Abstract

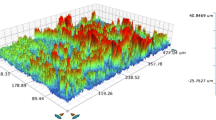

The use of titanium alloys in medical applications has always been controversial due to their corrosion properties. Ti–6Al–4V alloy is usually used due to its good mechanical properties. The poor corrosion properties of this alloy are mainly due to the formation of vanadium oxide, which is soluble in acidic solutions. In this study, to improve corrosion and surface properties and passive behavior, Ti–6Al–4V alloy was plasma-assisted oxy-nitrided in the gas mixtures of 30%N2 + 70% O2, 50% N2 + 50% O2, and 70% N2 + 30% O2 at 450, 500, and 550 °C temperatures for 2, 5, and 8 h. The effect of process temperature, time, and gas mixture on different characteristics of the samples was investigated. Multi-phase surface layers were studied using scanning electron microscopy (SEM) and X-ray diffraction analysis (XRD). It was found to increase surface roughness and hardness by the oxy-nitriding process slightly. With increasing process time and temperature up to 8 h and 500 °C, the surface hardness reached 676.1 Vickers in comparison with the untreated sample (139.8 VH). Also, the surface roughness increased from 23.57 to 49.82 nm for 8 h-450 °C-N2/O2 = 50/50 sample. Results showed higher resistance to corrosion of the samples treated by glow discharge assisted. The most polarization resistance to corrosion was related to sample 8h-550 °C-N2/O2 = 30/70 with a numerical value of 1892.78 Kohm cm2 Due to the formation of complex TiNxOy and TiN, which was increased compared to the untreated sample with polarization resistance of 1.01 Kohm cm2.

Similar content being viewed by others

Data Availability

The authors confirm that the data supporting the findings of this study are available within the article and its supplementary materials.

References

Zhang XC, Zhang YK, Lu JZ, Xuan FZ, Wang ZD, Tu ST (2010) Improvement of fatigue life of Ti–6Al–4V alloy by laser shock peening. Mater Sci Eng A 527(15):3411–3415

Aghajani H, Motlagh MS (2017) Effect of temperature on surface characteristics of nitrogen ion implanted biocompatible titanium. J Mater Sci Mater Med. https://doi.org/10.1007/s10856-016-5843-x

Dias Corpa Tardelli J, Bolfarini C, Cândido dos Reis A (2020) “Comparative analysis of corrosion resistance between beta titanium and Ti–6Al–4V alloys: a systematic review. J Trace Elem Med Biol 62(1):126618

Fojt J (2012) Ti–6Al–4V alloy surface modification for medical applications. Appl Surf Sci 262:163–167

Guleryuz H, Cimenoglu H (2005) Surface modification of a Ti–6Al–4V alloy by thermal oxidation. Surf Coatings Technol 192(2–3):164–170

Yerokhin AL, Nie X, Leyland A, Matthews A (2000) Characterisation of oxide films produced by plasma electrolytic oxidation of a Ti–6Al–4V alloy. Surf Coatings Technol 130(2–3):195–206

Ho WF (2008) A comparison of tensile properties and corrosion behavior of cast Ti-7.5Mo with c.p. Ti, Ti-15Mo and Ti–6Al–4V alloys. J Alloys Compd 464(1–2):580–583

Güleryüz H, Çimenoǧlu H (2004) Effect of thermal oxidation on corrosion and corrosion-wear behaviour of a Ti–6Al–4V alloy. Biomaterials 25(16):3325–3333

Guleryuz H, Cimenoglu H (2009) Oxidation of Ti–6Al–4V alloy. J Alloys Compd 472(1–2):241–246

Jaffery SI, Mativenga PT (2009) Assessment of the machinability of Ti–6Al–4V alloy using the wear map approach. Int J Adv Manuf Technol 40(7–8):687–696

López MF, Jiménez JA, Gutiérrez A (2003) Corrosion study of surface-modified vanadium-free titanium alloys. Electrochim Acta 48(10):1395–1401

Zhu Q, Yang X, Lan H, Wang D, Lou H, Li J (2023) Effect of solution treatments on microstructure and mechanical properties of Ti–6Al–4V alloy hot rolled sheet. J Mater Res Technol 23:5760–5771

Ciszak C, Popa I, Brossard JM, Monceau D, Chevalier S (2016) NaCl induced corrosion of Ti–6Al–4V alloy at high temperature. Corros Sci 110:91–104

Fojt J (2012) Ti–6Al–4V aloy surface modification for medical applications. Appl Surf Sci 262:163–167

Wai K et al (2013) Antimicrobial effects of oxygen plasma modified medical grade Ti–6Al–4V Alloy. Vacuum 89:271–279

