Abstract

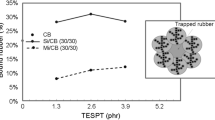

Silica dispersion and silica–natural rubber (NR) interaction are two major issues in determining the performance of a NR/silica composite in tire industry. In our research, the reaction product of 3-isocyanatopropyltrimethoxysilane and a crosslinking agent, poly(tert-butylphenol) disulphide, was used to modify silica. Then, the modified silica was added into NR by mechanical blending. The modification of silica can promote the silica dispersion and enhance silica–NR interaction. At silica loading of 50 phr, compared with the NR/pure silica composite containing 5 phr bis-(γ-triethoxysilylpropyl)-tetrasulfide, the NR/modified silica composite exhibits 18% shorter curing time, 16% higher 300% modulus, 9% higher crosslink density and 6% lower rolling resistance with comparable abrasion resistance even reducing the amount of silane coupling agent to 2 phr. This modification of silica by using the derivative of poly(tert-butylphenol) disulphide provides a novel approach to the preparation of the high-performance NR/silica composites and the reduction of the amount of bis-(γ-triethoxysilylpropyl)-tetrasulfide in tire tread formulations.

Similar content being viewed by others

References

Shi X, Sun S, Zhao A, Zhang H, Zuo M, Song Y, Zheng Q (2021) Influence of carbon black on the Payne effect of filled natural rubber compounds. Compos Sci Technol 203:108586. https://doi.org/10.1016/j.compscitech.2020.108586

Xu Z, Song Y, Zheng Q (2019) Payne effect of carbon black filled natural rubber compounds and their carbon black gels. Polymer 185:121953. https://doi.org/10.1016/j.polymer.2019.121953

Farida E, Bukit N, Ginting EM, Bukit BF (2019) The effect of carbon black composition in natural rubber compound. Case Stud Therm Eng 16:100566. https://doi.org/10.1016/j.csite.2019.100566

Xiao Y, Zou H, Zhang L, Ye X, Han D (2020) Surface modification of silica nanoparticles by a polyoxyethylene sorbitan and silane coupling agent to prepare high-performance rubber composites. Polym Test 81:106195. https://doi.org/10.1016/j.polymertesting.2019.106195

Bijina V, Jandas PJ, Joseph S et al (2022) Recent trends in industrial and academic developments of green tyre technology. Polym Bull. https://doi.org/10.1007/s00289-022-04445-2

Zheng J, Han D, Ye X, Wu X, Wu Y, Wang Y, Zhang L (2018) Chemical and physical interaction between silane coupling agent with long arms and silica and its effect on silica/natural rubber composites. Polymer 135:200–210. https://doi.org/10.1016/j.polymer.2017.12.010

Xia L, Song J, Wang H, Kan Z (2019) Silica nanoparticles reinforced natural rubber latex composites: the effects of silica dimension and polydispersity on performance. J Appl Polym Sci 136:47449. https://doi.org/10.1002/app.47449

Hussain M, Yasin S, Adnan Akram M, Xu H, Song Y, Zheng Q (2019) Influence of ionic liquids on structure and rheological behaviors of silica-filled butadiene rubber. Ind Eng Chem Res 58:18205–18212. https://doi.org/10.1021/acs.iecr.9b03494

Chen L, Jia Z, Tang Y, Wu L, Luo Y, Jia D (2017) Novel functional silica nanoparticles for rubber vulcanization and reinforcement. Compos Sci Technol 144:11–17. https://doi.org/10.1016/j.compscitech.2016.11.005

Borapak W, Chueangchayaphan N, Pichaiyut S et al (2021) Cure characteristics and physico-mechanical properties of natural rubber/silica composites: effect of natural rubber-graft-poly (2-hydroxyethyl acrylate) content. Polym Bull 78:2009–2023. https://doi.org/10.1007/s00289-020-03199-z

Wu X, Zheng J, Han B, Zhang L, Lu J, Ye X (2019) Designing novel epoxy-terminated polybutadiene to construct chemical interface between nanosilica and rubbers with green nature. Compos Part B-Eng 178:1074511. https://doi.org/10.1016/j.compositesb.2019.107451

Choi SS, Son CE (2016) Influence of silane coupling agent on bound rubber formation of NR/SBR blend compounds reinforced with carbon black. Polym Bull 73:3453–3464. https://doi.org/10.1007/s00289-016-1666-7

