1007/s10064-020-02035-y

Stuart C, Meredith P, Murrell S, Van MJ (1993) Anisotropic crack damage and stress memory effects in rocks under triaxial loading. Int J Rock Mech Min Sci 30(7):937–941. https://doi.org/10.1016/0148-9062(93)90048

Sufian A, Russell AR (2013) Microstructural pore changes and energy dissipation in Gosford sandstone during pre-failure loading using X-ray CT. Int J Rock Mech Min Sci 57:119–131. https://doi.org/10.1016/j.ijrmms.2012.07.021

Villaescusa E, Seto M, Baird G (2002) Stress measurement from oriented core. Int J Rock Mech Min Sci 39:603–615. https://doi.org/10.1016/S1365-1609(02)00059-X

Windsor CR, Villaescusa E, Machuca LA (2010) A comparison of rock stresses measured by the WASM AE with the results from other techniques that measure the complete rock stress tensor. In: Proceedings of the international symposium on in-situ rock stress. IRSM, Beijing

Worotnicki G, Walton RJ (1976) Triaxial "Hollow Inclusion" gauges for the determination of rock stresses in situ. In: Proceedings of the ISRM symposium on investigation of stresses in rock—advances in stress measurement. National Conference Publication, Australia

Yamamoto K, Kuwahara Y, Kato N, Hirasawa T (1990) Deformation rate analysis: a new method for in situ stress estimation from inelastic deformation of rock samples under uniaxial compressions. Tohoku Geophy J 33(5):127–147

Yoshikawa S, Mogi K (1981) New method for estimating crustal stress from cored rock samples. Tectonophysics 74(3–4):323–339. https://doi.org/10.1016/0040-1951(81)90196-7

Acknowledgements

The authors are grateful to the Australia Coal Industry’s research Program (ACARP) for funding this research. They also want to extend their gratitude to OZ Minerals for providing rock cores for in situ stress measurement.

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions. This project is financially supported by the Australian Coal Association Research Program (ACARP) under project C29010.

Author information

Authors and Affiliations

Contributions

Zulfiqar Ali: conceptualization, experiments, data collection, formal analysis, investigation, validation, methodology, writing original draft. Murat Karakus: Funding acquisition, methodology, formal analysis, conceptualization, review & editing, supervision, project administration, Giang D. Nguyen: Funding acquisition, formal analysis, conceptualization, review & editing, supervision, methodology. Khalid Amrouch: conceptualization, formal analysis, methodology, supervision, review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ali, Z., Karakus, M., Nguyen, G.D. et al. Secant Modulus Method: A Simplified Technique for Measuring in Situ Stresses in Rocks. Rock Mech Rock Eng (2024). https://doi.org/10.1007/s00603-024-03953-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00603-024-03953-z