Abstract

Non-destructive techniques of in-situ stress measurement from oriented cored rocks have great potential to be developed as a cost cost-effective and reliable alternative to the conventional overcoring and hydraulic fracturing methods. The tangent modulus method (TMM) is one such technique that can be applied to oriented cored rocks to measure in-situ stresses. Like the deformation rate analysis (DRA), the rock specimen is subjected to two cycles of uniaxial compression and the stress-tangent modulus curve for the two cycles is obtained from the stress–strain curve. A bending point in the tangent modulus curve of the first cycle is observed, separating it from the tangent modulus curve of the second cycle. The point of separation between the two curves is assumed to be the previously applied maximum stress. A number of experiments were conducted on coal and coal measured rocks (sandstone and limestone) to understand the effect of loading conditions and the time delay. The specimens were preloaded, and cyclic compressions were applied under three different modes of loading, four different strain rates, and time delays of up to one week. The bending point in the stress-tangent modulus curves occurred approximately at the applied pre-stress levels under all three loading modes, and no effect of loading rate was observed on the bending points in TMM. However, a clear effect of time delay was observed on the TMM, contradicting the DRA results. This could be due to the sensitivity of TMM and the range of its applicability, all of which need further investigation for the in-situ stress measurement.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the past few decades, several ingenious stress measurement techniques have been developed with their own advantages and some inherent problems (Villaescusa et al. 2002; Karakus 2014; Ali et al. 2021a, b). These methods can broadly be classified into four categories based on their application method, i.e., methods applied inside the borehole, methods used on the cored rock, methods performed on rock surface, and other geophysical and numerical methods. Out of all such methods, only two of them i.e., hydraulic fracturing and overcoring have been scientifically accepted and commercially adopted worldwide. However, these methods have their inherent problems i.e., they are cumbersome, time-consuming, and expensive. Also, these methods are difficult to be applied at greater depths and in the remote regions of the mines. Therefore, the non-destructive methods (NDTs) such as deformation rate analysis (DRA), acoustic emission (AE) and tangent modulus method (TMM), which are applied to the oriented cored rocks, have great potential to be developed as a cost-effective and reliable alternative to the conventional overcoring and hydraulic fracturing methods (Karakus et al. 2015; Ali et al. 2022). These methods can be easily applied in the laboratory to the cored rocks during the early stages of the mine development. These methods take advantage of the stress memory in rocks extensively studied and documented in the literature (Kaiser 1953; Kurita and Fujii 1979; Yamamoto et al. 1990; Seto et al. 1998).

However, like all other methods, the core-based stress measurement methods have been questioned by many researchers for their application in stress measurement. In a state-of-the-art literature review, Lavrov (2003) argues that the rock stress memory is affected by several factors, such as the duration of load applied (Filimonov et al. 2001), time delay (Jin et al. 2009; Fujii et al. 2018), water saturation and heating (Yoshikawa and Mogi 1981), rotation of principal axis (Stuart et al. 1993; Lavrov 2003) and the coring process (Sakaguchi et al. 2002). In addition to that, the conditions under which tests are performed in the laboratory are different from in-situ conditions, which are more complex as they include not only the compressive stresses but also tensile stresses (Lehtonen et al. 2011; Zhang et al. 2017; Chen et al. 2020; Ban et al. 2020). The complications associated with the stress redistribution after excavation and dynamic loadings due to earthquakes and blasting can further complicate the stress memory. Despite all these, several studies suggest an excellent correlation between the estimated stresses from the core-based methods and the conventional overcoring and hydrofracturing methods (Villaescusa et al. 2002), which provides the basis for further investigations.

