Abstract

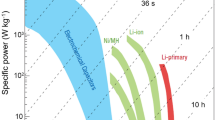

In the present review, we have focused importance of phase change material (PCM) in the field of thermal energy storage (TES) applications. Phase change material that act as thermal energy storage is playing an important role in the sustainable development of the environment. Especially solid–liquid organic phase change materials (OPCMs) have gained the more importance due to their high heat of fusion. Various microencapsulation techniques of PCMs and eutectic PCMs have been discussed in detail along with their potential applications in the field of textile, building, solar and battery composites for thermal energy storage applications. Eutectic combinations of fatty acids and their eutectic mixtures are useful for obtaining the suitable temperature range. Thermal conductivity modifications with graphene oxide, carbon nanotubes, and expanded graphite have been reviewed in detail. The phase change material properties are tailored and enhanced using microencapsulation techniques and thermal conductive material to be use as effective thermal energy storage material. In this review, the graphene-based composites and their potential thermal energy storage applications have been focused. The Microencapsulation of phase change material provides several benefits by storing and protecting the PCM for longer duration of time. In present study, encapsulations techniques, different forms of encapsulation, eutectics and its theoretical method for calculation and its applications in battery, buildings and textiles are discussed.

Similar content being viewed by others

Data and material availability

Not applicable

References

Wang EST, Lin HC (2017) Sustainable development: The effects of social normative beliefs on environmental behaviour. Sustain Dev 25:595–609

Wennersten R, Sun Q, Li H (2015) The future potential for Carbon Capture and Storage in climate change mitigation - An overview from perspectives of technology, economy and risk. J Clean Prod 103:724–736. https://doi.org/10.1016/j.jclepro.2014.09.023

Zhao CY, Zhang GH (2011) Review on microencapsulated phase change materials (MEPCMs): Fabrication, characterization and applications. Renew Sustain Energy Rev 15:3813–3832. https://doi.org/10.1016/j.rser.2011.07.019

Fallahi A, Guldentops G, Tao M et al (2017) Review on solid-solid phase change materials for thermal energy storage: Molecular structure and thermal properties. Appl Therm Eng 127:1427–1441. https://doi.org/10.1016/j.applthermaleng.2017.08.161

Sharma A, Tyagi VV, Chen CR, Buddhi D (2009) Review on thermal energy storage with phase change materials and applications. Renew Sustain Energy Rev 13:318–345

Amirante R, Cassone E, Distaso E, Tamburrano P (2017) Overview on recent developments in energy storage: Mechanical, electrochemical and hydrogen technologies. Energy Convers Manag 132:372–387. https://doi.org/10.1016/j.enconman.2016.11.046

Su W, Darkwa J, Kokogiannakis G (2015) Review of solid-liquid phase change materials and their encapsulation technologies. Renew Sustain Energy Rev 48:373–391. https://doi.org/10.1016/j.rser.2015.04.044

Nazir H, Batool M, Ali M, Kannan AM (2018) Fatty acids based eutectic phase change system for thermal energy storage applications. Appl Therm Eng 142:466–475. https://doi.org/10.1016/j.applthermaleng.2018.07.025

Sarier N, Onder E, Ukuser G (2015) Silver incorporated microencapsulation of n-hexadecane and n-octadecane appropriate for dynamic thermal management in textiles. Thermochim Acta 613:17–27. https://doi.org/10.1016/J.TCA.2015.05.015

Su JF, Wang LX, Ren L (2005) Preparation and characterization of double-MF shell microPCMs used in building materials. J Appl Polym Sci 97:1755–1762. https://doi.org/10.1002/app.21205

Ke H (2017) Phase diagrams, eutectic mass ratios and thermal energy storage properties of multiple fatty acid eutectics as novel solid-liquid phase change materials for storage and retrieval of thermal energy. Appl Therm Eng 113:1319–1331. https://doi.org/10.1016/j.applthermaleng.2016.11.158

Sharma A, Shukla A, Chen CR, Wu TN (2014) Development of phase change materials (PCMs) for low temperature energy storage applications. Sustain Energy Technol Assess 7:17–21. https://doi.org/10.1016/j.seta.2014.02.009

Yuan Y, Zhang N, Tao W et al (2014) Fatty acids as phase change materials: A review. Renew Sustain Energy Rev 29:482–498. https://doi.org/10.1016/j.rser.2013.08.107

