Abstract

Large quantities of mussel byssus are generated annually as a co-product of the mussel-processing industry. This fibrous material is a rich source of collagen, which when extracted has potential uses as an alternative source of collagen for food applications. However, due the complex structure of the material, the extraction of the collagenous components using food-friendly strategies has proved challenging to date. An enzyme-aided method, using a proline endoproteinase, was employed for the extraction of collagen from mussel byssus yielding 138.82 ± 2.25 mg collagen/g dry weight. Hydrolysates of the collagen extract were generated using five food-grade enzyme preparations with Corolase® PP giving the highest extent of hydrolysis. Reversed-phase and gel permeation high-performance liquid chromatography of the extracted collagen and its enzymatic hydrolysates showed significant hydrolysis of collagen. The hydrolysates generated with Corolase® PP showed the highest in vitro bioactivities: angiotensin-converting enzyme (ACE) IC50 = 0.79 ± 0.17 mg/ml, dipeptidyl peptidase-IV (DPP-IV) IC50 = 0.66 ± 0.17 mg/ml and oxygen radical absorbance capacity (ORAC) activity = 311.23 ± 13.41 µmol trolox equivalents (TE)/g. The results presented herein indicate that in addition to acting as an alternative source of collagen for food applications, mussel byssus collagen-derived hydrolysates have potential applications as functional food ingredients for the management of metabolic diseases such as type II diabetes and hypertension.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Large quantities of shellfish processing co-products are generated each year. Although rich in proteins, lipids and minerals they are often incinerated, are used as fertiliser or are diverted for animal feed [1, 2]. Several studies have shown alternative and valuable uses for shellfish co-product-derived proteins in areas relevant to the food, cosmetic and pharmaceutical industries [3,4,5]. Furthermore, shellfish-derived co-products have been identified as alternative non-land derived protein sources to meet the ever-increasing global protein demand.

The mussel-processing industry generates significant quantities of co-products. In Ireland, more than 1000 t of blue mussel (Mytilus edulis) co-products, which arise from undersized, cracked, and fouled mussels as well as mussel byssus, are produced each year and can correspond to approximately 10% of the annual production [6, 7]. Mussel byssus, a collagenous protein strand, which attaches mussels to each other and to shoreline rocks is separated from the mussel during processing [8, 9]. The byssus, which on a dry weight basis contains approximately 95% protein (w/w), is not used for human consumption as current extraction procedures include the use of acids and organic compounds which are not suitable for the food industry [10]. Mussel byssus contains a variety of different proteins, including collagen-like compounds known as preCols, which assemble into fibrils. The collagen from the byssus is composed of two pepsin-resistant fragments, each containing three identical alpha-like chains. Col-P, which is found predominantly at the proximal end of the byssus thread, has a molecular mass of 50 kDa. Col-D, which is found predominantly at the distal end of the thread has a molecular mass of 60 kDa [11]. Collagen and in particular gelatin, the partially hydrolysed form of collagen, is used extensively in the food, pharmaceutical and cosmetic industries due to its excellent techno- and biofunctional properties [3, 5, 12]. At present, gelatin is mainly obtained from porcine and bovine co-products. However, due to religious reasons, dietary changes and diseases associated with terrestrial animals, consumers are looking for alternative non-animal sources of this component [13]. As a result, a significant body of research has been performed in recent years to extract and characterise marine-derived collagen, and its partially hydrolysed soluble form, gelatin [14, 15]. Just like other sources of collagen, Col-P and Col-D, contain the repeat sequence [Gly-X–Y]n where X and Y are often proline or hydroxyproline and they contain high levels of other amino acids such as glutamic acid, glutamine and alanine (Ala) [11, 16]. However, Col-P and Col-D differ both in structure and amino acid composition from the collagen obtained from other marine sources and consequently may have different nutritional properties in addition to novel techno- and biofunctional properties [11, 17]. Due to the high degree of cross-linking within the byssus thread and the highly insoluble nature of the proteins the extraction of collagenous material from mussel byssus has proved challenging [18]. Traditional collagen extraction approaches such as acid solubilisation and pepsin-aided extraction have proved to be ineffective for the recovery of collagen from byssus threads [17, 18]. While a modified pepsin-aided extraction method was developed for extraction of collagen from Chilean mussel byssus threads the levels recovered were relatively low [17].

Beyond the provision of dietary protein, much interest has focussed on the generation of peptides with biological activities (bioactive peptides, BAPs) from marine protein-rich processing co-products, including shellfish. Different species of molluscs, crustaceans and cephalopods have been reported to be good sources of BAPs [1, 19]. Furthermore, reports have shown that enzymatic hydrolysis of gelatin/collagen from other marine sources has led to enhanced biofunctional activities [20, 21]. Antihypertensive, dipeptidyl peptidase-IV (DPP-IV) inhibitory and antioxidant activities have been found with peptides and fish skin gelatin hydrolysates from fish species such as hoki, bigeye snapper, pollock and salmon [20,21,22,23,24]. However, no studies appear to have been performed to date to investigate the potential of mussel byssus-derived collagen and its hydrolysates as biofunctional ingredients for the food industry. Therefore, the generation of BAPs from blue mussel collagen may represent a means of increasing the economic value of this co-product, which should be of interest to the shellfish processing and food industries.

The objectives of this study were to (a) employ a food-friendly method to extract collagen from mussel byssus, (b) generate enzymatic hydrolysates from the extracted collagen and (c) characterise the biofunctional properties, i.e. the in vitro angiotensin-converting enzyme (ACE) and DPP-IV inhibitory along with the antioxidative activities of the hydrolysates.

Materials and methods

Materials

Mussel (Mytilus edulis) byssus was kindly provided by Fastnet Mussels (Gearhies, Bantry, Co. Cork). ProtoGel®, ProtoGel® Resolving Buffer (4×), ProtoGel® Stacking Buffer (4×), Tris–Glycine-SDS-PAGE Buffer (10×) and Protein Loading Buffer Blue (2×) were obtained from National Diagnostics (Atlanta, USA). Quick Start Bradford 1 × Dye Reagent® was supplied by Bio-Rad (Dublin, Ireland). Bovine lung was kindly provided by Gaelic Meats and Livestock Ltd. (Limerick, Ireland), and H-Gly-Pro-AMC and Diprotin A were obtained from Bachem (Bubendorf, Switzerland). HPLC-grade acetonitrile (ACN) and water were obtained from VWR (Dublin, Ireland). Brewers Clarex® (Aspergillus niger derived prolyl endoproteinase (An-PEP) specific activity: 37 × 10−3 U/mg) was supplied as a gift from Dutch State Mines (DSM, Heerlen, Netherlands), Corolase® PP was provided by AB Enzymes (Darmstadt, Germany), Alcalase® 2.4 L and Flavourzyme® 500 L were obtained from Novozymes A/S (Bagsvaerd, Denmark), Promod 144MG was kindly provided by Biocatalysts Ltd (Parc Nantgarw, Wales, UK). All other reagents, including collagenase from Clostridium histolyticum (Type 1), were obtained from Sigma Chemical Company Ltd. (Gillingham, UK).