Among the core-based stress measurement methods, the DRA and AE are the preferred methods for estimating in-situ stresses. Although these methods are fairly accurate in estimating the preloads during the conventional uniaxial cyclic loading and unloading tests (UCLU), they can be problematic for stress measurement due to complex geological stress history. One of the challenges with these two methods is the accurate determination of the point of inflection. In most cases, multiple bending points are observed, which makes identification less accurate and thus hinders the accuracy of the stress reconstruction. For this reason, many researchers recommend using DRA and AE together to minimize the errors in estimating the point of inflection. The TMM was first introduced by Fujii et al. (2018) which is based on the inelastic properties of rock under uniaxial cyclic compression. Like the DRA method, rock specimens are subjected to two cycles of uniaxial compression at higher stress levels than the applied preloads or overburden stresses. The stress-tangent modulus curves of the two loading cycles separate at a point assumed to be the previously applied maximum stress. Since both TMM and DRA methods are based on the measurement of inelastic strains during the two successive cycles, the accuracy of strain measurement is critical as the stress–strain field in the rock specimen is not uniform primarily due to rock heterogeneity and then due to the complex geological stress history (Hsieh et al. 2014). In this regard application of the TMM together with the DRA could resolve the issues associated with the errors in the strain difference function in the DRA method.

This paper is organized in four sections. In section one, an introduction is provided on the TMM and the DRA. Section two discusses the specimens, experimental procedures, and instrumentations. In section three, the results of the experiments are presented together with a discussion, followed by the conclusion.

2 Inelastic deformation in rocks and principles of TMM and DRA

2.1 Inelastic deformation in rocks

When a rock specimen is subjected to uniaxial compression, it can undergo inelastic deformation, either due to either crack closure, sliding of pre-existing cracks, crack initiation, propagation or compaction caused by pore collapse (Hsieh et al. 2016). The basic model of the damage process in rocks was introduced by Brace et al. (1966) and Bieniawski (1967), and it has been extensively studied by researchers since (Wawersik and Fairhurst 1970; Martin and Chandler 1994; Diederichs et al. 2004; Hoek and Martin 2014; Zhao et al. 2015; Moradian et al. 2016; Taheri et al. 2020). According to these studies, the process can be characterized in to five distinct stages, namely: (1) crack closure, (2) linear elastic deformation, (3) crack initiation and stable crack growth, (4) crack damage and unstable crack growth, (5) failure and post peak behaviour as shown in Fig. 1.

Damage Mechanism in rocks (Bruning et al. 2018)

The crack closure only occurs at low stress, which increases modulus, resulting in a nonlinear region at the beginning of the stress–strain curve. This is followed by elastic deformation which results in an apparent linear region. The initiation and stable crack growth result in dilatancy and inelastic strains (Hsieh et al. 2016). Theoretically, since the elastic modulus is calculated from the linear elastic region in the stress–strain curve, it is believed that the modulus is not influenced by the inelastic strains caused by crack closure, sliding or propagation. Hence, the difference between the measured strain and elastic modulus would give us the inelastic strains produced by the crack closure at the low stress or by the dilatancy at the high stress. From here, one can delineate separate mechanisms of non-elastic deformation and identify the stages of crack closure and growth (Dyskin and Salganik 1987). However, sometimes the linear elastic region may not exist in the curve as the crack closure, sliding, and propagation may co-exist at the same stress levels.

2.2 Tangent modulus method (TMM)

In rock mechanics, the tangent modulus is the slope at any specified point on the stress strain curve as shown in Fig. 2. In the proportional limit, the tangent modulus is equal to the rock’s elastic modulus and above the proportional limit, it depends highly on the strains produced. It is typically used to study the behaviour of the materials beyond the elastic region. In simple words, it quantifies the softening or hardening of rocks when it starts to yield.

The tangent modulus was first used by Fujii et al. (2018) to study the stress memory in rocks under uniaxial cyclic compression. Like the DRA method, in this method, the rock specimen is preloaded and unloaded to a specific stress level, and two cycles of uniaxial compression are applied at a higher stress level. Stress-tangent modulus curve for both the loading cycles are obtained which yields a bending or a separation in the two stress-tangent modulus curves. The bending or the separation point is assumed to be the previously applied maximum stress as shown in Fig. 3.