Karaipekli A, Sari A (2007) Capric acid and palmitic acid eutectic mixture applied in building wallboard for latent heat thermal energy storage. J Sci Ind Res (India) 66:470–476

Sari A, Karaipekli A (2008) Preparation and thermal properties of capric acid/palmitic acid eutectic mixture as a phase change energy storage material. Mater Lett 62:903–906. https://doi.org/10.1016/j.matlet.2007.07.025

Shilei L, Neng Z, Guohui F (2006) Eutectic mixtures of capric acid and lauric acid applied in building wallboards for heat energy storage. Energy Build 38:708–711. https://doi.org/10.1016/j.enbuild.2005.10.006

Yanping Y, Wenquan T, Xiaoling C, Li B (2011) Theoretic prediction of melting temperature and latent heat for a fatty acid eutectic mixture. J Chem Eng Data 56:2889–2891. https://doi.org/10.1021/je200057j

Zhang N, Yuan Y, Wang X et al (2013) Preparation and characterization of lauric-myristic-palmitic acid ternary eutectic mixtures/expanded graphite composite phase change material for thermal energy storage. Chem Eng J 231:214–219. https://doi.org/10.1016/j.cej.2013.07.008

Sari A (2005) Eutectic mixtures of some fatty acids for low temperature solar heating applications: Thermal properties and thermal reliability. Appl Therm Eng 25:2100–2107. https://doi.org/10.1016/j.applthermaleng.2005.01.010

Wu S, Yan T, Kuai Z, Pan W (2020) Thermal conductivity enhancement on phase change materials for thermal energy storage: A review. Energy Storage Mater 25:251–295. https://doi.org/10.1016/j.ensm.2019.10.010

Tang Y, Lin Y, Jia Y, Fang G (2017) Improved thermal properties of stearyl alcohol/high density polyethylene/expanded graphite composite phase change materials for building thermal energy storage. Energy Build 153:41–49. https://doi.org/10.1016/j.enbuild.2017.08.005

Zhong Y, Zhou M, Huang F et al (2013) Effect of graphene aerogel on thermal behavior of phase change materials for thermal management. Sol Energy Mater Sol Cells 113:195–200. https://doi.org/10.1016/j.solmat.2013.01.046

Kim P, Shi L, Majumdar A, McEuen PL (2001) Thermal transport measurements of individual multiwalled nanotubes. Phys Rev Lett 87:215502-1-215502–4. https://doi.org/10.1103/PhysRevLett.87.215502

Xiao X, Zhang P, Li M (2014) Effective thermal conductivity of open-cell metal foams impregnated with pure paraffin for latent heat storage. Int J Therm Sci 81:94–105. https://doi.org/10.1016/j.ijthermalsci.2014.03.006

Wang J, Xie H, Guo Z et al (2014) Improved thermal properties of paraffin wax by the addition of TiO2 nanoparticles. Appl Therm Eng 73:1541–1547. https://doi.org/10.1016/j.applthermaleng.2014.05.078

Ding J, Zhang Y, Wang X et al (2005) Influence of additives on thermal conductivity of shape-stabilized phase change material. Int Sol Energy Conf. https://doi.org/10.1115/ISEC2005-76171

Conversion XE (2006) 01 Solid fuels ( derived solid fuels ) 06 • 01521 Study on paraffin / expanded graphite composite phase change thermal energy storage material 06 / 01516 Pulsed laser deposition of glass-like cluster assembled carbon films 06 / 01517 Pulsed laser depositi. 2151

Zhang Z, Fang X (2006) Study on paraffin/expanded graphite composite phase change thermal energy storage material. Energy Convers Manag 47:303–310. https://doi.org/10.1016/j.enconman.2005.03.004

Mills A, Farid M, Selman JR, Al-Hallaj S (2006) Thermal conductivity enhancement of phase change materials using a graphite matrix. Appl Therm Eng 26:1652–1661. https://doi.org/10.1016/j.applthermaleng.2005.11.022

Wang LW, Metcalf SJ, Critoph RE et al (2013) Two types of natural graphite host matrix for composite activated carbon adsorbents. Appl Therm Eng 50:1652–1657. https://doi.org/10.1016/j.applthermaleng.2011.07.011

