Abstract

Disc cutters wear and need to be replaced when using tunnel boring machines (TBMs) to excavate through rock, often becoming a high ticket item on the list of consumables in tunneling operation. The empirical models used for predicting cutter life are commonly based on the properties of intact rock, while the impact of rock mass characteristics on cutter wear is often ignored or not properly taken into account. Joints and discontinuities tend to decrease the strength of rock mass, as compared to intact rock. Joint properties can affect the interactions between the rock and the disc cutter in the boring process. In other words, the cutter wear and life in a jointed rock mass are different than the wear rate in intact rock. In this study, field data including the geomechanical parameters and observed cutter life in the Kerman water conveyance tunnel (KWCT) project was analyzed using multivariable regression to offer a new empirical prediction model for prediction of cutter life in the jointed rocks. The model presented in this study shows that cutter life is a function of the total fracturing factor and rock mass strength, representing rock mass properties and Cerchar abrasivity index as intact rock property. Furthermore, boring in jointed rock is easier than an intact rock, and as a result, the cutter life increases. The validation results show that this model can offer a more accurate prediction of the disc cutter life in tunneling projects involving jointed rock masses.

Similar content being viewed by others

References

Al-Ameen SI, Waller M (1994) The influence of rock strength and abrasive mineral content on the Cerchar abrasive Index. Eng Geol 36(3-4):293–301

Bruland A (1998) Hard rock tunnel boring. Dissertation, Norwegian University of Science and Technology (NTNU)

Capik M, Yilmaz A (2017) Correlation between Cerchar abrasivity index, rock properties, and drill bit life. Arab J Geosci 10(1):15

Er S, Tuğrul A (2016) Estimation of Cerchar abrasivity index of granitic rocks in Turkey by geological properties using regression analysis. Bull Eng Geol Environ 75(3):1325–1339. https://doi.org/10.1007/s10064-016-0853-y

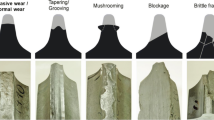

Farrokh E, Kim DY (2018) A discussion on hard rock TBM cutter wear and cutterhead intervention interval length evaluation. Tunn Undergr Space Technol 81:336–357

Farrokh E, Rostami J, Askilsrud, OG (2013) A discussion on TBM cutter change time and cutter life. SME Annual Meeting, Denver, pp 13–105

Frenzel C (2012) Modeling uncertainty in cutter wear prediction for tunnel boring machines. GeoCongress: State of the Art and Practice in Geotechnical Engineering, pp 3239–3247

Hassanpour J (2018) Development of an empirical model to estimate disc cutter wear for sedimentary and low to medium grade metamorphic rocks. Tunn Undergr Space Technol 75:90–99

Hassanpour J, Rostami J, Tarigh Azali S, Zhao J (2014) Introduction of an empirical TBM cutter wear prediction model for pyroclastic and mafic igneous rocks; a case history of Karaj water conveyance tunnel, Iran. Tunn Undergr Space Technol 43:222–231

Hoek E, Brown ET (2019) The Hoek–Brown failure criterion and GSI–2018 edition. J Rock Mech Geotech Eng 11(3):445–463

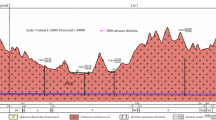

Karami M, Zare S, Rostami J (2021a) Study of common wear prediction models for hard rock TBM disc cutters and comparison with field observation in Kerman water conveyance tunnel. Bull Eng Geol Environ 80:1467–1476. https://doi.org/10.1007/s10064-020-01987-5

Karami M, Zare S, Rostami J (2021b) Tracking of disc cutter wear in TBM tunneling: a case study of Kerman water conveyance tunnel. Bull Eng Geol Environ 80:201–219. https://doi.org/10.1007/s10064-020-01931-7

Ko TY, Lee SS (2020) Effect of rock abrasiveness on wear of shield tunnelling in bukit timah granite. Appl Sci 10(9):3231. https://doi.org/10.3390/app10093231

Ko TY, Kim TK, Son Y, Jeon S (2016) Effect of geomechanical properties on Cerchar Abrasivity Index (CAI) and its application to TBM tunnelling. Tunn Undergr Space Technol 57:99–111

Kolymbas D (2008) Tunnelling and tunnel mechanics: a rational approach to tunnelling. Springer, Berlin

Liu Q, Liu J, Pan Y, Zhang X, Peng X, Gong Q, Du L (2017) A wear rule and cutter life prediction model of a 20-in. TBM cutter for granite: a case study of a water conveyance tunnel in China. Rock Mech Rock Eng 50(5):1303–1320

Macias FJ, Jakobsen PD, Seo Y, Bruland A (2014) Influence of rock mass fracturing on the net penetration rates of hard rock TBMs. Tunn Undergr Space Technol 44:108–120

Ren DJ, Shen SL, Arulrajah A, Cheng WC (2018) Prediction model of TBM disc cutter wear during tunnelling in heterogeneous ground. Rock Mech Rock Eng 51(11):3599–3611

Rostami J, Ozdemir L, Bruland A, Dahl F (2005) Review of issues related to Cerchar abrasivity testing and their implications on geotechnical investigations and cutter cost estimates. Proceedings of the Rapid Excavation and Tunneling Conference (RETC): 738–751

Sun Z, Zhao H, Hong K, Chen K, Zhou J, Li F, He R (2019) A practical TBM cutter wear prediction model for disc cutter life and rock wear ability. Tunn Undergr Space Technol 85:92–99

Tan Q, Xie LJ, Xia YM, Zhu ZH, Sun XJ, Wang YY (2015) Analysis of wear rate of TBM disc cutter. J Cent South Univ 46(3):843–848

Wang L, Kang Y, Cai ZC, Zhang Q, Zhao Y, Zhao H, Su P (2012) The energy method to predict disc cutter wear extent for hard rock TBMs. Tunn Undergr Space Technol 28:183–191

Wang F, Men C, Kong X, Meng L (2019) Optimum design and application research of eddy current sensor for measurement of TBM disc cutter wear. Sensors 19:4230. https://doi.org/10.3390/s19194230

Wijk G (1992) A model of tunnel boring machine performance. Geotech Geol Eng 10:19–40

Yagiz S (2003) A model for prediction of TBM performance in hard rock condition. 56th Geological Congress of Turkey

Yang Y, Hong K, Sun Z, Chen K, Li F, Zhou J, Zhang B (2018) The derivation and validation of TBM disc cutter wear prediction model. Geotech Geol Eng 36:3391–3398

Zhang H (2010) Analysis of damages of TBM disc cutters and countermeasures. Mod Tunn Technol 47:40–45

Zhang XP, Ji PQ, Liu Q, Liu Q, Zhang Q, Peng ZH (2018) Physical and numerical studies of rock fragmentation subject to wedge cutter indentation in the mixed ground. Tunn Undergr Space Technol 71:354–365

Zhang Z, Aqeel M, Li C, Sun F (2019) Theoretical prediction of wear of disc cutters in tunnel boring machine and its application. J Rock Mech Geotech Eng 11(1):111–120

Zhaohuang Z (2007) Study on the abrasion of disc cutters on full face rock tunnel boring machine. Mod Tunn Technol 44:32–36

Acknowledgements

The authors would like to express their sincere thanks to the assistance of the project manager and personnel of the Kerman water conveyance tunnel and HRT tunnel projects for sharing the actual data of these projects.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Karami, M., Zare, S. & Rostami, J. Introducing an empirical model for prediction of disc cutter life for TBM application in jointed rocks: case study, Kerman water conveyance tunnel. Bull Eng Geol Environ 80, 3853–3870 (2021). https://doi.org/10.1007/s10064-021-02166-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-021-02166-w