Abstract

Compared with other traditional welding, CO2 gas shielded arc welding has the advantages of high thermal stability, low heat input, and low melt depth. It is also widely used in manufacturing industry due to its low cost and high productivity, but its development is limited by large welding spatter and poor weld seam formation. In order to adapt to the development of new materials and welding environment, the development of new anti-spatter technology is of great significance. Through the collection, collation, and analysis of domestic and international CO2 gas shielded arc welding research data, this paper provides a review of the existing, representative and innovative welding processes. On the basis of existing research theories, the future development trend of the field is summarized and predicted.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this manuscript.

Code availability

The software is used in the trial state.

References

Dutra JC, Silva R, Riffel KC, Marques C (2020) High-performance GMAW process for deep penetration applications. Weld World Le Soudage Dans Le Monde 64(4). https://doi.org/10.1007/s40194-020-00889-0

Yoshizu T (2018) Study of steel backing material of CO2 arc welded joints of reinforcing bars. AIJ J Technol Des 24(57):507–511. https://doi.org/10.3130/aijt.24.507

Kamble AG, Rao RV (2013) Experimental investigation on the effects of process parameters of GMAW and transient thermal analysis of AISI321 steel. Adv Manuf 1(4):362–377

Albiter A (2020) Sulfide stress cracking assessment of carbon steel welding with high content of H2S and CO2 at high temperature: a case study. Engineering 12(12):863–885. https://doi.org/10.4236/eng.2020.1212061

Mariappan M, Parthasarathi NL, Ravindran R, Lenin K, Raja A (2021) Effect of alternating shielding gases in gas metal arc welding of SA515 Gr 70 carbon steel. Mater Res Express 8(9): 095601 (17pp). https://doi.org/10.1088/2053-1591/ac21e9

Phogat S, Singh KP (2017) Experimental study of effect of process parameter of GMAW welding on mechanical properties and microstructure of steel (SAILMA 350 HI). Int J Theor Appl Mech 12:113–123

Kuznetsov MA (2021) Solodsky SA, Kryukov AV, Ilyaschenko DP, Verkhoturova EV (2021) Study of the effect of shielding gas on the plasma flow of an electric arc and on the droplet of a molten metal. Plasma Phys Rep 47(1):100–104. https://doi.org/10.1134/S1063780X21010098

Yun TJ, Park MH, Oh WB, Lee BR, Kim IS (2019) A study on spatter tracking algorithm for a vertical GMA welding process. J Weld Join 37(4):347–356. https://doi.org/10.5781/JWJ.2019.37.4.9

Yamazaki K, Suzuki R, Shimizu H, Koshiishi F (2012) Spatter and fume reduction in CO2 gas-shielded arc welding by regulated globular transfer. Weld World 56(9):12–19. https://doi.org/10.1007/BF03321376

Saito H, Ojima J, Takaya M, Iwasaki T, Hisanaga N, Tanaka S, Arito H (2000) Laboratory measurement of hazardous fumes and gases at a point corresponding to breathing zone of welder during a CO2 arc welding. Ind Health 38(1):69–78. https://doi.org/10.2486/indhealth.38.69

Zhang G, Goett G, Uhrlandt D (2020) Study of the anode energy in gas metal arc welding. J Phys D Appl Phys. https://doi.org/10.1088/1361-6463/ab93f7

Haidar J, Lowke JJ (1997) Effect of CO2 shielding gas on metal droplet formation in arc welding. IEEE Trans Plasma Sci 25(5):931–936. https://doi.org/10.1109/27.649598

Carpenter KR, Monaghan BJ, Cuiuri D, Norrish J (2017) Optimising the welding conditions to determine the influence of shielding gas on fume formation rate and particle size distribution for gas metal arc welding. Weld World 61(3):473–481. https://doi.org/10.1007/s40194-017-0438-9

Matusiak J, Pfeifer T (2013) The research of technological and environmental conditions during low-energetic gas-shielded metal arc welding of aluminum alloys. Weld Int 27(5):338–344. https://doi.org/10.1080/09507116.2011.600040

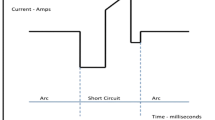

Chang YL, Liu XL, Lu L (2013) Research status and outlook for short-circuit transition CO2 welding. Weld Technol 42(3):1–5. https://doi.org/10.3969/j.issn.1002-025X.2013.03.001

Bruckner J (2005) Cold metal transfer has a future joining steel to aluminum. Weld J 84(6):38–40

Wu H, Chang YL, Lu L, Bai J (2017) Review on magnetically controlled arc welding process. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-017-0068-9

Pai N, Mehrotra S, Raja AR, Vashista M, Yusufzai MZK (2019) Development of hybrid welding processes incorporating GMAW and SMAW. Mater Today Proc 18(7):2924–2932. https://doi.org/10.1016/j.matpr.2019.07.162