According to Fujii et al. (2018) this bending point is more prominent in porous and soft rocks, while it is merely discernible in the hard crystalline rocks. This is probably why the authors believe that the mechanism of TMM is governed by the irrecoverable closures of rock voids such as micro cracks and pores (Fujii et al. 2018). To explain this phenomenon, they assume that point 1 in Fig. 4 denotes the in-situ stress condition under which a rock exhibits a few voids that are tabular and sufficiently large such that they can partly close. Once the rock is loaded under uniaxial cyclic compression, the rock is stiff during the first cyclic loading up to the in-situ stress level (3 to 4) because no further void closure take place. However, the stiffness decreases under further compression (4 to 5) due to the closure of the partly closed voids and other open voids. Hence, a bending point appears at point 4 as shown in Fig. 4b. Since the specimen is reloaded to the same maximum load in the second cycle, it is assumed that no further crack or void closure take place, thereby resulting in high stiffness throughout the second loading cycle (6 to 7). While this could be true at low stress levels, it fails to explain the bending in the tangent modulus curve when the specimens are preloaded at stresses beyond crack initiation threshold. This is further discussed in Sect. 3 of this paper.

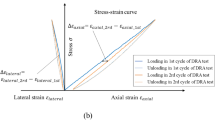

2.3 Deformation rate analysis (DRA)

The DRA method of stress measurement is based on the stress memory in the rock, which was first used by Yamamoto et al. (1990) to recollect the previously applied stresses using the inelastic strain in the rock specimen under uniaxial cyclic compression. In this method, the rock specimen is subjected to two cycles of loading and the strain difference values between the two loading cycles also known as the strain difference function, \({\Delta \varepsilon }_{j,i}(\sigma )\) is calculated as:

where σ is the applied axial stress and \({\varepsilon }_{i}(\sigma )\) is the reduced axial strain for the ith loading. \({\Delta \varepsilon }_{j,i}(\sigma )\) is calculated from the gradient of the line, which is positive initially and bends sharply to adopt a negative gradient after the peak, as shown in Fig. 5. According to Yamamoto (2009) the negative gradient at applied stresses is higher than the previously applied peak stress, indicating that the rock specimen can be easily deformed in the first loading than the successive ones. The strain resulting from this phenomenon is irreversible for two consecutive cycles and not cancelled in the strain difference function defined by Eq. (1).

3 Experimental procedures

3.1 Specimens

Three types of rocks are used in this study: coal, Gasford sandstone and Tuffeau limestone, as shown in Fig. 6. The coal samples were taken from an underground mine site in NSW, Australia. These coal specimens are usually bituminous with calcite and amorphous as the main mineral components. The samples were cored using 50 mm diameter drill bits which were carefully wrapped and sealed in plastic bags to prevent water evaporation before tests. The second rock type used in the study is the Gosford sandstone, a medium-grained (0.2–0.3 mm), poorly cemented, immature quartz sandstone containing 20%–30% feldspar and clay minerals (Sufan and Russell 2013; Shirani et al. 2021a). According to the X-ray computed tomography scans conducted by Sufan and Russell (2013), the total porosity of this sandstone is about 18%. The third type of rock used in the study was Tuffeau limestone, a yellowish-white sedimentary rock found in the Loire Valley in France and primarily used in the building industry (Shirani et al. 2021a, 2021b). X-ray diffraction (XRD) and Scanning Electron Microscopy (SEM) analyses conducted by Sherani et al. (2021b) suggest two main mineral components, calcite (≅ 50%) and silica (≅ 30%). Other minerals, such as mica and clayey minerals (e.g., muscovite, biotite) constitute about 20% of this limestone. Tuffeau limestone has an average density of 1.43 g/cm3 and is a lightweight and fine-grained limestone with a complex porous network (total porosity of 45% ± 5%).

