Abstract

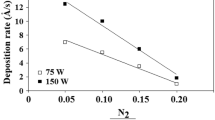

Tantalum nitride thin films are grown on silicon wafers using a mixture of Ar/N2 using DC magnetron sputtering. The influence of nitrogen concentration on various features of tantalum nitride thin films is systematically studied. X-ray diffraction results show characteristic peaks of FCC tantalum nitride with crystallite size gradually increasing upon an augmentation in the nitrogen concentration. Field emission scanning electron microscopy images indicate that the tantalum nitride thin films are made of crystal domains with almost regular boundaries. As nitrogen concentration increases from 10 to 25%, the average domain size increases. Atomic force microscopy (AFM) results show larger surface roughness for the tantalum nitride thin films with higher nitrogen concentration owing to grain boundary diffusivity. Furthermore, quantitative characterization of 3-D surface morphology from AFM micrographs is obtained by multifractal and stereometric analyses. The results of mechanical properties show a decrease in the hardness upon increasing the nitrogen concentration due to variation in the grain size. The obtained results from the four-point probe illustrate that the specimen with higher nitrogen content displays the minimum sheet resistance due to a decrease in inter-grain boundaries emanated from the larger grain size. The current study renders a new insight in controlling the conductivity and the hardness of TaN thin film based on the deposition conditions and provide a correlation between the structural and other properties of TaN films, which is useful for a variety of semiconductor devices.

Similar content being viewed by others

References

L.E. Toth (ed.), Transition Metal Carbides and Nitrides (Academic Press, New York, 1971), p. 279

W. Lengauer, in Nitrides and Carbonitrides: Handbook of Hard Materials, vol. 1. ed. by R. Riedel (Wiley-VCH, Weinheim, 2000), pp. 202–252

A. Jafari, Z. Ghoranneviss, A.S. Elahi, M. Ghoranneviss, N.F. Yazdi, A. Rezaei, Adv Mech Eng 6, 373847 (2021)

G. Bejarano-Gaitan, A.M. Echavarria-Garcia, A.C. Quirama-Ossa, J.A. Osorio-Velez, Rev. EIA 25, 69–80 (2016)

T. Riekkinen, J. Molarius, T. Laurila, A. Nurmela, I. Suni, J.K. Kivailahti, Microelectron. Eng. 64, 289–297 (2002)

N. Arshi, J. Lu, Y.K. Joo, J.H. Yoon, B.H. Koo, Surf. Interface Anal. 47, 154–160 (2015)

Y.J. Lee, B.S. Suh, S.K. Rha, C.O. Park, Thin Solid Film 320, 141–146 (1998)

G.S. Chen, S.T. Chen, L.C. Yang, P.Y. Lee, J. Vac. Sci. Technol. A 18, 720–723 (2000)

K.H. Min, K.C. Chun, K.B. Kim, J. Vac. Sci. Technol. B 14, 3263–3269 (1996)

J.C. Yang, B. Kolasa, J.M. Bibson, M. Yeadon, Appl. Phys. Lett. 73, 2841–2843 (1998)

O. Hugh, Pierson: Handbook of Refractory Carbides and Nitrides, Properties, Characteristics, Processing and Applications (Noyes Publications, New Jersey, 1996)

L.E. Thod, Transition Metal Carbides and Nitrides (Academic, New York, 1971)

N. Arshi, J. Lu, C.G. Lee, B.H. Koo, F.J. Ahmed, Miner. Met. Mater. Soc. 66, 1893–1899 (2014)

Q.X. Jia, H.J. Lee, E. Ma, W.A. Anderson, F.M. Collins, J. Mater. Res. 10, 1523 (1995)

S. Tsukimoto, M. Moriyama, M. Murakami, Thin Solid Films 460(1–2), 222–226 (2004)

J. Holloway et al., J. Appl. Phys. 71(11), 5433 (1992)

J. Grill et al., J. Mater. Res. 7(12), 3260 (1992)

J.L. Qi et al., Surf Coat Technol 405, 126724 (2021)

B. Reshi, S. Kumar, A. Misra, R. Varma, Mater. Res. Express 6(4), 046407 (2019)

S. Kumar, B. Reshi, R. Varma, Results Phys. 11, 461–474 (2018)

B. Reshi, M. Kartha, A. Misra, R. Varma, Mater. Res. Express 6(9), 096420 (2019)

M. Kartha, B. Reshi, P. Walke, D. Dastan, Ceram. Int. 48, 5066–5074 (2022)

A. Jafari, K. Tahani, D. Dastan, S. Asgary, Z. Shi, X.-T. Yin, W.-D. Zhou, H. Garmestani, Ş Ţălu, Surf. Interfaces 18, 100463 (2020)

J. Silva, K. Sekhar, R. Negrea, C. Ghica, D. Dastan, M. Gomes, Ceram. Int. 48, 6131–6137 (2022)

A. Jafari, M.H. Alam, D. Dastan, S. Ziakhodadadian, Zh. Shi, H. Garmestani, A.S. Weidenbach, Ş Ţălu, J. Mater. Sci. Mater. Electron. 30, 21185–21198 (2019)

Ş Ţălu, S. Kulesza, M. Bramowicz, K. Stępień, D. Dastan, Arch. Metall. Mater. 66(2), 443–450 (2021)

G. Tan, D. Tang, D. Dastan, A. Jafari, Z. Shi, Q. Chu, J. Silva, X. Yin, Ceram. Int. 47, 17153–17160 (2021)

H. Tajima, N. Shiobara, H. Katsumata, S. Uekusa, J. Surf. Anal. 17(3), dd247–dd251 (2011)

S.A. Shostachenko, R.V. Zakharchenko, R.V. Ryzhuk, S.V. Leshchev, I.O.P. Conf, IOP Conf. Ser. Mater. Sci. Eng. 498, 012014 (2019)

A. Zaman, E.I. Meletis, Coatings 7, 209 (2017)

S.M. Kang, S.G. Yoon, S.J. Suh, D.H. Yoon, Thin Solid Films 516(11), 3568–3571 (2008)

J.L. Vossen, S. Krommenhoek, A.V. Koss, J. Vac. Sci. Technol. A 3(9), 600–603 (1991)

M. Stavrev, D. Fischer, C. Wenzel, K. Drescher, N. Mattern, Thin Solid Films 307, 79–88 (1997)

D. Dastan, N.B. Chaure, J. Mater. Mech. Manuf. 2(1), 21–24 (2014)

S. Tsukimoto, M. Moriyama, M. Murakami, Thin Solid Films 460, 222–226 (2004)

D. Dastan, S.L. Panahi, N.B. Chaure, J. Mater. Sci: Mater. Electron. 27, 12291–12296 (2016)

G. Tan, D. Tang, D. Dastan, A. Jafari, J. Silva, X. Yin, Mater. Sci. Semicond. Process 122, 105506 (2021)

X. Yin, W. Zhou, J. Li, P. Lv, Q. Wang, D. Wang, F. Wu, D. Dastan, H. Garmestani, Z. Shi, Ş Ţălu, J. Mater. Sci. Mater. Electron. 30, 14687–14694 (2019)