Naidu GG, Jajimoggala S (2021) Mathematical modelling of engineering problems. J Homepage 8(3): 461–466. https://doi.org/10.18280/mmep.080317

Yang Z, Fang C, Wu M, Qi K, Chen Y, Ma R (2017) The mechanisms of arc coupling and rotation in cable-type welding wire CO2 welding. J Mater Process Technol 255(1–4). https://doi.org/10.1016/j.jmatprotec.2017.12.032

Luo J, Luo Q, Wang XJ, Wang XC (2010) EMS-CO2 welding: a new approach to improve droplet transfer characteristics and welding formation. Mater Manuf Process 25(11):1233–1241. https://doi.org/10.1080/10426914.2010.481000

Teixeira GS, Mazzaferro J (2019) GMA welding metal transfer mode study by high-speed imaging and electrical signal acquisition. J Braz Soc Mech Sci Eng 41(8). https://doi.org/10.1007/s40430-019-1814-8

Stava, Elliott K (2004) Surface tension transfer. Gases Weld Distrib 48(1):52–54

Liu S, Wang Y (2012) Research of CO2 welding inverter power source under current waveform control[C]//2012 IEEE International Conference on Automation and Logistics. IEEE 116–121

Deruntz BD (2003) Assessing the benefits of surface tension transfer welding to industry. J Ind Technol 19(4):2–7

Hong DIZ (2009) EWM cold arc welding: a gas metal arc welding technology with low energy and its application. Weld Join

Li YW, Dong ZH, Liu HF, Babkin A, Lee B, Chang YL (2022) Research progress on transition behavior control of welding droplets. Int J Adv Manuf Technol 1–12. https://doi.org/10.1007/s00170-022-08928-4

Era T, Ide A, Uezono T, Ueyama T, Hirata Y (2013) Controlled bridge transfer (CBT) gas metal arc process for steel sheets joining. Weld Int 27(4):268–273. https://doi.org/10.1179/136217109X406965

Era T, Ide A, Uezono T, Ueyama T (2008) Spatter reduction of steel sheets welding using controlled bridge transfer (CBT) GMA process. Adv Weld Micro Join 580:303–306. https://doi.org/10.4028/www.scientific.net/MSF.580-582.303

Kang DH, Lee WS, Choi SW, Lee JY, Lee IO, Park JS (2020) Torch motor control algorithm for low spatter CO2 arc welding of ultra-thin steel sheets. J Power Electron 20(4):1076–1087. https://doi.org/10.1007/s43236-020-00097-5

Meyster RA, Padar VA, Meyster AR, Bayandina OV, Vatslavskiy ES (2016) CO2 welding with straight polarity. Weld Int 30(4):293–295. https://doi.org/10.1080/01431161.2015.1058001

Jurica M, Kožuh Z, Bauer B, Garasic I (2017) Effect of the GMAW metal transfer mode on the weld metal structure of the HSLA X8. Mater Tehnol 51(3): 449–453. https://doi.org/10.17222/mit.2016.057

Wang X, Wang Y, Suo Z, Jiang F, Hu Q (2017) Influence of automatic CO2 gas protection welding process parameters on microstructure and performance of Q345 steel joint. Spec Cast Nonferrous Alloys. https://doi.org/10.15980/j.tzzz.2017.06.003

Furukawa K (2006) New CMT arc welding process-welding of steel to aluminum dissimilar metals and welding of super-thin aluminum sheets. Weld Int 20(6):440–445. https://doi.org/10.1533/wint.2006.3598

Ahsan MRU, Kim T, Kim DB, Changwook J, Park YD (2018) A study on the effect of wire composition on welding with gap and offset in cold metal transfer (CMT) GMAW. J Weld Join 36(5):12–18. https://doi.org/10.5781/JWJ.2018.36.5.2

Pickin CG, Williams SW, Lunt M (2011) Characterisation of the cold metal transfer (CMT) process and its application for low dilution cladding. J Mater Process Technol 211:496–502. https://doi.org/10.1016/j.jmatprotec.2010.11.005

Feng JC, Zhang HT, He P (2009) The CMT short-circuiting metal transfer process and its use in thin aluminum sheets welding. Mater Des 30:1850–1852. https://doi.org/10.1016/j.matdes.2008.07.015

Selvi S, Vishvaksenan A, Rajasekar E (2018) Cold metal transfer (CMT) technology-an overview. Defence Technol 14(1):28–44. https://doi.org/10.1016/j.dt.2017.08.002

Paranthaman V, Dhinakaran V, Shree MV (2021) Optimization of CO2 welding process on dissimilar metals. Mater Today Proc 39:420–423. https://doi.org/10.1016/j.matpr.2020.07.694

Suwannatee N, Wonthaisong S, Yamamoto M, Shinohara S, Phaoniam R (2021) Optimization of welding conditions for hot-wire GMAW with CO2 shielding on heavy-thick butt joint. Weld World 66(4):833–844. https://doi.org/10.1007/s40194-021-01227-8