Gonzalez GEG, Mirza-Rosca JC (1999) Study of the corrosion behavior of titanium and some of its alloys for biomedical and dental implant applications. J Electroanal Chem 471(2):109–115

Fu L, Makówka M, Januszewicz B, Kaczmarek Ł, Gu Y (2022) Improvement of Ti–6Al–4V alloy in terms of mechanical and tribological properties by oxidation and nitriding. Appl Surf Sci Adv 14(October):2023

Basiaga M, Kajzer W, Walke W, Kajzer A, Kaczmarek M (2016) Evaluation of physicochemical properties of surface modified Ti6Al4V and Ti6Al7Nb alloys used for orthopedic implants. Mater Sci Eng C 68:851–860

Bose S, Pathak LC, Singh R (2018) Response of boride coating on the Ti–6Al–4V alloy to corrosion and fretting corrosion behavior in Ringer’s solution for bio-implant application. Appl Surf Sci 433:1158–1174

Galliano F, Galvanetto E, Mischler S, Landolt D (2001) Tribocorrosion behavior of plasma nitrided Ti–6Al–4V alloy in neutral NaCl solution. Surf Coatings Technol 145(1–3):121–131

Oskooie MS, Motlagh MS, Aghajani H (2016) Surface properties and mechanism of corrosion resistance enhancement in a high temperature nitrogen ion implanted medical grade Ti. Surf Coatings Technol 291:356–364

Moussa M et al (2016) Modulation of osteoblast behavior on TiNxOy coatings by altering the N/O stoichiometry while maintaining a high thrombogenic potential. J Biomater Appl 30(8):1219–1229

Borisyuk YV, Oreshnikova NM, Berdnikova MA, Tumarkin AV, Khodachenko GV, Pisarev AA (2015) Plasma nitriding of titanium alloy Ti5Al4V2Mo. Phys Procedia 71(February):105–109

Oliveira VMCA, Aguiar C, Vazquez AM, Robin A, Barboza MJR (2014) Improving corrosion resistance of Ti–6Al–4V alloy through plasma-assisted PVD deposited nitride coatings. Corros Sci 88:317–327

Pohrelyuk IM, Fedirko VM, Tkachuk OV, Proskurnyak RV (2013) Corrosion resistance of Ti–6Al–4V alloy with nitride coatings in Ringer’s solution. Corros Sci 66:392–398

Pohrelyuk I, Tkachuk O, Proskurnyak R, Guspiel J, Beltowska-Lehman E, Morgiel J (2019) Influence of regulated modification of nitride layer by oxygen on the electrochemical behavior of Ti–6Al–4V alloy in the Ringer’s solution. Mater Corros 70(12):2320–2325

Pohrelyuk I, Morgiel J, Tkachuk O, Szymkiewicz K (2019) Effect of temperature on gas oxynitriding of Ti–6Al–4V alloy. Surf Coatings Technol 360(January):103–109

Galvanetto E, Galliano FP, Fossati A, Borgioli F (2002) Corrosion resistance properties of plasma nitrided Ti–6Al–4V alloy in hydrochloric acid solutions. Corros Sci 44(7):1593–1606

Wood FW, Metallurgy A, Paasche OG (1977) Dubious details of nitrogen diffusion in nitrided titanium. Thin Solid Films 40:131–137

Cassar G et al (2011) Evaluating the effects of plasma diffusion processing and duplex diffusion/PVD-coating on the fatigue performance of Ti–6Al–4V alloy. Int J Fatigue 33(9):1313–1323

Unnam J, Shenoy RN, Clark RK (1986) Oxidation of commercial purity titanium. Oxid Met 26(3–4):231–252

Zhao Y, Lu M, Fan Z, Huang S, Huang H (2020) Laser deposition of wear-resistant titanium oxynitride/titanium composite coatings on Ti–6Al–4V alloy. Appl. Surf. Sci. 531(April):147212

Yetim AF, Alsaran A, Efeoglu I, Çelik A (2008) A comparative study: The effect of surface treatments on the tribological properties of Ti–6Al–4V alloy. Surf Coatings Technol 202(11):2428–2432

El-Hossary FM, Negm NZ, Abd El-Rahman AM, Raaif M, Abd Elmula AA (2015) Properties of titanium oxynitride prepared by RF plasma. Adv Chem Eng Sci 05(01):1–14

Hosseini SR, Ahmadi A (2013) Evaluation of the effects of plasma nitriding temperature and time on the characterisation of Ti–6Al–4V alloy. Vacuum 87:30–39

Januszewicz B, Siniarski D (2006) The glow discharge plasma influence on the oxide layer and diffusion zone formation during process of thermal oxidation of titanium and its alloys. Vacuum 81(3):215–220

