Abstract

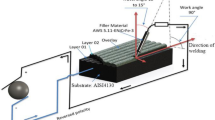

The influence of post-welding heat treatment (PWHT) on the microstructure, hardness, and corrosion behavior of Inconel 625 weld metal deposited by the Electro Slag Strip Cladding (ESSC) Process was investigated. Microstructural characterization was performed by scanning electron microscopy, X-ray diffraction, and transmission electron microscopy. Cyclic polarization technique as per ASTM G 61 to study the pitting potential, potentiostatic method as per ASTM G 150 to determine the critical pitting temperature, and immersion tests according to ASTM G 48 to measure the mass loss were performed to evaluate the corrosion behavior. The results revealed an increase of hardness up to 800 °C followed by a continuous decrease for higher temperatures due to the microstructural changes. The sparse precipitation of γ” observed at 600 °C was replaced by the δ-phase for higher temperatures. At 1000 °C, both γ” and δ phases dissolved, and the microstructure was composed solely of the matrix and coarser carbides. The corrosion test results showed that microstructural characteristics did not alter the corrosion behavior due to the low amount of secondary phases. These results indicate that weld metals obtained by the ESSC Process show suitable microstructure and corrosion properties after PWHT.

Similar content being viewed by others

References

Wasin M, Djukic M (2022) External corrosion of oil and gas pipelines: a review of failure mechanisms and predictive preventions. J Natural Gas Sci Eng 100:104467. https://doi.org/10.1016/j.jngse.2022.104467

Sanny O, Adeleke O, Ukoba K, Ren J, Jen T (2022) Application of machine learning models to investigate the performance of stainless steel type 904 with agricultural waste. J Mater Res Technol 20:4487–4499. https://doi.org/10.1016/j.jmrt.2022.08.076

Silva CC, Albuquerque VHC, Mina EM, Moura EPP, Tavares JMRS (2018) Mechanical properties and microstructural characterization of aged nickel-based alloy 625 weld metal. Mater Trans 49(5):1653–1673. https://doi.org/10.1007/s11661-018-4526-2

Dai T, Wheeling RA, Hartman-Vaeth K, Lippold JC (2019) Precipitation behavior and hardness response of alloy 625 weld overlay under different aging conditions. Weld World 63:1087–1100. https://doi.org/10.1007/s40194-019-00724-1

Shoemaker LE (2005) Alloys 625 and 725. In: Proceedings of the trends in properties and applications – superalloys 718, 625, and derivatives – E.A Loria – TMS. Miner Met Mat Soc. https://doi.org/10.7449/2005/Superalloys_2005_409

Guo LL, Zheng HZ, Liu SH, Li YQ, Feng CY, Xu XD (2016) Effect of heat treatment temperatures on microstructure and corrosion properties of Inconel 625 weld overlay deposited by PTIG. Int J Electrochem Sci 11:5507–5519. https://doi.org/10.20964/2016.07.97

Xu L, Zhang J, Han Y, Zhao L, Jing H (2019) Insights into the intergranular corrosion of overlay welded joints of X65-Inconel625 clad pipe and its relationship to damage penetration. Corr Sci 160:108169. https://doi.org/10.1016/j.corsci.2019.108169

Rajani HRZ, Mousavi SAAA, Madani SF (2013) Comparison of corrosion behavior between fusion cladded and explosive cladded Inconel 625/plain carbon steel bimetal plates. Mater Des 43:467–474. https://doi.org/10.1016/j.matdes.2012.06.053

Guo L, Xiao F, Wang F, Wei Z, Zhang Y (2021) Effect of post-weld heat treatment temperatures on microstructure, intergranular corrosion resistance, and mechanical properties of 4130 steel with Inconel 625 weld overlay. J Fail Anal Preven 21:1775–1783. https://doi.org/10.1007/s11668-021-01225-4

Guo L, Xiao F, Wang F, Wei W, He Y, Luo F (2020) Influence of heat treatments on microstructure, mechanical properties and corrosion resistance of Inconel 625 overlay cladded using PTIG. Mater Res Express 7(9):096517. https://doi.org/10.1088/2053-1591/abb858

Wang N, Shen J, Hu S, Liang Y (2020) Numerical analysis of the TIG arc preheating effect in CMT based cladding of Inconel 625. Eng Res Express 2:015030. https://doi.org/10.1088/2631-8695/ab70e9