Wang LW, Tamainot-Telto Z, Metcalf SJ et al (2010) Anisotropic thermal conductivity and permeability of compacted expanded natural graphite. Appl Therm Eng 30:1805–1811. https://doi.org/10.1016/j.applthermaleng.2010.04.014

Ling Z, Chen J, Fang X et al (2014) Experimental and numerical investigation of the application of phase change materials in a simulative power batteries thermal management system. Appl Energy 121:104–113. https://doi.org/10.1016/j.apenergy.2014.01.075

Silakhori M, Fauzi H, Mahmoudian MR et al (2015) Preparation and thermal properties of form-stable phase change materials composed of palmitic acid/polypyrrole/graphene nanoplatelets. Energy Build 99:189–195. https://doi.org/10.1016/j.enbuild.2015.04.042

Ghosh Swapan Kumar (ed) (2006) Functional Coatings: by Polymer Microencapsulation. Wiley. https://doi.org/10.1002/3527608478

Cho JS, Kwon A, Cho CG (2002) Microencapsulation of octadecane as a phase-change material by interfacial polymerization in an emulsion system. Colloid Polym Sci 280:260–266. https://doi.org/10.1007/s00396-001-0603-x

Liang C, Lingling X, Hongbo S, Zhibin Z (2009) Microencapsulation of butyl stearate as a phase change material by interfacial polycondensation in a polyurea system. Energy Convers Manag 50:723–729. https://doi.org/10.1016/j.enconman.2008.09.044

Zhang H, Sun S, Wang X, Wu D (2011) Fabrication of microencapsulated phase change materials based on n-octadecane core and silica shell through interfacial polycondensation. Colloids Surfaces A Physicochem Eng Asp 389:104–117. https://doi.org/10.1016/j.colsurfa.2011.08.043

Lu S, Shen T, Xing J et al (2018) Preparation and characterization of cross-linked polyurethane shell microencapsulated phase change materials by interfacial polymerization. Mater Lett 211:36–39. https://doi.org/10.1016/j.matlet.2017.09.074

Yang Z, Peng H, Wang W, Liu T (2010) Crystallization behavior of poly(ε-caprolactone)/layered double hydroxide nanocomposites. J Appl Polym Sci 116:2658–2667. https://doi.org/10.1002/app

Choi JK, Lee JG, Kim JH, Yang HS (2001) Preparation of microcapsules containing phase change materials as heat transfer media by in-situ polymerization. J Ind Eng Chem 7:358–362

Jyothi NVN, Prasanna PM, Sakarkar SN et al (2010) Microencapsulation techniques, factors influencing encapsulation efficiency. J Microencapsul 27:187–197. https://doi.org/10.3109/02652040903131301

Zhang XX, Tao XM, Yick KL, Wang XC (2004) Structure and thermal stability of microencapsulated phase-change materials. Colloid Polym Sci 282:330–336. https://doi.org/10.1007/s00396-003-0925-y

Alva G, Lin Y, Liu L, Fang G (2017) Synthesis, characterization and applications of microencapsulated phase change materials in thermal energy storage: A review. Energy Build 144:276–294. https://doi.org/10.1016/J.ENBUILD.2017.03.063

Naikwadi AT, Samui AB, Mahanwar PA (2020) Melamine-formaldehyde microencapsulated n-Tetracosane phase change material for solar thermal energy storage in coating. Sol Energy Mater Sol Cells 215:110676. https://doi.org/10.1016/j.solmat.2020.110676

Boh B, Knez E, Staresinic M (2005) Microencapsulation of higher hydrocarbon phase change materials by in situ polymerization. J Microencapsul 22:715–735. https://doi.org/10.1080/02652040500162139

Fang G, Li H, Yang F et al (2009) Preparation and characterization of nano-encapsulated n-tetradecane as phase change material for thermal energy storage. Chem Eng J 153:217–221. https://doi.org/10.1016/j.cej.2009.06.019

Zhang H, Wang X (2009) Fabrication and performances of microencapsulated phase change materials based on n-octadecane core and resorcinol-modified melamine-formaldehyde shell. Colloids Surf A Physicochem Eng Asp 332:129–138. https://doi.org/10.1016/j.colsurfa.2008.09.013

