Abstract

In assembly processes, collaborative robots (cobots) can provide valuable support to improve production performance (assembly time, product quality, worker wellbeing). However, there is a lack of models capable of evaluating cobot deployment and driving decision-makers to choose the most cost-effective assembly configuration. This paper tries to address this gap by proposing a novel cost model to evaluate and predict assembly costs. The model allows a practical and straightforward comparison of different potential assembly configurations in order to guide the selection towards the most effective one. The proposed cost model considers several cost dimensions, including manufacturing, setup, prospective, retrospective, product quality and wellbeing costs. The cost estimation also considers learning effects on assembly time and quality, particularly relevant in low-volume and mass customised productions. Three real manufacturing case studies accompany the description of the model.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Major advances in robotics have made it possible to replace humans with automated systems in many production processes. Until a few years ago, a common goal of manufacturing managers was to develop so-called automated factories, i.e. factories where humans supervise the work of automated equipment performing all the operations necessary for producing goods. This paradigm achieved fruitful results in contexts based on the production of large volumes of standardised products since the financial investment in automated production lines was quickly repaid over time by lower production costs and higher production capacity.

Nowadays, most industrial sectors are experiencing an increasing demand for mass-customised and servitised products, i.e. market goods modified to satisfy specific customer needs [1, 2].

Mass customisation and the resultant increase in product variety urge the development of modern manufacturing systems combining the flexibility and personalisation of custom-made products with the low unit costs [3,4,5]. In this context, total automation is not always the most economically, organisationally and socially efficient choice [6].

The implementation of collaborative robots (cobots) can be advantageous in contexts where a high degree of flexibility is required [7] since it consents the employment of “hybrid” automation in which the strengths of robots and humans are combined [8,9,10]. Traditional industrial robots are usually isolated from workers to avoid physical contact with humans. On the contrary, cobots are cooperating robots that can work safely with human workers in a shared workspace [11]. Moreover, cobots are less expensive than traditional industrial robots and are easier and faster to reprogramme and move, allowing greater flexibility of use. These characteristics also enable cobots to be employed by small- and medium-sized companies where low volumes are produced and where the amount of available budget for investment is limited.

Cobots proved to be particularly performant in supporting humans in assembly tasks since they can set up precisely repeatable and monotonous tasks (e.g., bolting, nut driving, part fitting, insertion), consequently reducing the physical and mental workload of the operators and increasing performances in terms of productivity and quality [12].

While cobots offer significant advantages; their deployment is still limited in manufacturing processes with high collaboration potential. Assembly is a typical process where collaborative robotics could provide substantial benefits, but its diffusion is limited by technological immaturity and lack of design tools helpful in promoting its deployment. Manufacturers are often faced with the choice of which assembly configuration to adopt. For this purpose, however, there is a lack of tools to guide decision-makers towards efficient decisions.

In order to bridge this gap, the present study tried to answer the following research questions (RQs):

(RQ1)When is it cost-effective to introduce a collaborative robot in an assembly process?

(RQ2)What are the main components of the assembly cost that a decision-maker must take into account?

Trying to address these questions, this paper provides a cost model capturing the most relevant decision drivers for the choice of the most cost-effective assembly configuration. The model shows how production volume, assembly lot sizes, quality requirements, technology and wellbeing costs influence the decision on the selection of assembly configuration. Learning processes that influence assembly performance in terms of productivity and defects are included in the model.

The formulation of the model is intended to be general, as it can be used for different assembly settings, and practical, since it introduces some reasonable approximations simplifying the evaluation process.

The remainder of the paper is organised as follows. Section 2 introduces the conceptual background of this study. Section 3 describes the proposed cost model. Section 4 provides recommendations for the production throughput analysis. Three case studies in different manufacturing contexts are presented in Section 5. Finally, the concluding section summarises the contributions of the work, its limitations and possible future research.

2 Conceptual background

2.1 Collaborative robots

The concept of a collaborative robot is not new: More than 25 years ago, Colgate [13] defined the term cobot (short for collaborative robot) as a passive mechanical device used to aid humans in solving industrial tasks. Over the years, the concept has evolved and been enriched with additional elements. Table 1 shows some differences between traditional industrial robots and cobots.

In addition to the technical characteristics listed in Table 1, other elements differentiate roles and operations performed by cobots and industrial robots. According to Gil-Vilda et al. [14], cobots should satisfy the following requirements to achieve effective collaboration with humans: (i) mobility, i.e. the ability to easily move the cobot in the production plant,(ii) intelligence, i.e. the awareness of the resources and job characteristics, and their implications; (iii) connectivity, i.e. human–cobot communication, and cobot system communication; (iv) actuation, i.e. the ability to develop safe and dynamic trajectories; and (v) human-centricity, the support to the human operator from the physical, mental and psychosocial point of view. These features allow cobots to interact closely with operators and assist them in their activities.

The study of the technical aspects related to collaborative robotics is often accompanied by studying the human and social factors strongly impacted by the new technology [8, 9]. In these regards, Gervasi et al. [15] proposed a conceptual framework to assess HRC composed of 8 latent dimensions: autonomy, information exchange, team organisation, adaptivity and training, task, human factors, ethics and cybersecurity.

The cobot market is rapidly expanding because of their flexibility, ease of use and affordability. In industrial contexts, cobots are deployed for performing tasks of packing, assembling, palletising, welding, handling material, inspecting parts and products, loading/unloading machines, part cleaning, bin picking and kitting [16]. To date, however, the collaborative features of cobots are not fully exploited: cobots are often used to perform simple repetitive tasks with very limited interactions with human operators. A possible reason for this might be found in the lack of practical and quantitative tools capable of demonstrating the benefits of the technology in new application contexts.