Petrzak P, Kowalski K, Blicharski M (2016) Analysis of phase transformations in Inconel 625 alloy during annealing. Acta Phys Polonica A 130(4):1041–14044. https://doi.org/10.12693/APhysPolA.130.1041

He K, Dong L, Wang Q, Zhang H, Li Y, Liu L, Zhang Z (2022) Comparison on the microstructure and corrosion behavior of Inconel 625 cladding deposited by tungsten inert gas and cold metal transfer process. Surf Coat Technol 435:128245. https://doi.org/10.1016/j.surfcoat.2022.128245

Evangeline A, Sathiya P (2019) Cold metal arc transfer (CMT) metal deposition of Inconel 625 superalloy on 316L austenitic stainless steel: microstructural evaluation, corrosion and wear resistance properties. Mater Res Express 6:066516. https://doi.org/10.1088/2053-1591/ab0a10

Abioye TE, McCartney TG, Clare AT (2015) Laser cladding of Inconel 625 wire for corrosion protection. J Mater Process Tech 217:232–240. https://doi.org/10.1016/j.jmatprotec.2014.10.024

Tuominen J, Vuoristo P, Mantyla T, Latokartano J, Vihinen J, Andersson PH (2003) Microstructure and corrosion behaviour of high power diode laser deposited Inconel 625 coatings. J Laser Appl 15:55. https://doi.org/10.2351/1.1536652

Kim JS, Park YI, Lee HW (2015) Effects of heat input on the pitting resistance of Inconel 625 welds by overlay welding. Met Mater Int 21(2):350–355. https://doi.org/10.1007/s12540-015-4245-9

Alvarães CP, Jorge JCF, Souza LFG, Araújo MMC, Farneze HN (2020) Microstructure and corrosion properties of single layer Inconel 625 weld cladding obtained by the electroslag welding process. J Mater Res Technol 9(6):16146–16158. https://doi.org/10.1016/j.jmrt.2020.11.048

Devletlian JH, Gao YP, Zhao QH, Wood WE (1993) Strip cladding of propeller shafts with nickel alloy 625 by electroslag surfacing. J Ship Prod 9(3):173–180

Matias JVS, Lourenço MJC, Jorge JCF, Souza LFG, Farneze HN, Mendes MC, Araújo LS (2021) Microstructure and corrosion properties of the AISI 904L weld cladding obtained by the electro slag process. J Mater Res Technol 15:5151–5164. https://doi.org/10.1016/j.jmrt.2021.10.094

Ban S, Shin Y, Lee SR, Lee H (2016) Corrosion resistance of Inconel 625 overlay welded inside pipes as a function of heat treatment temperature. Int J Electrochem Sci 11:7764–7774. https://doi.org/10.20964/2016.09.22

Gope DK, Chattopadhyaya S (2022) Dissimilar welding of nickel based superalloy with stainless steel: influence of post weld heat treatment. Mater Manufact Proc 37(2):136–142. https://doi.org/10.1080/10426914.2021.1945095

Cortial F, Corrieu JM, Vernot-Loier C (1995) Influence of heat treatments on microstructure, mechanical properties, and corrosion resistance of weld alloy 625. Metall Mater Trans A 26:1273–1286. https://doi.org/10.1007/BF02670621

Floreen S, Fuchs GE, Yang WJ (1994) The metallurgy of 625. In: Superalloys 718, 625, 706 and various derivatives, E.A. Loria, USA, 13-37. https://doi.org/10.7449/1994/SUPERALLOYS_1994_13_37

Lass EA, Stoudt MR, Williams ME, Katz MB, Levine LE, Phan TQ, Gnaeupel-Herold TH, Ng DS (2017) Formation of the Ni3Nb δ-phase in stress-relieved Inconel 625 produced via laser powder-bed fusion additive manufacturing. Metall Mater Trans A 48:5547–5558. https://doi.org/10.1007/s11661-017-4304-6

Zahrani EM, Alfantazi AM (2013) Hot corrosion of Inconel 625 overlay weld cladding in smelting off-gas environment. Met Mat Trans A 44A:4671–4699. https://doi.org/10.1007/s11661-013-1803-y

Guo Q, Li Y, Qian J, Yu H, Chen C (2017) Study of the pitting corrosion at welding joints of Inconel 625 alloy under high temperature and high H2S/CO2 partial pressure. Int J Electrochem Sci 12:8929–8943. https://doi.org/10.20964/2017.10.46

