Abstract

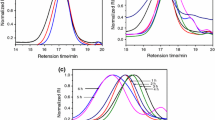

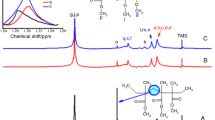

Miniemulsion copolymerization of ethylene and butyl methacrylate (BMA) was carried out at 60 °C using 4-cyano-4-(phenylcarbonothioylthio)pentanoic acid as the reversible addition fragmentation chain transfer (RAFT) agent, sodium dodecyl sulphate as emulsifier and potassium per sulphate as free radical initiator under extremely low ethylene feed pressure of 5–20 bar. In the absence of a co-stabilizer, very stable emulsion was obtained, wherein the RAFT agent acted both as the chain transfer agent and as the co-stabilizer. FT-IR as well as NMR analysis established the formation of poly(ethylene-co-BMA) copolymer nanoparticles. The SEM analysis was used to study the morphological behaviour of poly(ethylene-co-BMA) copolymer nanoparticles. DLS analysis confirmed that the particle diameter Zavg of copolymer nanoparticles is in the range 100–140 nm and confirmed miniemulsion polymerization. In order to establish the stability of copolymers against thermal degradation, the kinetics and mechanism of thermal degradation of copolymers were investigated by thermogravimetric analysis. Thermogravimertic analysis established that thermal decomposition of poly(ethylene-co-BMA) copolymer nanoparticles occurred in the range 250–450 °C. This range is lower than the decomposition temperature of neat polyethylene (350–580 °C). Kinetic parameters were determined according to the model-free approaches of Friedman and Flynn–Wall–Ozawa. The multivariate nonlinear regression analysis was performed to determine the kinetic model and the corresponding kinetic triplets.

Similar content being viewed by others

References

Hustad PD (2009) Frontiers in olefin polymerization: reinventing the world’s most common synthetic polymers. Science 325:704–707

Bryaskova R, Willet N, Degee P, Dubois P, Jerome R, Detrembleur C (2007) Copolymerization of vinyl acetate with 1-octene and ethylene by cobalt-mediated radical polymerization. J Polym Sci Part A Polym Chem 45:2532–2542

Schwendeman JE, Wagener KB (2004) Modeling ethylene/methyl methacrylate and ethylene/methacrylic acid copolymers using acyclic diene metathesis chemistry. Macromolecules 37:4031–4037

Boaen NK, Hillmyer MA (2005) Post-polymerization functionalization of polyolefins. Chem Soc Rev 34:267–275

Busch M, Roth M, Stenzel MH, Davis TP, Kowollik CB (2007) The use of novel F-RAFT agents in high temperature and high pressure ethene polymerization: can control be achieved? Aust J Chem 60:788–793

Ozturk T, Goktas M, Hazer B (2010) One-step synthesis of triarm block copolymers via simultaneous reversible-addition fragmentation chain transfer and ring-opening polymerization. J Appl Polym Sci 117:1638–1645

Dommanget C, D’Agosto F, Monteil V (2014) Polymerization of ethylene through reversible addition–fragmentation chain transfer (RAFT). Angew Chem Int Ed 53:6683–6686

Benaglia M, Chiefari J, Chong YK, Moad G, Rizzardo E, Thang SH (2009) Universal (switchable) RAFT agents. J Am Chem Soc 131:6914–6915

Chiefari J, Chong YK, Ercole F, Krstina J, Jeffery J, Le TPT, Mayadunne RTA, Meijs GF, Moad CL, Moad E, Rizzardo E, Thang SH (1998) Living free-radical polymerization by reversible addition–fragmentation chain transfer: the RAFT process. Macromolecules 31:5559–5562

Moad G, Chiefari J, Chong YK, Krstina J, Mayadunne RTA, Postma A, Rizzardo E, Thang SH (2000) Living free radical polymerization with reversible addition–fragmentation chain transfer (the life of RAFT). Polym Int 49:993–1001

Moad G, Rizzardo E, Thang SH (2008) Radical addition–fragmentation chemistry in polymer synthesis. Polymer 49:1079–1131