Collagen extraction

The byssus harvested during blue mussel processing was freeze-dried (Labconco Benchtop Freeze Dry System, Kansas City, USA) and was subsequently stored at room temperature in sealed bags until use.

Several different conditions were studied for the extraction of collagen from mussel byssus. In the first instance, collagen was extracted at a 1:10 (w:v) byssus:water, adjusting the pH to 7.0, 4.0, 3.0, 2.5 and 2.0, and extraction at different temperatures (50, 70, 90 and 100 °C) during incubation for 1, 12, 16 and 24 h. In some cases, the byssus was manually cut into 0.5 to 1 cm fragments prior to extraction. A soluble collagen extract was obtained following centrifugation at 4000×g for 15 min (Hettich Universal 320R, Andreas Hettich GmbH & Co. KG, Tuttlingen, Germany). Several proteolytic enzymes were also assessed for their ability to enhance the liberation of collagen from the mussel byssus. A 10% (w/w aq.) mussel byssus suspension was equilibrated at the optimum temperature (pepsin: 37 °C, collagenase: 37 °C, An-PEP: 50 °C) and pH (pepsin: pH 2.0, collagenase: pH 7.0, An-PEP: pH 4.0) for each enzyme. Enzyme was added at an enzyme:substrate (E:S) ratio of 1% (w/w) or (v/w). No enzyme was added to the control. The byssus was incubated with the enzymes for 16 h and the suspension was maintained at the respective pH using a pH stat (Titrando 843, Metrohm, Dublin, Ireland). Samples were taken at 0, 1, 2, 4, 8 and 16 h. Enzymes were inactivated by heating at 90 °C for 20 min, the supernatant was decanted, cooled to room temperature, and then freeze-dried (Labconco Benchtop Freeze Dry System, Kansas City, USA). Samples were stored at – 20 °C prior to further analysis. In some instances, the byssus was autoclaved (Rodwell Ambassador 60 L autoclave, London, UK) at 108 °C for 30 min prior to neutral and acid pH extraction.

Generation of collagen-derived hydrolysates

Collagen-derived hydrolysates were generated using five different food-grade proteolytic enzyme preparations. A 10% (w/v) extracted collagen suspension was equilibrated at 50 ˚C and adjusted to pH 7 with 2.0 N NaOH. This suspension was separated into six aliquots and the food-grade enzyme preparations Alcalase 2.4 L, Alcalase 2.4 L in combination with Flavourzyme, Corolase PP and Promod 144MG were added at an E:S of 1% (w/w or v/w). An aliquot was also adjusted to pH 4 with 1 N HCl, prior to incubation with An-PEP at an E:S ratio of 1% (v/w). No enzyme was added to the control. During hydrolysis (4 h) at 50 °C, the suspensions were maintained at pH 7 or 4 using a pH stat. Samples were taken at 0, 1, 2 and 4 h. All samples were inactivated by heating at 90 °C for 20 min, cooled to room temperature and then freeze-dried.

Monitoring the extent of hydrolysis

The extent of hydrolysis was determined using the 2,4,6-trinitrobenzene sulfonic acid (TNBS) method following the procedure of Spellman et al. [25]. In brief, hydrolysate samples were diluted in 1% (w/v) SDS, mixed with a 0.1% (w/v) TNBS solution and 0.2125 M sodium phosphate buffer (pH 8.21). The samples were placed in a 50 °C water bath for 1 h. A volume of 2 ml of 0.1 N HCl was added to terminate the reaction. The samples were allowed to cool in the dark for 30 min and the absorbance was then measured at 340 nm (Shimadzu UV mini-1240, Kyoto, Japan). All samples were analysed in triplicate (n = 3) and the amino nitrogen content of the hydrolysates (mg/g protein) was estimated by reference to an l-leucine standard curve in the range of 0 to 28 mg N/l.

Protein determination

The protein content in each extract was determined using the Bradford assay [26] with bovine serum albumin (BSA) as a standard and the assay was performed in a 96-well microplate (Synergy HT Multi-Mode Microplate Reader, Biotek, Mason Technology, Dublin, Ireland). The protein and standard solutions, 160 µl, was added to 40 µl of the dye reagent previously diluted 1:4 in distilled water. The absorbance was measured at 595 nm following 5 min incubation. All samples were analysed in triplicate (n = 3) and the protein content estimated by reference to a BSA standard curve in the range 8 to 80 μg/ml.

Sodium dodecyl sulphate–polyacrylamide gel electrophoresis (SDS-PAGE)

SDS-PAGE was performed using a Mini-Protean® Tetra Cell system (Bio-Rad, Hemel Hempstead, UK) according to the method of Laemmli [27] using a 4% (w/v) acrylamide stacking gel and 12.5% (w/v) acrylamide resolving gel. The quantity of protein added to each well was 20 µg. The molecular mass of the proteins was estimated by reference to the relative migration of the molecular weight standard having a range of molecular weights between 6.5 and 200 kDa. The gel was stained with a Coomassie Blue R-250 solution and destained in an aqueous solution of 40% (v/v) methanol and 10% (v/v) acetic acid.

Reverse-phase high-performance liquid chromatography (RP-HPLC)

The test samples were diluted to 0.8% (w/v) protein equivalent in distilled water containing 0.1% (v/v) trifluoroacetic acid (TFA) and filtered through 0.2 μm syringe filters (Whatman, Maidstone, Kent, UK). RP-HPLC was carried out according to the method of Flanagan and FitzGerald [28].

Gel permeation high-performance liquid chromatography (GP-HPLC)

The freeze-dried samples were prepared at 0.25% (w/v) in 80% ACN containing 0.1% (v/v) TFA and filtered through 0.2 μm syringe filters (Whatman, Maidstone, Kent, UK). GP-HPLC was carried out as previously described by Spellman et al. [29].

