Abstract

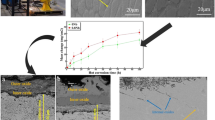

Ni–Cr–Mo clads are commonly used on carbon steels in the oil and gas industry due to the high resistant corrosion. In this study, a three-layer Ni–Cr–Mo clad was deposited using the GMAW process. The welding current of 200 A, the welding speed of 35 cm/min, and the electrode extension of 20 mm, as well as the torch angle of 25°, are utilized to obtain a low dilution. The results showed that Fe content in the second and third layers of the clad was below 2 wt%. The segregation of Nb and Mo to interdendritic regions contributed to the formation of secondary phases, such as Laves and MC carbide precipitates. The results of chemical analysis across some dendrites and interdendritic regions confirmed that the contents and distribution of secondary phases were insignificant. Also, the transition region where the chemical composition significantly changes to reach the composition of the first layer of the clad is apparent. The microstructure of this region changes from the planar to cellular. The corrosion behavior of the clad was investigated, and it was found that corrosion resistance is not affected when the Fe content is restricted to below 2%. A passive layer consisting of Mo, Nb, Ni and Cr with O is formed on the corroded surface.

Similar content being viewed by others

References

Guo L, Zheng H, Liu S, Li Y, Feng C, and Xu X, Int J Electrochem Sci 11 (2016) 5507.

Cuevas-Arteagaa C, Verhelstb D, and Alfantazia A, ECS Trans 28 (2010) 61.

Xing X, Xinjie D, and Baosen W, J Alloys Compd 593 (2014) 110.

Lippold J C, Kiser S D, and DuPont J N, Welding Metallurgy and Weldability of Nickel-Base Alloys, 1st edn, John Wiley & Sons Inc, New York (2011).

Petrzak P, Kowalski K, and Blicharski M, Acta Phys Pol A 130 (2016) 1041.

Razmus-Gornikowska M, and Blicharski M, Arch Metall Mater 60 (2015) 2599.

Silva C C, Miranda H C, Motta M F, Farias J P, Afonso C R M, and Ramirez A J, J Mater Res Technol 2 (2013) 228.

Elango P, Balaguru S, Indian J Sci Technol 8 (2015) 1.

Ban S, Shin Y T, Lee S R, and Lee H, Int J Electrochem Sci 11 (2016) 7764.

Jung E, and Lee H, Int J Electrochem Sci 11 (2016) 7125.

Kalivodova J, Baxter D, Schutze M, and Rohr V, Mater Corros 59 (2008) 367.

Banovic S W, Dupont I N, and Marder A, Metall Mater Trans B 32 (2001) 1171.

Shihab S K, Mohamed R M, and Mubarek E M, Mater Today Proc 16 (2019) 816.

Palani P K, and Murugan N, Int J Adv Manuf Technol 30 (2006) 669.

ASTM E407-07, Standard Practice for Microetching Metals and Alloys, ASTM International, Pennsylvania (2015).

Razmus-Gornikowska M, Cieniek L, Blicharski M, and Kusinski J, Arch Metall Mater 59 (2014) 1081.

Razmus-Gornikowska M, and Blicharski M, Arch Metall Mater 62 (2017) 787.

Araujo A A D, Bastian F L, and Castrodeza E M, Fatigue Fract Eng Mater Struct 39 (2016) 1477.

Alexandrov B T, Lippold J C, Sowards J W, Hope A T, and Saltzmann D R, Weld World 57 (2013) 39.

Sandes S S, Alvaraes C P, Mendes M C, Araujo L S D, Souza L F G D, and Jorge J C F, Weld Int 32 (2017) 179.

Zahran E M, and Alfantazi A M, Metall Mater Trans A 44 (2013) 4671.

Dupont J N, Banovic S W, and Marder A R, Weld J 82 (2003) 125.

Petrzak P, Blicharski M, Dymek S, and Solecka M, Solid State Phenom 231 (2015) 113.

Kim J S, and Lee H, Metall Mater Trans A 47 (2016) 6109.

Radhakrishna C H, and Rao K P, J Mater Sci 32 (1997) 1977.

International Standard NACE MR0175/ISO 15156, Petroleum and Natural Gas Industries Materials for Use in H2S-Containing Environments in Oil and Gas Production, NACE International, Houston (2003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Najafi, M., Moshkbar Bakhshayesh, M. & Farzadi, A. Microstructure and Phase Analysis of Multilayer Ni–Cr–Mo Clad for Corrosion Protection. Trans Indian Inst Met 74, 1663–1672 (2021). https://doi.org/10.1007/s12666-021-02256-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02256-z