Fortain JM, Rimano L, Vaidya VV (2008) Innovative process improves welding of sheet metal parts. Weld J 87(1):38–44. https://doi.org/10.1179/174591908X264374

Sarila VK, Cheepu MM, Babu TV, Devuri V (2019) Cold metal transfer (CMT) welding of dissimilar materials: an overview. Mater Sci Forum 969(1):685–690. https://doi.org/10.1016/j.dt.2017.08.002

Zhang P, Liu ZH, Yan H, Yu ZS (2021) Effect of longitudinal magnetic field on CMT welding of Al-Alloy. Met Mater Int 1–14. https://doi.org/10.1007/s12540-020-00932-1

Wang X, Wu Y, Pan H, Yao C, Huang J (2020) Microstructure and softening of advanced high-strength steel QP1180 lap joints welded with CMT. Mater Lett 287(9):129282. https://doi.org/10.1016/j.matlet.2020.129282

Kah P, Suoranta R, Martikainen J (2013) Advanced gas metal arc welding processes. Int J Adv Manuf Technol 67:655–674. https://doi.org/10.1007/s00170-012-4513-5

Dinbanghu PV, Vora JJ, Abhishek K (2021) Advances in gas metal arc welding process: modifications in short-circuiting transfer mode. Adv Weld Deform 67–104. https://doi.org/10.1016/B978-0-12-822049-8.00003-7

Dinbanghu PV, Vora JJ, Abhishek K (2020) Experimental studies of Regulated Metal Deposition (RMD™) on ASTM A387 (11) steel: study of parametric influence and welding performance optimization. J Braz Soc Mech Sci Eng 42(78):1–21. https://doi.org/10.1007/s40430-019-2155-3

Jaykumar V, Vishvesh J (2019) Advances in welding technologies for process development. CRC Press. Taylor and Francis, Boca raton

Sarin P, Kumar M, Sharma VK (2016) Optimization of gas metal arc welding on different ferrous materials using Taguchi method. Magnesium 1(1):85

Swami SA, Jadhav S, Deshpande A (2016) Influence of MIG welding process parameters on tensile properties of mild steel. Eur J Eng Technol Res 1(2):1–5

Kataoka T, Ikeda R, Yasuda K, Hirata Y (2009) Development of a low-spatter CO2 arc welding process with a high-frequency pulse current. Weld Int 23(5):353–359. https://doi.org/10.1080/09507110802542726

Tokihiko K, Rinsei I, Koichi Y, Yoshinori H (2009) Development of low spatter CO2 arc welding process with high frequency pulse current. Sci Technol Weld Join 14(8):740–746. https://doi.org/10.2207/qjjws.25.480

Yu JR, Jiang LP, Zou Y (2010) Oblique characteristic pulse CO2 welding digital power supply based on DSP. Trans China Weld Inst 31(05):69–72+116

Fan CL, Zhou L, Liu Z, Yang CL, Lin SB, Xie WF, Tong H (2018) Arc character and droplet transfer of pulsed ultrasonic wave-assisted GMAW. Int J Adv Manuf Technol 95(5):2219–2226. https://doi.org/10.1007/s00170-017-1414-7

Chen SJ, Zeng YB, Xiao Q (2018) Research on melt drop excitation technology for CO2 gas shielded welding based on arc force modulation. Welding (08): 1–5+65

Yang F, Wu C, Gao J (2014) Suppressing of humping bead using an external magnetic field in high-speed gas metal arc welding. China Weld 2:7. https://doi.org/10.3969/j.issn.1004-5341.2014.02.005

Wu CS, Yang FZ, Gao JQ (2016) Effect of external magnetic field on weld pool flow conditions in high-speed gas metal arc welding. Proc Inst Mech Eng B-J Eng Manuf 230(1):188–193. https://doi.org/10.1177/0954405414555591

Wang L, Wu CS, Gao JQ (2016) Suppression of humping bead in high speed GMAW with external magnetic field. Sci Technol Weld Join 21(2):131–139. https://doi.org/10.1179/1362171815Y.0000000074

Wang L, Wu CS, Chen J, Gao JQ (2018) Influence of the external magnetic field on fluid flow, temperature profile and humping bead in high speed gas metal arc welding. Int J Heat Mass Transf 116:1282–1291. https://doi.org/10.1016/j.ijheatmasstransfer.2017.09.130

Luo J, Luo Q, Wang XJ, Wang XC (2010) EMS-CO2 welding: a new approach to improve droplet transfer characteristics and welding formation. Mater Manuf Process 25(11):1233–1241. https://doi.org/10.1080/10426914.2010.481000

Liu YB, Sun QJ, Wang H, Zhang HM, Cai SJ, Feng JC (2016) Effect of the axial external magnetic field on copper/aluminum arc weld joining. