Abstract

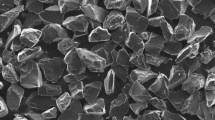

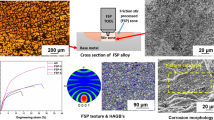

Wear resistance of extrusion shear-processed AZ61 magnesium samples with as-cast state and homogenization treatment state has been studied by wear tests using pin-on-disc experiments under dry sliding conditions. Wear rates and friction coefficients between AZ61 magnesium alloy and GCr15 steel have been used to evaluate wear resistances of AZ61 magnesium alloys, and obtained from dry sliding with different frequencies and loads. Scanning electron microscope (SEM) and energy dispersive X-ray spectrometer (EDS) were used to analyze microstructures before and after the wear tests to find the wear mechanisms of AZ61 magnesium samples with as-cast state and homogenization treatment state. The wear resistances of the homogeneous state samples prepared by extrusion-shear process are close to those of as cast state, which are due to the little differences of microstructures. In addition, the wear mechanisms change from mild wear to severe wear with rise of exerted loads and reciprocating frequencies.

Similar content being viewed by others

Change history

28 April 2023

A Correction to this paper has been published: https://doi.org/10.1007/s00339-023-06650-w

References

Z.D. Zhao, Q. Chen, H.Y. Chao, S.H. Huang, Microstructural evolution and tensile mechanical properties of thixoforged ZK60-Y magnesium alloys produced by two different routes. Mater Des. 31, 1906–1916 (2010)

J.C. Crivello, B. Dam, R.V. Denys, M. Dornheim, D.M. Grant, J. Huot et al., Review of magnesium hydride-based materials: development and optimisation. Appl. Phys. A 122, 1–20 (2016)

Q. Chen, Z.D. Zhao, G. Chen, B. Wang, Effect of accumulative plastic deformation on generation of spheroidal structure, thixoformability and mechanical properties of large-size AM60 magnesium alloy. J. Alloy Comp. 632, 190–200 (2015)

L. Feng, Y. Zhu, W. Fan, Y. Wang, X. Qiang, Y. Liu, Fabrication and corrosion resistance of superhydrophobic magnesium alloy. Appl. Phys. A 120, 561–570 (2015)

Q. Chen, B.G. Yuan, J. Lin, X.S. Xia, Z.D. Zhao, D.Y. Shu, Comparisons of microstructure, thixoformability and mechanical properties of high performance wrought magnesium alloys reheated from the as-cast and extruded states. J. Alloy Comp. 584, 63–75 (2014)

D.S. Meta, S.H. Masood, W.Q. Song, Investigation of wear properties of magnesium and aluminum alloys for automotive applications. J. Mater. Process. Technol. s155–156, 1526–1531 (2004)

X. Luo, L. Kang, Q. Li, & Y. Chai, Microstructure and hot compression deformation of the as-cast mg–5.0sn–1.5y–0.1zr alloy. Appl. Phys. A 120, 699–705 (2015)

Q. Chen, Z.D. Zhao, Z.X. Zhao, C.K. Hu, D.Y. Shu, Microstructure development and thixoextrusion of magnesium alloy prepared by repetitive upsetting-extrusion. J. Alloy Comp. 509, 7303–7315 (2011)

L. Deng, Y. Zhu, W. Fan, Y. Wang, X. Qiang, Y. Liu, Fabrication and corrosion resistance of superhydrophobic magnesium alloy. Appl. Phys. A 120, 561–570 (2015)

Q. Chen, G. Chen, L.N. Han, N. Hu, F. Han, Z.D. Zhao, X.S. Xia, Y.Y. Wan, Microstructure evolution of sicp/ZM6 (Mg–Nd–Zn) magnesium matrix composite in the semi-solid state. J. Alloy Comp. 656, 67–76 (2015)

M. Chen, X.D. Hu, B. Han, X.H. Deng, D.Y. Ju, Study on the microstructural evolution of az31 magnesium alloy in a vertical twin-roll casting process. Appl. Phys. A 122, 1–10 (2016)

