Abstract

Disc cutter wear is one of the comprehensive results of the rock–machine interaction in tunnel boring machine (TBM) tunneling. The replacement of the disc cutter is a time-consuming and costly activity that can significantly reduce the TBM utilization (U) and advance rate (AR), and has a major effect on the total time and cost of TBM tunneling projects. Therefore, the importance of predicting the cutter life accurately can never be overemphasized. Most cutter wear prediction models are only suitable for 17-in. or smaller disc cutters. However, use of large-diameter disc cutters has been an irresistible trend for large-section hard rock TBMs. This study attempts to reveal the genuine wear rule of a 20-in. disc cutter and develop a new empirical model for predicting the cutter life in granite based on field data collected from a water conveyance tunnel constructed by the TBM tunneling method in China. The field data including the actual cutter wear and the geological parameters along the studied tunnel were compiled in a special database that was subjected to statistical analysis to reveal the genuine wear rule of a 20-in. disc cutter and develop the reasonable correlations between some common intact rock parameters and the disc cutter life. These equations were developed based on data from massive to very massive granite with a UCS range of 40–100 MPa, which can be applied for the assessment of the cutter life of a 20-in. disc cutter in similar hard rock projects with similar rock strengths and rock abrasivities.

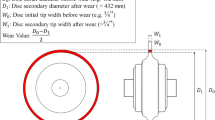

(modified from Frenzel 2011)

Similar content being viewed by others

References

Alber M, Yaralı O, Dahl F, Bruland A, Kasling H, Michalakopoulos TN, Cardu M, Hagan P, Aydın H, Ozarslan A (2014) ISRM suggested method for determining the abrasivity of rock by the CERCHAR abrasivity test. Rock Mech Rock Eng 47:261–266. doi:10.1007/s00603-013-0518-0

Bieniawski ZT (1989) Engineering rock mass classifications. Wiley, New York

Bieniawski ZT, Celada CB, Galera JM, Tardaguila IG (2009) Prediction of cutter wear using RME. ITA-AITES World Tunnel Congress, Budapest

Bruland A (1998) Hard rock tunnel boring. Dissertation, Norwegian University of Science and Technology

Dahl E, Grøv E, Breivik T (2007) Development of a new direct test method for estimating cutter life based on the Sievers’ J miniature drill test. Tunn Undergr Space Technol 22:106–116. doi:10.1016/j.tust.2006.03.001

Du SB (2006) Advantages of tunnelling by TBM with large diameter disc cutter. Water Resour Hydropower Eng 37(10):40–42. doi:10.13928/j.cnki.wrahe.2006.10.012 (in Chinese)

Du LJ, Ji SS, Zuo LF, Kong HX, Xu JL, Du YL (2015) Wear and consumption of large diameter disc cutters for hard rock TBM under giant porphyritic granite. J China Coal Soc 40(12):2974–2978. doi:10.13225/j.cnki.jccs.2015.3042 (in Chinese)

Ewendt G (1992) Erfassung der Gesteinsabrasivität und Prognose des Werkzeugverschleißes beim maschinellen Tunnelvortrieb mit Diskenmeißeln. Kurzberichte aus der Bauforschung 33(9):821–822

Frenzel C (2011) Disc cutter wear phenomenology and their implications on disc cutter consumption for TBM. In: 45th American Rock Mechanics/Geomechanics Symposium. San Francisco, USA

Frenzel C (2012) Modeling uncertainty in cutter wear prediction for tunnel boring machines. GeoCongress 2012: State of the Art and Practice in Geotechnical Engineering, pp 3239–3247

Frenzel C, Käsling H, Thuro K (2008) Factors influencing disc cutter wear. Geomech Tunn 1(1):55–60. doi:10.1002/geot.200800006

Gehring K (1995) Prognosis of advance rates and wear for underground mechanized excavations. Felsbau 13(6):439–448 (in German)

Hassanpour J, Rostami J, Azali ST, Zhao J (2014) Introduction of an empirical TBM cutter wear prediction model for pyroclastic and mafic igneous rocks; a case history of Karaj water conveyance tunnel, Iran. Tunn Undergr Space Technol 43:222–231. doi:10.1016/j.tust.2014.05.007

Ho YK, So STC, Lau TMF, Kwok RCM (2016) Abrasiveness of common rocks in Hong Kong. Rock Mech Rock Eng 49:2953–2958. doi:10.1007/s00603-015-0873-0

Hoek E, Brown ET (1997) Practical estimates of rock mass strength. Int J Rock Mech Min Sci 34(8):1165–1186. doi:10.1016/S1365-1609(97)80069-X

Jin YQ, Liu ZH, Yang L, Zheng GS (2011) Analyzing the cause of TBM disc cutter wear in Yintao project No.9 tunnel. Constr Mech 6:79–81. doi:10.13311/j.cnki.conmec.2011.06.022 (in Chinese)

Liu QS, Huang X, Gong QM, Du LJ, Pan YC, Liu JP (2016a) Application and development of hard rock TBM and its prospect in China. Tunn Undergr Space Technol 57:33–46. doi:10.1016/j.tust.2016.01.034