2.2 Assembly operations and cobots

Assembly is the operation where component parts and subassemblies are integrated together to obtain the end manufactured goods (Hu et al., 2011b). Assembly lines usually consist of many workstations in charge of carrying out a specific set of tasks, and the product moves from one workstation to the next in a well-defined order [17].

Assembly tasks can be performed (i) manually by human operators, (ii) in collaboration between human operators and collaborative robots, or (iii) exclusively by robots specifically designed and programmed [18] (see Fig. 1).

Some assembly tasks still require the flexibility and dexterity of human operators. These characteristics make the human element still a vital part of assembly lines [19]. Consider, for example, the final assembly of a car that is still mainly performed by human operators,the assembly tasks require a dexterity that existing robotic systems are unable to satisfy [20].

The combination of a human operator’s flexibility, dexterity and intelligence with the strength and precision of a robot allows for more efficient and effective assembly processes and improved worker wellbeing [21].

2.3 Evaluation and cost modelling of cobot implementation

A key aspect concerning the implementation of collaborative robots in industrial processes is the evaluation and prediction of production costs. In this view, some attempts have been made to define practical approaches and economic models to assess cobot deployment. Table 2 compares the state of the art on the topic comparing the different dimensions of analysis considered in the proposed models.

Bukchin and Tzur [17] developed a heuristic algorithm for the problem of designing a flexible assembly line when several equipment alternatives are available. The objective was to minimise total equipment costs.

Takata and Hirano [22] proposed a method for planning human and robot allocation in hybrid assembly systems to select the solution that minimises the expected total production cost, including robot investment and labour cost.

Fast-Berglund et al. [23] investigated the deployment of cobots for O-ring assembly applying the methodology Dynamo + + for measurement and analysis of the level of automation (cognitive and physical), cycle time and quality.

Dalle Mura and Dini [24] presented a genetic algorithm to approach the assembly line balancing problem in the case of human–robot collaborative work. The aim of the proposed approach was the minimisation of: (i) the assembly line cost, evaluated according to the number of workers and equipment on the line, (ii) the number of skilled workers on the line and (iii) workers energy expenditures.

Li et al. [25] addressed the cost-oriented assembly line balancing problem with collaborative robots, where several different types of collaborative robots with varying costs of purchasing are available. A multi-objective mixed-integer programming model was developed to minimise the cycle time and the total collaborative robot purchasing cost.

Fager et al. [26] presented a model aiming at supporting economic assessment of cobot implementation considering operators, equipment and quality costs. The model includes the relative cost difference between a manual and a cobot-supported process.

Peron et al. [27] proposed a decision support system based on tactical-level variables (i.e. throughput, operator and equipment cost, operation time and type).

Cohen et al. [12] presented a summary of the major considerations related to cobot acquisition and deployment and provided a productivity analysis procedure that supports cobot acquisition and deployment decisions. Their work presented a computational technique to analyse and support this decision for a single workstation per se and for a station in an assembly line.

The presented papers address the problem of economic evaluation of cobot implementation by focusing on individual aspects or specific application contexts. A general cost model capable of including all cost dimensions is still missing.

The next section presents a proposal of a more general cost model to support assembly designers and managers in analysing the convenience of introducing cobots into a production line.

3 A general cost model

To support the introduction of cobots in assembly production lines, this section introduces a general cost model aimed at estimating the unit assembly costs. The model can support decision-makers in choosing the most cost-effective assembly configuration by taking into account relevant elements defining the total assembly cost of a single unit. The model is designed to be applied in production contexts characterised by small lot production. In particular, it considers the learning processes of human operators, both from the productivity and product quality point of view. Nevertheless, the model can also be successfully applied in mass production, characterised by large volumes of standardised products.

3.1 Notation

The following notations are used in the remainder of the paper:

- \(i\):

-

Assembly configuration (for example: i={manual, collaborative, automated})

- \({C_A}_i\):

-

Unit assembly cost (€/unit)

- \({C_m}_i\):

-

Unit manufacturing costs (€/unit)

- \({C_s}_i\):

-

Unit setup costs (€/unit)

- \({C_{PC}}_i\):

-

Unit prospective costs (€/unit)

- \({C_{RC}}_i\):

-

Unit retrospective costs (€/unit)

- \({C_q}_i\):

-

Unit quality costs (€/unit)

- \({C_w}_i\):

-

Unit wellbeing costs (€/unit)

- \({c}_o\):

-

Cost of operative assembly time (€/hours)

- tai:

-

Operative assembly time (hours)

- \(t{(n)}_i\):

-

Operative assembly time for the n-th lot unit (hours)

- \(t{(1)}_i\):

-

Operative time for the 1st lot unit (hours)

- \({\overline{t_a}}_i\):

-

Average unit assembly time (hours)

- \({t_s}_i\):

-

Setup time attributable to the individual assembly operation (hours)

- \({T_s}_i\):

-

Total time required to setup the workstation. (hours)

- \({c_s}_i\):

-

Cost of setup time (€/hour)

- \({b}_i\):

-

Productivity leaning factor

- \({\varphi}_i\):

-

Productivity learning percentage ([0;1])

- \({K}_i\):

-

Total life-cycle cost of investments (€)

- \({v}_i\):

-

Service life of the equipment (years)

- \(\overline{N}\):

