Abstract

Membrane chromatography is mainly used for the separation and purification of proteins and biological macromolecules in the downstream processing process, also applications in sewage disposal. Membrane chromatography is recognized as an effective alternative to column chromatography because it significantly improves chromatography from affinity, hydrophobicity, and ion exchange; the development status of membrane chromatography in membrane matrix and membrane equipment is thoroughly discussed, and the applications of protein capture and intermediate purification, virus, monoclonal antibody purification, water treatment, and others are summarized. This review will provide value for the exploration and potential application of membrane chromatography.

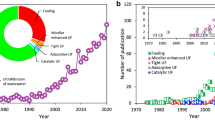

Graphical abstract

Similar content being viewed by others

Introduction

Traditional column chromatography has high adsorption capacity and separation accuracy for protein [1, 2]; so far, the downstream processing of biological agents has been highly dependent on the use of packed bed resin columns [3, 4]. However, traditional column chromatography generally suffers from a high-pressure drop; the intraparticle diffusion leads to the accumulation of solute molecules, which made the processing time increases, low ligand utilization, and long treatment time, which limits its productivity [5, 6]; meanwhile, column chromatography is expensive; more than 60% of the cost of the biopharmaceutical production process is concentrated in the downstream process of purification and recovery, in which the downstream purification of virus accounts for 70% of the total production cost [7, 8].

Compared with traditional column chromatography, membrane chromatography is more suitable for large proteins of separation and purification (MR > 250,000); such proteins rarely enter the pores of chromatographic particle matrix [9]. For viruses and macromolecules with obvious diffusion restrictions in conventional chromatographic media, it is particularly important [10]. Although the equilibrium binding capacity is generally low in the membrane, solutes in the membrane pores are mainly transported to the binding sites by convection, reducing the mass transfer resistance of the chromatography process (Fig. 1). Due to the advantage in mass transfer, membrane chromatography is an effective method for extracting trace proteins from large capacity feed, which can maintain their natural conformation by reducing the time in contact with adsorbents, maintaining the biological activity of the required biomolecules while removing impurities [11, 12]. Moenster et al. [13] used the SartobindQ exchange membrane adsorber method to separate and purify penicillin G amidase from cell lysate in one step, compared with previous multiple purification steps, which reduced the operating units and significantly improved the downstream processing efficiency.©

Schematic diagram of different solution transfer mode: a membrane chromatography. b packed bed chromatography [9]

The use of membranes changes the packing requirements and avoids bed compaction, reducing the amount of buffer, which decreases the main burden of industrial-scale chromatographic treatment [14]. Membrane adsorption is easy to expand the scale compared with the packed bed system; the membrane can be rolled up like a coiled paper and wound spiral winding the module in around way, realized in a very small volume with a large membrane surface, and industrial mass production only by increasing the membrane area; meanwhile, the membrane adsorber can be integrated with the existing chromatographic equipment, reducing the investment cost [15]. The membrane process based on biotechnology can be separated according to the charge or size of protein under the condition of high flux and high purity. Although membrane chromatography can be reused by elution and regeneration, most of the common membrane adsorbers on the market are disposable. These advantages make it possible for further research and practical application of membrane adsorbents in the process of biopharmaceutical production [16,17,18]. However, few binding sites on the membrane matrix and the specific surface area of the membrane are small, and the membrane binding strength is low, which hinders its practical application. Membrane chromatography on a commercial scale was not widely accepted until 2012. At present, membrane chromatography has been widely used in the fields of virus and endotoxins, monoclonal antibody purification, protein capture and intermediate purification, and water treatment [19].

Membrane chromatography separation mechanisms

Basic principles

The greatest advantage of the practical application of the membrane chromatography technique is that the bed height adsorption device in the millimeter range can be made under a very large cross-sectional area ratio and low back pressure. The following formula shows that the loading time depends on the maximum loading factor. LF* (matrix volumes loaded at 100% capacity utilization), the linear velocity (cm/min), and the bed height H (cm), the actual chosen capacity utilization cu (%) used

Therefore, under the same capacity utilization and treatment capacity, the membrane diffusion is faster than the resin diffusion. The typical process data show that the flux of the membrane adsorber is two orders of magnitude higher than that of the column chromatography in the flow mode [11].

The use of non-conventional geometric formats is another major advantage of membrane chromatography, which are hard to achieve for resins chromatography. Membrane adsorbers usually adopt hollow fiber, flat plate (usually disc shape), radial flow, spiral winding, cylindrical plug, and other membrane forms (Fig. 2) [20, 21]. Most of the membrane adsorbents are stacked, among which hollow fiber and stacked disc membrane adsorbents have been used in commercial applications. The radial flow and cross-flow membrane modules are easier to be applied in large-scale industrial production because they are difficult to produce membrane fouling.

Common types of membrane components: a stacked discs. b Cross-flow flat sheet. c Hollow- fiber. d Spiral wound. e Pleated sheet. The arrows represent the overall flow direction [20]

Membrane chromatography effectively combines the liquid chromatography of high resolution with the membrane of high throughput. Functional macroporous membrane or microporous membrane (pore size range: 0.65–3 µ m [3]) instead of traditional resin beads as chromatographic substrate [22]. The membrane pore contains functional ligands that can bind to the target substance. During the separation process, smaller molecules are easier to bind to the inside of the membrane pore because they can enter the membrane pore, while larger biomolecules are more likely to bind to the inlet of the membrane pore [23, 24]. In this way, the target substance is separated from the complex mixture. Chromatographic packing usually consists of stacked chromatographic membranes, membrane adsorbent acting as a short, wide column with a shorter bed height that reduces the requirement for pressure-resistant equipment [25]. The ideal adsorption membrane should have a hydrophilic surface and be kept neutral to prevent non-specific binding; the membrane has stable physical and chemical properties and mechanical strength under harsh conditions of adsorption, elution, and regeneration.

Membrane chromatography modules’ velocity of flows ranges from 3.5 mL/min to 50 L/min, and volumes ranging from 0.35 mL to 5 L, thus contains from laboratory research to industrial-scale applications.

Ion exchange membrane chromatography

Ion exchange membrane chromatography uses reversible electrostatic interactions between the surface charge of the target protein and the charged group on the membrane by coupling charged ligands to a rigid mechanical substrate membrane; biomolecules with different charge conditions but similar molecular weight can be easily separated [26]. Even samples with a difference of only one amino acid can be separated under suitable packing and process conditions. As one of the last polishing steps in numerous downstream processes, anion exchange chromatography has been proved to effectively remove existing viruses [27]. At present, the anion exchange membrane is the major method for the purification of monoclonal antibodies [28].

Ion exchange chromatographic ligands determine the type and degree of exchange reactions between adsorbents and solute molecules. According to the ionic charge properties of ion exchange chromatographic ligands, ion exchange ligands can be divided into cation exchange ligands and anion exchange ligands (Table 1).

Ion exchange technology is a high-resolution purification technology with strong versatility, low cost, and small non-specific capture, which can completely concentrate viral vectors and has a high dynamic binding capacity to viral vectors, which is twice that of any other chromatographic device and more than 40 times higher than that of particle packing chromatography equipment [27, 29, 30]. Studies have shown that the dynamic flow rate and volume of ion membrane chromatography are at least one order of magnitude higher than that of ionic resin chromatography for the separation of E. coli solutions [25]. Lysozyme is usually positively charged and is often used as a template for studying the purification performance of ion-exchange membranes [31, 32]. Lee et al. [33] modified polyacrylonitrile nanofibers through alkaline hydrolysis. The high density of carboxyl functional groups in a three-dimensional nanofiber weak ion exchange membrane could be achieved by changing the process parameters of alkaline hydrolysis with high porosity and high functional group density was obtained. The efficiency of the one-step purification of lysozyme was up to 98%, and the purification ratio reached 63%. Similar purification results were obtained during the amplification process, indicating the linear scalability of the purification technique [33].

Affinity membrane chromatography

The specific biological characteristics between the affinity ligand and the protein are determined by the main functional groups, besides the hydrogen bonding and hydrophobic multimolecule interactions, which are also based on van der Waals forces and static electricity interaction [34]. It based on reversible biospecific interactions between proteins and specific ligands that confer biospecific separation selectivity at the molecular level [35]; this allows the separation of target proteins from a mixture of complex biomolecules, such as antibodies and antigens, enzymes and substrates, and hormones and receptors. Compared with other techniques for separating proteins based on physical or chemical properties, it is the only method based on the biological function of a protein [36]. Because of the powerful interaction between the desired protein molecule and the affinity ligand, affinity chromatography usually requires harsh operating conditions to release the protein molecules bound to the ligand [37].

Affinity patterns are classified according to ligand types, including immune affinity, immobilized metal affinity, and dye affinity (Cibacron Blue F3GA, [38] Reactive Orange 4 [39]). The first belongs to the biologically specific model, and the latter two belong to the group-specific affinity type [40]. The selectivity of immobilized metal ion membranes can be changed and controlled by using specific metal ion immobilized membranes; Ni2+, Fe3+, Cu2+, and Zn2+ are usually used metal ions, which have specific interactions with nucleic acids, amino acids, proteins, peptides, and other target substances [34]. It reported that the recombinant DIII antigen was successfully isolated from the compound feed solution by metal affinity membrane absorption, which has great potential in the field of vaccine development [41]. Braemer et al. [42] reported a CO2+ fixed metal affinity chromatography. The purification of recombinant patchouli synthase from Escherichia coli lysate was optimized using three membrane adsorption units in a continuous chromatographic system [42].