Chong BYK, Krstina J, Le TPT, Moad G, Postma A, Rizzardo E, Thang SH (2003) Thiocarbonylthio compounds [S = C(Ph)S–R] in free radical polymerization with reversible addition–fragmentation chain transfer (RAFT polymerization). Role of the free-radical leaving group (R). Macromolecules 36:2256–2272

Zhu J, Zhou D, Zhu X, Cheng Z (2004) Reversible addition fragmentation chain transfer polymerization of isobutyl methacrylate. J Macromol Sci Part A Pure Appl Chem 41:1059–1070

Kwak Y, Goto A, Tsujii Y, Murata Y, Komatsu K, Fukuda T (2002) A kinetic study on the rate retardation in radical polymerization of styrene with addition–fragmentation chain transfer. Macromolecules 35:3026–3029

Yin H, Cheng Z, Zhu J, Zhu X (2007) RAFT polymerization of styrene in the presence of 2-nonyl-benzoimidazole-1-carbodithioic acid benzyl ester. J Macromol Sci Part A Pure Appl Chem 44:315–320

Moad G, Chong YK, Postma A, Rizzardo E, Thang SH (2005) Advances in RAFT polymerization: the synthesis of polymers with defined end-groups. Polymer 46:8458–8468

Perrier S, Davis TP, Carmichael AJ, Haddleton DM (2003) Reversible addition–fragmentation chain transfer polymerization of methacrylate, acrylate and styrene monomers in 1-alkyl-3-methylimidazolium hexfluorophosphate. Eur Polym J 39:417–422

Barner-Kowollik C, Quinn JF, Morsley DR, Davis TP (2001) Modeling the reversible addition–fragmentation chain transfer process in cumyl dithiobenzoate-mediated styrene homopolymerizations: assessing rate coefficients for the addition–fragmentation equilibrium. J Polym Sci Part A Polym Chem 39:1353–1365

Ray B, Isobe Y, Matsumoto K, Habaue S, Okamoto Y, Kamigaito M, Sawamoto M (2004) RAFT polymerization of N-isopropylacrylamide in the absence and presence of Y(OTf)3: simultaneous control of molecular weight and tacticity. Macromolecules 37:1702–1710

Patton DL, Advincula RC (2006) A versatile synthetic route to macromonomers via RAFT polymerization. Macromolecules 39:8674–8683

Zhang W, D’Agosto F, Boyron O, Rieger J, Charleux B (2011) One-pot synthesis of poly(methacrylic acid-co-poly(ethylene oxide) methyl ether methacrylate)-b-polystyrene amphiphilic block copolymers and their self-assemblies in water via RAFT-mediated radical emulsion polymerization. A kinetic study. Macromolecules 44:7584–7593

Soula R, Novat C, Tomov A, Spitz R, Claverie J, Drujon X, Malinge J, Saudemon T (2001) Catalytic polymerization of ethylene in emulsion. Macromolecules 34:2022–2026

Soula R, Saillard B, Spitz R, Claverie J, Llaurro MF, Monnet C (2002) Catalytic copolymerization of ethylene and polar and nonpolar α-olefins in emulsion. Macromolecules 35:1513–1523

Billuart G, Bourgeat-Lami E, Lansalot M, Monteil V (2014) Free radical emulsion polymerization of ethylene. Macromolecules 47:6591–6600

Baruah U, Gautam A, Saikia M, Borphukan S, Saikia PJ, Baruah SD (2017) Monodisperse copolymer nanosphere assembly by miniemulsion polymerization. Eur Polym J 96:111–118

Cunningham VJ, Alswieleh AM, Thompson KL, Williams M, Leggett GJ, Armes SP (2014) Poly(glycerol monomethacrylate)–poly(benzyl methacrylate) diblock copolymer nanoparticles via RAFT emulsion polymerization: synthesis, characterization and interfacial activity. Macromolecules 47:5613–5623

Boise S, Rieger J, Belal K, Di-Cicco A, Beaunier P, Li MH, Charleux B (2010) Amphiphilic block copolymer nano-fibers via RAFT-mediated polymerization in aqueous dispersed system. Chem Commun 46:1950–1952