-

Estimated lot size (unit)

- \(L\):

-

Estimated number of lots processed in a year

- \({\overline{d}}_{i}\):

-

Average defectiveness ([0;1])

- \(d{(n)}_i\):

-

Defectiveness related to the n-th lot unit ([0;1])

- \(d{(1)}_i\):

-

Defectiveness related to the 1st lot unit ([0;1])

- \({q}_i\):

-

Quality learning factor

- \({\vartheta}_i\):

-

Quality learning percentage ([0;1])

- \({c}_d\):

-

Average cost of a defective unit (€/unit)

- \({RC}_{TOT_i}\):

-

Total annual retrospective costs (€)

- \({CW}_{TOT_{MAX}}\):

-

Maximum wellbeing costs (€)

- \({\gamma}_i\):

-

Wellbeing costs reduction factor ([0;1])

- \({t}_{ws}\):

-

Duration of the work session (hour)

- \({n}_{ws}\):

-

Number of work sessions in a working day

- \({e}_{ws}\):

-

Efficiency in the use of the production resources (workforce and equipment) ([0;1])

- \(WD\) :

-

Number of working days in a year

Section 3.5 introduces some guideline for estimating model parameters.

3.2 Model assumptions

Before developing the model, basic assumptions and features associated with modelling problem are provided:

-

a.

In order to perform the assembly tasks, a specific set of equipment is required. Equipment costs vary according to the assembly configuration. Equipment costs are related to the overall expenditure arising in their entire life cycle (purchase, operating costs, maintenance, etc.).

-

b.

The process throughput is ex-ante predefined.

-

c.

The duration of the assembly task is deterministic and depends on the assembly configuration chosen. The implementation of an automatic or collaborative robotic systems can reduce operative time [28,29,30].

-

d.

It is possible to estimate model inputs using (i) pre-tests, (ii) historical data from similar previous projects/implementations and (iii) the experience of the equipment/technology suppliers (see Section 3.5)

-

e.

The defectiveness of the assembly process is deterministic and depends on the assembly configuration. The implementation of automatic or collaborative robotic systems can reduce assembly defectiveness [28,29,30].

3.3 Model formulation

The proposed model for assembly costs considers six different cost components:

-

Manufacturing costs (\({C}_{m}\)): referring to the cost of the time during which the human operator performs assembly operations.

-

Setup costs (\({C}_{s})\): referring to the cost of the time during which the human operator setup the assembly station between one production lot and the next.

-

Prospective costs (\({C}_{PC})\): referring to the acquisition of the relevant equipment required to perform the assembly process.

-

Retrospective costs (\({C}_{RC})\): referring to the costs that will still occur if the currently implemented assembly configuration is modified.

-

Product quality costs (\({C}_{q}\)): referring to the costs arising from the defectiveness of the assembly process.

-

Wellbeing cost (\({C}_{w}\)): referring to the costs resulting from excessive physical and cognitive workload for operators.

Similar to other analytical models in which the cost estimation is decomposed into a sum of multiple components [31], the unit cost of assembly in the \(i\) th assembly configuration can be calculated as follows:

3.3.1 Manufacturing costs

Unit manufacturing costs (\({C}_{m})\) can be calculated as the product of the cost of operative assembly time (\({c}_{o}\)) and the required operative assembly time (\({t}_{a}\)):

The operative assembly time (\({t}_{a}\)) is influenced by the number of tasks involved in the assembly process and their complexity. In mass productions, the assembly time can be approximated as a constant; it converges to a specific standard time (\({t}_{std}\)) as the number of units produced increases. Conversely, in low-volume productions (small lots), the assembly time is strongly influenced by the learning processes, and the standard time is not reached. The smaller the production lots, the more significant the impact of learning processes on average assembly time.

According to one of the prevalent mathematical model, learning processes are described by a power model [32]. The time required to produce the \(n\) th lot unit in the \(i\) th assembly configuration is equal to:

where:

-

\(n\) is the cumulative unit number;

-

\({t(1)}_{i}\) is the operative time required to assembly the 1st lot unit, i.e. the initial productivity performance, in the \(i\) th assembly configuration;

-

\({b}_{i}\) is the learning productivity factor in the \(i\) th assembly configurations.

The learning productivity factor can be related to the learning productivity percentage \(\varphi\) by the following:

The smaller is the value of \({\varphi }_{i}\), the larger is the value of \({b}_{i}\) and the higher is the productivity learning effect [33].

Figure 2 shows the examples of learning curves for an assembly operation performed in three different configurations: manual, collaborative and full automated (in this case, the production time can be considered almost constant over time). It can be observed that the support of cobots allows for shorter assembly times and faster learning with respect to manual configuration (Cohen et al., 2021).

The average unit assembly time (\({\overline{{t }_{a}}}_{i}\)) is influenced by the lot size, and it can be calculated as follows:

where \(\overline{N }\) is the estimated production lot size.

Considering this, the unit manufacturing costs in the \(i\) th assembly configuration can be calculated as follows:

3.3.2 Setup costs

Setup times in an assembly line and related costs cannot be neglected in a real-world scenario. Unit setup costs (\({C}_{s})\) originate from the passive time required to reorganise the workstation according to production requirements. When switching production from one lot to the next, passive time caused by the need to change tools, reprogram robotic systems or change the layout of the workstation should be taken into account.