Dye ligands depend on the reversible binding and selectivity of proteins and reactive dyes, and have the advantages of easy immobilization, low cost, high binding amount, and medium specificity. The ligand-ligand pair formed by CB F3GA and bovine serum albumin (BSA) is one of the classical models for affinity chromatography. Cibacron Blue F3GA is covalently immobilized on the nylon6-chitosan core–shell nanofiber mat prepared by coaxial solution blow molding. The experimental results show that the functionalized nanofiber mat has the advantages of high BSA adsorption capacity, high throughput, and low-pressure drop [43].

Mustafaoglu et al. [44] reported an affinity purification technique for capturing small antibody molecules using NBS (nucleotide-binding site) ligand-functionalized membranes, preparation an NBS targeting affinity membrane column through conjugating an NBS ligand, tryptamine, to regenerated cellulose membranes, purification of antibodies from compound culture medium samples containing variety of pollutants, the recovery and purity of antibody were above 98%, NBS targeting affinity membrane column was realized on the membrane chromatography platform, which promoted the further research of small molecule affinity membrane chromatography [44].

Hydrophobic membrane chromatography

In the process of separation by hydrophobic membrane chromatography, the hydrophobic interaction between the hydrophobic ligand coupled on the membrane and the non-polar region of the protein molecular surface is mainly considered. The hydrophobic ligand was connected to the substrate membrane, the biomacromolecules were adsorbed to the ligand by hydrophobic action, and the target macromolecule is separated by the interaction between the ligand and the biological macromolecule. Chromatographic processes are usually loaded at high salt concentrations and eluted as the salt concentration decreases [45]. Hydrophobic membranes generally possess superior mechanical strength, stable physical and chemical properties, and good durability of the membrane. When dealing with high viscosity feed, the excellent mechanical properties of membrane adsorber are very significant [10]. However, hydrophobic membranes have low water permeability and scale resistance, and there are fewer active groups that can be coupled to the ligand. By introducing a hydrophilic polymer or an environment-specific polymer onto the membrane, the hydrophilicity can be increased and the active group can be provided to increase the protein adsorption capacity [46, 47].

Some stimulus-responsive ligands are used in hydrophobic membrane chromatography, and these ligands change their conformation with the change in environmental conditions, and can well adjust the three-dimensional structure of ligands [48, 49]; in recent years, environmental responsive membranes have been widely used in hydrophobic interaction chromatography to improve the separation shortcomings of traditional hydrophobic membrane chromatography [50,51,52]. Temperature is an easily controlled variable in the environment. Environmentally responsive polymers can flexibly switch between insoluble and soluble according to temperature changes. Environmental responsive ligands exhibited hydrophobicity when heated, and hydrophilicity when releasing adsorbed target proteins at low temperatures [53, 54]. Poly(N-isopropyl acrylamide) is a classic temperature-sensitive polymer with a critical dissolution temperature of 31–32℃ in water. When the temperature was higher than the critical dissolution temperature, poly(N-isopropyl acrylamide) curled into an insoluble conformation; while the temperature was lower than the critical dissolution temperature, poly(N-isopropyl acrylamide) showed extended conformation [55]. As a low-cost material with a simple source, filter paper possesses good compatibility with biomacromolecules and good air permeability and is a suitable hydrophobic membrane matrix. Chen et al. [12] successfully grafted poly(N-isopropyl acrylamide) polymer onto the surface of wood fiber of filter paper and obtained a hydrophobic interaction membrane with temperature response function, which could regulate the binding and release of target proteins through controlling the temperature of the flowing water phase. Vu et al. [56] prepared hydrophobically interacting membrane adsorbents by grafting poly N-vinyl caprolactam from the surface of regenerated cellulose membrane by atom transfer radical polymerization. When loaded under high ionic strength, the ligand showed dehydration conformation. At the elution process in a low ionic strength buffer, hydrated conformation was been showed of ligand, has excellent recoveries for lysozyme, IgG4, and bovine serum albumin [56].

Based on the higher binding capacity and larger membrane surface area required for binding and elution. Kuczewski et al. [57] developed a Sartobind Phenyl™ membrane adsorber for large-scale purification of biomolecules; the hydrophobic membrane has almost no diffusion limitation, reduces the processing time, and is comparable to conventional hydrophobic interaction chromatography resins in protein binding capacity, and also has excellent resolution.

Multimodal membrane chromatography

To improve the purity of proteins, several separations and purification methods are usually combined. Fan et al. [58] use two-step membrane chromatography to extract α1-antitrypsin from human plasma. First capture plasma proteins in binding/elution mode by anion exchange membrane chromatography, further polished by hydrophobic interaction membrane chromatography in the flow mode [58]. Cordova et al. [59] reported a tandem membrane adsorber Sartobind® S and Phenyl for antibody–drug conjugate purification. Sartobind® S and Phenyl membranes are placed in tandem to integrate the whole antibody–drug conjugate purification process in a single-unit operation. Compared with the traditional purification method of antibody–drug conjugate, it consumes less time and saves the crude extract [59]. Multistage membrane chromatography, which combines several membrane adsorbents to purify substances, can greatly reduce operation time and improve purification accuracy, and is a promising separation mode. Through combined use, multiple modules can achieve higher dynamic binding capabilities or higher traffic, or both [10].

Membrane matrix

Natural polymer materials

Cellulose separation membrane has strong hydrophilicity because of abundantly hydroxyl groups, as a natural polymer, which has the advantages of being cheap, widely available, porous structure, and highly resistant to non-specific adsorption, and can minimize the non-specific binding between fiber surface and solute. Therefore, most of the membrane matrix comes from the cellulose membrane. However, the chemical and physical properties of cellulose membranes are unstable, which limits the reusability and service life of these membranes [10, 60]. Grafting onto the membrane surface and chemical modification of the membrane surface are the major approaches for preparing chromatographic membranes [61]. Ma et al. [32] attached maleic anhydride to the cellulose support membrane to prepare the modified cellulose nanofiber membrane, which showed high lysozyme adsorption capacity and realized the efficient purification of protein. Tafta et al. [62] reported a cellulose membrane adsorber modified with cellulose sulfate, which shows high selective pseudo-affinity with influenza virus, and the surface area is designed to be as close as possible to the virus, which greatly improves the selectivity and recovery of the product. The binding ability of the membrane to influenza virus was 5 times that of the commercial membrane under the condition of the same recovery and purity (Fig. 3). This has the potential to provide a new platform for the optimization and innovation of the vaccine industry [62].

a Adsorption model of the virus on traditional resin surface and SCMA membrane. b Comparative evaluation of SCMA membrane and commercially available sulfated cellulose resins [62]

Chitosan and chitin have unique degradability and biological effects. By using a natural chitosan/carboxymethylchitosan blend membrane as the matrix, we set up a chitosan-based membrane chromatography; ovalbumin and lysozyme were successfully separated from their binary mixture through the membrane chromatography [26]. Chitosan membrane adsorbers have been successfully used for the separation of some high-value-added biological products [63], and have great application potential in wastewater treatment [64]. Chitin membrane can stably exist in acidic, alkaline, and common organic solvents. Meanwhile, an important characteristic of the chitin membrane is that it contains N-acetyl-D-glucosamine units, which is affinity ligands for wheat embryo lectin and lysozyme; therefore, the N-acetyl-D glucosamine unit can be directly used for affinity separation of protein without chemical modification. Chitosan has drawn much attention because of its performance in membrane formation and fiber-forming ability and good hydrophilicity [65]. Chitin and chitosan are commonly used as membrane substrates or membrane coatings, and have been proved to improve membrane properties on other polymer carriers. It has been shown that chitosan-modified polyacrylonitrile (PAN) nanofiber membranes can effectively filter calcium phosphate from complex algal solutions [66].

Polymer membrane

The membranes prepared with polymer materials with good chemical resistance, mechanical stability, material surface modification ability, and pore properties are more advantageous than other membrane matrices, which usually include aliphatic polyamides (nylon 6, nylon 66), cellulose (cellulose acetate, cellulose nitrate), aromatic copolymers (polysulfone, polyether sulfone), hydrocarbon polymers (polyvinylidene fluoride), polyvinyl alcohol, synthetic copolymers [40].

Polysulfone ion imprinted porous adsorber membrane was used to remove mercury(II) from water [67]. Yu et al. [68] grafted a poly(glycidyl methacrylate) layer on the surface of a polyethersulfone membrane by UV-initiated free radical polymerization method, and covalently immobilized lysine molecule on the membrane surface via a zinc perchlorate-catalyzed, epoxide ring-opening reaction, and synthesized an amino acid-functionalized, lanthanide-binding membrane adsorber. Hamzah et al.’s [69] base membrane was prepared by phase conversion technology with 15% polysulfone, and the surface of the membrane was modified by soaking the base membrane in chitosan solution. Then, glutaraldehyde was used to activate the membrane and hydrophilic chain segments were led into the surface of the membrane by self-assembly of hydrophobic polysulfone and chitosan. A trypsin affinity membrane with high specificity was developed [69].

