Abstract

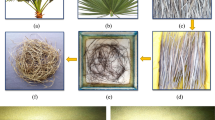

The treatment method of natural fiber is one of the factors that influences its properties. There are several reports on sodium hydroxide (NaOH) treatment of many natural fiber. Though there are works on NaOH treatment of the fruits fiber, however, works on Borassus flabellifer Leaf fiber (BFLF) is sparsely reported. Hence no report on the optimum conditions for sodium hydroxide treatment of Borassus Flabellifer Leaf fiber. Therefore, this study aimed at establishing the optimum concentration and time for alkaline treatment on the properties of BFLF. The fiber extraction was carried out using water retting method for 24 h. Experimental design was carried out using Design Expert 12.0 adopting Central composite design in response surface methodology. NaOH concentration of 0–5 wt% and time of 1–12 h were used as the independent variables. The responses were water absorption, elongation (%), modulus of elasticity and tensile strength. The surface morphology of the fiber was studied using scanning electron microscope (SEM) and the functional group changes established using Fourier transform infrared (FTIR) spectroscopy to indicate effect of NaOH treatment (FTIR) spectroscopy to show the functional group changes due to NaOH treatment. The optimum concentration and treatment time was established as 2 wt% NaOH and 4 h, respectively, with corresponding responses of water absorption, tensile strength, modulus of elasticity and elongation (%) were 2.07%, 977.378 MPa, 6971.02 MPa, 5.178%, respectively. Using these optimum treatment conditions of time and NaOH concentration, the responses were validated to be 1.88%, 920.019 MPa, 6943.73 MPa, 4.99 mm having a desirability of 0.963. The SEM revealed rough surfaces and increased porosity for the treated fiber compared to the untreated. The FTIR spectra showed reduction in peaks representing lignin at wavelength of 3321.1 cm−1 to 3306.1 cm−1, which indicated that the NaOH treatment resulted to decrease in lignin in the fiber. The properties of the BFLF obtained at the optimum treatment conditions were within range of other fibers used in composite materials development, hence, BFLF treated at these conditions is suitable for composite development.

Similar content being viewed by others

References

Thakur VK, Singha AS, Thakur MK (2012) Modification of natural biomass by graft copolymerization. Int J Polym Anal Charact 17(7):547–555

Taj S, Ali M, Khan S (2007) Review on natural fiber–reinforced polymer composites. Proc-Pakistan Acad Sci 44:129

Shehu U, Isa MT, Aderemi BO, Bello TK (2017) Effects of NaOH modification on the mechanical properties of baobab pod fiber reinforce d LDPE composites. Niger J Technol 36(1):87–95

Abdulrashid AH, Ahmad R, Jaafar M, Roslan MN, Ariffin S (2011) Mechanical properties evaluation of woven coir and kevlar reinforced epoxy composites. Adv Mater Res. 36–42

John M, Thomas S (2008) Biofibres and biocomposites. Carbohydrate Polymer 71:343–364

Warbhe NO, Shrivastava R, Adwani PS (2016) Mechanical properties of kevlar/jute reinforced epoxy composite. Int J Innov Res Sci. 16407–16418

Renato B, Edio L, Sergio M, Luis H (2015) Gaint bamboo fiber reinforced epoxy composite in multilayered ballistic armor. Pub Mater Res. 70–75

Kabir MM, Wang H, Lau TK, Candona F (2012) Chemical treatments on plant-based natural fibre reinforced polymer composites: an overview. Compos Part B Eng JOM 61:17–22

Vankatachalan N, Navaneethakrishnan P, Rajsekar R, Shankar S (2016) Effect of pretreatment methods on properties of natural fiber composites: a review. Polym Polym Compos 24(7):555–566

Nadendla S, Kumar JS, Reddy KV (2014). Manufacturing and Characterisation of Long Palmyra Palm/Borassus Flabellifer Petiole Fiber Reinforced Polyester Composites. 2nd International conference on innovations in autonation and mechatronics engineering Vol. 14 P 252 – 259.

Chandramohan D, Marimuthu K (2011) A review on natural fibers. Int J Recent Res Appl Sci. 194–206

Kumar R, Obrai S, Sharma A (2011) Chemical modification of natural fibre for composite material. Der Chemica Sinica 2(4):219–228

Reddy KO, Maheswari CU, Reddy RK, Shukla M, Muzenda E, Rajulu VA (2015) Effect of chemical treatment and Fiber loading on mechanical properties of borassus (Toddy Palm) fiber/epoxy composite. Int J Polym Anal Charact 20(7):P612-626

Singh JK, Rout AK, Kumari K (2021) A review on Borassus flabellifer lignocellulose fiber reinforced polymer composites. Carbohydr Polym 262:117929

Balakrishna A, Rao DN, Rakesh AS (2013) Characterization and modeling of process parameters on tensile strength of short and randomly oriented Borassus Flabellifer Asian Palmyra fiber reinforced composite. Composites: Part B, 55, 479–485.

