Abstract

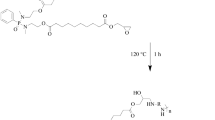

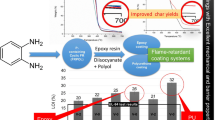

Depletion of the petroleum resources and poor flame-retardant properties of the epoxy resins drive researchers to develop an epoxy resin with good heat stability from bio-resources. In the current research work, we have reported the synthesis of a novel crosslinking agent for epoxy from the catechol as a bio-resource which can be further modified to form epoxy resin as well. The synthesis of the flame-retardant epoxy resin (TOMPP) was performed in two separate steps which include the reaction of the catechol with phosphoryl chloride followed by the reaction of the remaining hydroxyl groups with the epichlorohydrin. The structures of the synthesized products were confirmed using Fourier transform infrared spectroscopy, nuclear magnetic resonance spectroscopy and hydroxyl and epoxy values. The thermogravimetric analysis and differential scanning calorimetry were performed to analyse the thermal stability of the cured films which showed thermal degradation temperatures of both TOMPP and THPP formulations were decreased as the concentration of the TOMPP and THPP increased, while glass transition temperature (Tg) values increased. The char yield value of the THPP formulations was increased with increasing concentration of the intermediate, but for TOMPP it decreased. 40% THPP showed the least current density in electrochemical impedance spectroscopy suggesting the good corrosion resistance property. Mechanical properties were found to be similar for both THPP and TOMPP formulations. Flame retardancy was checked by LOI and UL-94 tests which revealed 40% THPP formulation had the maximum LOI as 28 and self-extinguishing behaviour.

Graphic abstract

Similar content being viewed by others

References

Wang X, Song L, Xing W et al (2011) A effective flame retardant for epoxy resins based on poly(DOPO substituted dihydroxyl phenyl pentaerythritol diphosphonate). Mater Chem Phys 125:536–541. https://doi.org/10.1016/j.matchemphys.2010.10.020

Jian R, Wang P, Duan W et al (2017) A facile method to flame-retard epoxy resin with maintained mechanical properties through a novel P/N/S-containing flame retardant of tautomerization. Mater Lett 204:77–80. https://doi.org/10.1016/j.matlet.2017.05.135

Gao LP, Wang DY, Wang YZ et al (2008) A flame-retardant epoxy resin based on a reactive phosphorus-containing monomer of DODPP and its thermal and flame-retardant properties. Polym Degrad Stab 93:1308–1315. https://doi.org/10.1016/j.polymdegradstab.2008.04.004

Liang WJ, Zhao B, Zhao PH et al (2017) Bisphenol-S bridged penta(anilino)cyclotriphosphazene and its application in epoxy resins: synthesis, thermal degradation, and flame retardancy. Polym Degrad Stab 135:140–151. https://doi.org/10.1016/j.polymdegradstab.2016.11.023

Xu Y, Wang J, Tan Y et al (2018) A novel and feasible approach for one-pack flame-retardant epoxy resin with long pot life and fast curing. Chem Eng J 337:30–39. https://doi.org/10.1016/j.cej.2017.12.086

Shao ZB, Zhang MX, Li Y et al (2018) A novel multi-functional polymeric curing agent: synthesis, characterization, and its epoxy resin with simultaneous excellent flame retardance and transparency. Chem Eng J 345:471–482. https://doi.org/10.1016/j.cej.2018.03.142

Jian R, Wang P, Xia L, Zheng X (2017) Effect of a novel P/N/S-containing reactive flame retardant on curing behavior, thermal and flame-retardant properties of epoxy resin. J Anal Appl Pyrolysis 127:360–368. https://doi.org/10.1016/j.jaap.2017.07.014

Sonnier R, Dumazert L, Livi S et al (2016) Flame retardancy of phosphorus-containing ionic liquid based epoxy networks. Polym Degrad Stab 134:186–193. https://doi.org/10.1016/j.polymdegradstab.2016.10.009

Wang P, Xia L, Jian R et al (2018) Flame-retarding epoxy resin with an efficient P/N/S-containing flame retardant: preparation, thermal stability, and flame retardance. Polym Degrad Stab 149:69–77. https://doi.org/10.1016/j.polymdegradstab.2018.01.026

Wang P, Yang F, Li L, Cai Z (2016) Flame retardancy and mechanical properties of epoxy thermosets modified with a novel DOPO-based oligomer. Polym Degrad Stab 129:156–167. https://doi.org/10.1016/j.polymdegradstab.2016.04.005

Liang WJ, Zhao B, Zhang CY et al (2017) Enhanced flame retardancy of DGEBA epoxy resin with a novel bisphenol-A bridged cyclotriphosphazene. Polym Degrad Stab 144:292–303. https://doi.org/10.1016/j.polymdegradstab.2017.08.027

Shen D, Xu YJ, Long JW et al (2017) Epoxy resin flame-retarded via a novel melamine-organophosphinic acid salt: thermal stability, flame retardance and pyrolysis behavior. J Anal Appl Pyrolysis 128:54–63. https://doi.org/10.1016/j.jaap.2017.10.025

Suresh S, Srivastava VC, Mishra IM (2012) Adsorption of catechol, resorcinol, hydroquinone, and their derivatives: a review. Int J Energy Environ Eng 3(32):1–19. https://doi.org/10.1186/2251-6832-3-32

Tan Y, Shao ZB, Chen XF et al (2015) Novel multifunctional organic–inorganic hybrid curing agent with high flame-retardant efficiency for epoxy resin. ACS Appl Mater Interfaces 7:17919–17928. https://doi.org/10.1021/acsami.5b04570