Lourenço JC, Souza LP, Faria MIST, Nunes CA, Tomachuk C, Baker MA (2021) Influence of the iron content on the microstructure and electrochemical behavior of as-cast modified Inconel 625. Corr Sci 193:109892. https://doi.org/10.1016/j.corsci.2021.109892

Alvarães CP, Sandes SS, Jorge JCF, Souza LFG, Araújo Mendes MC, Dille J (2020) Microstructural characterization of Inconel 625 nickel-based alloy weld cladding obtained by electroslag welding process. J Mater Eng Perform 29:3004–3015. https://doi.org/10.1007/s11665-020-04861-3

Volpi A, Serra G (2018) Weld overlay of highly corrosion resistant nickel, chromium, molybdenum alloys UNS N06059 on low alloy equipment operating at high temperature. In: Proceedings of the ASME 2018 symposium on elevated temperature application of materials for fossil, nuclear, and petrochemical industries ETAM2018 April 3–5. ASME; 2018, ETAM2018–6715. Seattle, WA, USA, Paper ETAM2018–6715. https://doi.org/10.1115/ETAM2018-6715

Sandes SS, Alvarães CP, Mendes MC, Araujo LS, Souza LFG, Jorge JCF (2016) Avaliação de revestimentos de liga de níquel 625 depositados pelo processo eletroescoria. Sold Insp 21(4):417–427. https://doi.org/10.1590/0104-9224/SI2104.03

American Welding Society (2005) Specification for nickel and nickel-alloy bare welding electrodes and rods, Standard AWS A5.14/A5.14M:2005, Miami, USA, March, 2005, 1–7

NORSOK (2016) Welding and inspection of piping, Standard M-601:2016, Oslo, Norway, April, 2016, 1–34

American Society for Testing and Materials (2009) Standard test method for conducting cyclic potentiodynamic polarization measurements for localized corrosion susceptibility of iron-, nickel-, or cobalt-based alloys. Standard ASTM G61-09, West Conshohocken, USA, May, 2009, 1–5

American Society for Testing and Materials (2013) Standard test method for electrochemical critical pitting temperature testing of stainless steels. Standard ASTM G150-13, West Conshohocken, USA, May, 2013, 1–13

American Society for Testing and Materials (2009) Standard test methods for pitting and crevice corrosion resistance of stainless steels and related alloys by use of ferric chloride. Standard ASTM G 48-03, West Conshohocken, USA, May, 2009, 1–11

Lorenzoni RA, Gasparini RP, Santos AC, Luz TS, Macêdo MCS (2019) A study on the intergranular corrosion and pitting resistance of Inconel 625 coating by PTA-P. Corr Eng Sci Tech 54(1):62–74. https://doi.org/10.1080/1478422X.2018.1533677

Abbasi H, Derakhshandeh-Haghighi R (2022) The effect of filler metal on microstructure and mechanical performance of GTAW inconel 625 at room and elevated temperature. Int J Pres Vessels Pip 199:104760. https://doi.org/10.1016/j.ijpvp.2022.104760

Baldan R, Silva AAAP, Tanno TM, Costa ET, Brentegani JVN, Couto AA (2020) Experimental investigation of delta phase precipitation in Inconel 625 superalloy aged at 550, 625 and 725 °C. Mater Res. 23(1):e20190546. https://doi.org/10.1590/1980-5373-MR-2019-0546

Tumer M, Karahan T, Mert T (2020) Evaluation of microstructural and mechanical properties of dissimilar Inconel 625 nickel alloy–UNS S32205 duplex stainless steel weldment using MIG welding. Weld World 64:21–35. https://doi.org/10.1007/s40194-019-00825-x

Dinda GP, Dasgupta AK, Mazumder J (2009) Laser aided direct metal deposition of Inconel 625 superalloy: microstructural evolution and thermal stability. Mater Sci Eng A 509:98–104. https://doi.org/10.1016/j.msea.2009.01.009

Xing X, Di X, Wang B (2014) The effect of post-weld heat treatment temperature on the microstructure of Inconel 625 deposited metal. J Alloys Comp 593:110–116. https://doi.org/10.1016/j.jallcom.2013.12.224