Biological activity assessment

ACE inhibitory activity was determined as described by Sentandreu and Toldrá [30]. The ACE used for this assay was extracted from fresh bovine lung by the method described by Kleekayai et al. [31]. ACE inhibitory activity was determined using a fluorometric microtitre assay as described by Norris et al. [32] with an enzyme extract containing 8 mU ACE/ml. One unit of ACE activity (U) was defined as the amount of enzyme capable of hydrolysing 1 µmol of Abz-Gly-Phe-(NO2)-Pro per min at 37 °C. Experiments were carried out as independent triplicates assayed in triplicate. The concentration of inhibitor that inhibits 50% of ACE activity (the IC50 value) was calculated using GraphPad® Prism 4.0 sigmoidal dose response plots of inhibitor concentration (μM) versus % inhibition. The values were expressed as the mean IC50 ± standard deviation (n = 3). Captopril™ was used as a positive control.

DPP-IV inhibitory activity analysis was performed as described by Harnedy and FitzGerald [33]. One unit (U) of DPP-IV activity was the amount of enzyme necessary for hydrolysis of 1 μmol of H-Gly-Pro-AMC/min at 37 °C. The positive control used was Diprotin A™ at a final concentration of 5 μM. Experiments were carried out as independent triplicates assayed in triplicate. IC50 values were calculated using GraphPad® Prism 4.0 sigmoidal dose response plots of inhibitor concentration (μM) versus % inhibition. The values were expressed as the mean IC50 ± standard deviation (n = 3).

The ORAC assay was performed as described by Harnedy and FitzGerald [33] using a BioTek Synergy plate reader. The ORAC results were represented as μmol of Trolox equivalents per g dry weight (dw) of freeze-dried powder (μmol of TE/g dw). Experiments were carried out as independent triplicates assayed in triplicate.

Statistical analysis

The results were analysed by one-way analysis of variance (ANOVA) with a significance level of P = 0.05. Independent sample t-test and Tukey’s multiple comparison tests were used, where applicable. The software employed for statistical analysis was GraphPad Prism, version 4.00 for Windows (GraphPad Software, San Diego, California, USA).

Results and discussion

Extraction of collagen from byssus

The first objective of this study was to assess the impact of various chemical and enzyme-aided extraction methods (including the targeted use of An-PEP an Aspergillus niger-derived prolyl endoproteinase which cleaves at the C-terminal side of proline) in increasing the yield of collagenous material recovered from blue mussel (Mytilus edulis) byssus. In the first instance, treatment under acidic conditions [34] was studied for the extraction of collagen from blue mussel byssus. These extractions were performed at a weight:volume of 1:10 since the texture of the byssus makes it technically impossible to work with lower mass to volume ratios. The pH shift method has been used with different pH values, temperatures and duration of incubation for the extraction of collagenous proteins from various marine sources [35, 36]. The pH shift method has also been used as part of an extraction method which involved a pepsin hydrolysis step [11, 37]. However, the extent of collagen extracted from mussel byssus with the pH shift method used herein was low (< 10 mg/g dw). The reason for the low level of protein obtained may be due to the resistant nature of the mussel byssal threads, which were not easily disrupted by acidic pH and high temperatures. Even when manually cut into small pieces and autoclaved at 120 °C for 30 min prior to extraction, the quantity of collagen extracted from byssus was essentially too low to quantify (< 10 mg/g dw) using the Bradford protein assay. Other studies have used acid extraction, in conjunction with reagents such as 4 mol/l urea [11]. However, collagen extracted using organic compounds would not be suitable for use in the food industry.

Three different enzyme preparations were then chosen for extraction of Col-P and Col-D by direct hydrolysis of the mussel byssus, i.e. pepsin, collagenase and An-PEP. Although the collagen fragments, Col-P and Col-D, found in the mussel byssus are reported to be pepsin resistant [11], prolonged pepsin digestion has been shown to release these fragments from the byssal thread. Collagenase has also been shown to degrade collagen from marine sources by cleaving collagen sequences and could potentially release collagen components from the mussel byssus [38]. The Clostridium histolyticum-derived preparation utilised herein contains two collagenases, clostripain, and a neutral protease which hydrolyses collagen. An-PEP is an Aspergillus niger-derived prolyl endoproteinase which cleaves at the C-terminal side of Pro and Ala (and to a lesser extent at Glu, Gly, Ser, Lys and Leu) residues [39]. Since collagen is rich in Pro residues, this enzyme was assessed to determine if it could be used to extract collagen from the blue mussel byssus. Direct hydrolysis (16 h) with pepsin and collagenase resulted in the recovery of 29.13 ± 0.65 mg/g dw and 10.63 ± 0.32 mg/g of collagen, respectively (Table 1). Incubation for 16 h resulted in the highest recovery of collagen (Table 1). However, these values were significantly lower than the quantity recovered on incubating the byssus with An-PEP (64.15 ± 2.15 mg/g dw, Table 1). This is possibly related to the cleavage specificity of this enzyme as mentioned above. Moreover, it was found that three sequential extractions for 1 h with An-PEP (where new enzyme was added after each extraction) led to a significantly higher total recovery of collagen (137.82 ± 2.25 mg/g dw) than when mussel byssus was treated for one 16 h incubation (Tables 1 and 2). This may indicate that the enzyme may not have been in sufficient quantity to mediate complete extraction. Table 2 shows that after the third 1 h hydrolysis, the collagen extracted after each subsequent hour was significantly lower suggesting that access to the collagen was reduced even with addition of new enzyme. While blue mussel (Mytilus edulis) byssus was the raw material under investigation in this study, the recovery of 137.82 ± 2.25 mg collagen/g was significantly higher than that reported (69 mg/g) when a modified pepsin-aided extraction method was utilised for extraction of collagen from disrupted Chilean mussel byssus threads [17]. While direct enzymatic hydrolysis with pepsin has been used previously to extract collagenous proteins including collagen from mussel byssus and from marine sources such as the skin from several fish species, their appears to be no previous studies reporting the use of a proline endoproteinase activity in the extraction of collagen from mussel byssus [17, 18, 40, 41].

