Abstract

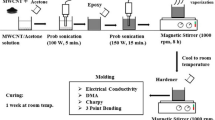

In this paper, the synthesis of a new trifunctional sulfur and phosphorus epoxy architecture based on hydroxy diphenyl sulfone bis para-ester phosphoric triglycidyl ether (TGEHDSEP) is presented. The viscometric properties of the synthesized resin using an Ubbelohde type capillary viscometer were investigated and were thermally crosslinked using the hardener methylene dianiline (MDA). The viscosity values of the new trifunctional epoxy resin TGEHDSEP increased as the pre-polymer mass concentrations increased, as expected, and as the sample temperature increased, the viscosity of the system (TGEHDSEP/ethanol) decreased. A new nanocomposite composed of the prepared resin, TGEHDSEP, and carbon nanotubes (CNT) was developed using a variety of formulations to optimize the rheological behavior and thermal stability of the epoxy matrix. The effect of the CNT filler in admixture with the TGEHDSEP/MDA system in this series of formulations on the nanocomposites rheological properties was studied. The rheological and thermal properties of the formulated materials were assessed using the RHM01-RD Haaks rheometer and the thermogravimetric analysis (TGA) in the dynamic regime, respectively. The results showed that the G′ (storage modulus) and G′′ (loss modulus) of various nanocomposites increase as the filler CNT content increases. Over the entire frequency range studied, the storage modulus G′ is much higher than the loss modulus G′′ for methylene–dianiline crosslinked nanocomposites formulated with varying percentages of CNT. The storage modulus G′ of all prepared nanocomposites increases as the percentage of CNTs increases. These results also show that the addition of carbon nanotubes to the epoxy matrix improves its thermal properties significantly. The morphology of the prepared nanocomposites, analyzed by scanning electron microscopy (SEM), varies significantly with the percentage of carbon nanotube filler incorporated into the studied matrix, and the carbon nanotube filler is uniformly distributed in this epoxy resin. Finally, we utilized the Materials Studio software package to investigate the mechanical and thermal conductivity properties of TGEHDSP and single-walled carbon nanotube (SWCNT). The material exhibited the following mechanical properties: Young's modulus: 7.1508 GPa, shear modulus: 2.6169 GPa, bulk modulus: 8.9116 GPa, Poisson's ratio: 0.3663. Additionally, its compressibility is approximately 105.9918 TPa. On the other hand, the epoxy resin, TGEHDSP, performs relatively well as a heat conductor among epoxy-based materials, while SWCNT's high thermal conductivity highlights its exceptional heat transfer capabilities, characteristic of nanoscale structures.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

El-Aouni N, Hsissou R, El Azzaoui J, El Bouchti M, Elharfi A (2020) Synthesis rheological and thermal studies of epoxy polymer and its composite. Chemical Data Collections 30:100584

El-Aouni N, Hsissou R, El Azzaoui J, El Bouchti M, Elbachiri A, Elharfi A et al (2021) One-pot synthesis of trifunctional epoxy resin and its nanocomposite: investigation of thermal and rheological properties. Biointerface Res Appl Chem 11:12403–12413

Dagdag O, Haldhar R, Kim S-C, Safi ZS, Wazzan N, Mkadmh AM et al (2022) Synthesis, physicochemical properties, theoretical and electrochemical studies of tetraglycidyl methylenedianiline. J Mol Struct 1265:133508

El Gouri M, El Bachiri A, Hegazi SE, Rafik M, El Harfi A (2009) Thermal degradation of a reactive flame retardant based on cyclotriphosphazene and its blend with DGEBA epoxy resin. Polym Degrad Stab 94:2101–2106

El Gouri M, Cherkaoui O, Ziraoui R, El Harfi A (2010) Physico-chemical study of DGEBA epoxy resin flame retarded with an ecological flame retardant based on cyclotriphosphazene. J Mater Environ Sci 3:157–162

Cassagnau P, Melis F (2003) Non-linear viscoelastic behaviour and modulus recovery in silica filled polymers. Polymer 44:6607–6615

Cassagnau P (2008) Melt rheology of organoclay and fumed silica nanocomposites. Polymer 49:2183–2196

Hsissou R, Bekhta A, Dagdag O, El Bachiri A, Rafik M, Elharfi A (2020) Rheological properties of composite polymers and hybrid nanocomposites. Heliyon 6:e04187

Shen L, Li Y, Zheng J, Lu M, Wu K (2015) Modified epoxy acrylate resin for photocurable temporary protective coatings. Prog Org Coat 89:17–25

Tyan H-L, Leu C-M, Wei K-H (2000) Effect of reactivity of organics-modified montmorillonite on the thermal and mechanical properties of montmorillonite/polyimide nanocomposites. Chem Mater 13:222–226

Lee A, Lichtenhan JD (1999) Thermal and viscoelastic property of epoxy–clay and hybrid inorganic–organic epoxy nanocomposites. J Appl Polym Sci 73:1993–2001

