Abstract

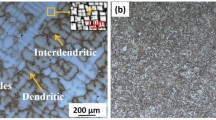

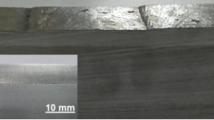

In the present study, the effect of the post weld heat treatment (PWHT) on mechanic and electrochemical behavior of weld overlay Inconel 182/AISI 4130 substrate using shielded metal arc welding (SMAW) process is investigated. The PWHT was carried out at 640°C for 3 hours under oxidant atmosphere. No apparent change was observed in the substrate microstructure after PWHT. Besides, the microstructure of the Inconel 182/AISI 4130 substrate interface was mainly composed of column Ni-γ grains that became coarser after PWHT. The energy dispersive X-ray (EDS) analysis showed that the diffusion gradient of Fe, Cr and Ni elements, from the melting limits toward the type II boundary near the interface, was more prominent after PWHT. Correspondingly, it was found that the adoption of PWHT was favorable to decrease the hardness mismatch between the Inconel 182 overlay and the AISI 4130 substrate. The effect of the PWHT on the tribological behavior of the Inconel 182 overlay was evaluated through a pin-on-disk test. The results showed an adhesive wear mechanism in both samples (as-welded and post-heat-treated) with severe plastic deformation, resulting in relatively higher volume loss in in both conditions. The electrochemical behavior of Inconel 182 overlay and the AISI 4130 substrate in H2SO4 solution revealed that the corrosion potential. (Ecorr), the current density (Icorr) and the corrosion rate were significantly enhanced after PWHT which considerably reduced the galvanic corrosion.

Similar content being viewed by others

References

C. Han, X. Yang, J. Zhang, X. Huang, Study of the damage and failure of the shear ram of the blowout preventer in the shearing process. Eng. Fail. Anal. 58, 83–95 (2015)

DL BOP, “High-pressure annular BOP.” CAMERON A Schloumberger company DRL-1007, (2016)

C. Han, J. Zhang, Study on well hard shut-in experiment based on similarity principle and erosion of ram rubber. Eng. Fail. Anal. 32, 202–208 (2013)

S. Metals, High-performance alloys for resistance to aqueous corrosion. SM Aqueous Corrosion Book. 28, 68 (2000)

C.W. Lyons, G.J. Plisga, Standard Handbook of Petroleum & Natural Gas Engineering, 2nd edn (Berlin, Springer, 2005)

A. Specification, Specification for wellhead and christmas tree equipment. API 6A. 552(3), 10 (2010)

BOP and Riser Recertification OEM recertification for maximized asset life BOP Recertification Program. CAMERON A Schloumberger company DRL-1002, (2016)

D.W. Rathod, S. Pandey, P.K. Singh, R. Prasad, Materials science & engineering a experimental analysis of dissimilar metal weld joint : ferritic to austenitic stainless steel. Mater. Sci. Eng. A. 639, 259–268 (2015)

B. Alexandrov, J. Lippold, J. Sowards, A. Hope, D. Saltzmann, Fusion boundary microstructure evolution associated with embrittlement of Ni–base alloy overlays applied to carbon steel. Weld. World. 57, 11 (2012)

R. Dehmolaei, M. Shamanian, A. Kermanpur, Microstructural characterization of dissimilar welds between alloy 800 and HP heat-resistant steel. Mater. Charact. 59(10), 1447–1454 (2008)

D. Rathod, S. Pandey, S. Aravindan, P. Singh, Diffusion control and metallurgical behavior of successive buttering on SA508 steel using Ni-Fe alloy and Inconel 182. Metallogr. Microstruct. Anal. ASM Int. 5, 450–460 (2016)

C. Sudha, V.T. Paul, S. Saroja, M. Vijayalakshmi, Microstructural changes in grade 22 ferritic steel clad successively with Ni-based and 9Cr filler metals. Weld. Int. 89, 13 (2010)

W.T. Tsai, C.-L. Yu, J.-I. Lee, Effect of heat treatment on the sensitization of Alloy 182 weld. Scripta Mater. 53(5), 505–509 (2005)