EBSCOhost | 64498639 | Production of Melamine-Formaldehyde PCM Microcapsules with Ammonia Scavenger used for Residual Formaldehyde Reduction. https://web.s.ebscohost.com/abstract?direct=true&profile=ehost&scope=site&authtype=crawler&jrnl=13180207&asa=Y&AN=64498639&h=DwH7SHfTPOBxFWHycRvPkr86prxdY6%2Fty9Pg4dOH0AKj64foKVSMPilkzn%2Fc1%2BqyqM0OKQ38mXco1atUKyuV%2BA%3D%3D&crl=c&resultNs=AdminWebAuth&resultLocal=ErrCrlNotAuth&crlhashurl=login.aspx%3Fdirect%3Dtrue%26profile%3Dehost%26scope%3Dsite%26authtype%3Dcrawler%26jrnl%3D13180207%26asa%3DY%26AN%3D64498639. Accessed 7 Dec 2021

Su JF, Wang SB, Zhang YY, Huang Z (2011) Physicochemical properties and mechanical characters of methanol-modified melamine-formaldehyde (MMF) shell microPCMs containing paraffin. Colloid Polym Sci 289:111–119. https://doi.org/10.1007/s00396-010-2328-1

Su JF, Wang SB, Zhou JW et al (2011) Fabrication and interfacial morphologies of methanol-melamine-formaldehyde (MMF) shell microPCMs/epoxy composites. Colloid Polym Sci 289:169–177. https://doi.org/10.1007/s00396-010-2334-3

Huang J, Wang T, Zhu P, Xiao J (2013) Preparation, characterization, and thermal properties of the microencapsulation of a hydrated salt as phase change energy storage materials. Thermochim Acta 557:1–6. https://doi.org/10.1016/j.tca.2013.01.019

Tang X, Li W, Zhang X, Shi H (2014) Fabrication and characterization of microencapsulated phase change material with low supercooling for thermal energy storage. Energy 68:160–166. https://doi.org/10.1016/j.energy.2014.03.002

Sánchez-Silva L, Rodríguez JF, Romero A et al (2010) Microencapsulation of PCMs with a styrene-methyl methacrylate copolymer shell by suspension-like polymerisation. Chem Eng J 157:216–222. https://doi.org/10.1016/j.cej.2009.12.013

Sánchez L, Sánchez P, de Lucas A et al (2007) Microencapsulation of PCMs with a polystyrene shell. Colloid Polym Sci 285:1377–1385. https://doi.org/10.1007/s00396-007-1696-7

Sari A, Alkan C, Karaipekli A (2010) Preparation, characterization and thermal properties of PMMA/n-heptadecane microcapsules as novel solid-liquid microPCM for thermal energy storage. Appl Energy 87:1529–1534. https://doi.org/10.1016/j.apenergy.2009.10.011

Alay S, Alkan C, Göde F (2011) Synthesis and characterization of poly(methyl methacrylate)/n-hexadecane microcapsules using different cross-linkers and their application to some fabrics. Thermochim Acta 518:1–8. https://doi.org/10.1016/j.tca.2011.01.014

Yin D, Ma L, Liu J, Zhang Q (2014) Pickering emulsion : A novel template for microencapsulated phase change materials with polymer e silica hybrid shell. Energy 64:575–581. https://doi.org/10.1016/j.energy.2013.10.004

Li C, Yu H, Song Y et al (2018) Preparation and characterization of PMMA/TiO2 hybrid shell microencapsulated PCMs for thermal energy storage. Energy. https://doi.org/10.1016/j.energy.2018.11.038

Shi J, Wu X, Fu X, Sun R (2015) Ac ce pt cr t. Thermochim Acta. https://doi.org/10.1016/j.tca.2015.08.022

Zhang B, Zhang Z, Kapar S et al (2019) Microencapsulation of phase change materials with polystyrene/ cellulose nanocrystal hybrid shell via pickering emulsion polymerization. ACS Sustain Chem Eng. https://doi.org/10.1021/acssuschemeng.9b04134

Onder E, Sarier N, Cimen E (2008) Encapsulation of phase change materials by complex coacervation to improve thermal performances of woven fabrics. Thermochim Acta 467:63–72. https://doi.org/10.1016/j.tca.2007.11.007

Jamekhorshid A, Sadrameli SM, Farid M (2014) A review of microencapsulation methods of phase change materials (PCMs) as a thermal energy storage (TES) medium. Renew Sustain Energy Rev 31:531–542