Oliveira M, Behrends SL, Rosa IR, Petzhold CL (2017) Use of a trithiocarbonyl RAFT agent without modification as (co)stabilizer in miniemulsion polymerization. J Polym Sci Part A Polym Chem 55:1687–1695

Skupov KM, Hobbs J, Marella P, Conner D, Golisz S, Goodall BL, Claverie JP (2009) Kinetic and mechanistic aspects of ethylene and acrylates catalytic copolymerization in solution and in emulsion. Macromolecules 42:6953–6963

Roy PK, Surekha P, Rajagopal C, Choudhary V (2007) Thermal degradation studies of LDPE containing cobalt stearate as pro-oxidant. Express Polym Lett 1:208–216

Kayacan I, Dogan OM (2008) Pyrolysis of low and high density polyethylene. Part I: non-isothermal pyrolysis kinetics. Energy Sources Part A 30:385–391

Razuvaev GA, Troitskii BB, Chochlova LV, Dubova ZB (1973) Thermal degradation of ethylene-vinyl acetate copolymer. J Polym Sci Polym Lett Ed 11:521–523

Koleva D, Atanassov A (2008) Non-isothermal kinetics of degradation of ultra-high molecular mass polyethene composite materials. J Therm Anal Calorim 91:213–218

Lee YJ, Litzinger TA (2002) Thermal decomposition of BAMO/AMMO with and without TiO2. Thermochim Acta 384:121–135

Das T, Baruah BP, Saikia BK (2016) Thermal behaviour of low-rank Indian coal fines agglomerated with an organic binder. J Therm Anal Calorim 126:435–446

Silvestri D, Gagliardi M, Cristallini C, Barbani N, Giusti P (2009) Different composition poly(methyl methacrylate-co-butyl methacrylate) copolymers through seeded semi-batch emulsion polymerization. Polym Bull 63:423–439

Thakare YG, Nemade SN, Ambekar RS, Patil BR, Palakudtewar OB (2017) Synthesis of high solid content acrylic resin by emulsion polymerization used as a binder in surface coating. Int J Res 5:915–920

Ozturk T, Goktas M, Savas B, Isiklar M, Atalar MN, Hazer B (2014) Synthesis and characterization of poly(vinyl chloride-graft-2-vinylpyridine) graft copolymers using a novel macroinitiator by reversible addition–fragmentation chain transfer polymerization. e-Polymers 14:27–34

Ozturk T, Kaygin O, Goktas M, Hazer B (2016) Synthesis and characterization of graft copolymers based on polyepichlorohydrin via reversible addition–fragmentation chain transfer polymerization. J Macromol Sci Pure Appl Chem 53:362–367

Assanvo EF, Konwar D, Baruah SD (2015) Thermal behaviour of Ricinodendron heudelotii oil polymer. J Therm Anal Calorim 119:1995–2003

Baruah U, Saikia M, Assanvo EF, Borphukan S, Phukan L, Gautam A, Baruah SD (2017) Synthesis and thermal analysis of poly(methyl methacrylate) oligomer functionalized polyethylene block copolymer. Polym Bull 74:2137–2158

Bakhshi H, Zohurrian-Mehr MJ, Bouhendi H, Kabiri K (2009) Spectral and chemical determination of copolymer composition of poly(butyl acrylate-co-glycidyl methacrylate) from emulsion polymerization. Polym Test 28:730–736

Guo J, Choi KY, Schorck FJ (2009) Miniemulsioncopolymerization of ethylene and vinyl acetate. Macromol React Eng 3:412–418

Saikia M, Borphukan S, Baruah U, Gautam A, Saikia PJ, Baruah SD (2018) Poly(ethylene-co-BMA) via dual concurrent ATRP–RAFT and its thermokinetic study. J Therm Anal Calorim 131:1517–1526

Guo TY, Tang D, Song M, Zhang B (2007) Copolymerizations of butyl methacrylate and fluorinated methacrylates via RAFT miniemulsion polymerization. J Polym Sci Part A Polym Chem 45:5067–5075

Brar AS, Sunita (1993) Compositional sequence determination of acrylonitrile-butyl acrylate copolymers by 13C n.m.r spectroscopy. Polymer 34:3391–3396

