Abstract

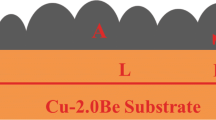

The effect of Ni nanoparticles on the microstructure evolution of a Sn-3.0Ag-0.5Cu (SAC305)-xNi (x = 0, 0.1)/Cu-2.0Be solder joint during reflow and aging was investigated. The results showed that the doped Ni nanoparticles changed the intermetallic compound (IMC) morphology from a scallop-like structure into a planar-like structure. The interfacial IMC layer thickness of the SAC305/Cu-2.0Be solder joint was greater than that of the SAC305-0.1Ni/Cu-2.0Be solder joint after reflow and aging. During reflow, the average IMC growth rate of the SAC305/Cu-2.0Be solder joint was 1.62 × 10−2 μm/s, while the average IMC growth rate of the SAC305-0.1Ni/Cu-2.0Be solder joint was 1.56 × 10−2 μm/s. During aging, the growth rates of the interfacial IMC layer of the SAC305/Cu-2.0Be solder joint and SAC305-0.1Ni/Cu-2.0Be solder joint were 1.86 × 10−5 μm/s and 1.46 × 10−5 μm/s, respectively. The results show that a trace amount of Ni nanoparticles can impede the growth rate of the interfacial IMC layer.

Similar content being viewed by others

References

A. Sharma, S. Bhattacharya, S. Das, H.J. Fecht, and K. Das, J. Alloys Compd. 574, 609 (2013).

M. Xiong and L. Zhang, J. Mater. Sci. 54, 1741 (2019).

L. Zhang and Z. Liu, J. Mater. Sci.: Mater. Electron. 31, 2466 (2020).

D.A. Shnawah, S.B.M. Said, M.F.M. Sabri, I.A. Badruddin, and F.X. Che, J. Electron. Mater. 41, 2631 (2012).

T. Kangasvieri, O. Nousiainen, J. Putaala, R. Rautioahob, and J. Vähäkangasa, Microelectron. Reliab. 46, 1335 (2006).

J.S. Chang and Y.W. Yen, 2018 International Conference on Electronics Packaging and iMAPS All Asia Conference (ICEP-IAAC). IEEE, 97 (2018).

S.M.A.A. Mohd, S. McDonald, and K. Nogita, Applied Mechanics and Materials. Trans. Tech. Publ. 421, 260 (2013).

J. Wu, S. Xue, J. Wang, and M. Wu, J. Alloys Compd. 784, 471 (2019).

G. Zeng, S. Xue, L. Zhang, L. Gao, W. Dai, and J. Luo, J. Mater. Sci.: Mater. Electron. 21, 421 (2010).

L. Zhang, L. Sun, Y. Guo, and C. He, J. Mater. Sci.: Mater. Electron. 25, 1209 (2014).

A.A. El-Daly, A.M. El-Taher, and S. Gouda, Mater. Des. 65, 796 (2015).

A.A. El-Daly, A.E. Hammad, G.S. Al-Ganainy, and M. Ragab, Mater. Sci. Eng., A 608, 130 (2014).

J. Wu, S. Xue, J. Wang, J. Wang, and S. Liu, J. Mater. Sci.: Mater. Electron. 28, 10230 (2017).

P. Xue, S. Xue, Y. Shen, H. Zhu, and L. Gao, J. Mater. Sci.: Mater. Electron. 23, 1272 (2012).

C.Y. Lee, J.W. Yoon, Y.J. Kim, and S.B. Jung, Microelectron. Eng. 82, 561 (2005).

Y. Tian, C. Wang, X. Ge, P. Liu, and D. Liu, Mater. Sci. Eng., B 95, 254 (2005).

H. Lee, C. Kim, C. Heo, C. Kim, J.H. Lee, and Y. Kim, Microelectron. Reliab. 87, 75 (2018).

J. Mittal, S.M. Kuo, Y.W. Lin, and K.L. Lin, J. Electron. Mater. 38, 2436 (2009).

T. Fouzder, Q. Li, Y.C. Chan, and D.K. Chan, J. Mater. Sci.: Mater. Electron. 25, 4012 (2014).

L. Zhang, X. Fan, Y. Guo, and C. He, Electron. Mater. Lett. 10, 645 (2014).

Y. Lv, W. Yang, J. Mao, Y. Li, X. Zhang, and Y. Zhan, J. Mater. Sci.: Mater. Electron. 31, 202 (2020).

K.M. Kumar, V. Kripesh, and A.A.O. Tay, J. Alloys Compd. 450, 229 (2008).

Z. Yang, W. Zhou, and P. Wu, Mater. Sci. Eng., A 590, 295 (2014).

A.K. Gain, Y.C. Chan, and W.K.C. Yung, Microelectron. Reliab. 51, 2306 (2011).

A. Fawzy, S.A. Fayek, M. Sobhy, E. Nassr, M.M. Mousa, and G. Saad, J. Mater. Sci.: Mater. Electron. 24, 3210 (2013).

L. Zhang and K.N. Tu, Mater. Sci. Eng., R 82, 1 (2014).

S.L. Tay, A.S.M.A. Haseeb, M.R. Johan, P.R. Munroe, and M.Z. Quadir, Intermetallics 33, 8 (2013).

K. Kanlayasiri and T. Ariga, Mater. Des. 86, 371 (2015).

K. Nogita, Intermetallics 18, 145 (2010).

F. Gao, T. Takemoto, and H. Nishikawa, Mater. Sci. Eng., A 420, 39 (2006).

A.A. El-Daly, A.M. El-Taher, and T.R. Dalloul, Mater. Des. 55, 309 (2014).

K. Nogita and T. Nishimura, Scr. Mater. 59, 191 (2008).

H.F. Zou, H.J. Yang, and Z.F. Zhang, Acta Mater. 56, 2649 (2008).

N. Zhao, Y. Zhong, M.L. Huang, H.T. Ma, and W. Dong, Sci. Rep. 5, 13491 (2015).

Acknowledgments

This work was supported by the Key Laboratory Foundation of Metal Material Microstructure Control of Jiangxi Province (EJ201903064), Doctoral Research Fund of Nanchang Hangkong University (EA202003209), Jiangxi Provincial Natural Science Foundation (20202BABL214025), Aviation Science Funds of China (201911056001).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yin, Z., Lin, M., Li, Q. et al. Effects of Ni Nanoparticles on the Growth Rate of Intermetallic Compounds (IMCs) Between Sn-3.0Ag-0.5Cu (SAC305) Solder and Cu-2.0Be Substrate. J. Electron. Mater. 49, 6721–6726 (2020). https://doi.org/10.1007/s11664-020-08453-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-020-08453-8