All specimens used for the tests were cored from the same rock blocks and prepared as per the ISRM standards for uniaxial compressive strength tests (Fairhurst and Hudson 1999). The aspect ratio of the cylindrical specimens was kept between 2 and 2.5 and the end surfaces were ground parallel to minimise the end friction effects and ensure a uniform stress applied to the specimen during the experiments. The rock samples used in the study and their mechanical properties are shown in Fig. 6 and Table 1, respectively.

3.2 Experimental setup

All the tests were conducted in an MTS 300 kN closed-loop servo-controlled testing machine, consisting of an axial dynamic loading frame and a data acquisition system as shown in Fig. 7. The deformation process was monitored using axial strain gauges of 20 mm length with a gauge factor of 2.11, and AE monitoring system developed by (Karakus 2014) which consist of AE Pico sensors (200–800 kHz frequency bandwidth) with a set of 2/4/6 series filters with 20/40/60 dB gain single-ended differential preamplifiers, and a NI PCI-6133 data acquisition unit.

The specimens were initially pre-stressed to simulate the in-situ stresses and subsequently, two-cycle compression was applied at approximately 20% higher stress levels to study the Kaiser effect (Fig. 8). To investigate the effect of applied preloads, the rocks were subjected to preloads between 30% and 80% of their compressive strengths. Three different loading modes and four different strain rates were adopted to investigate the influence of loading conditions and loading rates. Lastly, the effect of time delay was studied by removing the specimen from the load frame after preloading. The specimens were then subjected to two cycles of uniaxial compression after delays of 1 h, 6 h, 24 h, 72 h and 1-week time.

4 Results and discussion

During the uniaxial compression of rock specimens, the inelastic strains could result from pore/crack closure, crack sliding, crack initiation and propagation with the possibility of their coexistence at the same stress levels as discussed in Sect. 2 above. The mechanism for TMM explained by Fujii et al. (2018) may not be entirely true as the crack/pore closure is likely to happen at low stresses only, while the effect of inelastic strains is observed in the tangent modulus curve at considerably high-stress levels (80% of the UCS) in all the rock types used for this study. To demonstrate this, initially, the rock specimens were preloaded at 40% and 80% of their UCS and then two-cycles of compressions were applied at higher stress levels without any time delay to understand the stress memory and TMM in each rock type. The characteristic TMM and DRA curves were plotted for comparison purposes which showed clear separation point and bending point at the applied stress levels as shown in Figs. 9 and 10, respectively.

Though it could be argued that the inelastic strains at 40% of the rock compressive strength are due to pore closure, it is highly unlikely that the inelastic strains produced at stress levels as high as 80% of the rock compressive strength could be the result of pore closure. This suggests that the mechanism for the TMM is similar to the DRA which is governed by the inelastic strains resulting from the crack initiation and propagation at the first application of higher stresses. When the rock is first subjected to higher stresses, new cracks develop at inherently weak points inside the rock specimens producing inelastic strains. During the second cycle loading, no further cracks are generated, however due to stress concentration at the crack tips, stable crack propagation may occur resulting into negligible inelastic strains, which may not affect the tangent modulus. Thus, the tangent modulus curve for the second cycle does not yield a clear inflection or bending as observed in the first cycle.

The AE analysis further supplements this observation. When the rock is subjected to uniaxial compression, pore/crack closure occurs at low-stress levels, resulting in inelastic strains observed in the stress–strain curves. The AE activity is considerably low with negligible AE energy, as shown in Fig. 11a, b. A distinct surge in the AE activity is observed when crack initiation and propagation occur at higher stress levels. When the rock specimen is unloaded and reloaded to a higher stress level, limited or no AE activity occurs until the stress exceeds the previously applied maximum stress, as shown in Fig. 11c. This absence of AE activity in the subsequent loading cycles until the preload is exceeded supplements our discussion that negligible number of cracks or no new cracks are developed during the second cycle under the same stress levels, therefore, not affecting the tangent modulus curve.