Liu et al. [70] deposited polydopamine on the surface of nylon film as an intermediate connecting layer, and covalently grafted polyethyleneimine molecules onto the polydopamine layer through Michael’s addition reaction and/or Schiff base reaction. Then, polyethyleneimine-polydopamine/nylon membrane was modified by L-cysteine, and a thiol-functionalized nylon membrane adsorber was prepared, which has good removal ability and reusability for patulin [70].

Polymer blending coating is a promising strategy in membrane preparation, improving membrane properties by applying some or all of the properties of the two polymers at the same time or complementing each other, producing competitive membranes with protein binding capacity, which proved superior to commercial resins [71].

Commercial membrane matrix

The development of commercial membrane matrix is relatively mature; polypropylene (PP), polyethylene (PE), and PVDF are commonly used commercial polymer membranes with good mechanical strength, which are hydrophobic membranes with poor hydrophilicity and lack of reaction sites, and prone to specific binding [72,73,74]; thus, most of the polymer membranes used after modification are rarely directly used for separation and purification. The hydrophobicity of inert membranes can be improved by introducing hydrophilic functional polymers by coating or radiation induction. Coating dopamine on the surface of various polymer membranes is a common method to improve hydrophilicity. Because dopamine coating has a strong covalent chemical bond, the dopamine coating base membrane successfully connects to ligands such as polyethyleneimine, dodecyl mercaptan, and histidine, which enhances the adsorption capacity of the membrane [75]. Under alkaline operating conditions, dopamine can self-polymerize to form a polydopamine layer by forming strong non-covalent bonds on various substrates [76]. Fan et al. [46] adopt polydopamine intermediate layers formed on a commercial hydrophobic PVDF porous membrane for coupling polyallylamine-containing primary amine groups. The mechanical performance of commercial PVDF membranes was promoted after polydopamine deposition. Because dopamine is easy to deposit on the membrane surface and enter the membrane pores, the effective functionalization and hydrophilicity of the PVDF membrane are realized, and a salt-resistant anion exchange membrane is obtained (Fig. 4). Repeatedly binding and elution of proteins showed that the salt-tolerant anion-exchange membrane adsorber had a higher reuse rate and better mechanical properties than the commercial adsorption membrane, and possesses excellent potential in the efficient polishing of monoclonal antibodies (mAb) [46].

Schematic diagram of the preparation of salt-resistant anion exchange membrane adsorber [46]

Alginate dialdehyde is an excellent biological adhesive. Metal chelating ligands, peptides, sulfonic acid, and histidine were bonded to the commercial nylon membrane by Schiff base reaction using alginate dialdehyde as an intermediate layer without any solvent. Metal-affinity (Me-affinity), peptide-affinity (Pep-affinity), cation exchange, and histidine-affinity (His-affinity) membrane adsorbers were prepared, which created more platforms for the preparation of different membrane adsorbers [77].

Unlike other common commercial membrane substrates, the Natrix HD-C membrane is a polyacrylate porous hydrogel. Hydrogels have interconnected porous three-dimensional structures, which provide convenient pores for the high permeability of feed fluid and an accessible surface area for protein binding. Compared with traditional anion exchange resin, the Natrix HD-C membrane has the obvious preponderance of high load capacity and fast operation speed [78]. The following table summarizes some types of membrane adsorbers currently on the market (Table 2).

Electrospinning membrane matrix

Polymers can be made into nanofibers by electrospinning, which has larger specific surface area and higher porosity than traditional membranes, which has tunable tortuous open-porous structures and scalable synthesis from various materials, enhances immobilization efficiency, and increases the reusability and long-term stability. Based on different driving forces involving electrostatic interaction, dye − ligand affinity, hydrophobic affinity, and targeted affinity, various new types of electrospun nanofibrous chromatographic materials have been developed for use as protein adsorbents.

Yang et al. [79] through blending and electrospinning integrated the prefunctionalized quaternary amine PAN copolymer into the traditional PAN homopolymer, and designed an electrospun PAN-based composite membrane with a strong anion exchange function, which could be easily customized for different separation purposes. Tris(hydroxymethyl)aminomethane-functionalized electrospinning PAN nanofiber membrane prepared affinity membrane chromatography with powerful binding specificity and well adsorption ability for the corresponding target [80]. Electrospinning PAN nanofiber membrane was modified by grafting bromoacetic acid and ethylenediamine dihydrochloride for functionalization; polyacid ion exchange nanofiber membrane was prepared for the purification of lysozyme in egg white [81]. Ng et al. [39] immobilized Reactive Orange 4 on electrospinning PAN nanofiber membrane modified with chitosan molecule, and successfully prepared dye-affinity nanofiber membrane.

Ethylene–vinyl alcohol copolymers (EVOH) have water insolubility and good hydrophilicity, easy to functional modification, corrosion resistance, and biocompatibility; plenty of active hydroxyl groups can also be used for further derivatization, and is an ideal choice for the preparation of chromatographic materials. Fu et al. [31, 82] combined in situ modification technique with blend electrospinning technology; butane tetracarboxylic acid (BTCA) as the grafting agent was introduced into the EVOH solution to prepare the spinning solutions; after the spinning process, the pristine BTCA and EVOH blend nanofibrous membranes were dried and then thermally cured at 100 °C; BTCA-modified EVOH nanofibrous membrane (BTCA@EVOH NFM)–based cation-exchange chromatographic media were prepared for protein adsorption and separation (Fig. 5a). Meanwhile, they also used citric acid (CCA) as a modifier and the mixture of water and isopropanol as the spinning solution to prepare the EVOH nanofiber membrane; after vacuum drying, immersed in citric acid solution to modify the membrane surface; subsequently, the CCA-modified EVOH nanofibrous membranes (EVOH-CCA NFM) was obtained by heat treatment (Fig. 5c); these two membranes showed an exceptionally excellent adsorption capacity for lysozyme (Fig. 5b, d), which are attributed to the synergistic effects of introducing plentiful carboxyl groups adsorption groups (carboxyl groups) to the nanofibrous matrix; relatively long carbon chains can also serve as spacer arms that can decrease the steric hindrance between the adsorbed proteins and adsorption groups, thus greatly improving the conjugation between protein molecules and availability of active adsorption sites [31, 82].

The preparation and functionalization process of BTCA, CCA grafting agent EVOH nanofibrous membranes, and adsorption capacity. a Prepared BTCA@EVOH NFM and modification principle. b BTCA@EVOH NFM comparison of adsorption capacities with flat film and blended membranes. c Prepared EVOH-CCA NFM and modification principle, and protein adsorption process. d EVOH-CCA NFM comparison of adsorption capacities with flat film and blended membranes [31, 82]

Surface modification and a higher specific surface area of the new membrane technology provide a new prospect for the development of membrane chromatography; electrospinning nanofiber membranes have been used in continuous simulated moving bed processes, which increase the capacity compared to traditional membrane adsorbents while maintaining high throughput.

Membrane equipment

At present, the membrane equipment is generally in the form of radial flow, and the radial flow membrane chromatography channel is complex and the void volume is large [5]. Membrane thickness, uneven membrane porosity, and ligand grafting may lead to changes in flow resistance and inappropriate convection, resulting in premature saturation of binding sites in macropores; underutilization or non-use of small pores will reduce the binding capacity of membranes [20]. At the same time, the traditional membrane chromatography equipment has the advantages of wide elution peak, low resolution, large invalid volume, complex flow path, and poor separation performance. Most devices are designed for laboratory scale only, and are not used on a large scale.

Laterally fed membrane chromatography

To solve the above problems, the researchers proposed laterally fed membrane chromatography (LFMC). The transverse feeding device is better than the laminated disc device in flow distribution, utilization rate of film binding capacity, and peak resolution. Its advantages include low invalid volume and easy back mixing, which helps to form clearer and better peak resolution [83], suitable for combination-elution mode of high resolution, and multicomponent protein separation [84]. The flow path of the radial flow device and the LFMC is shown in the illustration (Fig. 6). LFMC-based technologies are capable of operating at pressures of approximately 165 kPa, and in less than 1.5 min analyze the aggregation content and type in different monoclonal antibody samples. Compared with HPLC, this method is more efficient. In addition, LFMC working pressure is less than 200 kPa, no need for expensive high-pressure pumps for chromatographic systems [85]. LFMC has been proved to be a flow mode suitable for fast and efficient separation, and can in the maximum extent possible minimize sample dilution [5, 83, 86]. Such is the separation of PEGylated proteins and monoclonal antibody aggregates [87].

a Radial-flow membrane chromatography device. b LFMC membrane chromatography device [15]

Kawka et al. [88] used a comprehensive approach that considered the enzyme chromatography and DNA digestion steps; purification of adenovirus using LFMC equipment containing Sartobind Q membrane was performed. The designed integrated process development approach improved DNA removal by approximately 80 times, and the flexible elution operation yielded good DNA removal and high viral recovery [88].

