Abstract

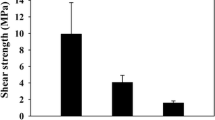

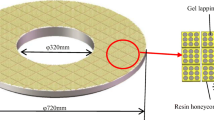

This paper presents a new bonding procedure for thick silicon wafers. Those wafers are less flexible and have usually a larger wafer bow. That implicates that standard bonding techniques, such as silicon fusion bonding or anodic bonding, produce non satisfactory yield results. A compliant layer is required to overcome this problem. For the new bonding principle, silicon wafers are structured by a self-masking deep reactive ion etching process. Thereby a forming of needle-shaped nanostructures (known as Black Silicon) on the surface is generated. Between both wafers a green LTCC (low temperature cofired ceramic) foil was placed which assumes multiple functions. The foil is able to compensate the wafer bow, is easy to structure and leads to a quasimonolithic compound after pressure assisted sintering. In the paper the fabrication steps for bonding are explained in detail, especially the adjustment of flexible and unflexible substrates. The interface and the mechanical properties were analyzed and discussed.

Similar content being viewed by others

References

Bley T, Pignanelli E, Fischer M, Günschmann S, Müller J, Schütze A (2012) “IR optical oil quality sensor system for high pressure applications”; mechatronics 2012—the 13th mechatronics forum international conference, Linz, Austria, September 17–19, 2012, Proceedings vol 2/3, ISBN 978-3-99033-046-5, pp 351–358

Fischer M, Bartsch de Torres H, Pawlowski B, Gade R, Barth S, Mach M, Stubenrauch M, Hoffmann M, Müller J (2009) Silicon on ceramics—a new integration concept for silicon devices to LTCC. J Microelectron Electron Packag 6:1–5

Müller E, Bartnitzek T, Bechtold F, Pawlowski B, Rothe P, Ehrt R, Heymel A, Weiland E, Schroeter T, Schundau S, Kaschlik K (2005) Development and processing of an anodic bondable LTCC tape. European Microelectronics and Packaging, Brugge

Acknowledgments

The authors gratefully acknowledge the financial support by the Federal Ministry of Education and Research (project: “NaMiFlu”; 16SV5360).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Günschmann, S., Fischer, M., Mannebach, H. et al. Silicon–ceramic–silicon-wafercompound fabricated by using nanostructured silicon surfaces and a ceramic with adapted thermal expansion coefficient. Microsyst Technol 21, 1029–1034 (2015). https://doi.org/10.1007/s00542-015-2434-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-015-2434-6