It was observed that the trends in the variation of tangent modulus depends on the rock types i.e., constant, and/or increasing. In the coal specimens the tangent modulus curve remains constant except at the pre-stress levels in the first cycle loading where a bending / negative gradient is observed. During the second cycle loading no change in gradient is observed due to the reasons discussed above. In the limestone and sandstone specimens an increase in the tangent modulus is observed showing a similar bend in the first cycle. This increase in the modulus can be associated with the crack closure together with the generation and propagation of new cracks during the loading which is more prominent phenomenon in the porous rocks.

4.1 Effect of loading/displacement rate

An important question in the study of rock stress memory is the influence of loading or displacement rate. It is important because the rock in the earth’s crust is subjected to different stress paths at various loading rates which is not known. This implies that the loading rates applied to the cored specimens in the laboratory is different from the loading rates under which the stress memory was formed. Moreover, there are dynamic loadings like earthquakes that form part of the geological stress history, which needs to be investigated. To understand the effect of loading rate on the stress memory and the tangent modulus method, tests were conducted on the specimens under three different modes of loading. The applied preloads and the subsequent cycles were performed at different loading rates. Four different loading/displacement rates i.e., 0.05, 0.10, 0.50, and 1.00 mm/min were studied, which corresponds to the strain rates in the range from 10–6 to 10–4 1/s. It was observed that the modes of loading and the loading rates has no considerable influence on the rock stress memory and the TMM. A clear change in gradient is observed in the tangent modulus curves at the applied stress levels irrespective of the loading rate. An example of coal specimen tested under different loading rates is shown in Fig. 12, and the scatter plot of measured stresses against applied stresses (Felicity ratio) is presented in Fig. 13.

In this study, the dynamic loadings were not investigated. However, under the quasi-static loading rates, both the TMM and DRA methods are effective in measuring the applied preloads. It was possible to estimate the preloads when the specimens were preloaded at a slower rate and subsequent cycles were performed at higher loading rates, implying that uniaxial cyclic compressions can measure the stresses memorized by the rocks at a slower rate at higher strain rates. Likewise, similar results were observed for the specimens preloaded at faster strain rates and cycles applied at slower strain rates. The overall ratio of the measured stresses to the applied stresses (Felicity Ratio) for the tested rock specimens remained between 0.9 and 1.1, which according to Lavrov (2003), is a good indication of the stress memory in rocks. Thus, it can be concluded from the results that loading rate does not influence the stress memory in rocks.

4.2 Effect of time delay

As the rock cores extracted in-situ can take several days to months before they reach the laboratory, an important question on the applicability of this method remains the influence of time delay. This aspect of the rock stress memory has been widely studied. However, there are contradicting views. Initial studies suggest that the stress memory in rocks is degraded with the time delay to the extent that time delays of only a few hours can eliminate the stress memory (Goodman 1963). On the other hand, many researchers have disputed the results and observed a very clear Kaiser effect after time delays of 300 days (Koerner and Lord 1989; Filimonov et al. 2001). Seto et al. (1999) reported that stress memory was detected after a delay time of several years. While the studies mentioned above mainly were undertaken using the AE and DRA methods, Fujii et al. (2018) reported the influence of time delay on sandstone and granite specimens using the TMM method.

In the study, the rock specimens were preloaded, and subsequent cycles were applied after time delays of 0.5 h, 1 h, 6 h, 72 h, and one week to investigate the influence of time delay. It was observed that the TMM shows its effectiveness under a certain range of time delay, and its results are comparable with those by DRA. However, for large enough time delays exceeding 24 h, the results for all rocks are sensitive to the duration of time delay. It was observed that after a delay of 24 h, the separation point in tangent modulus curves appears at a lower stress level than the applied stresses. This is contradictory to what is observed using the DRA method, where no apparent influence of the time delay is observed. A possible reason for this could be a hysteresis loop. When a rock specimen is subjected to uniaxial cyclic loading, the loading and unloading curves do not coincide in the same cycle and form a hysteresis loop. Due to residual deformation and inelastic strains resulting from pore closure/collapse, the first hysteresis loop is relatively large. But as the number of cycles increase these loops get denser and closer together as shown in Fig. 14. A manifestation of the same can be observed in the tangent modulus curves for each cycle. A larger gap is observed between the first and the second cycle curves, whereby the curves overlap each other, and the inflection occurs at the previously applied maximum stress levels.