Figure 1 shows the SDS-PAGE profiles of the collagen extracts obtained following incubation of mussel byssus with An-PEP. Protein bands ranging between 30 and 60 kDa were observed. The byssus samples incubated with An-PEP for 1, 2, 4, 8 or 16 h show similar SDS-PAGE profiles. This suggests that over the time course of incubation with An-PEP, similar protein molecules were released (Fig. 1). Previous studies report that mussel byssal threads are composed of two main collagen fragments. The two bands with molecular masses of 60 and 55 kDa shown in Fig. 1 are consistent with the Col-D and Col-P profiles reported previously by Waite et al. [9]. However, the exact mechanism by which collagen is released from the threads is unknown. The two bands with molecular masses of 35 and 30 kDa are potentially due to hydrolysis of Col-D and Col-P or the domains flanking the Col proteins in the pre-Col components. These products are also evident in the RP-HPLC profile (Fig. 3) where multiple peaks are seen in the soluble extract and in the soluble extract separated using GP-HPLC where the existence of low molecular mass peptides were observed (Fig. 4, control). Peaks corresponding to Col-P and Col-D were not evident in the GP-HPLC profiles as these proteins are extremely hydrophobic and were not soluble in mobile phase A and were removed during the standard HPLC sample preparation process.

Sodium dodecyl sulphate–polyacrylamide gel electrophoresis profiles of blue mussel (Mytilus edulis) byssus-derived collagen. Lane 1: molecular weight markers in Daltons (Da), lane 2: byssus incubated without enzyme, lanes 3 to 7: collagen extract on incubation with Aspergillus niger-derived prolyl endoproteinase (An-PEP) for 1 h (lane 3), 2 h (lane 4), 4 h (lane 5), 8 h (lane 6) and 16 h (lane 7). Col_D: collagen D; Col-P: collagen P

To the best of our knowledge, no previous study appears to report on the extraction of collagen from this blue mussel-processing co-product using a targeted proline endoproteinase-aided approach. The collagen extracted with the method employed herein has the potential to be used as a novel ingredient in the food industry as no potentially hazardous reagents are used during extraction. Furthermore, the value of blue mussel-derived protein could be further increased through the exploitation of the collagenous material as a source of high-value health enhancing peptide ingredients for human food applications, particularly through targeted release of proline-rich peptides, which are known to possess a range of bioactivities.

Characterisation of collagen-derived hydrolysates

Hydrolysates were generated from the collagen extract using the food-grade proteolytic enzyme preparations Corolase PP, Alcalase 2.4 L, Alcalase 2.4 L plus Flavourzyme 500 L and Promod 144MG. The proteolytic preparation containing An-PEP was also used for hydrolysis of the extracted collagen to assess the potential for further hydrolysis of the proline-rich substrate by this enzyme. Figure 2 shows that incubation with Corolase PP, Alcalase 2.4 L, and Alcalase 2.4 L plus Flavourzyme led to a higher extent of hydrolysis than when Promod 144MG and An-PEP were used. Except for Corolase PP, hydrolysis mainly occurred during the first hour of incubation. No previous studies appear to have been performed on the hydrolysis of mussel byssus collagen with these enzymes.

Amino nitrogen content as a function of hydrolysis time for the blue mussel (Mytilus edulis) byssus collagen-derived hydrolysates. Values represent means ± SD (n = 3). For each enzyme, values with different letters are significantly different (P < 0.05). An-PEP: Aspergillus niger-derived prolyl endoproteinase

Several food-grade proteolytic preparations derived from plant, animal or microbial sources are used for the generation of protein hydrolysates in the food industry. Alcalase, which is derived from Bacillus licheniformis, contains subtilisin endoproteinase and glutamyl endopeptidase activity [42]. Corolase PP, derived from porcine pancreas, contains serine proteinase (trypsin, chymotrypsin and elastase) as well as metallopeptidase activities [43]. Flavourzyme, derived from Aspergillus oryzae, has endoproteinase and exopeptidase activities [44]. Promod 144MG, derived from Carica papaya contains broad specificity cysteine proteinases [45].

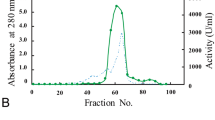

RP-HPLC analysis (Fig. 3) showed different profiles when the collagen was hydrolysed for 4 h with the different enzyme preparations which may be related to the differences in enzyme hydrolytic specificity. However, the 1, 2 and 4 h hydrolysate profiles for a given enzyme preparation were similar (Fig. 3). This was also seen during GP-HPLC analysis of the hydrolysates which indicates that the hydrolysis reaction was essentially complete in all cases after 1 h of incubation (Fig. 4). The byssus-derived collagen samples incubated with Promod 144MG and An-PEP contain components with molecular masses > 20 kDa which indicates the limited ability of the activities within these enzyme preparations to digest the extracted collagen. GP-HPLC analysis showed that the highest quantity of lower molecular weight peptides was seen with those hydrolysates generated with Corolase PP and Alcalase 2.4 L plus Flavourzyme. This corresponds to hydrolysates with the highest extent of hydrolysis (Fig. 2). It must be noted that the GP-HPLC data presented herein is associated with the soluble extract following resuspension in the mobile phase and filtration through a 0.22 μM filter. High extents of hydrolysis and content of low molecular mass peptides have been linked with better techno- (solubility, viscosity, turbidity, heat and pH stability) and biofunctional (antioxidant and DPP-IV inhibition) properties in hydrolysates [46,47,48,49,50].

Reverse-phase high-performance liquid chromatography profiles of the collagen extract (A) and its associated hydrolysates (soluble portion) after 1, 2 and 4 h incubation with (B) Alcalase 2.4 L, (C) Alcalase 2.4 L + Flavourzyme 500 L, (D) Corolase PP, (E) Promod 144MG and (F) Aspergillus niger-derived prolyl endoproteinase (An-PEP)

Molecular mass distribution profiles of the soluble portion of blue mussel (Mytilus edulis) byssus-derived collagen and associated hydrolysates after 1, 2 and 4 h incubation with different enzyme preparations. An-PEP: Aspergillus niger-derived prolyl endoproteinase. The shaded areas represent different molecular mass ranges in kDa

Biological activities

The ACE inhibitory capacity of the hydrolysates generated from the blue mussel byssus-derived collagen (Table 3) differed depending on which enzyme preparation was used for hydrolysis. The ACE IC50 values ranged from 1.37 ± 0.19 mg/ml when hydrolysed with An-PEP for 2 h, to 0.77 ± 0.06 mg/ml when hydrolysed with Corolase PP for 4 h. Highest ACE inhibitory activity was obtained when Corolase PP was used. No significant difference (p > 0.05) was observed between the 1, 2 or 4 h Corolase PP hydrolysates, which had IC50 values of 0.79 ± 0.17, 0.79 ± 0.09 and 0.77 ± 0.06 mg/ml, respectively. Hydrolysis of the byssus collagen with Alcalase 2.4 L and Flavourzyme also led to hydrolysates with relatively potent ACE inhibitory activity (IC50 = 0.84 ± 0.15 mg/ml) when hydrolysed for 4 h. All hydrolysates had a significantly higher ACE inhibitory activity than the unhydrolysed collagen extract (IC50 = 3.16 ± 0.52 mg/ml).