Other improvements

Chen et al. [89] designed an annual flow hollow fiber member chromatography device, which ensures narrow solute residence time distribution, low dead volume, and minimum fluid back mixing from the point of view of hydrodynamics. The introduction of inserts in the annular-flow hollow-fiber membrane chromatography equipment can reduce the invalid volume at the feed side. The introduction of inserts also results in annular flow at the feed side, which improves the flow performance on both sides of the hollow fiber membrane (Fig. 7). Annular-flow hollow-fiber membrane chromatography device can achieve fast and high-resolution separation of proteins with near isoelectric points, and is an effective substitute for stacked disc assembly [89].

a Exploded view of the AHMC. b Flow path diagram of AHMC [89]

Ghosh et al. [90] proposed a flow distribution of the Z2 chromatography device, and combined LFMC and Z2 to improve the separation efficiency of membrane chromatography; the fluid flow path in the device has three levels (Fig. 8). The direct channel design minimizes back-mixing, and the inclined combination of membrane stacks reduces the residence time of the solute in the equipment. Experiments have shown that the resolution of the device is similar to that of packed resin chromatography, and the flow rate is 40 times higher than that of column chromatography, suitable for high-resolution separation of biological pharmaceutical under the same flow rate and column chromatography, the significantly higher degree of separation [91]. Roshankhah et al. [28] purified trastuzumab by cation-exchange Z2 laterally fed membrane chromatography (Z2LFMC); the purity of trastuzumab obtained by the Z2LFMC method is equivalent to that of protein A chromatography method, but recovery rate of the Z2LFMC method is significantly higher than that of the protein A method, and elution speed of Z2LFMC is faster. The productivity of the monoclonal antibody obtained by the Z2LFMC process is more than three times that of the column-based purification process [28].

Madadkar et al. [92] proposed to set a flow-directing layer on the front or back of the disc. Re-directing the liquid flow could solve the problem of the long solute stay time in the disc membrane chromatography and thus improve the separation efficiency [92]. Chen et al. [89] reported an annular-flow hollow-fiber membrane chromatography installation designed from the perspective of fluid; this device solves poor fluid dynamics and invalid volume. Borneman et al. [93] designed a novel particle-loaded membrane adsorption module by winding the adsorption fiber, by rearranging the absorbent fiber fillers. By raising the interval between two adjacent annulus fibers during winding, the porosity of the module is increased. The larger layout spacing produces less flow resistance, and facilitates the flow of fluid around the fibers, and the adsorption performance and flow rate height correlation, thus a faster adsorption process can be achieved [93].

Ligand optimization

To obtain ideal chromatographic results, the membranes need advanced porous materials with high internal surface area, easy functionalization, high porosity, diverse functions, and adjustable porosity. The membrane pore size should be at least 5 times bigger than the average diameter of the target substance [94]. However, excessively large holes can also lead to reducing the total surface area of ligand grafting, or the target material not having enough time to bind to the ligand on the membrane and lose target substance [23].

The binding capacity of membrane adsorbers depends not only on the size of target biomolecules and membrane pore size but also on the ligand design. Studies have shown that when viral vectors are purified by ion exchange membrane chromatography, increasing the ligand density does not lead to the corresponding virus increase in binding ability [95]. However, the increase in ligand density was positively related to the binding capacity when purified by membrane affinity chromatography [96]. These phenomena can be attributed to steric hindrance and spatial repulsion between biological macromolecules; the efficient three-dimensional structure of ligands is important for maximizing recovery and capacity [56].

Yoshimoto et al. [98] reported a cation-exchange membrane containing mixed ligands. The composite membrane contains not only hydrophobic ligands but also enhanced ion exchange groups containing cellulose. Compared with the traditional cation-exchange membrane, it has higher protein binding ability at higher conductivity. Although the exact interaction and separation mechanism for such phases have not been fully elucidated, a double interaction mechanism is proposed [97, 98]. This technique has been effectively used to separate high-value proteins from high-salt solutions.

Compared with the traditional membrane adsorber, membrane matrix ligand optimization has a larger specific surface area, higher ligand density, and better three-dimensional binding environment.

Spacer arms

The membrane surface has micropores or microporous structures for mixture flow, and spacer arms or active groups for coupling functional ligands [99]. When the ligand ratio is quite small, the target protein biological site is difficult to contact with the ligand on the membrane because of the steric hindrance. A too-long spacer arm will lead to non-specific adhesion, and a spacer arm too short is ineffective. Meanwhile, the spacer arm promotes the ligand to rotate and advances the favorable orientation of the ligate-ligand complex. The too-long spacer arm will result in non-specific binding and the too-short spacer arm is ineffective. Most choose spacer arms with 6–10 carbon atoms [100, 101]. The spacer arm of choice is necessarily able to interact with the ligand and membrane matrix, but no other active sites for non-specific adsorption should be present [40]. Studies have shown that spacer arms significantly affect related properties, such as recovery, selectivity, and binding ability; however, systematic experiments have not been carried out to study the effect of the spacer arm itself on non-specific binding, thus affecting protein recovery [96].

Polymer brush

The polymer brush is a polymer chain with high grafting density [102]; a strong repulsive force made the unique tensile structure, increasing the volume of the internal three-dimensional structure. Proteins bind to the polymer brush through hydrophobic or electrostatic non-specific interactions, or through specific interactions between receptors and ligands [103,104,105,106]. As a potential protein-binding medium, a polymer brush–modified membrane surface can increase the surface concentration of affinity ligand and optimize the quality of purification, which is an important tool for protein purification [107]. Hu et al. [108] worked by immobilizing a cholic acid-containing polymer brush on a poly-2-hydroxyethyl methacrylate grafted microporous polypropylene membrane. A modified membrane containing a polymer brush containing cholic acid was prepared for affinity adsorption of albumin. The modified microporous polypropylene membrane has a high affinity for albumin and has poor non-specific adsorption of hemoglobin. Affinity membrane is about 24 times more binding than a single layer.

Applications

Protein capture and intermediate purification

Membrane chromatography is a large-scale separation method for separating, purifying, and recovering proteins and enzymes, which is a comprehensive protein purification technology. Honjo et al. [35] synthesized several surfactant-like ligands by using the affinities between proteins and ligands; the affinity membrane was prepared by introducing them into a porous polymer membrane by thermally induced phase separation. The modification functionalized membrane can selectively purify target proteins from cell lysates [35].

Phycocyanin of high purity is usually obtained by several purification processes; different column chromatography ways are involved, discouraging large-scale development. Mah et al. [49] use a commercial PVDF membrane and obtained phycocyanin of analytical grade in a few minutes by two-step hydrophobic interaction; a simple and efficient purification method is provided [109].

Eldin et al. [110] grafted methyl methacrylate (MMA) and methacrylate (MAA) onto cellophane membranes, respectively, and further immobilized Cu2+ on the grafted membranes to prepare two kinds of immobilized metal affinity membranes, separation of the His-tag chitinase enzyme from BSA protein mixture. The PMAA-grafted membrane showed a higher affinity for chitinase enzyme separation than the PMMA-grafted membrane, but the affinity advantage of the PMAA-grafted membrane was smaller. In addition, Cu2+ leakage was not detected in the two kinds of affinity membranes during protein elution, which solved the problem of metal ion leakage [110].

Teepakorn et al. [111] successfully separated two proteins with different isoelectric points but similar molecular weights by using strong cation and anion exchange membrane chromatography. For mixtures of lactoferrin (LF) and bovine serum BSA, when using a cation exchange membrane, LF is completely adsorbed to the membrane, and the flux per unit area of BSA is the largest; the opposite is true when using an anion exchange membrane. Membrane chromatography separation of BSA-LF mixtures can be operated at high flow rates without affecting any selectivity [111].

Pegylated protein can enhance the acceptability and clinical of therapeutic proteins, most PEGylated proteins purified by column chromatography. Yu et al. [112] isolated mono-pegylated lysozyme from natural lysozyme and other PEGylated forms using commercial cation exchange Sartobind S membranes. The results show that the Sartobind S membrane can well separate single PEGylated lysozyme, high-order PEGylated form, and natural lysozyme, which is an effective replaceable to the PEGylated protein purification technology [112].

Shi et al. [113] prepared composite membranes with uniform thickness, and uniform porosity distribution by depositing silica on anodic aluminum oxide (AAO) membrane by the sol–gel method. Through activation of glutaraldehyde, lysine was attached to the AAO-SiO2 composite membrane as a ligand. The dynamic adsorption results showed that the affinity membrane has been successfully used to remove bilirubin from plasma [113].