When a rock specimen is preloaded, and cyclic compressions are applied immediately, the tangent modulus curves overlap. A separation is observed at the pre-stress levels due to change of gradient in the first cycle curve. The time delay causes stress relaxation resulting in the reopening of pores and cracks. When the specimen is reloaded after a specific time delays the two tangent modulus curves don’t overlap due to the hysteresis loop resulting from pore closure at low stresses. As a result, the separation in the two curves appears at a lower stress level. More stress relaxation occurs for more prolonged time delays, resulting in a larger hysteresis loop when cyclically loaded, as shown in Fig. 15. If true, this effect of time delay would be more prominent in porous rocks compared to hard crystalline rocks, which should be further investigated.

The result of the tests conducted at various time delays are summarized in the scatter plot shown in Fig. 16. It can be observed that the FR remains close to 1 for all the rock types when the preloads are measured using the DRA method. In contrary, a considerable drop is observed in the FR values measured using the TMM method when the time delays exceed 24 h. The results show that the rock stress memory is unaffected by the time delay, and a change in the gradient can be observed in both DRA and TMM curves. The influence of the time delay observed in the TMM method is primarily a limitation in the method, not a material property. The two cycles’ separation in tangent modulus curves is possibly not the proper criteria to determine the previously applied maximum stresses. The method can be improved with further studies on hard crystalline rocks.

5 Conclusions

We investigated the influence of loading rates and time delay on the stress memory in coal, Gasford sandstone and Tuffeau limestone using the TMM and DRA methods. The TMM method is a unique method of investigating the stress memory in rocks which takes advantage of the inelastic strains produced during the uniaxial cyclic compression of the rock. It was observed that the TMM could effectively measure the applied preloads when the specimens were loaded between 40% and 80% of the rock UCS. Since the method is effective at high-stress levels (60%–80% of UCS) where the inelastic strains are mostly produced due to crack generation and coalescence, it can be inferred that the mechanism behind the TMM is similar to the DRA as opposed to the pore collapse mechanism. TMM showed no sensitivity to the modes of loading and strain rates. However, the method shows its effectiveness under a certain range of time delays and for large enough time delays exceeding 24 h; the results for all rocks show sensitivity to the duration of time delay. This indicates the possible limitation of the method, compared to DRA which restricts its application as a stress measurement method from oriented cores. While further investigations at the microscopic level can confirm this limitation and its reasons, the results visibly suggest that the sensitivity of the rock stress memory to the factors studied could be associated with the methodology applied for the studies.

Availability of data and materials

The raw data for this research can be provided on request through the corresponding author.

References

Ali Z, Karakus M, Nguyen G D, Amrouch K (2021a) Understanding the Kaiser effect in concrete using deformation rate analysis and acoustic emission. In: 10th Australasian conference on applied mechanics

Ali Z, Karakus M, Nguyen G D, Amrouch K (2021b) Effect of time delay and strain rate on tangent modulus method (TMM) in coal and coal measured rocks. In: 5th international symposium on mine safety science and engineering, Katowice, Poland

Ali Z, Karakus M, Nguyen G D, Amrouch K (2022) Stress memory in rocks; insight from deformation rate analysis and acoustic emission. In: EGU general assembly, Vienna, Austria