El-Aouni N, Dagdag O, Haldhar R, Kim S-C, Azogagh M, Berisha A et al (2023) One-pot synthesis of epoxy resin composite: thermal, rheological and Monte Carlo investigations. Iran Polym J 33:1–11

El Azzaoui J, El-Aouni N, Berradi M, Hsissou R, El Yacoubi A, El Bouchti M et al (2023) Viscometric, rheological, and thermodynamic studies of octafunctional epoxy resins OGDHDPBA and OGDHDPDS. J Mol Liq 384:121886

Hsissou R, Bekhta A, Elharfi A (2017) Viscosimetric and rheological studies of a new trifunctional epoxy pre-polymer with noyan ethylene: Triglycidyl Ether of Ethylene of Bisphenol A (TGEEBA). J Mater Environ Sci 8:603–610

Dagdag O, El Gana L, Haldhar R, Berisha A, Kim S-C, Berdimurodov E et al (2023) Study on thermal conductivity and mechanical properties of cyclotriphosphazene resin-forced epoxy resin composites. Crystals 13:478

Jeyranpour F, Alahyarizadeh G, Minuchehr A (2016) The thermo-mechanical properties estimation of fullerene-reinforced resin epoxy composites by molecular dynamics simulation–A comparative study. Polymer 88:9–18

Fu Y, Michopoulos JG, Song J-H (2017) On investigating the thermomechanical properties of cross-linked epoxy via molecular dynamics analysis. Nanoscale Microscale Thermophys Eng 21:8–25

Aghadavoudi F, Golestanian H, Tadi Beni Y (2017) Investigating the effects of resin crosslinking ratio on mechanical properties of epoxy-based nanocomposites using molecular dynamics. Polym Compos 38:E433–E442

Zhang W, Li H, Gao L, Zhang Q, Zhong W, Sui G et al (2018) Molecular simulation and experimental analysis on thermal and mechanical properties of carbon nanotube/epoxy resin composites with different curing agents at high-low temperature. Polym Compos 39:E945–E954

Liu Z, Li J, Zhou C, Zhu W (2018) A molecular dynamics study on thermal and rheological properties of BNNS-epoxy nanocomposites. Int J Heat Mass Transf 126:353–362

Yang X, Wan Y, Wang X, Fu Y, Huang Z, Xie Q (2019) Molecular dynamics studies of the mechanical behaviors and thermal conductivity of the DGEBA/MTHPA/CNB composites. Compos B Eng 164:659–666

Elaouni N, El Harfi A (2016) Rheologic study and thermal behavior of a new sulphurated and phosphorous tri-functional epoxy resin. Moroccan J Chem 4:4–1

Dagdag O, Hsissou R, Safi Z, Haldhar R, Berdimurodov E, Bouchti ME et al (2022) Rheological and simulation for macromolecular matrix epoxy bi-functional aromatic amines. Polym Bull 79:7571–7587

Dagdag O, Berisha A, Mehmeti V, Haldhar R, Berdimurodov E, Hamed O et al (2022) Epoxy coating as effective anti-corrosive polymeric material for aluminum alloys: Formulation, electrochemical and computational approaches. J Mol Liq 346:117886

Dagdag O, El Gouri M, Safi ZS, Wazzan N, Safi SK, Jodeh S et al (2021) Flame retardancy of an intumescent epoxy resin containing cyclotriphosphazene: experimental, computational and statistical studies. Iran Polym J 30:1169–1179

Dagdag O, El Harfi A, El Bachiri A, Jodeh S (2021) Thermal and anti-corrosive properties of titanium dioxide/epoxy resin composite coating for steel preservation in a marine-environment. Portugal Electrochim Acta 39:183–198

Qi-lin X, Xin T (2017) Effect of polymer matrix and nanofiller on non-bonding interfacial properties of nanocomposites. J Polym Res 24:1–9

Sun H, Jin Z, Yang C, Akkermans RLC, Robertson SH, Spenley NA et al (2016) COMPASS II: extended coverage for polymer and drug-like molecule databases. J Mol Model 22:1–10

Guo M, Liu B, Li L, Liu C, Wang L, Jiang Z (2010) Preparation of sulfonated poly (ether ether ketone) s containing amino groups/epoxy resin composite membranes and their in situ crosslinking for application in fuel cells. J Power Sources 195:11–20

Fernandez-Francos X, Cook WD, Serra A, Ramis X, Liang GG, Salla JM (2010) Crosslinking of mixtures of DGEBA with 1, 6-dioxaspiro [4, 4] nonan-2, 7-dione initiated by tertiary amines. Part IV. Effect of hydroxyl groups on initiation and curing kinetics. Polymer 51:26–34

El Gouri M, El Harfi A, Rafik M, Hegazi S, Grich M, Meghraoui H (2010) Viscosimetry study, NMR and IR structural characterization of diglycidyl ether of bisphenol and tetraglycidyl diamino aromatic resins. Phys Chem News 52:112–128

Bekhta A, Hsissou R, El Bouchiti M, Harfi AE (2016) Synthesis, Structural, Viscosimetric, and Rheological Study, of a new trifunctional phosphorus epoxyde prepolymer, tri-glycidyl ether tri-mercaptoethanol of phosphore (TGETMEP). Mediterranean J Chem 6:665–673