Monoclonal antibodies play an important role in the current biopharmaceutical industry because they can greatly extent reduce the side effects of drugs [10, 114]. Masuda et al. [115] found mAb1 asymmetric surface charge distribution, under the condition of standard chromatographic mAb1 bind to anion exchange resin and unable to achieve separation and purification effect. They used the Natrifo HD-Q anion exchange membrane adsorber under standard chromatographic norms and successfully isolated mAb1 from the virus, which solved the problem that mAb1 could not be separated from anion exchange resin, and achieved a satisfactory virus clearance rate [115]. Hydrophobic charging-induction chromatography, as a multimodal chromatography technique, is an effective way for antibody purification [116, 117]; Ma et al. [118] put forward a scalable surface modification method for the preparation of hydrophobic charging-induction chromatography mixed-mode membrane absorbers. First, commercially regenerated cellulose membranes were modified by the cationic ring-opening polymerization of diethylene glycol diglycidyl ether; then, it was modified by the ring-opening reaction between the epoxy group and the sulfhydryl group in the four mercapto heterocyclic ligands. A membrane adsorber with typical hydrophobic charging-induction chromatography performance was obtained. The experimental results showed that the membrane adsorber could achieve up to 96% antibody recovery for IgG monomer [118]. Sadavarte et al. [73] used hydrophobic membrane chromatography technology not only to directly purify humanized chimeric heavy chain monoclonal antibody from cell culture supernatant in one step but also to separate aggregates from humanized chimeric heavy chain monoclonal antibody in monomer form, greatly improving purification efficiency [73].

Virus

Membrane chromatography as an effective technique for the purification of viruses has been successfully used in industrial biopharmaceuticals [27]. Hejmowski et al. [119] used Mustang Q membrane anion exchange chromatography to enrich full adeno-associated particles. During the elution process, the conductivity gradient increased by around 1 mS cm–1 step gradient can more effectively separate full and empty adeno-associated virus serum in the membrane medium. This elution method can be applied to a scalable process, providing a reference for the development of elution methods for other adeno-associated virus serotypes [119].

Fortuna et al. [120] used a three-column periodical counter-current device with Sartobind® SC membrane adsorber in combined elution mode continuous purification of influenza A virus A/PR/8/34 virus particles. The effective usage of binding capacity can be increased to 80%, which can be successfully used as a continuous mode for the purification of cell-derived influenza virus particles [120].

Lee et al. [121] reported the polishing of adenovirus by metal affinity membrane chromatography (immobilization of Zn2+ ions on the membrane unit as an affinity ligand). The average yield of the membrane is significantly higher than that of resin chromatography with the same buffer system. More importantly, the membrane can well separate defective adenovirus particles and intact adenoviruses [121].

Water treatment

Membrane adsorber, which combines the advantages f adsorption and membrane separation, has received great attention in the removal of pollutants from aqueous solutions. Fan et al. [122] coated polydopamine on the base membrane, and then grafted polyethyleneimine to prepare a membrane adsorber. In the flow mode, laccase was captured from the crude fermentation solution, and laccase was selectively immobilized on the membrane adsorber to construct a biocatalytic membrane. The biocatalytic membrane exhibited a commendable removal efficiency of bisphenol A in water only under the action of gravity (Fig. 9) [122]. The removal of bisphenol A micropollutants from water using a biocatalytic membrane immobilized by the enzyme has been extensively studied [123, 124].

Removal of bisphenol A from water by immobilized Laccase by membrane chromatography [122]

Sepesy et al. [125] synthesized amine-functionalized membrane adsorbers to adsorb Cu2+ from acidic solutions at 70 kPa; the filtration time is 25 times faster than the current resin-packed column technology. Hu et al. [126] designed a porous poly(N-vinyl imidazole) gel-filled membrane adsorber with good stability in alkaline or acidic conditions, and realized rapid removal of anionic dyes from water by adsorption filtration, and can be regenerated effectively with NaOH solution.

Basement membrane coating or grafting chitosan greatly improves hydrophilic ability due to rich hydroxyl and amino groups on chitosan, which can bind to heavy metal ions by electrostatic attraction or chelation [127], such as Cr6+, Cu2+, Cd2+, and Pb2+in water systems, and shows a good application prospect in the removal of heavy metal ions in water [128, 129]. Wang et al. [130] prepared chitosan microporous thin membranes with connectivity and symmetry using silica as the pore-forming agent by immersion precipitation method. The experimental results show that the membrane, as an adsorption layer, has a good ability to adsorb low-concentration copper ions. With the increase of the bed thickness, the load of copper ions increases, which provides a potential alternative technology for deep wastewater treatment at low concentrations [130].

The excellent hydrophilicity of polyvinyl alcohol makes it a competitive choice for the preparation of membrane adsorbent. de Almeida et al. [131] based on the preparation of histidine modified nylon membrane adsorber of endotoxin; the surface modification of nylon membrane was carried out with polyvinyl alcohol as coating polymer and dioxane as a spacer; nylon is coated with polyvinyl alcohol to reduce non-specific adsorption, and used to remove endotoxin in aqueous solution. The service life of the modified membrane was up to 30 months with high stability.

Chen et al. [132] prepared one PVDF composite membrane based on β-cyclodextrin and zeolitic imidazole skeleton-8 (β-CD@ZIF-8) nanoparticles through the deep-permeation synthesis-manufacturing method of synergistic percolation reaction; β-CD@ZIF-8 is anchored in each membrane pore along the membrane thickness direction and assembled in situ in the PVDF membrane pores. With the help of the high specific surface area and uniformity of the membrane pores, more active sites are provided; PVDF composite membrane shows good adsorption for heavy metal ions Pb2+ and Cu2+ in wastewater (Fig. 10) [132].

a assembly of Zn(II) on the PVDF: fabrication of the β-CD@ZIF-8/PVDF. b Assembly of ZIF-8 and formation of β-CD. c Structure of the membrane. d Sketch map of β-CD@ZIF-8 binding. e Adsorption mechanism of the Pb2+ and Cu.2+ [132]

Lee et al. [133] used an electrospun PAN nanofiber membrane as the membrane matrix, and the PAN membrane was hydrolyzed to obtain a P − COOH membrane; then, the P − COOH membrane coupling with BSA prepared a cation exchange nanofiber membrane (P − COOH-BSA). Because bovine serum albumin can bind to trivalent or divalent metal ions, the P − COOH-BSA membrane showed a satisfactory binding ability to Ca2+ in the industrial feasibility wastewater treatment process [133].

At present, most membrane adsorbers are only applicable to the aqueous solution of a single target material, in the complex water environment will lose their adsorption performance for target material and have no selectivity for target material. There are few reports of adsorption experiments under real conditions.

Other applications

Wang et al. [134] researched the inhibition effect of the built-in electrode based on sodium alginate affinity chromatography membrane on the severe shuttle effect of polysulfide ions in lithium-sulfur batteries. This is the first time that the membrane for protein selective adsorption has been used in the battery field. This innovation is expected to improve the stability of lithium-sulfur batteries in practice and provide a simple and large-scale preparation method for PS shuttling in lithium-sulfur batteries [134]. Pei et al. [135] reported a membrane chromatography system for the adsorption separation of lithium isotopes (7 Li and 6 Li). It was filled in the chromatographic column with a porous membrane of polysulfone-GRAFT-4′-aminobenzo-15-crown-5-ether (PSF-G-AB15C5) as the stationary phase. To optimize the separation performance of lithium isotopes, a four-stage series membrane chromatography system was designed. The membrane chromatography system shows a better separation efficiency for lithium isotopes [++135].

Summary and outlook

As an effective alternative to chromatographic column packing, membrane chromatography has been widely studied in the past to explore the use of virus purification; purified viruses have been used for gene treatment and production of vaccines. Ion-exchange membrane chromatography is currently used for the polishing of monoclonal antibody production processes in the biopharmaceutical industry; hydrophobic interaction chromatography membrane adsorbers are usually in flow mode and are rarely used. At present, the chromatographic process of membrane chromatography combined with column packing or monolithic column has been applied in the field of biological production processes, and has shown good application potential in the treatment of trace harmful matters such as heavy metal ions or dyes in water.

Given the relatively high raw material manufacturing cost of membrane materials, the purification capacity of membrane chromatography must reach a relatively high value, or have a high cycle of reuse to ensure a low commercial cost, to have a relatively high economic value. Predictable and high-precision theoretical models are developing to better clarify the potential mass transfer phenomena and thus improve the separation performance of membranes. Disposable membrane sorbent methods are a small market branch for chromatographic packing at present, from an adoption and evaluation perspective, in the downstream processing technology, which development is more advanced.

The two-dimensional planar structure of the membrane leads to a low binding rate, and the ligand density, pore size distribution, and thickness uniformity of the membrane are difficult to reach the ideal requirements, which is the main limitation of membrane chromatography. Although there are numerous challenges and obstacles, the research trends in the past decade show that the preparation and application of various chromatographic membranes have been many improved. Optimizing the structure of the membrane and the arrangement of the ligand groups can greatly improve the capture by the chromatography membrane. The industry still needs more revolutionary development. It’s worth noting that the development and industrial research on this subject is considered confidential, although part of membrane chromatography technology has been commercialized; most of the literature available for reading is in the experimental research stage.

References

Sun M-H, Huang S-Z, Chen L-H, Li Y, Yang X-Y, Yuan Z-Y, et al. Applications of hierarchically structured porous materials from energy storage and conversion, catalysis, photocatalysis, adsorption, separation, and sensing to biomedicine. Chem Rev. 2016;45(12):3479–563. https://doi.org/10.1039/c6cs00135a.