The ACE inhibitory capacity of these hydrolysates is comparable with other collagen hydrolysates such as those from Alaska pollack skin gelatin (IC50 = 0.63 to 1.40 mg/ml) [51], Atlantic salmon trimming-derived gelatin (IC50 = 0.13–1.16 mg/ml) [20] or from sea bream scales (IC50 = 0.57 mg/ml) [52]. An IC50 of 15 nM was obtained for the positive control, Captopril, which is in agreement with that reported in the literature [32].

Table 3 shows that the hydrolysates generated with Alcalase 2.4 L, Alcalase 2.4 L plus Flavourzyme, Corolase PP and Promod 144MG had DPP-IV IC50 values < 2 mg/ml. Again, the most potent hydrolysates were generated with Corolase PP (IC50 = 0.66 ± 0.17 mg/ml). No significant difference (p > 0.05) was seen between hydrolysates generated at 1, 2 and 4 h (IC50 = 0.66 ± 0.17 – 0.80 ± 0.26 mg/ml) in the case of the hydrolysates generated with Corolase PP. This trend was seen with all the enzyme preparations, which again indicates that the hydrolysis reaction was essentially complete after 1 h incubation. All hydrolysates had a significantly higher DPP-IV inhibitory activity than the unhydrolysed collagen (IC50 = 3.18 ± 0.26 mg/ml). Peptides with DPP-IV inhibitory activity have been identified from different marine sources and specifically from other marine collagenous sources such as Atlantic salmon skin gelatin hydrolysates (IC50 = 0.08 to > 5 mg/ml) [20, 53, 54]. However, no previous studies have been carried out determining the DPP-IV inhibitory properties of blue mussel byssus collagen-derived hydrolysates. An IC50 of 5 µM was obtained for the positive control, Diprotin A, which agrees with the literature.

While the structure–activity relationship of bioactive peptides has not yet been fully elucidated, some structural features, e.g. the presence of a proline residue, have been shown to positively influence activities such as ACE and DPP-IV inhibitory activity [55,56,57]. ACE is a carboxydipeptidase, which is centrally involved in the control of blood pressure. This enzyme, when overly active, may lead to hypertension, therefore, its inhibition has been shown to lead to cardiovascular protective effects [55]. DPP-IV is a dipeptidase involved in the degradation of the incretin hormones, glucagon-like peptide-1 (GLP-1) and glucose-dependent insulinotropic peptide (GIP). These incretins are involved in the control of insulin secretion, and thus glycemic control [57]. Inhibiting this enzyme leads to an increase in the half-life of GLP-1 and GIP which leads to an increase of the production of insulin [57]. Among other structural features, the presence of a proline residue(s) in the C-terminal tripeptide region of a peptide is believed to mediate a positive effect on ACE inhibitory activity [58]. While a proline residue at the penultimate N-terminal position or at the C-terminus has been reported to influence the DPP-IV inhibitory potential of a peptide [56]. Therefore, enzymatic hydrolysis of a proline-rich substrate has the potential to release of peptides with such structural features and associated activities. Furthermore, hydrophobic amino acids including Val, Leu, Ile, Ala, Met and Pro and Gly (which is found in abundance in byssus-derived collagen) is believed to influence antioxidant activity [59, 60].

Bioactive peptides from marine processing co-products have been identified as having different antioxidant activities [1, 61]. Some of these sources are often rich in collagenous proteins [20, 61]. The ORAC assay has been used to evaluate the bioactivity of several antioxidants by monitoring the decay in fluorescence in the presence of 2,2′-azobis(2-amidino-propane) dihydrochloride [62, 63]. The results of the ORAC analysis of the collagen-derived hydrolysates generated from the blue mussel byssus (Table 3) show that the antioxidant capacity ranged between 139.78 ± 7.47 µmol TE/g when incubated with Promod 144MG for 1 h and 311.23 ± 13.41 µmol TE/g when incubated with Corolase PP from the same time period. These values are lower than the ORAC values obtained from hydrolysates generated from other marine collagenous proteins such as shark skin gelatin hydrolysates, when generated with papaya latex enzyme, where ORAC values ranging from 268.16 to 709.42 μmol TE/g have been reported [23] but in a similar range to those derived from salmon (Salmo salar) trimmings gelatin (103.00–540.94 µmol TE/g) [20].

Since most of the hydrolysis seems to occur in the first hour of incubation (Fig. 2), no significant difference was observed between the antioxidant potency of the collagen hydrolysed for 1, 2 or 4 h. The difference in antioxidant capacity as related with the choice of hydrolytic enzyme preparation is also shown in Table 3. This again demonstrates that hydrolysis with Corolase PP led to the release of more potent antioxidative peptides. However, all hydrolysates had a significantly higher antioxidant capacity than unhydrolysed collagen (76.54 ± 8.54 µmol TE/g).