X. Wang, X. Gong, K. Chou, Review on powder-bed laser additive manufacturing of Inconel 718 parts. Proceedings of the Institution of Mechanical Engineers. Part B J. Eng. Manuf. 1, 1–14 (2016)

X. Wang, X. Gong, K. Chou, Scanning speed effect on mechanical properties of Ti–6Al–4V alloy processed by electron beam additive manufacturing. Proc. Manuf. 1, 287–295 (2015)

H.-J. Hu, H. Wang, Z.-Y. Zhai, Y.-Y. Li, J.-Z. Fan, Z.-W. Ou, Effects of channel angles on extrusion-shear for AZ31 magnesium alloy: modeling and experiments. Int. J. Adv. Manuf. Technol. 76, 1621–1630 (2015)

H.-J. Hu, J.-Z. Fan, The effects of billet temperature on compound extrusion of magnesium alloy by three-dimensional finite element modeling and experiments. Proceedings of the Institution of Mechanical Engineers. Part B J. Eng. Manuf. 228, 1449–1457, (2014)

C. Taltavull, B. Torres, A.J. López, J. Rams, Dry sliding wear behavior of AM60b magnesium alloy. Wear 30, 615–6251 (2013)

S.A. Selvan, S. Ramanathan, Dry sliding wear behavior of as-cast ze41a magnesium alloy. Mater. Des. 31, 1930–1936 (2010)

J. An, R.G. Li, C.M. Chen, Y. Xu, X. Chen, Z.X. Guo et al., Comparative studies on wear behaviour between as cast az91 and mgznymagnesium alloys. Mater. Sci. Technol. 23(10), 1208–1214 (2007)

A.W. DEl-Morsy, Dry sliding wear behavior of hot deformed magnesium AZ61 alloy as influenced by the sliding conditions. Mater. Sci. Eng. A, 473, 330–335 (2008)

C.Y.H. Lim, S.C. Lim, M. Gupta, Wear behaviour of sic p-reinforced magnesium matrix composites. Wear 255(1), 629–637 (2003)

A.K. Mondal, S. Kumar, Dry sliding wear behaviour of magnesium alloy based hybrid composites in the longitudinal direction. Wear 267(1), 458–466 (2009)

H.I. Demirci, H. Evlen, Effect of extrusion ratio on the wear behaviour of al–si and al–mg alloys. J. Alloy Comp. 510(1), 26–32 (2012)

S.A. Selvan, S. Ramanathan, A comparative study of the wear behavior of as-cast and hot extruded ze41a magnesium alloy. J. Alloy Comp. 502(2), 495–502 (2010)

Y. Niu, R. Cui, Y. He, Z. Yu, Wear and corrosion behavior of mg–gd–y–zr alloy treated by mixed molten-salt bath. J. Alloy Comp. 610(3), 294–300 (2014)

H.J. Hu, Y.L. Ying, Z.W. Ou, X.Q. Wang, Comparisons of microstructures and texture and mechanical properties of magnesium alloy fabricated by compound extrusion and direct extrusion. Mater. Sci. Eng. A 695, 360–366 (2017)

Acknowledgements

This research is funded by Chongqing Research Program of Basic Research and Frontier Technology (cstc2015jcyjBX0054), National Science Foundation of China (51771038 and 51571040), China Postdoctoral Science Foundation funded Project (2015T81087 and 2014M552575).

Author information

Authors and Affiliations

Corresponding author

Additional information

The original online version of this article was revised: Fig .3 should be replaced.

Rights and permissions

About this article

Cite this article

Hu, HJ., Ying, YL., OU, ZW. et al. The effects of homogenization treatment on wear resistance of AZ61 magnesium alloy fabricated by extrusion-shear process. Appl. Phys. A 123, 762 (2017). https://doi.org/10.1007/s00339-017-1387-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-017-1387-2