Nweke MC, Rathore AS, Bracewell DG. Lifetime and aging of chromatography resins during biopharmaceutical manufacture. Trends Biotechnol. 2018;36(10):992–5. https://doi.org/10.1016/j.tibtech.2018.01.001.

Liu Z, Wickramasinghe SR, Qian X. Membrane chromatography for protein purifications from ligand design to functionalization. Sep Purif Technol. 2017;52(2):299–319. https://doi.org/10.1080/01496395.2016.1223133.

Ye J, Wang X, Chu J, Yao D, Zhang Y, Meng J. Electrospun poly(styrene-co-maleic anhydride) nanofibrous membrane: a versatile platform for mixed mode membrane adsorbers. Appl Surf Sci. 2019;484:62–71. https://doi.org/10.1016/j.apsusc.2019.04.106.

Madadkar P, Yu Z, Wildfong J, Ghosh R. Comparison of membrane chromatography devices in laboratory-scale preparative flow-through separation of a recombinant protein. Sep Purif Technol. 2018;53(18):2990–7. https://doi.org/10.1080/01496395.2018.1481090.

Erturk G, Mattiasson B. Cryogels-versatile tools in bioseparation. J Chromatogr A. 2014;1357:24–35. https://doi.org/10.1016/j.chroma.2014.05.055.

Nestola P, Peixoto C, Silva RRJS, Alves PM, Mota JPB, Carrondo MJT. Improved virus purification processes for vaccines and gene therapy. Biotechnol Bioeng. 2015;112(5):843–57. https://doi.org/10.1002/bit.25545.

Bhut BV, Wickramasinghe SR, Husson SM. Preparation of high-capacity, weak anion-exchange membranes for protein separations using surface-initiated atom transfer radical polymerization. J Membr Sci. 2008;325(1):176–83. https://doi.org/10.1016/j.memsci.2008.07.028.

Ghosh R. Protein separation using membrane chromatography: opportunities and challenges. J Chromatogr A. 2002;952(1–2):13–27. https://doi.org/10.1016/s0021-9673(02)00057-2.

Zhou JX, Tressel T. Basic concepts in Q membrane chromatography for large-scale antibody production. Biotechnol Prog. 2006;22(2):341–9. https://doi.org/10.1021/bp050425v.

Vogel JH, Huong N, Giovannini R, Ignowski J, Garger S, Salgotra A, et al. A new large-scale manufacturing platform for complex biopharmaceuticals. Biotechnol Bioeng. 2012;109(12):3049–58. https://doi.org/10.1002/bit.24578.

Chen J, Peng R, Chen X. Hydrophobic interaction membrane chromatography for bioseparation and responsive polymer ligands involved. Front Mater Sci. 2017;11(3):197–214. https://doi.org/10.1007/s11706-017-0390-z.

Moenster A, Villain L, Scheper T, Beutel S. One-step-purification of penicillin G amidase from cell lysate using ion-exchange membrane adsorbers. J Membr Sci. 2013;444:359–64. https://doi.org/10.1016/j.memsci.2013.05.054.

Knudsen HL, Fahrner RL, Xu Y, Norling LA, Blank GS. Membrane ion-exchange chromatography for process-scale antibody purification. J Chromatogr A. 2001;907(1–2):145–54. https://doi.org/10.1016/s0021-9673(00)01041-4.

Madadkar P, Ghosh R. High-resolution protein separation using a laterally-fed membrane chromatography device. J Membr Sci. 2016;499:126–33. https://doi.org/10.1016/j.memsci.2015.10.041.

Krogman KC, Lowery JL, Zacharia NS, Rutledge GC, Hammond PT. Spraying asymmetry into functional membranes layer-by-layer. Nat Mater. 2009;8(6):512–8. https://doi.org/10.1038/nmat2430.

Teeters MA, Conrardy SE, Thomas BL, Root TW, Lightfoot EN. Adsorptive membrane chromatography for purification of plasmid DNA. J Chromatogr A. 2003;989(1):165–73. https://doi.org/10.1016/s0021-9673(03)00027-x.

Rao CS. Purification of large proteins using ion-exchange membranes. Process Biochem. 2001;37(3):247–56. https://doi.org/10.1016/s0032-9592(01)00207-2.

Ghosh R. Ultrahigh-speed, ultrahigh-resolution preparative separation of protein biopharmaceuticals using membrane chromatography. J Sep Sci. 2022;45(12):2024–33. https://doi.org/10.1002/jssc.202200183.

Orr V, Zhong L, Moo-Young M, Chou CP. Recent advances in bioprocessing application of membrane chromatography. Biotechnol Adv. 2013;31(4):450–65. https://doi.org/10.1016/j.biotechadv.2013.01.007.

Saxena A, Tripathi BP, Kumar M, Shahi VK. Membrane-based techniques for the separation and purification of proteins: an overview. Adv Colloid Interfac. 2009;145(1–2):1–22. https://doi.org/10.1016/j.cis.2008.07.004.

van Reis R, Zydney A. Membrane separations in biotechnology. Curr Opin Chem Biol. 2001;12(2):208–11. https://doi.org/10.1016/s0958-1669(00)00201-9.

Wickramasinghe SR, Carlson JO, Teske C, Hubbuch J, Ulbricht M. Characterizing solute binding to macroporous ion exchange membrane adsorbers using confocal laser scanning microscopy. J Membr Sci. 2006;281(1–2):609–18. https://doi.org/10.1016/j.memsci.2006.04.032.

Riordan W, Brorson K, Lute S, Etzel M. Examination of the adsorption of large biological molecules to anion exchange surfaces using surface plasmon resonance. Separation Sep Sci Technol. 2010;45(1):1–10. https://doi.org/10.1080/01496390903401770.

Endres HN, Johnson JAC, Ross CA, Welp JK, Etzel MR. Evaluation of an ion-exchange membrane for the purification of plasmid DNA. Biotechnol appl bioc. 2003;37:259–66. https://doi.org/10.1042/ba20030025.

Liu Y, Feng Z, Shao Z, Chen X. Chitosan-based membrane chromatography for protein adsorption and separation. Mat Sci Eng C-Mater. 2012;32(6):1669–73. https://doi.org/10.1016/j.msec.2012.04.063.

Dolan S, Nolan P, Carey S, Quinney C, Littlejohn L. Using anion exchange membrane adsorbers to ensure effective virus clearance of challenging parvoviruses. Biopharm Int. 2021;34(4):32–7.

Roshankhah R, Chen G, Xu Y, Butani N, Durocher Y, Pelton R, et al. Purification of monoclonal antibody using cation exchange z(2) laterally-fed membrane chromatography - a potential alternative to protein A affinity chromatography. Biochem Eng J. 2022;178:108293. https://doi.org/10.1016/j.bej.2021.108293.

Zimmermann K, Scheibe O, Kocourek A, Muelich J, Jurkiewicz E, Pfeifer A. Highly efficient concentration of lenti- and retroviral vector preparations by membrane adsorbers and ultrafiltration. BMC Biol. 2011;11:55. https://doi.org/10.1186/1472-6750-11-55.

McNally DJ, Darling D, Farzaneh F, Levison PR, Slater NKH. Optimised concentration and purification of retroviruses using membrane chromatography. J Chromatogr A. 2014;1340:24–32. https://doi.org/10.1016/j.chroma.2014.03.023.

Fu Q, Si Y, Liu L, Yu J, Ding B. Elaborate design of ethylene vinyl alcohol (EVAL) nanofiber-based chromatographic media for highly efficient adsorption and extraction of proteins. J Colloid Interface Sci. 2019;555:11–21. https://doi.org/10.1016/j.jcis.2019.07.065.

Ma J, Wang X, Fu Q, Si Y, Yu J, Ding B. Highly carbonylated cellulose nanofibrous membranes utilizing maleic anhydride grafting for efficient lysozyme adsorption. Acs Appl Mater Inter. 2015;7(28):15658–66. https://doi.org/10.1021/acsami.5b04741.

Lee SY, Liu B-L, Wu J-Y, Chang Y-K. Egg white lysozyme purification by a stirred cell contactor equipped with a weak ion-exchange nanofiber membrane: process development and scale-up. Food Chem. 2021;338:128144. https://doi.org/10.1016/j.foodchem.2020.128144.

El Khoury G, Khogeer B, Chen C, Ng KT, Jacob SI, Lowe CR. Bespoke affinity ligands for the purification of therapeutic proteins. Pharm Bioprocessing. 2015;3(2):139–52. https://doi.org/10.4155/pbp.14.60.

Honjo T, Hoe K, Tabayashi S, Tanaka T, Shimada J, Goto M, et al. Preparation of affinity membranes using thermally induced phase separation for one-step purification of recombinant proteins. Anal Biochem. 2013;434(2):269–74. https://doi.org/10.1016/j.ab.2012.11.027.

Zou HF, Luo QZ, Zhou DM. Affinity membrane chromatography for the analysis and purification of proteins. J Biochem Biophys Methods. 2001;49(1–3):199–240. https://doi.org/10.1016/s0165-022x(01)00200-7.

Arakawa T, Kita Y, Ejima D, Gagnon P. Solvent modulation of column chromatography. Protein Peptide Lett. 2008;15(6):544–55. https://doi.org/10.2174/092986608784966994.