Except for An-Pep, which has highly specific hydrolytic activity, the other food-grade proteolytic enzymatic preparations utilised herein contain enzymes with broad substrate specificities. As previously indicated the porcine pancreatic-derived enzyme Corolase PP, contains serine proteinases with the main activities associated with trypsin and chymotrypsin [43]. Using this information, in silico analysis was performed using the Peptide Cutter tool available on the BIOPEP website (http://www.uwm.edu.pl/biochemia/index.php/pl/biopep, [64]). A search of the BIOPEP database [64] revealed that some of the peptide sequences predicted to be released from byssus-derived collagen following hydrolysis with An-Pep and Corolase PP have previously been identified as being potent inhibitors of ACE and DPP-IV, and as having antioxidant activity. Several potent ACE inhibitory peptides (GP, SGP, QGP and KGP) identified in porcine gelatin hydrolysates following targeted hydrolysis with An-PEP were also predicted to be released from mussel byssus collagen by the action of the An-Pep [55]. Furthermore, the bioactive peptides GPVA, GF and PP and YP, VP and YP which were identified from salmon gelatin and trimmings hydrolysates generated with Corolase PP were also predicted to be released from Col-P and Col-D by the action of Corolase PP [20, 65]. GPVA was shown to exhibit in vitro DPP-IV inhibitory activity, YP was shown to exhibit ACE inhibitory activity, VP, YP and PP exhibited antioxidant activity and the dipeptide GF mediated all three activities [20, 65]. The tripeptide QPG previously reported as having potent DPP-IV inhibitory activity (IC50 value: 70.90 μM) was also predicted to be release following Corolase PP hydrolysis [66]. The bioactivity observed in the An-PEP and Corolase PP digests of byssus-derived collagen could potentially be associated with the presence of these peptides as well as other as of yet unidentified peptides. Further studies are required to confirm this. In addition, fractionation, peptide identification and confirmatory studies are required to identify the peptides associated with the bioactivity in the hydrolysates generated with Alcalase 2.4 L and Alcalase 2.4 L in combination with Flavourzyme. Amino acid composition data for mussel byssus and byssus collagen extracts is available [17], however, the acquisition of total and free amino acid data for each of the hydrolysates may aid in the identification of components associated with the observed in vitro bioactivities, whether it is peptide or amino acid derived or a synergy of both. It must also be noted that the An-PEP generated porcine gelatin hydrolysate and hydrolysate generated from salmon gelatin using Corolase PP described above have previously been shown to display antihypertensive activity in spontaneously hypertensive rat [20, 55]. These porcine and salmon gelatin hydrolysates contain peptides predicted to be released from byssus-derived collagen upon hydrolysis with An-PEP. It is possible that the byssus collagen-derived hydrolysates generated with An-PEP and Corolase PP herein that show in vitro ACE inhibitory activity may also mediate hypotensive effects. However, in vivo studies are required to confirm this.

Conclusion

The results of this study demonstrate that incubation with An-PEP is a useful step in the enzyme-aided extraction of collagen from blue mussel byssus. Following three sequential 1 h incubations with this enzyme, 138.82 ± 2.25 mg collagen/g dw of protein was obtained. The SDS-PAGE profiles show bands at 55 and 60 kDa, which correspond with the molecular masses of Col-P and Col-D, respectively, however, the exact mechanism by which collagen is release is unknown. To the best of our knowledge, no previous study has reported on the extraction of collagen from mussel byssus using such a food-friendly protocol or on the use of An-PEP to aid in the extraction process. The structure and amino acid composition of blue mussel-derived collagen is different to that of other marine-derived collagens, and consequently, it may be considered as a new ingredient for the food industry. When incubated with different proteolytic enzyme preparations, the extracted collagen was hydrolysed to different extents. This is reflective of the different specificities of the enzymes used. Incubation with Corolase PP and a combination of Alcalase 2.4 L plus Flavourzyme led to the highest extent of hydrolysis. Hydrolysates generated with Corolase PP showed the highest ACE and DPP-IV inhibition potencies along with ORAC activity. To the best of our knowledge, no other study has previously reported on these biological activities with hydrolysed collagen extracted from blue mussel byssus. The results of this in vitro study show that this co-product from mussel processing may have potential as a functional food ingredient for the management of cardiovascular diseases and type II diabetes. However, in vivo studies need to be carried out to validate these effects. Further work is also required to identify the peptides directly responsible for these biological activities. Ultimately, valorisation of co-products such as mussel byssus represents an innovative strategy to increase their value and reduce waste associated with marine processing side streams. This ultimately enhances environmental and commercial sustainability, and meets the United Nations Sustainable Development Goals to achieve a better and more sustainable future for all (https://sdgs.un.org/goals).

Data availability

The data that support the findings of this study are available from the corresponding author, upon reasonable request.

Code availability

Not applicable.

References

Harnedy PA, FitzGerald RJ (2012) Bioactive peptides from marine processing waste and shellfish: a review. J Funct Food 4:6–24

Rattanaki N, Plikomol A, Yano S, Wakayama M, Tachiki T (2002) Utilization of shrimp shellfish waste as a substrate for solid-state cultivation of Aspergillus sp. S1–13: evaluation of a culture based on chitinase formation which is necessary for chitin-assimilation. J Biosci Bioeng 93:550–556

Anal AK, Noomhorm A, Vongsawasdi P (2013). In: Kim SK (ed) Marine proteins and peptides: biological activities and applications, 1st edn. Wiley, Chichester

Neves AC, Harnedy PA, FitzGerald RJ (2016). In: Dhillon GS (ed) Protein byproducts: transformation from environmental burden into value-added products, 1st edn. Academic Press, Cambridge

Nuñez SM, Guzmán F, Valencia P, Almonacid S, Cárdenas C (2020) Collagen as a source of bioactive peptides: a bioinformatics approach. Electron J Biotechno 48:101–108

BIM (2020). Bord Iascaigh Mhara. The Business of Seafood 2019. http://www.bim.ie/media/bim/content/publications/corporate-other-publications/BIM-Business-of-Seafood-2019-Spreads.pdf

Naik AS, Hayes M (2019) Bioprocessing of mussel by-products for value added ingredients. Trends Food Sci Technol 92:111–121

Waite JH (1986) Mussel glue from Mytilus californianus Conrad: a comparative study. J Comp Physiol B 156:491–496

Waite JH, Hansen D, Little K (1989) The glue protein of ribbed mussels (Geukensia demissa): a natural adhesive with some features of collagen. J Comp Physiol B 159:517–525

Torres FG, Troncoso OP, Torres CE (2012). In: John MJ, Thomas S (eds) Natural polymers: volume 1: composites. The Royal Society of Chemistry, Cambridge

Qin X, Waite JH (1995) Exotic collagen gradients in the byssus of the mussel Mytilus edulis. J Exp Biol 198:633–644

Nasri M (2019). In: Simpson BK, Aryee AN, Toldrá F (eds) Byproducts from agriculture and fisheries: adding value for food, feed, pharma, and fuels, 1st edn. Wiley, NY

Gudipati V (2013). In: Kim SK (ed) Marine proteins and peptides: biological activities and applications, 1st edn. Wiley, Chichester