A. Jafari, M. Mosavat, A. Meidanchi, H. Hossienkhani, J. Chem. Res. 42(2), 73–76 (2018)

D. Dastan, P.U. Londhe, N.B. Chaure, J. Mater. Sci: Mater. Electron. 25, 3473–3479 (2014)

K. Shan, F. Zhai, Z. Yi, X. Yin, D. Dastan, F. Tajabadi, A. Jafari, S. Abbasi, Surf. Interfaces 23, 100905 (2021)

W. Zhou, D. Dastan, J. Li, X. Yin, Q. Wang, Nanomaterials 10(4), 785 (2020)

W. Zhou, D. Dastan, X. Yin, S. Nie, S. Wu, Q. Wang, J. Li, J. Mater. Sci. Mater. Electron. 31, 18412–18426 (2020)

D. Dastan, J. At. Mol. Condens. Nano Phys. (JAMCNP) 2(2), 109–114 (2015)

K. Shan, Z. Yi, X. Yin, D. Dastan, S. Dadkhah, B. Coates, H. Garmestani, Adv. Powder Technol. 31, 4657–4664 (2020)

K. Shan, Z. Yi, X. Yin, D. Dastan, F. Altaf, H. Garmestani, F. Alamgir, Surf. Interfaces 21, 100762 (2020)

T. Rikkinen, J. Molarius, T. Laurila, A. Nurmela et al., Microelectron. Eng. 64, 289 (2002)

R. Gonçalves, R. Toledo, N. Joshi, O. Berengue, Mater. Adv. 2, 4190 (2021)

N. Joshi, T. Hayasaka, Y. Liu, H. Liu, O. Oliveira Jr., L. Lin, Microchim. Acta 185, 213 (2018)

C.S. Shin, Y.W. Kim, D. Gall, J.E. Greene, I. Petrov, Thin Solid Films 402, 172–182 (2002)

G.F. Iriarte, J.G. Rodríguez, F. Calle, Mater. Res. Bull. 45(9), 1039–1104 (2021)

D. Dastan, Appl. Phys. A 123(699), 1–13 (2017)

M. Naftaly et al., Electronics 10, 960 (2021)

A.J. Dammers, S. Radelaar, Textures Microstruct. 14, 757 (1991)

D. Dastan, N. Chaure, M. Kartha, J. Mater. Sci. Mater. Electron. 28, 7784–7796 (2017)

M. Asadzadeh, F. Tajabadi, D. Dastan, P. Sangpour, Z. Shi, N. Taghavinia, Ceram. Int. 47, 5487–5494 (2021)

N.D. Cuong, J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 24, 1398 (2006)

S.K. Mukherjee, L. Joshi, P.K. Barhai, Surf. Coat. Technol 205, 4582–4595 (2011)

A. Tiwari, H. Wang, D. Kumar, J. Naryan, Mod. Phys. Lett. B 16, 1143 (2002)

H. Qiu, F. Wang, P. Wu, L. Pan, Vacuum 66, 447–452 (2002)

K. Mech, R. Kowalik, P. Zabinski, Arch. Metall. Mater. 56, 903–908 (2011)

N. Bahlawane, P.A. Premkumar, F. Reilmann, K. Kohse-Höinghaus, J. Wang, F. Qi, B. Gehl, M. Bäumer, J. Electrochem. Soc. 156, D452–D455 (2009)

Y. Jiao, Z. Huang, W. Hu, X. Li, Q. Yu, Y. Wang, Y. Zhou, D. Dastan, Mater. Sci. Eng. A 820, 141524 (2021)

L. Liu, Y.Y. Sheng, M. Liu, M. Dienwiebel, Z. Zhang, D. Dastan, Tribol. Int. 140, 105727 (2019)

L. Liu, C. Yang, J. Zhou, H. Garmestani, D. Dastan, Prot. Met. Phys. Chem. Surf. 57(2), 367–373 (2021)

S. Xu et al., Surf. Coat. Technol. 307, 470–475 (2016)

C.S. Shin, D. Gall, P. Desjardins, A. Vailionis, H. Kim, I. Petrov, J.E. Greene, Appl. Phys. Lett. 75, 3808 (1999)

D. Kim, H. Lee, D. Kim, Y.K. Kim, J. Cryst. Growth 283, 404–408 (2005)

S.-I. Baik, Y.-W. Kim, Appl. Microsc. 50, 7 (2020)

D. Bernoulli, U. Müller, M. Schwarzenberger, R. Hauert, R. Spolenak, Thin Solid Films 548, 157–161 (2013)

S.K. Kim, B.C. Cha, Thin Solid Films 475, 202–207 (2005)

Acknowledgements

A. Jafari thanks the Foundation for Polish Science financed by the European Union under the European Regional Development Fund (POIR.04.04.00-00-3ED8/17). This work was funded by the University of Jeddah, Jeddah, Saudi Arabia, under grant No. (UJ-21-DR-31). The authors, therefore, acknowledge with thanks the University of Jeddah technical and financial support.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dastan, D., Shan, K., Jafari, A. et al. Influence of nitrogen concentration on electrical, mechanical, and structural properties of tantalum nitride thin films prepared via DC magnetron sputtering. Appl. Phys. A 128, 400 (2022). https://doi.org/10.1007/s00339-022-05501-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-022-05501-4