Nie H-L, Zhu L-M. Adsorption of papain with Cibacron Blue F3GA carrying chitosan-coated nylon affinity membranes. Int J Biol Macromol. 2007;40(3):261–7. https://doi.org/10.1016/j.ijbiomac.2006.08.005.

Ng IS, Song CP, Ooi CW, Tey BT, Lee YH, Chang Y-K. Purification of lysozyme from chicken egg white using nanofiber membrane immobilized with Reactive Orange 4 dye. J Biol Macromol. 2019;134:458–68. https://doi.org/10.1016/j.ijbiomac.2019.05.054.

Suen SY, Liu YC, Chang CS. Exploiting immobilized metal affinity membranes for the isolation or purification of therapeutically relevant species. J Chromatogr B. 2003;797(1–2):305–19. https://doi.org/10.1016/s1570-0232(03)00490-2.

Tan LCM, Chua AJS, Goh LSL, Pua SM, Cheong YK, Ng ML. Rapid purification of recombinant dengue and West Nile virus envelope Domain III proteins by metal affinity membrane chromatography. Protein Expres Purif. 2010;74(1):129–37. https://doi.org/10.1016/j.pep.2010.06.015.

Braemer C, Ekramzadeh K, Lammers F, Scheper T, Beutel S. Optimization of continuous purification of recombinant patchoulol synthase from Escherichia coli with membrane adsorbers. Biotechnol Prog. 2019;35(4):e2812. https://doi.org/10.1002/btpr.2812.

Di Y, Wang W, Zhao Z, Wang M. Solution-blown nylon 6-chitosan core-shell nanofiber for highly efficient affinity adsorption. Polym Adv Technol. 2017;28(7):905–8. https://doi.org/10.1002/pat.3990.

Mustafaoglu N, Kiziltepe T, Bilgicer B. Antibody purification via affinity membrane chromatography method utilizing nucleotide binding site targeting with a small molecule. Analyst. 2016;141(24):6571–82. https://doi.org/10.1039/c6an02145j.

Kosior A, Antosova M, Faber R, Villain L, Polakovic M. Single-component adsorption of proteins on a cellulose membrane with the phenyl ligand for hydrophobic interaction chromatography. J Membr Sci. 2013;442:216–24. https://doi.org/10.1016/j.memsci.2013.04.013.

Fan J, Luo J, Chen X, Wan Y. Facile preparation of salt-tolerant anion-exchange membrane adsorber using hydrophobic membrane as substrate. J Chromatogr A. 2017;1490:54–62. https://doi.org/10.1016/j.chroma.2017.02.016.

Qadir D, Mukhtar H, Keong LK. Mixed matrix membranes for water purification applications. Sep Purif Technol. 2017;46(1):62–80. https://doi.org/10.1080/15422119.2016.1196460.

Himstedt HH, Qian X, Weaver JR, Wickramasinghe SR. Responsive membranes for hydrophobic interaction chromatography. J Membr Sci. 2013;447:335–44. https://doi.org/10.1016/j.memsci.2013.07.020.

Mah KZ, Ghosh R. Paper-based composite lyotropic salt-responsive membranes for chromatographic separation of proteins - ScienceDirect. J Membr Sci. 2010;360(1):149–54. https://doi.org/10.1016/j.memsci.2010.05.016.

Qi H, Cao J, Xin Y, Mao X, Xie D, Luo J, et al. Dual responsive zein hydrogel membrane with selective protein adsorption and sustained release property. Mat Sci Eng C-Mater. 2017;70:347–56. https://doi.org/10.1016/j.msec.2016.09.010.

Salehi SM, Di Profio G, Fontananova E, Nicoletta FP, Curcio E, De Filpo G. Membrane distillation by novel hydrogel composite membranes. J Membr Sci. 2016;504:220–9. https://doi.org/10.1016/j.memsci.2015.12.062.

Lucantonio A, Teresi L, DeSimone A. Continuum theory of swelling material surfaces with applications to thermo-responsive gel membranes and surface mass transport. J Mech Phys Solids. 2016;89:96–109. https://doi.org/10.1016/j.jmps.2016.02.001.

Kursun F, Isiklan N. Development of thermo-responsive poly(vinyl alcohol)-g-poly(N-isopropylacrylamide) copolymeric membranes for separation of isopropyl alcohol/water mixtures via pervaporation. J Ind Eng Chem. 2016;41:91–104. https://doi.org/10.1016/j.jiec.2016.07.011.

Yuan X, Li W, Zhu Z, Han N, Zhang X. Thermo-responsive PVDF/PSMA composite membranes with micro/nanoscale hierarchical structures for oil/water emulsion separation. Colloid Surf A. 2017;516:305–16. https://doi.org/10.1016/j.colsurfa.2016.12.047.

Lin SC, Lin KL, Chiu HC, Lin SY. Enhanced protein renaturation by temperature-responsive polymers. Biotechnol Bioeng. 2000;67(5):505–12. https://doi.org/10.1002/(sici)1097-0290(20000305)67:5%3c505::Aid-bit1%3e3.0.Co;2-c.

Vu A, Qian X, Wickramasinghe SR. Membrane-based hydrophobic interaction chromatography. Sep Sci Technol. 2017;52(2):287–98. https://doi.org/10.1080/01496395.2016.1247865.

Kuczewski M, Fraud N, Faber R, Zarbis-Papastoitsis G. Development of a polishing step using a hydrophobic interaction membrane adsorber with a PER.C6 (R)-derived recombinant antibody. Biotechnol Bioeng. 2010;105(2):296–305. https://doi.org/10.1002/bit.22538.

Fan J, Luo J, Song W, Chen X, Wan Y. Directing membrane chromatography to manufacture alpha(1)-antitrypsin from human plasma fraction IV. J Chromatogr A. 2015;1423:63–70. https://doi.org/10.1016/j.chroma.2015.10.050.

Cordova JC, Sun S, Bos J, Thirumalairajan S, Ghone S, Hirai M, et al. Development of a single-step antibody-drug conjugate purification process with membrane chromatography. J Clin Med. 2021;10(3):552. https://doi.org/10.3390/jcm10030552.

Zhang L, Menkhaus TJ, Fong H. Fabrication and bioseparation studies of adsorptive membranes/felts made from electrospun cellulose acetate nanofibers. J Membr Sci. 2008;319(1–2):176–84. https://doi.org/10.1016/j.memsci.2008.03.030.

Yu B, Luo Y, Zhang X, Usman M, Ahmed A, Shen Y, et al. Preparation of pocket shaped microfiltration membranes with binary porous structures. Soft Matter. 2018;14(42):8660–5. https://doi.org/10.1039/c8sm01637b.

Tafta F, Köhlera R, van Teeffelenb S, Fortunab A, Wolffb M, Reichlb U, et al., editors. Influenza virus capture using membrane chromatography: improving selectivity by matrix design and pseudo-affinity ligand interactions. 2016. https://dc.engconfintl.org/vt_vii/75/.

Wang SS-S, Yang S-M, Hsin A, Chang Y-K. Dye-affinity nanofibrous membrane for adsorption of lysozyme: preparation and performance evaluation. Food Technol Biotech. 2018;56(1):40–50. https://doi.org/10.17113/ftb.56.01.18.5456.

Zia Q, Tabassum M, Meng J, Xin Z, Gong H, Li J. Polydopamine-assisted grafting of chitosan on porous poly (L-lactic acid) electrospun membranes for adsorption of heavy metal ions. Int J Biol Macromol. 2021;167:1479–90. https://doi.org/10.1016/j.ijbiomac.2020.11.101.

Salehi E, Daraei P, Shamsabadi AA. A review on chitosan-based adsorptive membranes. Carbohydr Polym. 2016;152:419–32. https://doi.org/10.1016/j.carbpol.2016.07.033.

Ng IS, Tang MSY, Show PL, Chiou Z-M, Tsai J-C, Chang Y-K. Enhancement of C-phycocyanin purity using negative chromatography with chitosan-modified nanofiber membrane. Int J Biol Macromol. 2019;132:615–28. https://doi.org/10.1016/j.ijbiomac.2019.03.235.

Esmali F, Mansourpanah Y, Farhadi K, Amani S, Rasoulifard A, Ulbricht M. Fabrication of a novel and highly selective ion-imprinted PES-based porous adsorber membrane for the removal of mercury(II) from water. Sep Purif Technol. 2020;250:117183. https://doi.org/10.1016/j.seppur.2020.117183.

Yu M, Renner JN, Duval CE. A lysine-modified polyethersulfone (PES) membrane for the recovery of lanthanides. Front Chem. 2020;8:512. https://doi.org/10.3389/fchem.2020.00512.

Hamzah S, Ali Na, Ariffin MM, Mohammad AW, editors. Characterization study of a highly specific affinity membrane for trypsin purification. 2014;625: 592-+. https://doi.org/10.4028/www.scientific.net/AMM.625.592

Liu L, Luo J, Wan Y, Chen X, Wu Y. Mussel-inspired membrane adsorber with thiol ligand for patulin removal: adsorption and regeneration behaviors. Macromol Mater Eng. 2019;304(6):1800790. https://doi.org/10.1002/mame.201800790.