Hawlader MNA, Uddin MS, Zhu HJ (2000) Preparation and evaluation of a novel solar storage material: Microencapsulated paraffin. Int J Sol Energy 20:227–238. https://doi.org/10.1080/01425910008914357

Nielsen P (2009) Coastal and estuarine processes. World Scientific, Singapore

Özonur Y, Mazman M, Paksoy HÖ, Evliya H (2006) Microencapsulation of coco fatty acid mixture for thermal energy storage with phase change material. Int J Energy Res 30:741–749. https://doi.org/10.1002/er.1177

Fang G, Li H, Liu X (2010) Preparation and properties of lauric acid/silicon dioxide composites as form-stable phase change materials for thermal energy storage. Mater Chem Phys 122:533–536. https://doi.org/10.1016/j.matchemphys.2010.03.042

Li H, Fang G, Liu X (2010) Synthesis of shape-stabilized paraffin/silicon dioxide composites as phase change material for thermal energy storage. J Mater Sci 45:1672–1676. https://doi.org/10.1007/s10853-009-4146-8

Tang B, Qiu M, Zhang S (2012) Thermal conductivity enhancement of PEG/SiO 2 composite PCM by in situ Cu doping. Sol Energy Mater Sol Cells 105:242–248. https://doi.org/10.1016/j.solmat.2012.06.012

Greco J, Ernest S (2017) Front Matter | Enhanced Reader. 1–451

Noyori R (1999) Supercritical fluids: Introduction. Chem Rev 99:353–354. https://doi.org/10.1021/cr980085a

Wu HT, Yang MW (2011) Precipitation kinetics of PMMA sub-micrometric particles with a supercritical assisted-atomization process. J Supercrit Fluids 59:98–107. https://doi.org/10.1016/j.supflu.2011.08.001

Haldorai Y, Shim JJ, Lim KT (2012) Synthesis of polymer-inorganic filler nanocomposites in supercritical CO 2. J Supercrit Fluids 71:45–63. https://doi.org/10.1016/j.supflu.2012.07.007

(2003) OWO1831 residence Electrical energy saving in a passive-solar-heated using a direct gain attached sunspace Ozone coloration of Ni and Cr oxide films Evaluation of solar fraction ( FJ for quonset type empty greenhouse : an experimental validation in Poland 2003

Borreguero AM, Valverde JL, Rodríguez JF et al (2011) Synthesis and characterization of microcapsules containing rubitherm®RT27 obtained by spray drying. Chem Eng J 166:384–390. https://doi.org/10.1016/j.cej.2010.10.055

Wang Y, Zheng H, Feng HX, Zhang DY (2012) Effect of preparation methods on the structure and thermal properties of stearic acid/activated montmorillonite phase change materials. Energy Build 47:467–473. https://doi.org/10.1016/j.enbuild.2011.12.021

Fortuniak W, Slomkowski S, Chojnowski J et al (2013) Synthesis of a paraffin phase change material microencapsulated in a siloxane polymer. Colloid Polym Sci 291:725–733. https://doi.org/10.1007/s00396-012-2782-z

Sarkar S, Mestry S, Mhaske ST (2022) Developments in phase change material ( PCM ) doped energy efficient polyurethane ( PU ) foam for perishable food cold-storage applications : A review. J Energy Storage 50:104620. https://doi.org/10.1016/j.est.2022.104620

Li W, Zhang R, Jiang N et al (2013) Composite macrocapsule of phase change materials/expanded graphite for thermal energy storage. Energy 57:607–614. https://doi.org/10.1016/j.energy.2013.05.007

Cui H, Liao W, Mi X et al (2015) Study on functional and mechanical properties of cement mortar with graphite-modified microencapsulated phase-change materials. Energy Build 105:273–284. https://doi.org/10.1016/j.enbuild.2015.07.043

Gao G, Zhang T, Jiao S, Guo C (2020) Preparation of reduced graphene oxide modified magnetic phase change microcapsules and their application in direct absorption solar collector. Sol Energy Mater Sol Cells 216:110695. https://doi.org/10.1016/j.solmat.2020.110695

Liu H, Wang X (2019) Innovative design of microencapsulated phase change materials for thermal energy storage and versatile applications : a review. Sustain Energy Fuels 3(5):1091–1149

Yuan K, Liu J, Fang X, Zhang Z (2018) Novel facile self-assembly approach to construct graphene oxide-decorated phase-change microcapsules with enhanced photo-to-thermal conversion performance. J Mater Chemy A. https://doi.org/10.1039/c8ta00215k