Fassini D, Oliveira SM, Silva TH, Reis RL (2020). In: Kim SK (ed) Encyclopedia of marine biotechnology. Chicester, Wiley-Blackwell

Pozzolini M, Scarfì S, Giovine M (2020). In: Kim SK (ed) Encyclopedia of marine biotechnology. Chicester, Wiley-Blackwell

Benedict CV, Waite JH (1986) Location and analysis of byssal structural proteins of Mytilus edulis. J Morphol 189:171–181

Rodríguez F, Morán L, González G, Troncoso E, Zúñiga RN (2017) Collagen extraction from mussel byssus: a new marine collagen source with physicochemical properties of industrial interest. J Food Sci Tech 54:1228–1238

Vallejos N, González G, Troncoso E, Zúñiga RN (2014) Acid and enzyme-aided collagen extraction from the byssus of Chilean mussels (Mytilus Chilensis): effect of process parameters on extraction performance. Food Biophys 9:322–331

Wang X, Yu H, Xing R, Li P (2017) Characterization, preparation, and purification of marine bioactive peptides. BioMed Res Int 2017:9746720

Neves AC, Harnedy PA, O’Keeffe MB, Alashi MA, Aluko RE, FitzGerald RJ (2017) Antihypertensive, dipeptidyl peptidase IV inhibitory and antioxidant activities of salmon gelatin derived peptides. Food Res Int 100:112–120

Jin R, Teng X, Shang J, Wang D, Ning Liu N (2020) Identification of novel DPP–IV inhibitory peptides from Atlantic salmon (Salmo salar) skin. Food Res Int 133:109–161

Mendis E, Rajapakse N, Byun HG, Kim SK (2005) Investigation of jumbo squid (Dosidicus gigas) skin gelatin peptides for their in vitro antioxidant effects. Life Sci 77:2166–2178

Kittiphattanabawon P, Benjakul S, Visessanguan W, Shahidi F (2012) Effect of extraction temperature on functional properties and antioxidative activities of gelatin from shark skin. Food Bioprocess Technol 5:2646–2654

Phanturat P, Benjakul S, Visessanguan W, Roytrakul S (2010) Use of pyloric caeca extract from bigeye snapper (Priacanthus macracanthus) for the production of gelatin hydrolysate with antioxidative activity. LWT Food Sci Technol 43:86–97

Spellman D, McEvoy E, O’Cuinn G, FitzGerald RJ (2003) Proteinase and exopeptidase hydrolysis of whey protein: comparison of the TNBS, OPA and pH stat methods for quantification of degree of hydrolysis. Int Dairy J 13:447–453

Bradford MT (1976) Protein measurement with the folin phenol reagent. Biochem 72:248–254

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685

Flanagan J, FitzGerald RJ (2003) Functional properties of Bacillus proteinase hydrolysates of sodium caseinate incubated with transglutaminase pre-and posthydrolysis. Int Dairy J 13:135–143

Spellman D, Kenny P, O’Cuinn G, FitzGerald RJ (2005) Aggregation properties of whey protein hydrolysates generated with Bacillus licheniformis proteinase activities. J Agr Food Chem 53:1258–1265

Sentandreu MÁ, Toldrá F (2006) A rapid, simple and sensitive fluorescence method for the assay of angiotensin-I converting enzyme. Food Chem 97:546–554

Kleekayai T, Harnedy PA, O’Keeffe MB, Poyarkov AA, CunhaNeves A, Suntornsuk W, FitzGerald RJ (2015) Extraction of antioxidant and ACE inhibitory peptides from Thai traditional fermented shrimp pastes. Food Chem 176:441–447

Norris R, Casey F, FitzGerald RJ, Shields D, Mooney C (2012) Predictive modelling of angiotensin converting enzyme inhibitory dipeptides. Food Chem 133:1349–1354

Harnedy PA, FitzGerald RJ (2013) In vitro assessment of the cardioprotective, anti-diabetic and antioxidant potential of Palmaria palmata protein hydrolysates. J App Phycol 25:1793–1803

Hultin HO, Kelleher SD (1999) Process for isolating a protein composition from a muscle source and protein composition. U.S. Patent no. 6005073, 08/797,929

Ahmad M, Benjakul S, Nalinanon S (2010) Compositional and physicochemical characteristics of acid solubilized collagen extracted from the skin of unicorn leatherjacket (Aluterus monoceros). Food Hydrocolloid 24:588–594

Yan M, Li B, Zhao X, Ren G, Zhuang Y, Hou H, Zhang X, Chen L, Fan Y (2008) Characterization of acid-soluble collagen from the skin of walleye pollock (Theragra chalcogramma). Food Chem 107:1581–1586

Nagai T, Ogawa T, Nakamura T, Ito T, Nakagawa H, Fujiki K, Nakao M, Yano T (1999) Collagen of edible jellyfish exumbrella. J Sci Food Agric 79:855–858

Song E, Kim SY, Chun T, Byun HJ, Lee YM (2006) Collagen scaffolds derived from a marine source and their biocompatibility. Biomaterials 27:2951–2961

Norris R, Poyarkov A, O’Keeffe MB, FitzGerald RJ (2014) Characterisation of the hydrolytic specificity of Aspergillus niger derived prolyl endoproteinase on bovine β-casein and determination of ACE inhibitory activity. Food Chem 156:29–36

Nalinanon S, Benjakul S, Visessanguan W, Kishimura H (2007) Use of pepsin for collagen extraction from the skin of bigeye snapper (Priacanthus tayenus). Food Chem 104:593–601

Nalinanon S, Benjakul S, Visessanguan W, Kishimura H (2008) Improvement of gelatin extraction from bigeye snapper skin using pepsin-aided process in combination with protease inhibitor. Food Hydrocolloid 22:615–622

Kalyankar P, Zhu Y, O’Keeffe MB, O’Cuinn G, FitzGerald RJ (2013) Substrate specificity of glutamyl endopeptidase (GE): hydrolysis studies with a bovine αcasein preparation. Food Chem 136:501–512

Mullally MM, O’Callaghan DM, FitzGerald RJ, Donnelly W, Dalton JP (1994) Proteolytic and peptidolytic activities in commercial pancreatic protease preparations and their relationship to some whey protein hydrolyzate characteristics. J Agric Food Chem 42:2973–2981

Smyth M, FitzGerald RJ (1998) Relationship between some characteristics of WPC hydrolysates and the enzyme complement in commercially available proteinase preparations. Int Dairy J 8:819–827

