Abstract

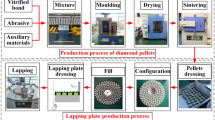

SiC crystal has been widely used in semiconductor substrates because of its excellent physical, chemical, and photoelectric properties. As a semiconductor substrate, the SiC wafer not only needs good surface quality but also requires surface shape accuracy. In the present study, a novel lapping plate was designed for SiC wafers to improve their surface quality and shape accuracy. In the novel lapping plate, epoxy resin and a soft gel body containing diamond abrasives are combined to form a hard honeycomb structure. The cellular structure is used to support the lapping pressure to reduce the deformation of the lapping plate and improve the surface shape accuracy. The cellular structure is filled with soft gel with diamond abrasives which play the role of semifixed lapping to obtain good surface quality. Two crystalline forms of silicon carbide (4H-SiC and 6H-SiC) were selected to carry out double-sided lapping experiments with the novel lapping plate. The experimental results show that the lapped wafers have good surface quality with low surface roughness, some small scratches, and acceptable cracks. In addition, the surface shape accuracy is improved; the values of bow, warp, and total thickness variation (TTV) are all reduced after lapping. Under the same lapping conditions, the 6H-SiC has a smaller surface roughness than 4H-SiC, and for a specific crystalline form, the surface roughness of the C face is smaller than that of the Si face. The bow and warp of 4H-SiC are smaller, but the TTV is larger. The material removal rate is basically the same for 4H-SiC and 6H-SiC.

Similar content being viewed by others

References

Morkoc H, Strite S, Gao GB, Lin ME, Sverdlov B, Burns M (1994) Large-band-gap SiC, III-V nitride, and II-VI ZnSe-based semiconductor device technologies. J Appl Phys 76(3):1363–1398

Levinshtein ME, Rumyantsev SL, Shurn MS (2001) Properties of advanced semiconductor materials: GaN, AIN, InN, BN, SiC. John Wiley & Sons, SiGe

Presser V, Nickel KG (2008) Silica on silicon carbide. Crit Rev Solid State Mater Sci 33(1):1–99

Falk AL, Buckley BB, Calusine G, Koehl WF, Dobrovitski VV, Politi A, Awschalom DD (2013) Polytype control of spin qubits in silicon carbide. Nat Commun 4(5):1819

Pedersen H, Leone S, Kordina O (2012) Chloride-based CVD growth of silicon carbide for electronic applications. Chem Rev 112(4):2434

Oliveros A, Guiseppi-Elie A, Saddow SE (2013) Silicon carbide: a versatile material for biosensor applications. Biomed Microdevices 15(2):353–368

Iveković A, Novak S, Dražić G, Blagoeva D, Vicente SG (2013) Current status and prospects of SiCf/SiC for fusion structural applications. J Eur Ceram Soc 33(10):1577–1589

Pan JS Research on ultra precision abrasive machining mechanism of monocrystalline SiC substrates. (Doctoral dissertation, Guangdong University of Technology)

Zhou H (2014) Ultra-precision machining technology of substrates. Science Publishing of China

Wang D, Zhang YX, Gao W, Yang LL, Su JX (2014) Study on the subsurface damage depth of the lapped SiC wafers. J Synth Cryst 43(6):1500–1503 +1508

Tan TH, Yan J (2017) Atomic-scale characterization of subsurface damage and structural changes of single-crystal silicon carbide subjected to electrical discharge machining. Acta Mater 123:362–372

Hossain TK, Maclaren S, Engel JM, Liu C, Adesida I, Okojie RS (2006) The fabrication of suspended micromechanical structures from bulk 6H-SiC using an ICP-RIE system. J Micromech Microeng 16(4):751–756

Zhao F, Du W, Huang CF (2014) Fabrication and characterization of single-crystal 4H-SiC microactuators for MHz frequency operation and determination of Young’s modulus. Microelectron Eng 129:53–57

Luo X, Goel S, Reuben RL (2012) A quantitative assessment of nanometric machinability of major polytypes of single crystal silicon carbide. J Eur Ceram Soc 32(12):3423–3434

Yashiro H, Fujimoto T, Ohtani N, Hoshino T, Katsuno M, Aigo T (2009) Development of lapping and polishing technologies of 4H-SiC wafers for power device applications. Mater Sci Forum 600-603:819–822

Li J, Chen XF, Ma DY (2006) High-prcesion processing of silicon carbide. J Funct Mater

Yu ZT (2012) Research on lapping 6H-SiC crystal substrate (0001) C face using diamond abrasive. (Doctoral dissertation, Nanjing University of Science and Technology)

Huo FW, Guo DM, Kang RK, Feng G (2012) Nanogrinding of SiC wafers with high flatness and low subsurface damage. Trans Nonferrous Metals Soc China 22(12):3027–3033

Eto H, Lin W, Watanabe Y (2006) 407 ELID grinding of large SiC mirror// The Manufacturing & Machine Tool Conference. JSME 2006:61–62

Li M, Zhu YW, Ye JF, Fan JL, Li J (2010) Removal mechanism in fixed abrasive lapping process. Diamond & Abrasive Engineering 30(4):1–6

Yuan J, Wang Z, Hong T, Deng Q, Wen D, Lv B (2009) A semi-fixed abrasive machining technique. J Micromech Microeng 19(19):054006

Nakamura H, Yan JW, Syoji K, Wakamatsu Y (2003) Development of a polishing disc containing granulated fine abrasives. Key Eng Mater 238-239(6):257–262

Lv BH, Yuan JL, Wang ZW (2009) Simulation of compacting process for semi-fixed abrasive wheel. Key Eng Mater 416:87–92

Luo QF, Lu J, Xu XP (2016) A comparative study on the material removal mechanisms of 6H-SiC polished by semi-fixed and fixed diamond abrasive tools. Wear 350–351:99–106

Luo Q, Lu J, Xu X (2016) Study on the processing characteristics of SiC and sapphire substrates polished by semi-fixed and fixed abrasive tools. Tribol Int 104:191–203

Wang P , Liu Y , Zhang B (2016) Correction on the edge collapse during the synchrospeed polishing process. Eighth International Symposium on Advanced Optical Manufacturing & Testing Technology. International Society for Optics and Photonics

Wang WS, Hu ZW, Zhao H (2019) Preparation and application of semi-fixed abrasive lapping plates with cecullar structure. Opt Precis Eng 27(01):74–82

Lu J, Luo Q, Xu X, Huang H, Jiang F (2017) Removal mechanism of 4H- and 6H-SiC substrates (0001 and 0001¯) in mechanical planarization machining. Proc Inst Mech Eng B J Eng Manuf 233(1):69–76

Goal S, Yan JW, Luo XC et al (2014) Incipient plasticity in 4H-SiC during quasistatic nanoindentation. J Mech Behav Biomed 34(1):330–337

Funding

This work was supported by National Natural Science Foundation of China (Grant Nos. 51575197 and 51675192), Science and Technology Projects of Xiamen (Grant No. 3502Z20173047), and China Postdoctoral Science Foundation (Grant No. 2016M592081).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yiqing, Y., Zhongwei, H., Wenshan, W. et al. The double-side lapping of SiC wafers with semifixed abrasives and resin–combined plates. Int J Adv Manuf Technol 108, 997–1006 (2020). https://doi.org/10.1007/s00170-019-04592-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04592-3