Qiao Z, Mao J (2017) Materials science & engineering B microcapsules with low infrared emissivity and high thermal conductivity. Mater Sci Eng B 226:86–93. https://doi.org/10.1016/j.mseb.2017.08.016

Su J, Wang X, Han S et al (2017) Preparation and physicochemical properties of microcapsules containing phase-change material with graphene / organic hybrid structure shells. J Mater Chem A. https://doi.org/10.1039/c7ta06980d

He L, Wang H, Yang F, Zhu H (2018) Preparation and properties of polyethylene glycol/unsaturated polyester resin/graphene nanoplates composites as form-stable phase change materials. Thermochim Acta 665:43–52. https://doi.org/10.1016/j.tca.2018.04.012

Tang Y, Jia Y, Alva G et al (2016) Synthesis, characterization and properties of palmitic acid/high density polyethylene/graphene nanoplatelets composites as form-stable phase change materials. Sol Energy Mater Sol Cells 155:421–429. https://doi.org/10.1016/j.solmat.2016.06.049

Karaipekli A, Sari A, Kaygusuz K (2008) Part A Thermal properties and long-term reliability of capric acid / lauric acid and capric acid / myristic acid mixtures for thermal energy storage thermal properties and long-term reliability of capric acid / lauric acid and capric acid. Energy Sour. https://doi.org/10.1080/15567030701258295

Liu S, Zhang X, Zhu X, Xin S (2021) A low-temperature phase change material based on capric-stearic acid/expanded graphite for thermal energy storage. ACS Omega 6:17988–17998. https://doi.org/10.1021/acsomega.1c01705

Kahwaji S, Johnson MB, Kheirabadi AC et al (2016) Stable, low-cost phase change material for building applications : The eutectic mixture of decanoic acid and tetradecanoic acid. Appl Energy 168:457–464. https://doi.org/10.1016/j.apenergy.2016.01.115

He Y, Zhang X, Zhang Y et al (2016) Utilization of lauric acid-myristic acid/expanded graphite phase change materials to improve thermal properties of cement mortar. Energy Build 133:547–558. https://doi.org/10.1016/j.enbuild.2016.10.016

Fauzi H, Metselaar HSC, Mahlia TMI et al (2015) Thermal characteristic reliability of fatty acid binary mixtures as phase change materials (PCMs) for thermal energy storage applications. Appl Therm Eng. https://doi.org/10.1016/j.applthermaleng.2015.01.047

Gallart-sirvent P, Mart M, Barrenche C, Cabeza F (2017) Fatty acid eutectic mixtures and derivatives from non-edible animal fat as phase change materials. RSC Adv. https://doi.org/10.1039/c7ra03845c

Kant K, Shukla A, Sharma A (2016) Ternary mixture of fatty acids as phase change materials for thermal energy storage applications. Energy Rep 2:274–279. https://doi.org/10.1016/j.egyr.2016.10.002

Zhao P, Yue Q, He H et al (2014) Study on phase diagram of fatty acids mixtures to determine eutectic temperatures and the corresponding mixing proportions. Appl Energy 115:483–490. https://doi.org/10.1016/j.apenergy.2013.10.048

Cai Y, Ke H, Lin L et al (2012) Preparation, morphology and thermal properties of electrospun fatty acid eutectics / polyethylene terephthalate form-stable phase change ultrafine composite fibers for thermal energy storage. Energy Convers Manag 64:245–255. https://doi.org/10.1016/j.enconman.2012.04.018

Huang X, Alva G, Liu L, Fang G (2017) Solar energy materials & solar cells preparation, characterization and thermal properties of fatty acid eutectics / bentonite / expanded graphite composites as novel form – stable thermal energy storage materials. Sol Energy Mater Sol Cells 166:157–166. https://doi.org/10.1016/j.solmat.2017.03.026

Ceden FO (2000) Measurements and Estimate of Heat Capacity for Some Pure Fatty Acids and Their Binary and Ternary Mixtures. J Chem Eng Data 45(1):64–69

Nelson G (2002) Application of microencapsulation in textiles. Int j pharm 242:55–62

Bourbigot S, Rochery M, Vroman I (2005) Flame retarded polyurea with microencapsulated ammonium phosphate for textile coating. Polymer Degradation Stability 88:106–113. https://doi.org/10.1016/j.polymdegradstab.2004.01.028

