Abstract

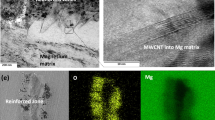

The study presents the surface modification of β-titanium alloy by the electrical discharge chemical treatment (EDCT) to achieve a corrosion-resistant surface. This technique incorporated multi-walled carbon nanotubes (MWCNTs) in the dielectric medium to alter the surface properties of the substrate. Herein, the MWCNTs act as potential candidates due to its chemical inertness and physical as well as electrical properties for achieving desired surface properties. For the sake of comparison, the μ-hydroxyapatite (μHAp) powder was also utilized in the dielectric medium. Surface morphology, topography, and elemental composition of the treated surfaces were investigated by FE-SEM, EDS, and XRD techniques, respectively. The electrochemical potentiodynamic test was carried out to investigate the corrosion resistance of untreated and treated surfaces. The treated surfaces were also evaluated in terms of change in surface morphology, wettability, and surface free energy. The outcome revealed that the alloy treated with MWCNTs favors the synthesis of the chemically stable corrosion-resistant surface. The existence of TiO2, ZrO2, Nb2O5, TaO, ZrO2, TiC2, and NbC phases detected from XRD examination affirmed that the corrosion resistance of the substrate is significantly affected by multi-walled carbon nanotube deposition. The MWCNT-treated surface presented the improved wettability and surface free energy which are twofold higher than the untreated surface.

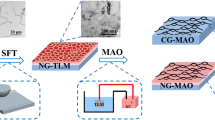

Graphic abstract

Similar content being viewed by others

References

G. Singh, H. Singh, B.S. Sidhu, Appl. Surf. Sci. 284, 811 (2013)

W.P. Freire, M.V.L. Fook, E.F. Barbosa, C.S. dos Araújo, R.C. Barbosa, I.M. Pinheiro, Mater Sci Forum 805, 19 (2015)

L.S. Kubie, G.M. Shults, J. Exp. Med. 42, 565 (1925)

G. Manivasagam, D. Dhinasekaran, A. Rajamanickam, Recent Pat. Corros. Sci. 2, 40 (2010)

G.T. Burstein, P.C. Pistorius, Corrosion 51, 380 (1995)

K. Avsec, M. Jenko, M. Conradi, A. Kocijan, A. Vesel, J. Kovač, M. Godec, I. Belič, B. Šetina-Batič, C. Donik, M. Gorenšek, Coatings 9, 868 (2019)

F. Rupp, L. Scheideler, N. Olshanska, M. De Wild, M. Wieland, J. Geis-Gerstorfer, J. Biomed. Mater. Res. A 76, 323 (2016)

Y. Su, C. Luo, Z. Zhang, H. Hermawan, D. Zhu, J. Huang, Y. Liang, G. Li, L. Ren, J. Mech, Behav. Biomed. Mater. 77, 90 (2018)

B. Kasemo, J. Prosthet. Dent. 49, 832 (1983)

K.R. Rakesh, S. Bontha, M.R. Ramesh, M. Das, V.K. Balla, Appl. Surf. Sci 480, 70 (2019)

G. Zhao, Z. Schwartz, M. Wieland, F. Rupp, J. Geis-Gerstorfer, D.L. Cochran, B.D. Boyan, J. Biomed. Mater. Res. A 74, 49 (2005)

G. Wang, S. Moya, Z. Lu, D. Gregurec, H. Zreiqat, Nanomedicine 10, 1327 (2015)

K. Das, A. Bandyopadhyay, S. Bose, J. Am. Ceram. Soc. 91, 2808 (2008)

S. Tamilselvi, V. Raman, N. Rajendran, Electrochim. Acta 52, 839 (2006)

I. Gurappa, Mater. Charact. 49, 73 (2002)

B. Sivakumar, S. Kumar, T.S. Narayanan, Wear 270, 317 (2011)

M. Lewandowska, A. Roguska, M. Pisarek, B. Polak, M. Janik-Czachor, K.J. Kurzydłowski, Biomol. Eng. 24, 438 (2007)

B. Sivakumar, R. Singh, L.C. Pathak, Mat. Sci. Eng. C 48, 243 (2015)

X. Nie, A. Leyland, A. Matthews, Surf. Coat. Tech. 125, 407 (2000)

Y. Usui, K. Aoki, N. Narita, N. Murakami, I. Nakamura, K. Nakamura, N. Ishigaki, H. Yamazaki, H. Horiuchi, H. Kato, S. Taruta, SMALL 4, 240 (2008)

T. Sun, G. Wang, H. Liu, L. Feng, L. Jiang, D. Zhu, J. Am. Ceram. Soc. 125, 14996 (2003)

X. Dai, X. Huang, F. Yang, X. Li, J. Sightler, Y. Yang, C. Li, Appl. Phys. Lett. 102, 161605 (2013)

S. Vardharajula, S.Z. Ali, P.M. Tiwari, E. Eroğlu, K. Vig, V.A. Dennis, S.R. Singh, Int. J. Nanomed. 7, 5361 (2012)

E.D. Yildirim, Y. Xin, K. Nair, W. Sun, J. Biomed. Mater. Res. B 87, 406 (2008)

X.H. Chen, C.S. Chen, H.N. Xiao, F.Q. Cheng, G. Zhang, G.J. Yi, Surf. Coat. Tech. 191, 351 (2005)