Liu QS, Liu JP, Shi K, Pan YC, Huang X, Liu XW, Wei L (2016b) Evaluation of rock brittleness indexes on rock fragmentation efficiency by disc cutter. Chin J Rock Mech Eng 35(3):498–510. doi:10.13722/j.cnki.jrme.2015.0569 (in Chinese)

Maidl B, Schmidz L, Ritz W, Herrenknecht M (2008) Hard rock tunnel boring machines. Wiley, New York

Nelson PP, Al-Jalil YA, Laughton C (1994) Tunnel boring project data bases and construction simulation. Geotechnical engineering report GR94-4, University of Texas at Austin

Plinninger RJ (2010) Hardrock abrasivity investigation using the Rock Abrasivity Index (RAI). In: Williams et al (eds) Geologically active. Taylor, London, pp 3445–3452

Plinninger RJ, Spaun G, Thuro K (2002) Prediction and classification of tool wear in drill and blast tunnelling. In: Proceedings of the 9th IAEG Congress, Durban, pp 2226–2236

Plinninger R, Kasling H, Thuroc K, Spaun G (2003) Testing conditions and geomechanical properties influencing the CERCHAR abrasiveness index (CAI) value. Int J Rock Mech Min Sci 40:259–263. doi:10.1016/S1365-1609(02)00140-5

Roby J, Sandell T, Kocab J, Lindbergh L (2008) The current state of disc cutter design and development directions. In: Proceedings of 2008 North American Tunnel Congress. San Francisco, USA, pp 36–45

Rostami J (1997) Development of a force estimation model for rock fragmentation with disc cutters through theoretical modeling and physical measurement of crushed zone pressure. Dissertation, Colorado School of Mines

Schneider E, Thuro K, Galler R (2012) Forecasting penetration and wear for TBM drives in hard rock–results from the ABROCK research project. Geomech Tunn 5(5):537–546. doi:10.1002/geot.20120

The National Standards Compilation Group of People’s Republic of China (2007) DL/T5368–2007 Code for rock tests of hydroelectric and water conservancy engineering. China Planning Press, Beijing (in Chinese)

The National Standards Compilation Group of People’s Republic of China (2009) GB50487–2008 Code for engineering geological investigation of water resources and hydropower. China Planning Press, Beijing (in Chinese)

Thuro K (1997) Prediction of drillability in hard rock tunnelling by drilling and blasting. In: World Tunnel Congress, Rotterdam, pp 103–108

Thuro K, Käsling H (2009) Classification of the abrasiveness of soil and rock. Geomech Tunn 2(2):179–188. doi:10.1002/geot.200900012

Wan ZC, Sha MY, Zhou YL (2002a) Study on disc cutters for hard rock (1)—Application of TB880E TBM in Qinling tunnel. Mod Tunnel Technol 39(5):1–11. doi:10.13807/j.cnki.mtt.2002.05.001 (in Chinese)

Wan ZC, Sha MY, Zhou YL (2002b) Study on disc cutters for hard rock (2)—application of TB880E TBM in Qinling tunnel. Mod Tunnel Technol 39(6):1–12. doi:10.13807/j.cnki.mtt.2002.06.001 (in Chinese)

Wang LH, Kang YL, Cai ZX, Zhang Q, Zhao Y, Zhao HF, Su PC (2012) The energy method to predict disc cutter wear extent for hard rock TBMs. Tunn Undergr Space Technol 28:183–191. doi:10.1016/j.tust.2011.11.001

Wei NZ, Sha MY (1999) The analysis of TBM cutter wear characteristic in the construction of Qinling tunnel. J Shijiazhuang Rail Inst 12(2):86–89. doi:10.13319/j.cnki.sjztddxxbzrb.1999.02.023 (in Chinese)

Wijk G (1992) A model of tunnel boring machine performance. Geotech Geol Eng 10:19–40. doi:10.1007/BF00881969

Yang YD, Chen K, Li FY, Zhou JJ (2015) Wear prediction model of disc cutter. J China Coal Soc 40(6):1290–1296. doi:10.13225/j.cnki.jccs.2014.3037 (in Chinese)

Zhao ZX (2015) Research on the wear of TBM disc cutter during the excavating of the mountain tunnel. Chin J Undergr Space Eng 11(S1):367–372 (in Chinese)

Zhao J, Gong QM, Eisensten Z (2007) Tunnelling through a frequently changing and mixed ground: a case history in Singapore. Tunn Undergr Space Technol 22(4):388–400. doi:10.1016/j.tust.2006.10.002

Acknowledgements

The authors would like to thank Jianfeng Zhou of Sinohydro Bureau 3 Company Limited for helping in the collection of the field data and acknowledge the funds provided by the National Key Basic Research Program of China under Grant Nos. 2014CB046904 and 2015CB058102. The authors are also grateful to the anonymous reviewers for their careful reading of our manuscript and their many valuable comments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Q., Liu, J., Pan, Y. et al. A Wear Rule and Cutter Life Prediction Model of a 20-in. TBM Cutter for Granite: A Case Study of a Water Conveyance Tunnel in China. Rock Mech Rock Eng 50, 1303–1320 (2017). https://doi.org/10.1007/s00603-017-1176-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-017-1176-4