Kim J, Cho G (2002) Functional finishing of acrylic and cationic dyeable fabrics: Intermolecular interactions. Text Res J. https://doi.org/10.1177/004051750207201209

Shin Y, Yoo D, Son K (2004) Development of thermoregulating textile materials with microencapsulated phase change materials ( PCM ). II .preparation and application of PCM. J Appl Polym Sci. https://doi.org/10.1002/app.21438

Hawes DW (1993) Latent heat storage in building materials. Energy build 20:77–86

Tyagi VV, Kaushik SC, Tyagi SK, Akiyama T (2011) Development of phase change materials based microencapsulated technology for buildings: A review. Renew Sustain Energy Rev 15:1373–1391. https://doi.org/10.1016/j.rser.2010.10.006

Schossig P, Henning HM, Gschwander S, Haussmann T (2005) Micro-encapsulated phase-change materials integrated into construction materials. Sol Energy Mater Sol Cells 89:297–306. https://doi.org/10.1016/j.solmat.2005.01.017

Kuznik F, Virgone J (2009) Experimental assessment of a phase change material for wall building use. Appl Energy 86:2038–2046. https://doi.org/10.1016/j.apenergy.2009.01.004

You M, Zhang XX, Li W, Wang XC (2008) Effects of MicroPCMs on the fabrication of MicroPCMs/polyurethane composite foams. Thermochim Acta 472:20–24. https://doi.org/10.1016/j.tca.2008.03.006

You M, Zhang X, Wang J, Wang X (2009) Polyurethane foam containing microencapsulated phase-change materials with styrene-divinybenzene co-polymer shells. J Mater Sci 44:3141–3147. https://doi.org/10.1007/s10853-009-3418-7

Mulligan JC, Colvin DP, Bryant YG (1996) Microencapsulated phase-change material suspensions for heat transfer in spacecraft thermal systems. J Spacecr Rockets 33:278–284. https://doi.org/10.2514/3.26753

Griffiths PW, Eames PC (2007) Performance of chilled ceiling panels using phase change material slurries as the heat transport medium. Appl Therm Eng 27:1756–1760. https://doi.org/10.1016/j.applthermaleng.2006.07.009

Wang X, Niu J (2009) Performance of cooled-ceiling operating with MPCM slurry. Energy Convers Manag 50:583–591. https://doi.org/10.1016/j.enconman.2008.10.021

Hao YL, Tao YX (2004) A numerical model for phase-change suspension flow in microchannels. Numer Heat Transf Part A Appl 46:55–77. https://doi.org/10.1080/10407780490457545

Sabbah R, Farid MM, Al-Hallaj S (2009) Micro-channel heat sink with slurry of water with micro-encapsulated phase change material: 3D-numerical study. Appl Therm Eng 29:445–454. https://doi.org/10.1016/j.applthermaleng.2008.03.027

Rao Y, Dammel F, Stephan P, Lin G (2007) Convective heat transfer characteristics of microencapsulated phase change material suspensions in minichannels. Heat Mass Transf und Stoffuebertrag 44:175–186. https://doi.org/10.1007/s00231-007-0232-0

Zhu H, Zhang P, Meng Z, Li M (2015) Thermal characterization of lauric-stearic acid/expanded graphite eutectic mixture as phase change materials. J Nanosci Nanotechnol 15:3288–3294. https://doi.org/10.1166/jnn.2015.9659

Huang YH, Cheng WL, Zhao R (2019) Thermal management of Li-ion battery pack with the application of flexible form-stable composite phase change materials. Energy Convers Manag 182:9–20. https://doi.org/10.1016/j.enconman.2018.12.064

Peng G, Dou G, Hu Y et al (2020) Phase change material (PCM) microcapsules for thermal energy storage. Adv Polym Technol. https://doi.org/10.1155/2020/9490873

Funding

No funding available.

Author information

Authors and Affiliations

Contributions

Not applicable

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yadav, M., Pasarkar, N., Naikwadi, A. et al. A review on microencapsulation, thermal energy storage applications, thermal conductivity and modification of polymeric phase change material for thermal energy storage applications. Polym. Bull. 80, 5897–5927 (2023). https://doi.org/10.1007/s00289-022-04369-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04369-x