Z. Yang, H. Xu, Y.L. Shi, M.K. Li, Y. Huang, H.L. Li, Mater. Res. Bull. 40, 1001 (2005)

B.M. Praveen, T.V. Venkatesha, Y.A. Naik, K. Prashantha, Surf. Coat. Tech. 201, 5836 (2007)

M. Terada, S. Abe, T. Akasaka, M. Uo, Y. Kitagawa, F. Watari, Biomed Mater Eng 19, 45 (2009)

A. Mahajan, S.S. Sidhu, J. Mater. Res. 34, 2837 (2019)

S.S. Sidhu, A. Batish, K. Kumar, Mater. Manuf. Process. 29, 46 (2014)

L. Li, L. Zhao, Z.Y. Li, L. Feng, X. Bai, Mater. Manuf. Process. 32, 83 (2017)

N. Zaveri, G.D. McEwen, R. Karpagavalli, A. Zhou, J. Nanoparticle Res. 12, 1609 (2010)

A.M. Abdul-Rani, A.M. Nanimina, T.L. Ginta, Key. Eng. Mater. 724, 61 (2017)

T.T. Opoz, H. Yasar, M.F. Murphy, N. Ekmekci, B. Ekmekci, Int. J. Adv. Eng. Pure Sci. 31, 1 (2019)

S. Devgan, S.S. Sidhu, Mater. Chem. Phys. 239, 122005 (2020)

P.V. Ramarao, M.A. Faruqi, Precis. Eng. 4, 111 (1982)

H.K. Kansal, S. Singh, P. Kumar, J. Mater. Process. Tech. 169, 427 (2005)

T. Pratap, K. Patra, Surf. Coat. Tech. 349, 71 (2018)

R. Junker, A. Dimakis, M. Thoneick, J.A. Jansen, Clin Oral Implants Res. 20, 185 (2009)

A.F. Azevedo, E.J. Corat, N.G. Ferreira, V.J. Trava-Airoldi, Surf. Coat. Tech. 194, 271 (2005)

D.G. Waugh, C. Toccaceli, A.R. Gillett, C.H. Ng, S.D. Hodgson, J. Lawrence, Rev. Adhes. Adhes. 4, 69 (2016)

D.K. Owens, R.C. Wendt, J. Appl. Polym. 13, 1741 (1969)

A. Escudeiro, T. Polcar, A. Cavaleiro, J. Mech. Behav. Biomed. Mater. 39, 316 (2014)

A. Ranella, M. Barberoglou, S. Bakogianni, C. Fotakis, E. Stratakis, Acta Biomater. 6, 2711 (2010)

C.W. Chan, S. Lee, G. Smith, G. Sarri, C.H. Ng, A. Sharba, H.C. Man, Appl. Surf. Sci 367, 80 (2016)

D. Raducanu, E. Vasilescu, V.D. Cojocaru, I. Cinca, P. Drob, C. Vasilescu, S.I. Drob, J Mech Behav Biomed Mater 4, 1421 (2011)

J. Izquierdo, G. Bolat, N. Cimpoesu, L.C. Trinca, D. Mareci, R.M. Souto, Appl. Surf. Sci 385, 368 (2016)

S.D. Puckett, P.P. Lee, D.M. Ciombor, R.K. Aaron, T.J. Webster, Acta Biomater. 6, 2352 (2010)

C.C. Chen, C.F. Chen, I.H. Lee, C.L. Lin, Diam. Relat. Mater. 14, 1897 (2005)

F.C. Cowlard, J.C. Lewis, J. Mater. Sci. 2, 507 (1967)

D. Krupa, J. Baszkiewicz, J. Kozubowski, A. Barcz, J. Sobczak, A. Biliński, B. Rajchel, Vacuum 63, 715 (2001)

D. Krupa, J. Baszkiewicz, J.W. Sobczak, A. Biliński, A. Barcz, J. Mater. Process. Tech. 143, 158 (2003)

M. Jenko, M. Gorensek, M. Godec, M. Hodnik, B.S. Batic, C. Donik, D. Dolinar, Appl. Surf. Sci. 427, 584 (2018)

B.M. Im, E. Akiyama, H. Habazaki, A. Kawashima, K. Asami, K. Hashimoto, Corros. Sci. 37, 709 (1995)

D.J. Blackwood, A.W.C. Chua, K.H.W. Seah, R. Thampuran, S.H. Teoh, Corros. Sci 42, 481 (2000)

A. OrjuelaG, R. Rincón, J.J. Olaya, Surf. Coat. Tech. 259, 667 (2014)

X. Gai, Y. Bai, J. Li, S. Li, W. Hou, Y. Hao, X. Zhang, R. Yang, R.D.K. Misra, Corros. Sci 145, 80 (2018)

J. Pan, D. Thierry, C. Leygraf, Electrochemical impedance spectroscopy study of the passive oxide film on titanium for implant application. Electrochim. Acta 41, 1143 (1996)

Acknowledgements

The authors thank IKG Punjab Technical University, Kapurthala for its support of this research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Devgan, S., Sidhu, S.S. Potential of electrical discharge treatment incorporating MWCNTs to enhance the corrosion performance of the β-titanium alloy. Appl. Phys. A 126, 211 (2020). https://doi.org/10.1007/s00339-020-3391-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-3391-1