G. Bao, K. Shinozaki, S. Iguro, M. Inkyo, Y. Mahara, H. Watanabe, Influence of heat treatments and chemical composition on SCC susceptibility during repairing procedure of overlaying of Inconel 182 by laser surface melting. Sci. Technol. Weld. Joining. 10(6), 706–716 (2005)

N. Venkateswararao, G. Madhusudhan Reddy, S. Nagarjuna, Weld overlay cladding of high strength low alloy steel with austenitic stainless steel–structure and properties. Mater. Des. 32(4), 2496–2506 (2011)

A. Brown, Weld overlay cladding–the solution to pump corrosion? World Pumps. 2005(469), 50–53 (2005)

L. Guo, Effect of heat treatment temperatures on microstructure and corrosion properties of Inconel 625 weld overlay deposited by PTIG. Int. J. Electrochem. Sci. 11, 5507–5519 (2016)

Steels for Oil- and Gas- Exploration Providing special steel solutions. Deutsche Edelstahlwerke Gmbh

G. Gittos, M. Gooch, The interface below stainless steel and nickel-alloy claddings. Carbon. 2, 4 (1992)

D. Bourgeois, Hydrogen Assisted Crack in Dissimilar Metal Welds for Subsea Service Under Cathodic Protection (The Ohio State University, Ohio, 2015)

X. Xing, X. Di, B. Wang, The effect of post-weld heat treatment temperature on the microstructure of Inconel 625 deposited metal. J. Alloy. Compd. 593, 110–116 (2014)

T. Nelson, J. Lippold, M. Mills, Investigation of boundaries and structures in dissimilar metal welds. Sci. Technol. Weld. Joining. 3(5), 249–255 (1998)

J. Frei, B.T. Alexandrov, M. Rethmeier, Low heat input gas metal arc welding for dissimilar metal weld overlays part III: hydrogen-assisted cracking susceptibility. Weld. World. 63(3), 591–598 (2019)

T. Dai, J.C. Lippold, The effect of postweld heat treatment on hydrogen-assisted cracking of 8630/Alloy 625 overlay. Weld. World. 62(3), 581–599 (2018)

G. Bao, M. Yamamoto, K. Shinozaki, Precipitation and Cr depletion profiles of Inconel 182 during heat treatments and laser surface melting. J. Mater. Process. Technol. 209(1), 416–425 (2009)

V. Tandon, M.A. Thombre, A.P. Patil, R.V. Taiwade, H. Vashishtha, Effect of heat input on the, microstructural mechanical, and corrosion properties of dissimilar weldment of conventional austenitic stainless steel and low-nickel stainless steel. Metallogr. Microstruct. Anal. 9(5), 668–677 (2020)

A. Shariatpanahi, H. Farhangi, Microstructure and mechanical properties of dissimilar ferritic and austenitic steel joints with an intermediate Inconel-182 buttering layer. Adv. Mater. Res. 6, 449–456 (2010)

H.E. Emre, R. Kaçar, Effect of post weld heat treatment process on microstructure and mechanical properties of friction welded dissimilar drill pipe. Mater. Res. 18, 503–508 (2015)

K. Dawson, Dissimilar Metal Welds (Citeseer, London, 2012)

J.C. Lippold, Welding Metallurgy and Weldability (Wiley, London, 2014)

L. Larabi, Y. Harek, Effect of iodide ions on corrosion inhibition of mild steel in 0.5 M H2SO4 by poly (4-vinylpyridine). Portugaliae Electrochimica Acta. 22(3), 227–247 (2004)

Acknowledgements

The authors gratefully acknowledge the Research Center in Industrial Technologies (CRTI) for its financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Allou, D., Ould Brahim, I., Cheniti, B. et al. Effect of Post Weld Heat Treatment on Microstructure and Mechanical Behaviors of Weld Overlay Inconel 182 on 4130 Steel Substrate Using SMAW Process. Metallogr. Microstruct. Anal. 10, 567–578 (2021). https://doi.org/10.1007/s13632-021-00773-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-021-00773-3