Wang J, Sproul RT, Anderson LS, Husson SM. Development of multimodal membrane adsorbers for antibody purification using atom transfer radical polymerization. Polymer. 2014;55(6):1404–11. https://doi.org/10.1016/j.polymer.2013.12.023.

Yang H-C, Luo J, Lv Y, Shen P, Xu Z-K. Surface engineering of polymer membranes via mussel-inspired chemistry. J Membr Sci. 2015;483:42–59. https://doi.org/10.1016/j.memsci.2015.02.027.

Sadavarte R, Spearman M, Okun N, Butler M, Ghosh R. Purification of chimeric heavy chain monoclonal antibody EG2-hFc using hydrophobic interaction membrane chromatography: an alternative to protein- A affinity chromatography. Biotechnol Bioeng. 2014;111(6):1139–49. https://doi.org/10.1002/bit.25193.

Zhu J, Sun G. Facile fabrication of hydrophilic nanofibrous membranes with an immobilized metal-chelate affinity complex for selective protein separation. Acs Appl Mater Inter. 2014;6(2):925–32. https://doi.org/10.1021/am4042965.

Fan J, Luo J, Chen X, Wan Y. Polydopamine meets porous membrane: a versatile platform for facile preparation of membrane adsorbers. J Chromatogr A. 2016;1448:121–6. https://doi.org/10.1016/j.chroma.2016.04.063.

Zhao Y, Yang Z, Fan W, Wang Y, Li G, Cong H, et al. Carbon nanotube/carbon fiber electrodes via chemical vapor deposition for simultaneous determination of ascorbic acid, dopamine and uric acid. Arab J Chem. 2020;13(1):3266–75. https://doi.org/10.1016/j.arabjc.2018.11.002.

Khan MK, Luo J, Wang Z, Khan R, Chen X, Wan Y. Alginate dialdehyde meets nylon membrane: a versatile platform for facile and green fabrication of membrane adsorbers. J Mater Chem B. 2018;6(11):1640–9. https://doi.org/10.1039/c7tb02966g.

Hou Y, Brower M, Pollard D, Kanani D, Jacquemart R, Kachuik B, et al. Advective hydrogel membrane chromatography for monoclonal antibody purification in bioprocessing. Biotechnol Prog. 2015;31(4):974–82. https://doi.org/10.1002/btpr.2113.

Yang X, Hsia T, Merenda A, Al-Attabi R, Dumee LF, Thang SH, et al. Constructing novel nanofibrous polyacrylonitrile (PAN)-based anion exchange membrane adsorber for protein separation. Sep Purif Technol. 2022;285:120364. https://doi.org/10.1016/j.seppur.2021.120364.

Liu B-L, Ooi CW, Ng IS, Show PL, Lin K-J, Chang Y-K. Effective purification of lysozyme from chicken egg white by tris (hydroxymethyl)aminomethane affinity nanofiber membrane. Food Chem. 2020;327:127038. https://doi.org/10.1016/j.foodchem.2020.127038.

Chang Y-K, Cheng H-I, Ooi CW, Song CP, Liu B-L. Adsorption and purification performance of lysozyme from chicken egg white using ion exchange nanofiber membrane modified by ethylene diamine and bromoacetic acid. Food Chem. 2021;358:129914. https://doi.org/10.1016/j.foodchem.2021.129914.

Fu Q, Wang X, Si Y, Liu L, Yu J, Ding B. Scalable fabrication of electrospun nanofibrous membranes functionalized with citric acid for high-performance protein adsorption. Acs Appl Mater Inter. 2016;8(18):11819–29. https://doi.org/10.1021/acsami.6b03107.

Ghosh R, Madadkar P, Wu Q. On the workings of laterally-fed membrane chromatography. J Membr Sci. 2016;516:26–32. https://doi.org/10.1016/j.memsci.2016.05.064.

Madadkar P, Sadavarte R, Butler M, Durocher Y, Ghosh R. Preparative separation of monoclonal antibody aggregates by cation-exchange laterally-fed membrane chromatography. J Chromatogr B. 2017;1055:158–64. https://doi.org/10.1016/j.jchromb.2017.04.036.

Madadkar P, Umatheva U, Hale G, Durocher Y, Ghosh R. Ultra-fast separation and analysis of monoclonal antibody aggregates using membrane chromatography. Anal Chem. 2017;89(8):4716–20. https://doi.org/10.1021/acs.analchem.7b00580.

Kawka K, Madadkar P, Umatheva U, Shoaebargh S, Medina MFC, Lichty BD, et al. Purification of therapeutic adenoviruses using laterally-fed membrane chromatography. J Membr Sci. 2019;579:351–8. https://doi.org/10.1016/j.memsci.2019.02.056.

Madadkar P, Nino SL, Ghosh R. High-resolution, preparative purification of PEGylated protein using a laterally-fed membrane chromatography device. J Chromatogr B. 2016;1035:1–7. https://doi.org/10.1016/j.jchromb.2016.09.014.

Kawka K, Wilton AN, Madadkar P, Medina MFC, Lichty BD, Ghosh R, et al. Integrated development of enzymatic DNA digestion and membrane chromatography processes for the purification of therapeutic adenoviruses. Sep Purif Technol. 2021;254:117503. https://doi.org/10.1016/j.seppur.2020.117503.

Chen G, Umatheva U, Alforque L, Shirataki H, Ogawa S, Kato C, et al. An annular-flow, hollow-fiber membrane chromatography device for fast, high-resolution protein separation at low pressure. J Membr Sci. 2019;590:117305. https://doi.org/10.1016/j.memsci.2019.117305.

Ghosh R, Chen G, Umatheva U, Gatt P. A flow distribution and collection feature for ensuring scalable uniform flow in a chromatography device. J Chromatogr A. 2020;1618:460892. https://doi.org/10.1016/j.chroma.2020.460892.

Ghosh R, Chen G, Roshankhah R, Umatheva U, Gatt P. A z(2) laterally-fed membrane chromatography device for fast high-resolution purification of biopharmaceuticals. J Chromatogr A. 2020;1629:461453. https://doi.org/10.1016/j.chroma.2020.461453.

Madadkar P, Mahansaria R, Mukherjee J, Ghosh R. Enhancing the efficiency of disc membrane chromatography modules by using a flow directing layer. J Membr Sci. 2019;580:154–60. https://doi.org/10.1016/j.memsci.2019.03.026.

Borneman Z, Groothuis B, Willemsen M, Wessling M. Coiled fiber membrane chromatography. J Membr Sci. 2010;346(2):327–34. https://doi.org/10.1016/j.memsci.2009.09.054.

Sousa A, Sousa F, Queiroz JA. Advances in chromatographic supports for pharmaceutical-grade plasmid DNA purification. J Sep Sci. 2012;35(22):3046–58. https://doi.org/10.1002/jssc.201200307.

Vicente T, Fabar R, Alves PM, Carrondo MJT, Mota JPB. Impact of ligand density on the optimization of ion-exchange membrane chromatography for viral vector purification. Biotechnol Bioeng. 2011;108(6):1347–59. https://doi.org/10.1002/bit.23058.

Boi C, Dimartino S, Hofer S, Horak J, Williams S, Sarti GC, et al. Influence of different spacer arms on mimetic ligand (TM) A2P and B14 membranes for human IgG purification. J Chromatogr B. 2011;879(19):1633–40. https://doi.org/10.1016/j.jchromb.2011.03.059.

Gieseler G, Pepelanova I, Stuckenberg L, Villain L, Noelle V, Odenthal U, et al. Purification of bone morphogenetic protein-2 from refolding mixtures using mixed-mode membrane chromatography. Appl Microbiol Biot. 2017;101(1):123–30. https://doi.org/10.1007/s00253-016-7784-1.

Yoshimoto N, Itoh D, Isakari Y, Podgornik A, Yamamoto S. Salt tolerant chromatography provides salt tolerance and a better selectivity for protein monomer separations. Biotechnol J. 2015;10(12):1929–34. https://doi.org/10.1002/biot.201400550.

Charcosset C. Purification of proteins by membrane chromatography. J Biotechnol. 1998;71(2):95–110. https://doi.org/10.1002/(sici)1097-4660(199802)71:2%3c95::Aid-jctb823%3e3.0.Co;2-j.

Zamolo L, Salvalaglio M, Cavallotti C, Galarza B, Sadler C, Williams S, et al. Experimental and theoretical investigation of effect of spacer arm and support matrix of synthetic affinity chromatographic materials for the purification of monoclonal antibodies. J Phys Chem B. 2010;114(29):9367–80. https://doi.org/10.1021/jp1017168.

Busini V, Moiani D, Moscatelli D, Zamolo L, Cavallotti C. Investigation of the influence of spacer arm on the structural evolution of affinity ligands supported on agarose. J Phys Chem B. 2006;110(46):23564–77. https://doi.org/10.1021/jp0622278.

Lee PW, Isarov SA, Wallat JD, Molugu SK, Shukla S, Sun JEP, et al. Polymer structure and conformation alter the antigenicity of virus-like particle-polymer conjugates. J Am Chem Soc. 2017;139(9):3312–5. https://doi.org/10.1021/jacs.6b11643.