Lalolau A, Bale J, Soemardi T, Polit O (2021) Lontar Borassus flabellifer fiber composite: energy dissipation and thermal response under dynamic tensile testing. J Eng Sci Technol 16:1258–1271

Srinivasababu N, Kumar JS, Vijaya K, Reddy K (2014) Manufacturing and characterization of long palmyra palm/borassus flabellifer petiole fibre reinforced polyester composites. Procedia Technol 14:252–259

Singh JK, Rout AK (2022) Characterization of raw and alkali-treated cellulosic fibers extracted from Borassus flabellifer L. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-022-03238-x

Dhoria SH, Vijaya M (2015) Investigation of mechanical properties of borassus flabellifer fiber reinforced polymer composites. J Emerg Technol Innov Res 2(12):88–93

Reddy KO, Maheswari CU, Rajulu VA, Guduri BR (2009) Thermal degradation parameters and tensile properties of borassus flabelllifer fruit fiber reinforcement. J Reinf Plast Compos 28(18):2297–2301

Rout AK, Kar J, Jesthi DK, Sutar AK (2016) Effect of surface treatment on the physical, chemical, and mechanical properties of palm tree leaf stalk fibers. BioResources 11(2):4432–4445

Desalegn A, Rotich KG (2018) Extraction and characterization of ethiopian palm leaf fibers. Res J Text Appar 22:15–25

Nayak NC, Mishra A (2013) Development and mechanical characterization of palmyra fruit fiber reinforced epoxy composite. JPE 16(2):69–72

Vijayan SN, Vadivel S, Melvinjone A, Dhinesh K, Ganesh MM, Sneha D (2018) Investigation of mechanical properties of palmrya palm leaf stalk/carbon fiber reinforced polyester hybrid composite. Int J Eng Adv Technol (IJEAT) 8:223–227

Arasu PT, Seenidurai PS, Murugan A, Elangovan S (2021) Functional modification of borassus flabellifer shealth fibers using isocyanate. Lett Appl NanoBioSci (LIANBS) 10(1):1889–1895

Shanmugan D, Thiruchitrambalam M, Thirumurugan R (2014) Continuous unidirectional palmyra palm leaf stalk fiber/glass-polyester composite: static and dynamic mechanical properties. J Reinf Plast Compos 33(9):836–850

David R (2009) Stress_strain curves. Massachusetts Int. of technology, Cambridge MA, pp 3–15

Yuhazr YM, Phongskon PT, Jeefferie AR, Perumal P, Kammal AM, Rassiah K (2011) Mechanical properties of kenaf/polyester composites. Int J Eng Technol 11(1):127–131

Aydin M, Tozlu H, Kemaloglu S, Aytac A, Ozkoc G (2011) Effects of Alkali Treatment on the properties of short flax fiber–poly(lactic acid) eco-composites. J Polym Environ 19:11–17

Kumar RD, Mohanraj P (2017) Review on natural fiber in various pretreatment conditions for preparing perfect fiber. Asian J. Appl. Sci. Technol. (AJAST) 1(2):66–78

Sen D, Nayak C, Sudhakar KG, Birla S (2021) Mechanical properties of fabricated hybrid composites infused with heat-treated alkali sisal fiber and sic particles: a quantitative analysis. Polym Bull 78:4629–4648

Ray D, Sarkar BK, Rana AK, Bose RN (2001) Effect of alkali treated jute fibers on composite properties. Bull Mater Sci 24:129–135

ASTM D570-98 (2018) Standard test method for water absorption of Plastics. ASTM Int, West Conshohocken. https://doi.org/10.1520/D0570-98R18

3822 - 07 (2007). Standard Test Method for Tensile Properties of Single Textile, ASTM International West Conshoshocken, Philadelphia USA. Vol. 8(1).

Jayamani E, Loong TG, Khusairy Bin Bakri M (2019) Comparative study of Fourier Transform Infrared Spectroscopy (FTIR) analysis of natural fibres treated with chemical, physical and biological methods. Polym Bull 22:5245. https://doi.org/10.1007/s00289-019-02824-w

Ridzuan MJM, Abdulmajid MS, Afendi M, Azduwin K, Kanafiah ASN, Dan-mallam Y (2015) The effect of the alkaline treatment’s soaking expose on the tensile strength of napier fiber. SciDirect-Elsevier 2:353–358

Musanif IS, Thomas A (2015) Effect of alkali treatments of physical and mechanical properties of coir fiber. Chem Mater Eng 3(2):23–28

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abubakar, M.N., Bello, T.K., Isa, M.T. et al. Effect of alkaline treatment on the physical and mechanical properties of borassus flabellifer leaf fiber. Polym. Bull. 80, 12577–12590 (2023). https://doi.org/10.1007/s00289-022-04666-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04666-5