O’Sullivan D, FitzGerald RJ (2012) Physicochemical properties and residual antigenicity of transglutaminase cross-linked sodium caseinate hydrolysates. Int Dairy J 23:18–23

Adler-Nissen J (1976) Enzymic hydrolysis of proteins for increased solubility. J Agric Food Chem 24:1090–1093

Shahidi F, Han XQ, Synowiecki J (1995) Production and characteristics of protein hydrolysates from capelin (Mallotus villosus). Food Chem 53:285–293

Kristinsson HG, Rasco BA (2000) Biochemical and functional properties of Atlantic salmon (Salmo salar) muscle proteins hydrolyzed with various alkaline proteases. J Agric Food Chem 48:657–666

Gbogouri G, Linder M, Fanni J, Parmentier M (2004) Influence of hydrolysis degree on the functional properties of salmon by-products hydrolysates. J Food Sci 69:C615–C622

Decourcelle N, Sabourin C, Aubry T, Guerard F (2014) Emulsifying and antioxidant properties of a shrimp (Pandalus borealis) hydrolysate conjugated with xylose or dextran through the Maillard reaction by dry-heating in mild conditions. J Food Res 3:144–157

Byun HG, Kim SK (2001) Purification and characterization of angiotensin I converting enzyme (ACE) inhibitory peptides from Alaska pollack (Theragra chalcogramma) skin. Process Biochem 36:1155–1162

Fahmi A, Morimura S, Guo HC, Shigematsu T, Kida K, Uemura Y (2004) Production of angiotensin I converting enzyme inhibitory peptides from sea bream scales. Process Biochem 39:1195–1200

Li-Chan EC, Hunag SL, Jao CL, Ho KP, Hsu KC (2012) Peptides derived from Atlantic salmon skin gelatin as dipeptidyl-peptidase IV inhibitors. J Agric Food Chem 60:973–978

Guo LH, Harnedy PA, Li B, Zhang Z, Hou H, Zhao X, FitzGerald RJ (2014) In vitro assessment of the multi-functional bioactive potential of Alaska pollock skin collagen following simulated gastrointestinal digestion. J Agric Food Chem 95:1514–1520

O’Keeffe MB, Norris R, Alashi MA, Aluko RE, FitzGerald RJ (2017) Peptide identification in a porcine gelatin prolyl endoproteinase hydrolysate with angiotensin converting enzyme (ACE) inhibitory and hypotensive activity. J Funct Food 34:77–88

Nongonierma AB, FitzGerald RJ (2016) Structure activity relationship modelling of milk protein-derived peptides with dipeptidyl peptidase IV (DPP-IV) inhibitory activity. Peptides 79:1–7

Harnedy-Rothwell PA, McLaughlin CM, O’Keeffe MB, Le Gouic AV, Allsopp PJ, McSorley EM, Sharkey S, Whooley J, McGovern B, O’Harte FPM, FitzGerald RJ (2020) Identification and characterisation of peptides from a boarfish (Capros aper) protein hydrolysate displaying in vitro dipeptidyl peptidase-IV (DPP-IV) inhibitory and insulinotropic activity. Food Res Int 131:108989

Norris R, O’Keeffe MB, Poyarkov A, FitzGerald RJ (2015) Peptide identification and angiotensin converting enzyme (ACE) inhibitory activity in prolyl endoproteinase digests of bovine αs-casein. Food Chem 188:210–217

Wang T, Zhao Q, Wang Q (2013). In: Kim SK (ed) Marine proteins and peptides: biological activities and applications, 1st edn. Wiley, Chichester

Zou TB, He TP, Li HB, Tang HW, Xia EQ (2016) The structure-activity relationship of the antioxidant peptides from natural proteins. Molecules 21:72

Ucak I, Afreen M, Montesano D, Carrillo C, Tomasevic I, Simal-Gandara J, Barba FJ (2021) Functional and bioactive properties of peptides derived from marine side streams. Mar Drugs 19:71

Wu X, Beecher GR, Holden JM, Haytowitz DB, Gebhardt SE, Prior RL (2004) Lipophilic and hydrophilic antioxidant capacities of common foods in the United States. J Agric Food Chem 52:4026–4037

Cao G, Alessio HM, Cutler RG (1993) Oxygen-radical absorbance capacity assay for antioxidants. Free Radic Biol Med 14:303–311

Minkiewicz P, Dziuba J, Iwaniak A, Dziuba M, Darewicz M (2008) BIOPEP database and other programs for processing bioactive peptide sequences. J AOAC Int 91:965–980

Neves AC, Harnedy PA, O’Keeffe MB, FitzGerald RJ (2017) Bioactive peptides from Atlantic salmon (Salmo salar) with angiotensin converting enzyme and dipeptidyl peptidase IV inhibitory, and antioxidant activities. Food Chem 218:396–405

Taga Y, Hayashida O, Kusubata M, Ogawa-Goto K, Hattori S (2017) Production of a novel wheat gluten hydrolysate containing dipeptidyl peptidase-IV inhibitory tripeptides using ginger protease. Biosci Biotech Biochem 81:1823–1828

Funding

Open Access funding provided by the IReL Consortium. The Marine Functional Foods Research Initiative (NutraMara project) is a programme for marine-based functional food development. This project (Grant-Aid Agreement No. MFFRI/07/01) was carried out under the Sea Change Strategy with the support of the Marine Institute and the Department of Agriculture, Food and the Marine, Ireland, funded under the National Development Plan 2007–2013. It was also funded by the Department of Agriculture, Food and the Marine, Ireland under grant reference 17/F/260.

Author information

Authors and Affiliations

Contributions

All the authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by AC. The work was supervised by PAH and RJF. The first draft of the manuscript was written by AC, and all the authors contributed to editing the subsequent manuscript drafts. All the authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Compliance with ethics requirements

This original research paper does not contain any studies with human or animal subjects. Not applicable.

Consent to participate

Not applicable.

Consent for publication

All the authors consent to the publication of the manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

CunhaNeves, A., Harnedy-Rothwell, P.A. & FitzGerald, R.J. In vitro angiotensin-converting enzyme and dipeptidyl peptidase-IV inhibitory, and antioxidant activity of blue mussel (Mytilus edulis) byssus collagen hydrolysates. Eur Food Res Technol 248, 1721–1732 (2022). https://doi.org/10.1007/s00217-022-04000-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-022-04000-3