In operations performed in manual configuration, setup times are usually very limited. However, the issue is quite different when robotic systems are implemented. Robotic systems cannot yet completely reprogram their activities autonomously, and consequently, human intervention is still needed to (i) select trajectories, (ii) reprogram task sequence and task allocation and (iii) change tools and grippers to be used [34].

Cobots are very flexible, can be moved with agility and reprogrammed very intuitively and quickly. High expertise is often not required to reprogram cobots. In contrast, traditional industrial robots usually cannot be moved, and their reprogramming is highly complex and time-consuming.

Unit setup costs (\({C}_{s})\) can be calculated as the product of the cost of setup time (\({c}_{s}\)) and the time required to setup the assembly station attributable to an individual unit produced (\({t}_{s})\). Note that the cost of setup time may be very different from the cost of operative time because higher skills may be required for workstation setup. Unit setup costs vary depending on the assembly configuration and can be calculated as follows:

The setup time that can be associated to the individual assembly operation is a function of the estimated lot size (\(\overline{N })\):

where \({{T}_{s}}_{i}\) is the total time required to setup the workstation in the \(i\) th assembly configuration.

3.3.3 Prospective costs

Investments related to new instrumentation, equipment, operator support systems and robotic systems need to be included in the prospective costs. Prospective costs should include any cost that the current decision on assembly configuration can alter.

Unit prospective costs in the \(i\) th assembly configuration can be calculated as follows:

where \({K}_{i}\) is the total life-cycle cost of investments needed to perform the \(i\) th assembly configuration, \({v}_{i}\) is the service life of the equipment (expressed in years) in the \(i\) th assembly configuration, \(\overline{N }\) is the estimated production lot size and \(L\) is the estimated number of lots processed in a year.

Unit prospective costs should consider only those costs affected by the current decision. So-called sunk costs, such as costs for instrumentation already purchased in the past, should not be considered. If the workstation is newly organised, all investments in equipment fall into this category.

3.3.4 Retrospective costs

Retrospective costs, on the other hand, emerge when the assembly systems already exist, and the decision maker has to choose whether and how to introduce changes. In these cases, there may be active costs due to past decisions that must be taken into account for future choices. A typical example of retrospective costs is the cost of employees that cannot be dismissed or allocated to other activities.

Unit retrospective costs in the \(i\) th assembly configuration can be calculated as follows:

where \({{RC}_{TOT}}_{i}\) are total annual retrospective costs in the \(i\) th assembly configuration.

3.3.5 Product quality costs

Product quality costs are caused by errors or failures in the assembly process that generate defects in the final product. Product quality costs have significant impact on production costs in many industries. Consider, for example, aerospace or precision manufacturing productions where product defectiveness is critical, and the presence of defects can imply very high economic costs. Product quality costs may be due to various factors, including re-manufacturing costs, costs for discarded products, image loss and after-sales repair costs [35,36,37].

As a first approximation, an estimate of product quality costs for the \(i\) th assembly configuration can be calculated as the product between the average defectiveness (\({\overline{d} }_{i}\)), i.e. the proportion of defective assembled unit and the average cost of a defective unit \(\left({C}_{{d}_{i}}\right)\):

Alternatively, more sophisticated quality cost estimation models can be applied whenever the application requires it. Some examples are the methods proposed by Caputo et al. [38], 36, 37, Fager et al. [26] and Verna et al. [39].

The defectiveness, as a first approximation, can be assumed constant for large-volume productions. However, similarly to productivity, defectiveness is also influenced by a learning process; consequently, the observed average defectiveness can be affected by the size of the assembled lot. The defectiveness related to the assembly of the \(n\) th unit in the \(i\) th assembly configuration can be calculated as follows [40]:

where:

-

\(n\) is the cumulative unit number;

-

\({d(1)}_{i}\) is the defectiveness related to the 1st unit, i.e. the initial quality performance, in the \(i\) th assembly configuration;

-

\({q}_{i}=-{\mathrm{log}}_{2}\left({\vartheta }_{i}\right)\) is the quality learning factor;

-

\({\vartheta }_{i}\) is the quality learning percentage in the \(i\) th assembly configuration. The smaller is the value of \({\vartheta }_{i}\) , the larger is the value of \({q}_{i}\) and the higher is the quality learning effect [41].

Figure 3 shows examples of quality learning curves that compare the performance of an assembly operation performed in manual, collaborative or automated configuration.

The cost of quality in the \(i\) th assembly configuration can be expressed as a function of the estimated lot size:

where \({\overline{d } }_{i}\) is the average defectiveness and can be calculated as follows:

3.3.6 Wellbeing cost

In order to optimise both human wellbeing and overall system performance, physical and mental ergonomics need to be considered in the design of modern workplaces [42]. In this perspective, considering worker wellbeing costs is crucial in evaluating an assembly configuration.

The use of human support systems in repetitive and physically demanding tasks is often designed to promote the operator’s wellbeing [8, 9]. Cobots can improve work conditions and can provide a valuable support to relieve human operators' physical and mental workload [43,44,45,46].

Highly advanced and quantitative wellbeing cost models are available in the literature [42]. However, for a preliminary analysis, a rough estimation of wellbeing costs in the \(i\) th assembly configuration can be taken into account as follows:

where \({{CW}_{TOT}}_{i}\) are the total wellbeing costs for the ith assembly configuration.