Bekhta A, Hsissou R, Berradi M, El Bouchti M, Elharfi A (2019) Viscosimetric and rheological properties of epoxy resin TGEUBA and their composite (TGEUBA/MDA/TGEMDA+ TSP). Results Eng 4:100058

Wang X, Gillham JK (1991) Competitive primary amine/epoxy and secondary amine/epoxy reactions: Effect on the isothermal time-to-vitrify. J Appl Polym Sci 43:2267–2277

Lovell R, Windle A (1990) WAXS investigation of local structure in epoxy networks. Polymer 31:593–601

Lim HT, Ahn KH, Hong JS, Hyun K (2013) Nonlinear viscoelasticity of polymer nanocomposites under large amplitude oscillatory shear flow. J Rheol 57:767–789

Hsissou R, Berradi M, Grich MH, Bahaj H, El Bouchti M, Khudhair M et al (2019) synthesis and inVestiGatiOn OF PentaGLyCidyL etheR PentaPhenOXy PhOsPhORiC POLyMeR and FORMULatiOn OF nanOCOMPOsite (PGePPP/Mda/tiO2). J Chem Technol Metallurgy 54:893–901

Ma AW, Mackley MR, Chinesta F (2008) The microstructure and rheology of carbon nanotube suspensions. IntJ Mater Form 1:75–81

Fan Z, Advani SG (2007) Rheology of multiwall carbon nanotube suspensions. J Rheol 51:585–604

Grich M, El Gouri M, Ziraoui R, Rami N, Meghraoui H, Cherkaoui O, et al. (2014) Thermal and rheological study of blended carbon nanotube/epoxy resin nanocomposites, J Mater Environ Sci. 5.

Hassanzadeh-Aghdam M, Ansari R, Darvizeh A (2017) Micromechanical modeling of thermal expansion coefficients for unidirectional glass fiber-reinforced polyimide composites containing silica nanoparticles. Compos A Appl Sci Manuf 96:110–121

Haghgoo M, Ansari R, Hassanzadeh-Aghdam M, Nankali M (2019) Analytical formulation for electrical conductivity and percolation threshold of epoxy multiscale nanocomposites reinforced with chopped carbon fibers and wavy carbon nanotubes considering tunneling resistivity. Compos A Appl Sci Manuf 126:105616

Hasanzadeh M, Ansari R, Hassanzadeh-Aghdam M (2019) Evaluation of effective properties of piezoelectric hybrid composites containing carbon nanotubes. Mech Mater 129:63–79

Ma A, Yearsley K, Chinesta F, Mackley M (2008) A review of the microstructure and rheology of carbon nanotube suspensions. Proc Insti Mech Eng Part N: J Nanoeng Nanosyst 222:71–94

Tanaka F, Okamura K (2005) Characterization of cellulose molecules in bio-system studied by modeling methods. Cellulose 12:243–252

Watt JP, Davies GF, O’Connell RJ (1976) The elastic properties of composite materials. Rev Geophys 14:541–563

Weiner JH (2012) Statistical mechanics of elasticity. Courier Corporation.

Jund P, Jullien R (1999) Molecular-dynamics calculation of the thermal conductivity of vitreous silica. Phys Rev B 59:13707

Liu X, Rao Z (2019) Molecular dynamics simulations on the heat and mass transfer of hypercrosslinked shell structure of phase change nanocapsules as thermal energy storage materials. Int J Heat Mass Transf 132:362–374

Tlili I, Alkanhal TA, Barzinjy AA, Dara RN, Shafee A, Li Z (2019) Investigation of thermal characteristics of carbon nanotubes: Measurement and dependence. J Mol Liq 294:111564

Acknowledgements

This research is a research project supported by the “Renewable Energy Core Technology Development Project” of the Ministry of Trade, Industry and Energy (MOTIE) and the Korea Institute of Energy Technology Evaluation and Planning (KETEP). (NO. 2022303004020A). In addition, this work was also supported by the “Automotive Industry Technology Development Project” of the Ministry of Trade, Industry and Energy (MOTIE) and the Korea Planning & Evaluation Institute of Industrial Technology (KEIT). (NO. 20015346).

Author information

Authors and Affiliations

Contributions

Naoual El-Aouni involved in formal analysis. Omar Dagdag took part in investigation, methodology. Mohamed Berradi took part in resources. Avni Berisha involved in software. Hansang Kim involved in writing—original draft. Shehdeh Jodeh and Othman Hamed took part in writing—review & editing. Mohamed Rafik involved in methodology, resources. Lahoucine El Gana took part in formal analysis, resources. Abderrahim EL Bachiri took part in conceptualization, resources, review.

Corresponding authors

Ethics declarations

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

El-Aouni, N., Dagdag, O., Berradi, M. et al. Synthesis and study of the thermal and rheological behavior of carbon nanotubes reinforced new epoxy nanocomposite. Polym. Bull. (2024). https://doi.org/10.1007/s00289-024-05263-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00289-024-05263-4