Ban Y, Fu X, Xie Q, Duan J (2020) Time-sensitivity mechanism of rock stress memory properties under tensile stress. J Rock Mech Geotech Eng 12:528–540

Bieniawski ZT (1967) Mechanism of brittle fracture of rock, part II - experimental studies. Int J Rock Mech Min Sci 4:407–423

Brace WF, Paulding JBW, Scholz C (1966) Dilatancy in the fracture of crystalline rocks. J Geophys Res 71:3939–3953

Bruning T, Karakus M, Nguyen GD, Goodchild D (2018) Experimental study on the damage evolution of brittle rock under triaxial confinement with full circumferential strain control. Rock Mech Rock Eng 51:3321–3341

Chen Y, Meng Q, Li Y, Pu H, Zhang K (2020) Assessment of appropriate experimental parameters for studying the Kaiser effect of rock. Appl Sci 10:7324

Diederichs MS, Kaiser PK, Eberhardt E (2004) Damage initiation and propagation in hard rock during tunnelling and the influence of near-face stress rotation. Int J Rock Mech Min Sci 41(5):785–812

Dyskin AV, Salganik RL (1987) Model of dilatancy of brittle materials with cracks under compression. Mech Solids 22:165–173

Fairhurst CE, Hudson JA (1999) Draft ISRM suggested method for the complete stress-strain curve for intact rock in uniaxial compression. Int J Rock Mech Min Sci 36:281–289

Filimonov Y, Lavrov A, Shafarenko Y, Shkuratnik V (2001) Memory effects in rock salt under triaxial stress state and their use for stress measurement in a rock mass. Rock Mech Rock Eng 34(4):275–291

Fujii Y, Makasib M, Kodamaa J, Fukudaa D, Gotoc K, Kumakurac S, Kanaokad M (2018) Tangent modulus method–an original method to measure in-situ rock stress. Tunn Undergr Space Technol 82:148–155

Goodman RE (1963) Subaudible noise during compression of rocks. Bull Geol Soc Am 74:487–490

Hoek E, Martin CD (2014) Fracture initiation and propagation in intact rock–a review. J Rock Mech Geotech Eng 6(4):287–300

Hsieh A, Dight P, Dyskin AV (2014) Ghost KE at low stress. Int J Rock Mech Min Sci 68:15–21

Hsieh A, Dight P, Dyskin AV (2016) The tangent modulus in rock under uniaxial compression test. In: 47th US rock mechanics/geomechanics symposium, San Francisco

Jin Y, Qi Z, Chen M, Zhang G, Xu G (2009) Time-sensitivity of the Kaiser effect of acoustic emission in limestone and its application to measurements of in situ stress. Pet Sci 6(2):176–180

Kaiser EJ (1953) A study of acoustic phenomena in tensile test. Technische Hochschule, München, Munich

Karakus M, Perez S, Goodchild D (2015) In-situ stress measurement from oriented sub-cores using Kaiser effect. In: international mining congress and exhibition of Turkey, Antalya

Karakus M (2014) Quantifying the discrepancy in preloads estimated by acoustic emission and deformation rate analysis. In: European rock mechanics symposium, Vigo

Koerner RM, Lord AE (1989) AE detection of pre-stress in soil and rock. In: Proceedings of the fourth conference on AE/MA in geologic structures and materials. Clausthal-Zellerfeld: Trans Tech Publications, pp 73–86

Kurita K, Fujii N (1979) Stress memory of crystalline rocks in acoustic emission. Geophys Res Lett 6(1):9–12

Lavrov A (2003) The KE in rocks: principles and stress estimation techniques. Int J Rock Mech Min Sci 40(2):151–171

Lehtonen A, Cosgrove J, Hudson J, Johansson E (2011) An examination of in-situ rock stress estimation using KE. Eng Geol 124:24–37

Martin CD, Chandler NA (1994) The progressive fracture of Lac du Bonnet granite. Int J Rock Mech Min Sci 31:643–659