Sengloyluan K, Sahakaro K, Dierkes WK, Noordermeer JWM (2016) Reduced ethanol emissions by a combination of epoxidized natural rubber and silane coupling agent for silica-reinforced natural rubber-based tire treads. Rubber Chem Technol 89:419–435. https://doi.org/10.5254/rct.16.84813

Kaewsakul W, Sahakaro K, Dierkes WK, Noordermeer JWM (2015) Mechanistic aspects of silane coupling agents with different functionalities on reinforcement of silica-filled natural rubber compounds. Polym Eng Sci 55:836. https://doi.org/10.1002/pen.23949

Pickering KL, Khimi SR, Ilanko S (2015) The effect of silane coupling agent on iron sand for use in magnetorheological elastomers Part 1: surface chemical modification and characterization. Compos Part A-Appl Sci Manuf 68:377–386. https://doi.org/10.1016/j.compositesa.2014.10.005

Zhang C, Yu S, Tang Z, Guo B (2022) Catalyzed silanization by supporting ceria on silica towards rubber composites with improved mechanical properties. Compos Commun 32:101168. https://doi.org/10.1016/j.coco.2022.101168

Yao B, Xia L, Wang H, Kan Z (2019) The effects of natural astaxanthin-modified silica on properties of natural rubber. J Appl Polym Sci 136:47287. https://doi.org/10.1002/app.47287

Zhai X, Chen Y, Han D, Zheng J, Wu X, Wang Z, Li X, Ye X, Zhang L (2021) New designed coupling agents for silica used in green tires with low VOCs and low rolling resistance. Appl Surf Sci 558:149819. https://doi.org/10.1016/j.apsusc.2021.149819

Luginsland HD, Röben C (2016) The development of sulphur-functional silanes as coupling agents in silica-reinforced rubber compounds. Their historical development over several decades. Int Polym Sci Technol 43:1–6. https://doi.org/10.1177/0307174X1604300401

Zhong B, Jia Z, Hu D, Luo Y, Jia D, Liu F (2017) Enhancing interfacial interaction and mechanical properties of styrene-butadiene rubber composites via silica-supported vulcanization accelerator. Compos Part A-Appl Sci Manuf 96:129–136. https://doi.org/10.1016/j.compositesa.2017.02.016

Dileep P, Narayanankutty SK (2020) Styrenated phenol modified nanosilica for improved thermo-oxidative and mechanical properties of natural rubber. Polym Test 82:106302. https://doi.org/10.1016/j.polymertesting.2019.106302

Zhong B, Jia Z, Luo Y, Jia D (2015) A method to improve the mechanical performance of styrene-butadiene rubber via vulcanization accelerator modified silica. Compos Sci Technol 117:46–53. https://doi.org/10.1016/j.compscitech.2015.05.012

Lorenz O, Parks CR (1961) The crosslinking efficiency of some vulcanizing agents in natural rubber. J Appl Polym Sci 50:299–312. https://doi.org/10.1002/pol.1961.1205015404

Zhang C, Tang Z, Guo B, Zhang L (2019) Concurrently improved dispersion and interfacial interaction in rubber/nanosilica composites via efficient hydrosilane functionalization. Compos Sci Technol 169:217–223. https://doi.org/10.1016/j.compscitech.2018.11.016

Charmas B, Kucio K, Sydorchuk V, Khalameida S, Zięzio M, Nowicka A (2019) Characterization of multimodal silicas using TG/DTG/DTA, Q-TG, and DSC methods. Colloids Interfaces 3:6. https://doi.org/10.3390/colloids3010006

Braun U, Eisentraut P, Fuchs S, Deglmann P (2015) Sulphurous additives for polystyrene: influencing decomposition behavior in the condensed phase. J Appl Polym Sci. https://doi.org/10.1002/app.41665

Xie Y, Hassan AA, Song P, Zhang Z, Wang S (2019) High scission of butadiene rubber vulcanizate under thermo-oxidation. Polym Degrad Stab 167:292–301. https://doi.org/10.1016/j.polymdegradstab.2019.07.015