Heinen W, Rosenmoller CH, Wenzel CB, de Groot HJM, Lugtenburg J, Duin MV (1996) 13C NMR study of the grafting of maleic anhydride onto polyethene, polypropene, and ethene–propene copolymers. Macromolecules 29:1151–1157

Yazdimamaghani M, Pourvala T, Motamedi E, Fathi B, Vashaee D, Tayebi L (2013) Synthesis and characterization of encapsulated nanosilica particles with an acrylic copolymer by in situ emulsion polymerization using thermoresponsive nonionic surfactant. Materials 6:3727–3741

Pan J, Miao J, Zhang L, Si Z, Zhang C, Cheng Z, Zhu X (2013) Iron-mediated (dual) concurrent ATRP–RAFT polymerization of water-soluble poly(ethylene glycol) monomethyl ether methacrylate. Polym Chem 4:5664–5670

Fan L, Zhao D, Bian C, Wang Y, Liu G (2011) Glass transition temperatures of copolymers from methyl methacrylate, styrene, and acrylonitrile: binary copolymers. Polym Bull 67:1311–1323

Malhotra SL, Minh LY, Blanchard LP (1983) Thermal decomposition and glass transition temperature of poly(ethyl methacrylate) and poly(n-butyl methacrylate). J Macromol Sci Chem 19:559–578

Jankovic B, Mentus A, Jankovic M (2008) A kinetic study of the thermal decomposition process of potassium metabisulfite: estimation of distributed reactivity model. J Phy Chem Solids 69:1923–1933

Czech Z, Pełech R, Zych K, Swiderska J (2012) Thermal degradation of copolymers based on selected alkyl methacrylates. J Therm Anal Calorim 109:573–576

Opfermann J (2000) Kinetic analysis using multivariate non-linear regression. I. Basic concepts. J Therm Anal Calorim 60:641–658

Budrugeac P (2009) Application of model-free and multivariate non-linear regression methods for evaluation of the thermo-oxidative endurance of a recent manufactured parchment. J Therm Anal Calorim 97:443–451

Jain AA, Mehra A, Ranade VV (2016) Processing of TGA data: analysis of isoconversional and model fitting methods. Fuel 165:49–498

Venkatesh M, Ravi P, Tewari SP (2013) Isoconversional kinetic analysis of decomposition of nitroimidazoles: Friedman method vs Flynn–Wall–Ozawa method. J Chem Phys 117:10162–10169

Peterson JD, Vyazovkin S, Wigh CA (2001) Kinetics of the thermal and thermo-oxidative degradation of polystyrene, polyethylene and poly(propylene). Macromol Chem Phys 202:775–784

Sava BA, Elisa M, Bartha C, Iordanescu R, Feraru I, Plapciau C, Patrascu R (2014) Non-isothermal free-model kinetic analysis on crystallisation of europium-doped phosphate glasses. Ceram Int 40:12387–12395

Nikolaidis AK, Achilias DS (2018) Thermal degradation kinetics and viscoelastic behaviour of poly(methyl methacrylate)/organomodified montmorillonite nanocomposites prepared via in situ bulk radical polymerization. Polymers 10:491–506

Vyazovkin S, Sbirrazzuoli N (2006) Isoconversional kinetic analysis of thermally stimulated processes in polymers Macromol. Rapid Commun 27:1515–1532

Budrugeac P (2008) Kinetics of the complex process of thermo-oxidative degradation of poly(vinyl alcohol). J Therm Anal Calorim 92:291–296

Acknowledgements

Authors are very much grateful to Director, CSIR-NEIST, Jorhat for his permission to publish the results. The authors are also thankful to CSIR, New Delhi, for financial support from the Network Project CSC-0206. The authors also offer their special thanks to Dr. Binoy K. Saikia and Mr. Tankeswar Das for their assistance in thermal analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saikia, M., Baruah, U., Borphukan, S. et al. RAFT mediated miniemulsion copolymerization of ethylene and BMA and their non-isothermal model-free kinetic analysis. Polym. Bull. 76, 6437–6458 (2019). https://doi.org/10.1007/s00289-019-02715-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-02715-0