In order to further simplify the estimation of these parameters, \({{CW}_{TOT}}_{i}\) can be approximately determined for a specific \(i\) th assembly configuration as the product between the wellbeing costs of the most onerous assembly configuration for the operator (\({CW}_{{TOT}_{MAX}})\) and a reduction factor specific for the \(i\) th assembly configuration (\({\gamma }_{i}\)):

where \({\gamma }_{i}\in \left[0;1\right]\). If, for example, the implementation of cobots allows a 30% reduction in wellbeing costs with respect to the manual assembly configuration (considered the most onerous assembly configuration), then \({\gamma }_{collaborative\; assembly}=0.7.\)

3.4 Overall assembly cost

The overall assembly cost resulting from the proposed model is a function of (i) the specific input parameters of the process, (ii) the assembly configuration and (iii) the estimated lots size processed by the assembly station (\(\overline{N }\)). The output is a cost curve representing the cost of assembly of a single unit in relation to the average size of the processed lots. As an example, three cost curves for three different assembly configurations are shown in Fig. 4. Through the analysis of the cost curves, it is possible to identify the most cost-effective assembly configuration of a specific application.

For the fictitious example of Fig. 4, manual assembly is the most cost-effective choice when assembling lots are smaller than eight units. The collaborative assembly configuration is the most cost-effective option if the estimated lot size is between 8 and 29. The automated assembly configuration is preferable for processes where the estimated lot size is above 29.

The cost curves highlighted by the model clearly show the potential of collaborative robotics to make small lot assembly processes more efficient.

3.5 Model parameter estimation

The prediction of the performance and features of a production process still at the design stage is a critical aspect, as it is usually performed at an early development phase characterised by the non-abundance of information and data to be used [31]. In order to make the proposed model easily applicable in real production contexts, Table 3 provides some suggestions for roughly estimating model parameters.

3.6 Preliminary sensitivity analysis

A sensitivity analysis can be conducted on the proposed cost model to identify which cost components had the greatest impact on the total cost. To perform the analysis, the individual cost components were preliminary assumed to be independent. The sensitivity analysis was conducted on the case study reported in Section 5.3 (input parameters are reported in Table 7 — scenario 2).

For each cost component, the impact on the assembly unit cost was calculated, as well as the impact that a 10% variation could have on the assembly unit cost. As an example, if the manufacturing cost increases by 10% \(\left(\frac{\Delta {C}_{m}}{{C}_{m}}\%\right)\), the impact on the total cost is as follows:

where \({C}_{A}\) is the initial unit cost of assembly; \({C}_{m}\) is the initial value of the cost of manufacturing; \({C}_{A}^{^{\prime}}\) is the total unit increased cost of assembly; and \({C}_{m}^{^{\prime}}\) is the increased value of the cost of manufacturing.

The output of this preliminary sensitivity analysis is reported in Table 4.

For this specific case study, the results of the sensitivity analysis showed that manufacturing costs, prospective costs and retrospective costs had the greatest impact on the total cost of assembly. This means that changes in these cost components had a significant effect on the overall cost of the assembly process. In particular, their variation had a correspondingly large impact on the total cost, showing that these cost components are sensitive to changes and are therefore important to consider when seeking to optimise or minimise costs. In contrast, again for the considered case study, setup costs, quality costs and wellbeing costs had a lesser impact on the total cost of assembly. These findings suggest that, while these cost components may still be worth considering as part of assembly costs, efforts to reduce or optimise them may have a less significant impact on the overall cost.

It is worth noting that the relative importance of different cost components may vary depending on the considered context. Overall, the sensitivity analysis provides interesting insights into the factors that drive the cost of the assembly operations and can help decision-making about cost optimization strategies.

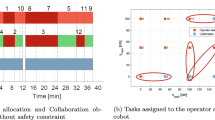

4 Production throughput analysis

Throughput analysis is essential for designing, operating and managing production systems. This aspect should also be included in the analysis to evaluate and select the best assembly configuration. Assembly configurations can perform differently and can provide distinct volumes of units. Figure 5 shows the maximum throughput for three different assembly configurations. It can be noted that the expected amount of units that the assembly station can process varies as the assembly configuration and estimated lot size change. An assembly configuration might perform better from an economic point of view than the others, but it could not be sufficiently productive for the required demand. In this view, the cost analysis should always be complemented by a productivity analysis to verify if the selected assembly configuration can fulfil the required demand.

A rough estimate of the maximum annual throughput for the ith assembly configuration can be calculated as follows:

where:

-

tws is the duration of the work session

-

ews is the efficiency in the use of the production resources (workforce and equipment)

-

nws is the number of work sessions in a working day

-

WD is the number of working days in a year

-

\({\overline{t_a}}_i\) is average unit assembly time

-

tsj is setup time attributable to the individual assembly operation

The maximum annual throughput should be compared with throughput required by the production system:

where:

-

\(\overline N\) is the estimated lot size

-

L is the estimated number of lots processed in a year

The ith assembly configuration allows the required demand to be fulfilled, if the following condition is satisfied:

5 Case studies

This section aims to show the use of the proposed model. The cost model is applied to three different case studies, each showing how process variables can influence technology deployment choices in assembly processes.

5.1 Case study 1 — Choice of the best assembly configuration

The first case study concerns the final assembly process of an electric motor for agricultural machinery (see an exemplificative representation of the product in Fig. 6). The assembly process is implemented in a medium-sized manufacturing company that, on average, produces 150 production lots per year, each consisting of about 15 units.

A decision must be taken whether to perform the final assembly operation in a manual, collaborative or fully automated configuration. Estimated model parameters for the three assembly configurations are shown in Table 5.