Chen ZX, Wang WX, Takao Y, Matsubara T, Ren LM (2012) Characterization and fatigue damage of TiO2 layer on spark-anodized titanium before and after hot water treatment. Appl Surf Sci 262:2–7

Del Valle JI, Chang Diaz FR, Granados VH (2022) Plasma-surface interactions within helicon plasma sources. Front Phys 10(April):1–15

Abd El-Rahman AM et al (2007) Surface improvement and biocompatibility of TiAl 24 Nb 10 intermetallic alloy using rf plasma nitriding. Appl. Surf. Sci. 253(23):9067–9072

Nakai M et al (2008) Surface hardening of biomedical Ti–29Nb–-13Ta–4.6Zr and Ti–6Al–4V ELI by gas nitriding. Mater Sci Eng A 486(1–2):193–201

Banakh O et al (2014) Sputtered titanium oxynitride coatings for endosseous applications: physical and chemical evaluation and first bioactivity assays. Appl Surf Sci 317:986–993

Rossi S, Fedrizzi L, Bacci T, Pradelli G (2003) Corrosion behaviour of glow discharge nitrided titanium alloys. Corros Sci 45(3):511–529

Shahmoradi AR, Talebibahmanbigloo N, Nickhil C, Nisha R, Javidparvar AA, Ghahremani P, Bahlakeh G, Ramezanzadeh B (2022) Molecular-MD/atomic-DFT theoretical and experimental studies on the quince seed extract corrosion inhibition performance on the acidic-solution attack of mild-steel. J Mol Liq 346:117921

Mahdavian M, Attar MM (2006) Another approach in analysis of paint coatings with EIS measurement: phase angle at high frequencies. Corros Sci 48(12):4152–4157

Suhadolnik L, Lašič Jurković D, Likozar B, Bele M, Drev S, Čeh M (2019) Structured titanium oxynitride (TiOxNy) nanotube arrays for a continuous electrocatalytic phenol-degradation process: Synthesis, characterization, mechanisms and the chemical reaction micro-kinetics. Appl Catal B Environ. 257(June):117894

Blackwood DJ, Peter LM, Williams DE (1988) Stability and open circuit breakdown of the passive oxide film on titanium. Electrochim Acta 33(8):1143–1149

Chang SH, Lin YK, Huang KT (2012) Study on the thermal erosion, wear and corrosion behaviors of TiAlN/oxynitriding duplex-treated AISI H13 alloy steel. Surf Coatings Technol 207:571–578

Biswas B, Purandare Y, Sugumaran A, Khan I, Hovsepian PE (2018) Effect of chamber pressure on defect generation and their influence on corrosion and tribological properties of HIPIMS deposited CrN/NbN coatings. Surf Coatings Technol 336:84–91

Qi J, Yang Y, Zhou M, Chen Z, Chen K (2019) Effect of transition layer on the performance of hydroxyapatite/titanium nitride coating developed on Ti–6Al–4V alloy by magnetron sputtering. Ceram Int 45(4):4863–4869

Hussein MA, Yilbas B, Kumar AM, Drew R, Al-Aqeeli N (2018) Influence of laser nitriding on the surface and corrosion properties of Ti–20Nb–13Zr alloy in artificial saliva for dental applications. J Mater Eng Perform 27(9):4655–4664

Saqib M et al (2021) Evaluation of in vitro corrosion behavior of titanium oxynitride coated stainless steel stents. IEEE Access 9:59766–59782

Wang H, Zhang R, Yuan Z, Shu X, Liu E, Han Z (2015) A comparative study of the corrosion performance of titanium (Ti), titanium nitride (TiN), titanium dioxide (TiO2) and nitrogen-doped titanium oxides (N–TiO2), as coatings for biomedical applications. Ceram Int 41(9):11844–11851

Razavi RS, Salehi M, Ramazani M, Man HC (2009) Corrosion behaviour of laser gas nitrided Ti–6Al–4V in HCl solution. Corros Sci 51(10):2324–2329

Funding

The authors declare that they have no funding or financial investment from any person(s) or institution(s). Also, the authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Author information

Authors and Affiliations

Contributions

AB has conducted the experiments during her MSc thesis. HA was the supervisor of the thesis and helped in English writing and editing. OA helped in data processing and developing the discussion section.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Badr, A., Aghajani, H. & Abbaszadeh, O. Evaluation of Microstructure, Corrosion, and Surface Properties of Plasma-Assisted Oxy-Nitrided Ti–6Al–4V Alloy. J Bio Tribo Corros 10, 27 (2024). https://doi.org/10.1007/s40735-024-00832-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-024-00832-6