Jue C, Juan L, Wantai Y (2009) Curing behavior and thermal properties of trifunctional epoxy resin cured by 4,4′-diaminodiphenylmethane. J Appl Polym Sci 114:1976–1983. https://doi.org/10.1002/app.30630

Gan J, Goodson A (2003) Flame retardant phosphorus element-containing epoxy resin compositions. US Patent 6,645,631B2

Mestry S, Mhaske ST (2019) Synthesis of epoxy resins using phosphorus-based precursors for flame-retardant coating. J Coat Technol Res. https://doi.org/10.1007/s11998-018-00157-3

Suresh S, Srivastava VC, Mishra IM (2012) Adsorption of catechol, resorcinol, hydroquinone, and their derivatives: a review. Int J Energy Environ Eng. https://doi.org/10.1186/2251-6832-3-32

Wu J, Cai C, Zhou Z et al (2016) Low-cost mussel inspired poly(catechol/polyamine) coating with superior anti-corrosion capability on copper. J Colloid Interface Sci 463:214–221. https://doi.org/10.1016/j.jcis.2015.10.056

Sa R, Wei Z, Yan Y et al (2015) Catechol and epoxy functionalized ultrahigh molecular weight polyethylene (UHMWPE) fibers with improved surface activity and interfacial adhesion. Compos Sci Technol 113:54–62. https://doi.org/10.1016/j.compscitech.2015.03.017

Wang L, Shi Y, Chen S et al (2017) Highly efficient mussel-like inspired modification of aramid fibers by UV-accelerated catechol/polyamine deposition followed chemical grafting for high-performance polymer composites. Chem Eng J 314:583–593. https://doi.org/10.1016/j.cej.2016.12.015

Liu Y, Wang R, Zhu Y et al (2015) Photoelectrochemical sensing of catechol based on CdS-DNA-pristine graphene nanocomposite film. Sens Actuat B Chem 210:355–361. https://doi.org/10.1016/j.snb.2014.12.124

González MG, Cabanelas JC, Baselga J (1998) In-Tech applications of FTIR on epoxy resins-identification, monitoring the curing process, phase separation and water uptake, infrared spectroscopy—materials science, engineering and technology. IntechOpen Publisher, New York

Jeng RJ, Shau SM, Lin JJ et al (2002) Flame retardant epoxy polymers based on all phosphorus-containing components. Eur Polym J 38:683–693. https://doi.org/10.1016/S0014-3057(01)00246-4

Wang S, Xu C, Liu Y et al (2017) Vanillin-derived high-performance flame retardant epoxy resins: facile synthesis and properties. Macromolecules. https://doi.org/10.1021/acs.macromol.7b00097

Chen X, Jiao C (2008) Thermal degradation characteristics of a novel flame retardant coating using TG-IR technique. Polym Degrad Stab 93:2222–2225. https://doi.org/10.1016/j.polymdegradstab.2008.09.005

Quin L, Ye L, Xu G, Liu J (2011) The non-halogen flame retardant epoxy resin based on a novel compound with phosphaphenanthrene and cyclotriphosphazene double functional groups. Polym Degrad Stab 96:1118–1124. https://doi.org/10.1016/j.polymdegradstab.2011.03.001

Chuan S, Ying L, Yie S (2002) Epoxy resins possessing flame retardant elements from silicon incorporated epoxy compounds cured with phosphorus or nitrogen containing curing agents. Polymer (Guildf) 43:4277–4284. https://doi.org/10.1016/S0032-3861(02)00234-3

Lokhande G, Chambhare S, Jagtap R (2017) Synthesis and properties of phosphate-based diacrylate reactive diluent applied to UV-curable flame-retardant wood coating. J Coat Technol Res 14:255–266. https://doi.org/10.1007/s11998-016-9849-6

Choi J, Seo J, Khan S (2011) Effect of acrylic acid on the physical properties of UV-cured poly(urethane acrylate-co-acrylic acid) films for metal coating. Prog Org Coat 71:110–116. https://doi.org/10.1016/j.porgcoat.2011.01.005

Chang CH, Huang TC, Peng CW et al (2012) Novel anticorrosion coatings prepared from polyaniline/graphene composites. Carbon 50:5044–5051. https://doi.org/10.1016/j.carbon.2012.06.043

Qing Y, Yang C, Yu N et al (2016) Superhydrophobic TiO2/polyvinylidene fluoride composite surface with reversible wettability switching and corrosion resistance. Chem Eng J 290:37–44. https://doi.org/10.1016/j.cej.2016.01.013

Yeh TC, Huang TC, Huang HY et al (2012) Electrochemical investigations on anticorrosive and electrochromic properties of electroactive polyurea. Polym Chem 3:2209–2216. https://doi.org/10.1039/c2py20061a

Hosseini MG, Yardani P (2015) Electrochemical impedance spectroscopy evaluation on the anticorrosive performance of epoxy/polyaniline—ZnO nanocomposite coated mild steel under cathodic polarization. In: The 6th international color and coating congress electrochemical impedance spectroscope, pp 3–5

Xing C, Zhang Z, Yu L et al (2014) Anti-corrosion performance of nanostructured poly(aniline-co-metanilic acid) on carbon steel. Prog Org Coat 77:354–360. https://doi.org/10.1016/j.porgcoat.2013.10.010

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Patel, M., Mestry, S., Phalak, G. et al. Novel catechol-derived phosphorus-based precursors for coating applications. Polym. Bull. 77, 2183–2203 (2020). https://doi.org/10.1007/s00289-019-02855-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-02855-3