Figure 7A shows the cost curves for the three configurations related to the case study. The choice regarding the most appropriate assembly configuration clearly depends on the estimated lot size (see Fig. 7A). The manual assembly configuration appears to be the most cost-effective solution for the assembly of a lot composed of less than six units. The collaborative assembly configuration is more convenient for productions with lot sizes between 6 and 21. The automated assembly configuration is progressively more economically efficient for the assembly of lot sizes larger than 21.

In our case study (\(\overline{N }\) =15), collaborative assembly appears to be the most efficient configuration.

As previously introduced, production capacity must also be taken into account. Figure 7B shows the maximum throughputs for the three assembly configurations under consideration. In detail, the manual configuration is not able to satisfy the demand (\(\overline{N} \cdot L=2250\space{units}\)). In contrast, for lots with an estimated size of 15 units, the collaborative assembly configuration can generate a maximum throughput of around 2600 units per year, which is higher than the required throughput.

From the reported evidence (see Fig. 7), we observed that the collaborative configuration is the most efficient solution for the assembly process under investigation.

5.2 Case study 2 — Effects of product quality costs

The second case study focuses on the effects of product quality costs on the selection of the assembly configuration. The case concerns the design of a new assembly station for actuators used in the aerospace industry (see an exemplificative product in Fig. 8). The assembled unit is a critical component, and the presence of defects can compromise its operation. For this reason, the costs of the occurrence of defects are very high. The process under analysis involves the assembly of highly customised products, and each production lot includes one or two units.

In the past, the company considered the implementation of a fully automated assembly process to reduce the defectiveness of final products. However, it was estimated that the production costs were too high. The implementation of collaborative robots to support the operator in the final assembly operations is to be evaluated. In detail, it was estimated that cobot deployment could reduce assembly defectiveness. The model parameters for the three potential assembly configurations are reported in Table 6. Two different scenarios have been analysed, the first in which defect costs are limited and the second in which defect costs are the actual costs of the company (high cost of defects).

Figure 9 shows the cost curves of the three assembly configurations in the two scenarios (low defect cost, high defect cost). It is evident that collaborative configuration performs better than manual configuration even for very small lots (also for single unit lots), when product quality costs are high and collaborative automation enables defectiveness reduction.

The assembly of small lots is more convenient in the manual configuration in the scenario with limited costs of defects. In contrast, the collaborative assembly configuration becomes more cost-effective if high costs of defects are considered. In this case, the expenses of the necessary technological equipment and the costs of cobot setup are largely repaid by the improved production performance in terms of quality and productivity.

Figure 10 shows that all three assembly configurations allow the production demand to be satisfied.

5.3 Case study 3 — Effects of retrospective costs

This last case study aims to show the effect of retrospective costs on the assembly configuration choice. In previous case studies, the design of the workstation regarded assembly processes that were either new or where the existing resources were allocated to other operations. In this sense, the two previous case studies did not consider retrospective costs.

This case study concerns an existing assembly process of premium leather shoes. On average, about 5,000 pairs of shoes are produced each year, divided into 50 lots of around 100 units each. The process involves assembling, stitching and gluing the different shoe components. Two workers were handling the assembly tasks in two work shifts. Consideration is being given to how to make the assembly process more efficient. Specifically, the aim was to evaluate whether:

-

1)

Automating the process with the acquisition of a fully automated robotic system, thus excluding the two workers from the assembly process;

-

2)

Supporting a human worker with a collaborative robot. In this case, the increased efficiency of the assembling process allows the number of workers involved in each working shift to be reduced to 1.

-

3)

Continuing to assemble the shoes manually without making relevant investments.

The costs of workers not employed in the assembly process should be considered as retrospective costs since for the company it is not possible to dismiss or assign workers to other activities.

The model parameters for the three potential assembly configurations are reported in Table 7. Two different scenarios were developed (the first one does not consider retrospective costs, while the second one also includes retrospective costs).

The model provides the cost curves shown in Fig. 11.

Not considering retrospective costs, the automated assembly configuration appears to be the most cost-effective solution. On the contrary, the collaborative assembly configuration emerges as the most cost-effective alternative when considering the existing human resources and their related costs.

Figure 12 shows that the analysed collaborative assembly configurations allow the production demand (5000 unit) to be satisfied.

6 Discussion and conclusions

The main objective of this research was to explore how to evaluate the adoption of collaborative robotics in industrial assembly processes. To achieve this goal, a new cost model that takes into account the main factors that influence the selection of an assembly configuration, such as manufacturing costs, setup costs, prospective costs, retrospective costs, product quality costs and wellbeing costs, was developed. Importantly, the model also considers the learning dynamics associated with productivity and quality, which are especially relevant in small batch productions. Overall, this study provides a comprehensive framework for evaluating the potential costs and benefits of adopting collaborative robotics in assembly operations.

Three application cases followed the presentation of the proposed model. The preliminary findings suggests that the use of collaborative robots in assembly operations can be a cost-effective alternative to manual or fully automated configurations. Specifically, the deployment of cobots is likely to be beneficial when (i) the assembly lot size is small, (ii) cobots can help reduce defects and resulting quality costs and (iii) it is not possible to dismiss or reallocate existing workers. These conditions are often present in assembly production processes in small- or medium-sized enterprises (SMEs) and in manufacturing contexts that involve mass customization. Our findings imply that cobots can be a valuable tool for improving the efficiency and cost-effectiveness of assembly operations in these types of settings.