Moradian Z, Einstein HH, Ballivy G (2016) Detection of cracking levels in brittle rocks by parametric analysis of the acoustic emission signals. Rock Mech Rock Eng 49:785–800

Sakaguchi K, Lino W, Matsuki K (2002) Damage in a rock core caused by induced tensile stress and its relation to differential strain curve analysis. Int J Rock Mech Min 39(3):367–380

Seto M, Utagawa M, Katsuyama K, Kiyama T (1998) In-situ stress determination using AE and DRA techniques. Int J Rock Mech Min Sci 35(4–5):458–459

Seto M, Nag DK, Vutukuri VS (1999) In situ rock stress measurement from rock cores using the acoustic emission method and deformation rate analysis. Geotech Geol Eng 17:241–266

Shirani FR, Taheri A, Karakus M (2021a) Failure behavior of a sandstone subjected to the systematic cyclic loading: insights from the double-criteria damage-controlled test method. Rock Mech Rock Eng 54:5555–5575

Shirani FR, Taheri A, Karakus M (2021b) Post-peak behavior of rocks under cyclic loading using a double criteria damage-controlled test method. Bull Eng Geol Environ 80:1713–1727

Stuart C, Meredith P, Murrell S, Van MJ (1993) Anisotropic crack damage and stress-memory effects in rocks under triaxial loading. Int J Rock Mech Min Sci 30(7):937–941

Sufan A, Russell AR (2013) Microstructural pore changes and energy dissipation in Gosford sandstone during pre-failure loading using X-ray CT. Int J Rock Mech Min Sci 57:119–131

Taheri A, Zhang Y, Munoz H (2020) Performance of rock crack stress thresholds determination criteria and investigating strength and confining pressure effects. Constr Build Mater 243:118263

Villaescusa E, Seto M, Baird G (2002) Stress measurement from oriented core. Int J Rock Mech Min Sci 39:603–615

Wawersik WR, Fairhurst C (1970) A study of brittle rock fracture in laboratory compression experiments. Int J Rock Mech Min Sci 7(5):561–564

Yamamoto K (2009) A theory of rock core-based methods for in-situ stress measurement. Earth Planets Space 61:1143–1161

Yamamoto K, Kuwahara Y, Kato N, Hirasawa T (1990) Deformation rate analysis: a new method for in situ stress estimation from inelastic deformation of rock samples under uniaxial compressions. Tohoku Geophys J 3(5):127–147

Yoshikawa S, Mogi K (1981) A new method for estimation of the crustal stress from cored rock samples: laboratory study in the case of uniaxial compression. Tectonophysics 74(4):323–339

Zhang Y, Chen YL, Yu RG, Hu LQ, Irfan M (2017) Effect of loading rate on the felicity effect of three rock types. Rock Mech Rock Eng 50:1673–1681

Zhao XG, Cai M, Wang J, Li PF, Ma LK (2015) Objective determination of crack initiation stress of brittle rocks under compression using AE measurement. Rock Mech Rock Eng 48(6):2473–2484

Acknowledgements

The authors are grateful to the Australia Coal Industry’s research Program (ACARP) for funding this research.

Funding

This project is financially supported by the Australian Coal Association Research Program (ACARP) under project C29010.

Author information

Authors and Affiliations

Contributions

ZA: conceptualization, experiments, data collection, formal analysis, investigation, validation, methodology, writing original draft. MK: funding acquisition, methodology, formal analysis, conceptualization, review & editing, supervision, project administration, GDN: funding acquisition, formal analysis, conceptualization, review & editing, supervision, methodology. KA: conceptualization, formal analysis, methodology, supervision, review & editing. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ali, Z., Karakus, M., Nguyen, G.D. et al. Effect of loading rate and time delay on the tangent modulus method (TMM) in coal and coal measured rocks. Int J Coal Sci Technol 9, 81 (2022). https://doi.org/10.1007/s40789-022-00552-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40789-022-00552-7