Abstract

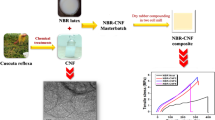

In this work, cellulose nanoparticles (CNP) reinforcement on synthetic rubber (SR)/polylactic acid (PLA) blend was investigated. Initially, SR/PLA blend was prepared by varying SR from 5 to 20 wt%. Later, a fixed amount (3 wt%) of CNP was added and resulting effect on mechanical, thermal, and dynamic properties was studied. The results show the addition of CNP in SR/PLA blend resulted in ~147 and ~196% improvement in tensile strength and storage modulus, respectively. In addition, impact strength of SR/PLA blend was almost doubled after CNP incorporation. An improvement of ~4.5% in the thermal stability of SR/PLA was also observed.

Similar content being viewed by others

References

AL-Oqla FM, Alothman OY, Jawaid M, Sapuan S, Es-Saheb M (2014) Processing and properties of date palm fibers and its composites. In: Hakeem KR, Jawaid M, Rashid U (eds) Biomass Bioenergy, vol 1. Springer, Cham, Switzerland, pp 1–25. doi:10.1007/978-3-319-07641-6_1

Râpă M, Miteluţ AC, Tănase EE, Grosu E, Popescu P, Popa ME et al (2016) Influence of chitosan on mechanical, thermal, barrier and antimicrobial properties of PLA-biocomposites for food packaging. Compos B Eng 102:112–121

Veccharelli KM, Tong VK, Young JL, Yang J, Gianneschi NC (2016) Dual responsive polymeric nanoparticles prepared by direct functionalization of polylactic acid-based polymers via graft-from ring opening metathesis polymerization. Chem Commun 52(3):567–570

Xu H, Yang Y (2012) Bioplastics from waste materials and low-value byproducts. Degradable polymers and materials: principles and practice, 2nd edn. ACS Publications, United States, pp 113–140. doi:10.1021/bk-2012-1114.ch008

Frone AN, Berlioz S, Chailan J-F, Panaitescu DM (2013) Morphology and thermal properties of PLA–cellulose nanofibers composites. Carbohyd Polym 91(1):377–384

Lim L-T, Auras R, Rubino M (2008) Processing technologies for poly (lactic acid). Prog Polym Sci 33(8):820–852

Marra A, Silvestre C, Duraccio D, Cimmino S (2016) Polylactic acid/zinc oxide biocomposite films for food packaging application. Int J Biol Macromol 88:254–262

Bitinis N, Verdejo R, Cassagnau P, Lopez-Manchado M (2011) Structure and properties of polylactide/natural rubber blends. Mater Chem Phys 129(3):823–831

Hashima K, Nishitsuji S, Inoue T (2010) Structure-properties of super-tough PLA alloy with excellent heat resistance. Polymer 51(17):3934–3939

Ock HG, Kim DH, Ahn KH, Lee SJ, Maia JM (2016) Effect of organoclay as a compatibilizer in poly (lactic acid) and natural rubber blends. Eur Polymer J 76:216–227

Wu N, Zhang H, Fu G (2016) Super-tough poly (lactide) thermoplastic vulcanizates based on modified natural rubber. ACS Sustain Chem Eng 5(1):78–84

Wang Y, Chen K, Xu C, Chen Y (2015) Supertoughened biobased poly (lactic acid)–epoxidized natural rubber thermoplastic vulcanizates: fabrication, co-continuous phase structure, interfacial in situ compatibilization, and toughening mechanism. J Phys Chem B 119(36):12138–12146

Bitinis N, Verdejo R, Maya EM, Espuche E, Cassagnau P, Lopez-Manchado MA (2012) Physicochemical properties of organoclay filled polylactic acid/natural rubber blend bionanocomposites. Compos Sci Technol 72(2):305–313

Jaratrotkamjorn R, Khaokong C, Tanrattanakul V (2012) Toughness enhancement of poly (lactic acid) by melt blending with natural rubber. J Appl Polym Sci 124(6):5027–5036

Jawaid M, Khalil HA, Hassan A, Dungani R, Hadiyane A (2013) Effect of jute fibre loading on tensile and dynamic mechanical properties of oil palm epoxy composites. Compos B Eng 45(1):619–624

Spinella S, Re GL, Liu B, Dorgan J, Habibi Y, Leclere P et al (2015) Polylactide/cellulose nanocrystal nanocomposites: efficient routes for nanofiber modification and effects of nanofiber chemistry on PLA reinforcement. Polymer 65:9–17

Braun B, Dorgan JR (2008) Single-step method for the isolation and surface functionalization of cellulosic nanowhiskers. Biomacromol 10(2):334–341

Oksman K, Mathew AP, Bondeson D, Kvien I (2006) Manufacturing process of cellulose whiskers/polylactic acid nanocomposites. Compos Sci Technol 66(15):2776–2784

Jang JY, Jeong TK, Oh HJ, Youn JR, Song YS (2012) Thermal stability and flammability of coconut fiber reinforced poly (lactic acid) composites. Compos B Eng 43(5):2434–2438

Petersson L, Kvien I, Oksman K (2007) Structure and thermal properties of poly(lactic acid)/cellulose whiskers nanocomposite materials. Compos Sci Technol 67(11–12):2535–2544

Porras A, Maranon A (2012) Development and characterization of a laminate composite material from polylactic acid (PLA) and woven bamboo fabric. Compos B Eng 43(7):2782–2788

Waser H (1974) Elastomer blends and tire sidewalls prepared therefrom. Google Patents

Dinsmore RP (1929) Synthetic rubber and method of making it. Google Patents

Suttivutnarubet C, Jaturapiree A, Chaichana E, Praserthdam P, Jongsomjit B (2016) Synthesis of polyethylene/coir dust hybrid filler via in situ polymerization with zirconocene/MAO catalyst for use in natural rubber biocomposites. Iran Polym J 25(10):841–848

Shimizu A, Kusano M, Takami T (1977) Rubber compositions and methods for production thereof stabilized. Google Patents

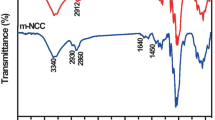

Mohammad Reza K, Mohammad K, Chantara TR, Rashmi W, Md Enamul H (2016) Sonosynthesis of cellulose nanoparticles (CNP) from Kenaf fibre: effects of process parameters. Fibers Polym 17(9):1352–1358

Ketabchi MR, Khalid M, Ratnam CT, Manickam S, Walvekar R, Hoque ME (2016) Sonosynthesis of cellulose nanoparticles (CNP) from kenaf fiber: effects of processing parameters. Fibers Polym 17(9):1352–1358

Ketabchi MR, Khalid M, Ratnam CT, Walvekar R (2016) Mechanical and thermal properties of polylactic acid composites reinforced with cellulose nanoparticles extracted from kenaf fibre. Mater Res Express 3(12):125301

Wan Y, Luo H, He F, Liang H, Huang Y, Li X (2009) Mechanical, moisture absorption, and biodegradation behaviours of bacterial cellulose fibre-reinforced starch biocomposites. Compos Sci Technol 69(7):1212–1217

Granda L, Espinach F, Tarrés Q, Méndez J, Delgado-Aguilar M, Mutjé P (2016) Towards a good interphase between bleached kraft softwood fibers and poly (lactic) acid. Compos Part B Eng 99:514–520. doi:10.1016/j.compositesb.2016.05.008

Suksut B, Deeprasertkul C (2011) Effect of nucleating agents on physical properties of poly(lactic acid) and its blend with natural rubber. J Polym Environ 19(1):288–296

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15(1):25–33

Lee S-Y, Mohan DJ, Kang I-A, Doh G-H, Lee S, Han SO (2009) Nanocellulose reinforced PVA composite films: effects of acid treatment and filler loading. Fibers Polym 10(1):77–82

Khalid M, Ratnam CT, Abdullah LC, Walvekar R, Ching YC, Ketabchi MR (2016) Mechanical and physical performance of cowdung‐based polypropylene biocomposites. Polym Compos. doi:10.1002/pc.23928

Zaaba NF, Ismail H, Jaafar M (2015) A study of the degradation of compatibilized and uncompatibilized peanut shell powder/recycled polypropylene composites due to natural weathering. J Vinyl Addit Technol. doi:10.1002/vnl.21504

Grigoriadi K, Giannakas A, Ladavos AK, Barkoula N-M (2015) Interplay between processing and performance in chitosan-based clay nanocomposite films. Polym Bull 72(5):1145–1161

Nair KG, Dufresne A (2003) Crab shell chitin whisker reinforced natural rubber nanocomposites. 2. Mechanical behavior. Biomacromolecules-Washington 4(3):666–674

Gong X, Liu J, Baskaran S, Voise RD, Young JS (2000) Surfactant-assisted processing of carbon nanotube/polymer composites. Chem Mater 12(4):1049–1052

Xu C, Yuan D, Fu L, Chen Y (2014) Physical blend of PLA/NR with co-continuous phase structure: preparation, rheology property, mechanical properties and morphology. Polym Test 37:94–101

Gregorova A, Sedlarik V, Pastorek M, Jachandra H, Stelzer F (2011) Effect of compatibilizing agent on the properties of highly crystalline composites based on poly(lactic acid) and wood flour and/or mica. J Polym Environ 19(2):372–381

Pei A, Zhou Q, Berglund LA (2010) Functionalized cellulose nanocrystals as biobased nucleation agents in poly (l-lactide)(PLLA)—crystallization and mechanical property effects. Compos Sci Technol 70(5):815–821

Bokobza L (2004) The reinforcement of elastomeric networks by fillers. Macromol Mater Eng 289(7):607–621

Kang H, Qiao B, Wang R, Wang Z, Zhang L, Ma J et al (2013) Employing a novel bioelastomer to toughen polylactide. Polymer 54(9):2450–2458

Quaresimin M, Schulte K, Zappalorto M, Chandrasekaran S (2016) Toughening mechanisms in polymer nanocomposites: from experiments to modelling. Compos Sci Technol 123:187–204

Sun Q, Mekonnen T, Misra M, Mohanty AK (2016) Novel biodegradable cast film from carbon dioxide based copolymer and poly(lactic acid). J Polym Environ 24(1):23–36

Ropers S, Kardos M, Osswald TA (2016) A thermo-viscoelastic approach for the characterization and modeling of the bending behavior of thermoplastic composites. Compos Part A Appl Sci Manuf 90:22–32. doi:10.1016/j.compositesa.2016.06.016

Aranguren MI, Marcovich NE, Salgueiro W, Somoza A (2013) Effect of the nano-cellulose content on the properties of reinforced polyurethanes. A study using mechanical tests and positron anihilation spectroscopy. Polym Test 32(1):115–122

Lee C-K, Cho MS, Kim IH, Lee Y, Do Nam J (2010) Preparation and physical properties of the biocomposite, cellulose diacetate/kenaf fiber sized with poly (vinyl alcohol). Macromol Res 18(6):566–570

Jawaid M, Abdul Khalil HPS, Alattas OS (2012) Woven hybrid biocomposites: dynamic mechanical and thermal properties. Compos A Appl Sci Manuf 43(2):288–293

Zhang C, Wang W, Huang Y, Pan Y, Jiang L, Dan Y et al (2013) Thermal, mechanical and rheological properties of polylactide toughened by expoxidized natural rubber. Mater Des 45:198–205

Cao X, Mohamed A, Gordon S, Willett J, Sessa D (2003) DSC study of biodegradable poly (lactic acid) and poly (hydroxy ester ether) blends. Thermochim Acta 406(1):115–127

Sarasua J-R, Prud’Homme RE, Wisniewski M, Le Borgne A, Spassky N (1998) Crystallization and melting behavior of polylactides. Macromolecules 31(12):3895–3905

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ketabchi, M.R., Ratnam, C.T., Khalid, M. et al. Mechanical properties of polylactic acid/synthetic rubber blend reinforced with cellulose nanoparticles isolated from kenaf fibres. Polym. Bull. 75, 809–827 (2018). https://doi.org/10.1007/s00289-017-2061-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-017-2061-8