Zhang M, Zhao F, Luo Y (2019) Self-healing mechanism of microcracks on waterborne polyurethane with tunable disulfide bond contents. ACS Omega 4:1703–1714. https://doi.org/10.1021/acsomega.8b02923

Yang X, Li Z, Jiang Z, Wang S, Liu H, Xu X et al (2020) Mechanical reinforcement of room-temperature-vulcanized silicone rubber using modified cellulose nanocrystals as cross-linker and nanofiller. Carbohydr Polym 229:115509. https://doi.org/10.1016/j.carbpol.2019.115509

Li S, Li H, Li Z, Zhou H, Guo Y, Chen F et al (2017) Polysiloxane modified phenolic resin with co-continuous structure. Polymer 120:217–222. https://doi.org/10.1016/j.polymer.2017.05.063

Zheng J, Han D, Zhao S, Ye X, Wang Y, Wu Y et al (2018) Constructing a multiple covalent interface and isolating a dispersed structure in silica/rubber nanocomposites with excellent dynamic performance. ACS Appl Mater Interfaces 10:19922–19931. https://doi.org/10.1021/acsami.8b02358

Qian Z, Peng Z (2019) Reinforcing styrene-butadiene rubber composites by constructing multiple interaction between rubber and silica. Polym Compos 40:1740–1747. https://doi.org/10.1002/pc.24928

Bokobza L (2004) The reinforcement of elastomeric networks by fillers. Macromol Mater Eng 289:607–621. https://doi.org/10.1002/mame.200400034

Qu L, Yu G, Xie X, Wang L, Jing L, Zhao Q (2013) Effect of silane coupling agent on filler and rubber interaction of silica reinforced solution styrene butadiene rubber. Polym Compos 34:1575–1582. https://doi.org/10.1002/pc.22554

Tang Z, Wu X, Guo B, Zhang L, Jia D (2012) Preparation of butadiene–styrene–vinyl pyridine rubber–graphene oxide hybrids through co-coagulation process and in situ interface tailoring. J Mater Chem 22:7492–7501. https://doi.org/10.1039/C2JM00084A

Bokobza L, Erman B (2000) A theoretical and experimental study of filler effect on stress-deformation-segmental orientation relations for poly(dimethylsiloxane) networks. Macromolecules. https://doi.org/10.1021/ma000261t

Tang Z, Wei Q, Lin T, Guo B, Jia D (2013) The use of a hybrid consisting of tubular clay and graphene as a reinforcement for elastomers. Rsc Adv 3:17057–17064. https://doi.org/10.1039/C3RA42568A

Tang Z, Zhang C, Wei Q, Weng P, Guo B (2016) Remarkably improving performance of carbon black-filled rubber composites by incorporating MoS2 nanoplatelets. Compos Sci Technol 132:93–100. https://doi.org/10.1016/j.compscitech.2016.07.001

Manoharan P, Naskar (2016) Exploring a highly dispersible silica–elastomer composite for tire applications. J Appl Polym Sci. https://doi.org/10.1002/app.43531

Zhang C, Tang Z, Guo B et al (2018) Significantly improved rubber-silica interface via subtly controlling surface chemistry of silica. Compos Sci Technol 156:70–77. https://doi.org/10.1016/j.compscitech.2017.12.020

Qin X, Han B, Lu J, Wang Z, Sun Z, Wang D et al (2018) Rational design of advanced elastomer nanocomposites towards extremely energy-saving tires based on macromolecular assembly strategy. Nano Energy 48:180–188. https://doi.org/10.1016/j.nanoen.2018.03.038

Sarkawi SS, Dierkes WK, Noordermeer JWM (2014) Elucidation of filler-to-filler and filler-to-rubber interactions in silica-reinforced natural rubber by TEM network visualization. Eur Polym J 54:118–127. https://doi.org/10.1016/j.eurpolymj.2014.02.015

Park JT, Seo JA, Ahn SH, Kim JH, Kang SW (2010) Surface modification of silica nanoparticles with hydrophilic polymers. J Ind Eng Chem 16:517–522. https://doi.org/10.1016/j.jiec.2010.03.030

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jiang, Y., Wang, S. & Zhang, Y. Improving performance of natural rubber composites through the novel silica modified by a crosslinking agent. Polym. Bull. 80, 12373–12392 (2023). https://doi.org/10.1007/s00289-022-04662-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04662-9