The deployment of cobots has been shown to have positive effects on job retention, worker wellbeing and industrial production performance [41]. However, a number of technological, organisational and economic barriers still hinder the widespread adoption of cobots. The cost model proposed in this study may be useful for policy makers as they develop targeted interventions to encourage the use of cobots in manufacturing companies. These interventions could help overcome some of the barriers to adoption and facilitate the integration of cobots into manufacturing operations.

The model developed in this study was specifically designed for applications related to assembly processes. However, with slight modifications, it can be applied to a wide range of other situations where a decision needs to be made about whether to fully automate or partially automate a manufacturing process using collaborative robots. This flexibility makes the model a useful tool for evaluating the potential benefits and costs of implementing cobots in various types of manufacturing contexts.

One of the main limitations of this study is that it only focuses on the evaluation of a single assembly station. While this allows the potential benefits of deploying cobots in a specific setting to be examined, it does not provide a complete picture of how cobots might perform in a more complex and dynamic environment like an assembly line. Therefore, in future research, it is needed to extend the model to consider the deployment of cobots in a variety of assembly stations, with the goal of identifying the most suitable locations for integrating these technologies.

Additionally, it is worth noting that the calculation of certain cost drivers, such as those related to quality and worker wellbeing, involves some level of approximation. This was done in order to create a model that is both easily applicable in real-world manufacturing contexts and readily understandable by a wide range of stakeholders. However, we recognise that these approximations may not capture all of the nuances of how cobots impact these important factors. Therefore, further modelling work is needed to determine how to more accurately assess the impact of collaborative robotics on the above-mentioned costs.

Data availability

Not applicable

References

Mastrogiacomo L, Barravecchia F, Franceschini F (2019) A worldwide survey on manufacturing servitisation. Int J Adv Manuf Technol 103(9–12):3927–3942

Qi Y, Mao Z, Zhang M, Guo H (2020) Manufacturing practices and servitisation: the role of mass customisation and product innovation capabilities. Int J Prod Econ 228:107747

Hu SJ, Ko J, Weyand L, ElMaraghy HA, Lien TK, Koren Y, Bley H, Chryssolouris G, Nasr N, Shpitalni M (2011) Assembly system design and operations for product variety. CIRP Ann 60(2):715–733

Schmitt RH, Huettemann G, Münker S (2021) A priori performance assessment of line-less mobile assembly systems. CIRP Ann 70(1):389–392

Wiendahl H-P, ElMaraghy HA, Nyhuis P, Zäh MF, Wiendahl H-H, Duffie N, Brieke M (2007) Changeable manufacturing-classification, design and operation. CIRP Ann 56(2):783–809

Inkulu AK, Bahubalendruni MVAR, Dara A, SankaranarayanaSamy K (2021) Challenges and opportunities in human robot collaboration context of Industry 4.0-a state of the art review. Ind Robot Int J Robot Res Appl 49(2):226–239

Krüger J, Bernhardt R, Surdilovic D, Spur G (2006) Intelligent assist systems for flexible assembly. CIRP Ann 55(1):29–32

Gervasi R, Barravecchia F, Mastrogiacomo L, Franceschini F (2022) Applications of affective computing in human-robot interaction: state-of-art and challenges for manufacturing. Proc Ins Mech Eng Part B, In press(In press). https://doi.org/10.1177/0954405422112188

Gervasi R, Mastrogiacomo L, Maisano DA, Antonelli D, Franceschini F (2022) A structured methodology to support human–robot collaboration configuration choice. Prod Eng Res Devel 16(4):435–451

Weiss A, Wortmeier A-K, Kubicek B (2021) Cobots in Industry 4.0: a roadmap for future practice studies on human–robot collaboration. IEEE Trans on Human-Machine Syst 51(4):335–345

Pauliková A, Gyurák Babeľová Z, Ubárová M (2021) Analysis of the impact of human–cobot collaborative manufacturing implementation on the occupational health and safety and the quality requirements. Int J Environ Res Public Health 18(4):1927

Cohen Y, Shoval S, Faccio M, Minto R (2022) Deploying cobots in collaborative systems: major considerations and productivity analysis. Int J Prod Res 60(6):1815–1831

Colgate JE, Edward J, Peshkin MA, Wannasuphoprasit W (1996) Cobots: robots for collaboration with human operators (Proceedings of the 1996 ASME International Mechanical Engineering Congress and Exposition, Ed.)

Gil-Vilda F, Sune A, Yagüe-Fabra JA, Crespo C, Serrano H (2017) Integration of a collaborative robot in a U-shaped production line: a real case study. Procedia Manufacturing 13:109–115

Gervasi R, Mastrogiacomo L, Franceschini F (2020) A conceptual framework to evaluate human-robot collaboration. Int J Adv Manuf Technol 108(3):841–865

Vojić S (2020) Applications of collaborative industrial robots. Machines Technol Mater 14(3):96–99

Bukchin J, Tzur M (2000) Design of flexible assembly line to minimise equipment cost. IIE Transactions (Institute of Industrial Engineers) 32(7):585–598

Rosati G, Faccio M, Carli A, Rossi A (2013) Fully flexible assembly systems (F‐FAS): a new concept in flexible automation. Assembly Automation, 8–21

Culleton M, McGinn C, Kelly K (2017) Framework for assessing robotic dexterity within flexible manufacturing. J Intell Rob Syst 87(3):507–529

Charalambous G, Fletcher S, Webb P (2015) Identifying the key organisational human factors for introducing human-robot collaboration in industry: an exploratory study. Int J Adv Manuf Technol 81(9):2143–2155