Dai Z, Su Y, Yang T, Wang Y, Liang X, Wei Z, Zhang X (2022) Study on intermediate temperature brittleness mechanism of Inconel 625 deposited metal. J Mater Res Technol 17:1812–1821. https://doi.org/10.1016/j.jmrt.2022.01.143

Cao GH, Sun TY, Wang CH, Li X, Liu M, Zhang ZX et al (2018) Investigation of γ’, γ” and δ precipitated in heat-treated Inconel 718 alloy fabricated by selective laser melting. Mater Charact 136:398–406. https://doi.org/10.1016/j.matchar.2018.01.006

Rong Y, Chen S, Hu G, Gao M, Wei RP (1999) Prediction and characterization of variant electron diffraction patterns for γ” and δ precipitates in an Inconel 718 alloy. Met Mater Trans A 30A:2297–2303. https://doi.org/10.1007/s11661-999-0239-x

Najafi M, Moshkbar Bakhshayesh M, Farzadi A (2021) Microstructure and phase analysis of multilayer Ni–Cr–Mo clad for corrosion protection. Trans Indian Inst Met 74:1663–1672. https://doi.org/10.1007/s12666-021-02256-z

Kreitcberg A, Brailovski V (2022) Effect of Fe and C contents on the microstructure and high-temperature mechanical properties of IN625 alloy processed by laser powder bed fusion. Mater 15:6606. https://doi.org/10.3390/ma15196606

Yin Y, Li H, Pan S, Zhang J, Han Q, Yang S (2022) Electrochemical behaviour of passivation film formed on SLM-fabricated Hastelloy X superalloy surface in 10 wt% NaNO3 solution. Corrosion Science 206:110494. https://doi.org/10.1016/j.corsci.2022.110494

Frazão I, Magnabosco R, Delblanc A (2017) Comparison between stainless steels and nickel alloys through pitting corrosion resistance electrochemical tests. Mater Res 24(4):e20200386. https://doi.org/10.1590/1980-5373-MR-2020-0386

Klapper HS, Zadorozne NS, Rebak RB (2017) Localized corrosion characteristics of nickel alloys: a review. Acta Metall Sin (Engl Lett) 30:296–305. https://doi.org/10.1007/s40195-017-0553-z

Mishra A, Richesin MD, Rebak RB (2015) Localized corrosion study of Ni-Cr-Mo alloys for oil and gas applications. In: Proceedings of the CORROSION 2015, Dallas, Texas, March 2015. Paper Number: NACE-2015-5802

Gittos MF, Gooch TG (1996) Effect of iron dilution on corrosion resistance of Ni-Cr-Mo alloy cladding. British Corr J 31(4):309–314. https://doi.org/10.1179/bcj.1996.31.4.309

Han JW, Jung SH, Cho H, Lee HW (2018) Investigation of the weld properties of Inconel 625 based on Nb content. Int J Electrochem Sci 13:2829–2841. https://doi.org/10.20964/2018.03.01

Banovic SW, Dupont JN, Marder AR (2002) Dilution and microsegregation in dissimilar metal welds between super austenitic stainless steel and nickel base alloys. Sci Technol Weld Join 7:374–383. https://doi.org/10.1179/136217102225006804

Chattopadhyay P, Van der Mee V, Zhang Z (2019) Hybrid electroslag cladding (H-ESC): an innovation in high speed electroslag strip cladding. Weld World 63:663–672. https://doi.org/10.1007/s40194-018-00692-y

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

Manuel Joaquim de Castro Lourenço—formal analysis; investigation; validation; roles/writing—original draft; and writing—review & editing.

Jorge Carlos Ferreira Jorge—conceptualization, methodology, project administration, and writing—reviewing and editing.

Luís Felipe Guimarães de Souza—formal analysis, investigation, supervision, validation, and writing—review and editing.

Matheus Campolina Mendes—formal analysis, investigation, methodology, validation, and writing—review and editing.

Humberto Nogueira Farneze—formal analysis, investigation, methodology, validation, and writing—review and editing.

Leonardo Sales Araújo —formal analysis, investigation, methodology, validation, and writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lourenço, M.J.C., Jorge, J.C.F., de Souza, L.F.G. et al. Microstructure evolution, hardness response, and corrosion resistance of Inconel 625 weld overlay obtained by the ESSC process after post-welding heat treatments. Int J Adv Manuf Technol 127, 3357–3369 (2023). https://doi.org/10.1007/s00170-023-11752-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11752-z