Cohen Y, Shoval S, Faccio M (2019) Strategic view on cobot deployment in assembly 4.0 systems. IFAC-PapersOnLine 52(13):1519–1524

Takata S, Hirano T (2011) Human and robot allocation method for hybrid assembly systems. CIRP Ann 60(1):9–12

Fast-Berglund Å, Palmkvist F, Nyqvist P, Ekered S, Åkerman M (2016) Evaluating cobots for final assembly. Procedia CIRP 44:175–180

Dalle Mura M, Dini G (2019) Designing assembly lines with humans and collaborative robots: a genetic approach. CIRP Ann 68(1):1–4

Li Z, Janardhanan MN, Tang Q (2021) Multi-objective migrating bird optimisation algorithm for cost-oriented assembly line balancing problem with collaborative robots. Neural Comput Appl 33(14):8575–8596

Fager P, Sgarbossa F, Calzavara M (2021) Cost modelling of onboard cobot-supported item sorting in a picking system. Int J Prod Res 59(11):3269–3284

Peron M, Sgarbossa F, Strandhagen JO (2022) Decision support model for implementing assistive technologies in assembly activities: a case study. Int J Prod Res 60(4):1341–1367

Liu Q, Liu Z, Xu W, Tang Q, Zhou Z, Pham DT (2019) Human-robot collaboration in disassembly for sustainable manufacturing. Int J Prod Res 57(12):4027–4044

Wang X, Ong SK, Nee AYC (2016) A comprehensive survey of augmented reality assembly research. Advances in Manufacturing 4(1):1–22

Yuan ML, Ong SK, Nee AYC (2008) Augmented reality for assembly guidance using a virtual interactive tool. Int J Prod Res 46(7):1745–1767

Salmi A, David P, Blanco E, Summers JD (2016) A review of cost estimation models for determining assembly automation level. Comput Ind Eng 98:246–259

Glock CH, Grosse EH, Jaber MY, Smunt TL (2019) Applications of learning curves in production and operations management: a systematic literature review. Comput Ind Eng 131:422–441

Wu MC, Sun SH (2006) A project scheduling and staff assignment model considering learning effect. Int J Adv Manuf Technol 28(11):1190–1195

Pellegrinelli S, Orlandini A, Pedrocchi N, Umbrico A, Tolio T (2017) Motion planning and scheduling for human and industrial-robot collaboration. CIRP Ann 66(1):1–4

Franceschini F, Galetto M, Genta G, Maisano DA (2018) Selection of quality-inspection procedures for short-run productions. Int J Adv Manuf Technol 99(9):2537–2547

Galetto M, Verna E, Genta G (2020) Accurate estimation of prediction models for operator-induced defects in assembly manufacturing processes. Qual Eng 32(4):595–613

Galetto M, Verna E, Genta G, Franceschini F (2020) Uncertainty evaluation in the prediction of defects and costs for quality inspection planning in low-volume productions. Int J Adv Manuf Technol 108(11):3793–3805

Caputo AC, Pelagagge PM, Salini P (2015) Modeling errors in kitting processes for assembly lines feeding. IFAC-PapersOnLine 48(3):338–344

Verna E, Genta G, Galetto M, Franceschini F (2022) Economic impact of quality inspection in manufacturing: a proposal for a novel cost modeling. Proc Inst Mech Eng Part B: J Eng Manuf 236(11):1508–1517

Franceschini F, Galetto M (2002) Asymptotic defectiveness of manufacturing plants: an estimate based on process learning curves. Int J Prod Res 40(3):537–545

Probst L, Frideres L, Pedersen B, Caputi C (2015) Service innovation for smart industry: human–robot collaboration. European Commission, Luxembourg

Weckenborg C, Spengler TS (2019) Assembly line balancing with collaborative robots under consideration of ergonomics: a cost-oriented approach. IFAC-PapersOnLine 52(13):1860–1865

el Makrini I, Merckaert K, de Winter J, Lefeber D, Vanderborght B (2019) Task allocation for improved ergonomics in Human-Robot Collaborative Assembly. Interact Stud 20(1):102–133

Kim W, Lorenzini M, Balatti P, Nguyen PDH, Pattacini U, Tikhanoff V, Peternel L, Fantacci C, Natale L, Metta G (2019) Adaptable workstations for human-robot collaboration: a reconfigurable framework for improving worker ergonomics and productivity. IEEE Robot Autom Mag 26(3):14–26

Maurice P, Padois V, Measson Y, Bidaud P (2017) Human-oriented design of collaborative robots. Int J Ind Ergon 57:88–102

Pearce M, Mutlu B, Shah J, Radwin R (2018) Optimising makespan and ergonomics in integrating collaborative robots into manufacturing processes. IEEE Trans Autom Sci Eng 15(4):1772–1784

Funding

Open access funding provided by Politecnico di Torino within the CRUI-CARE Agreement. This work has been partially supported by the “Italian Ministry of Education, University and Research”, Award “TESUN‐ 83486178370409 finanziamento dipartimenti di eccellenza CAP. 1694 TIT. 232 ART. 6”.

Author information

Authors and Affiliations

Contributions

The authors have provided an equal contribution to the drafting of the paper.

Corresponding author

Ethics declarations

Ethical approval

The authors respect the Ethical Guidelines of the Journal.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Barravecchia, F., Mastrogiacomo, L. & Franceschini, F. A general cost model to assess the implementation of collaborative robots in assembly processes. Int J Adv Manuf Technol 125, 5247–5266 (2023). https://doi.org/10.1007/s00170-023-10942-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-10942-z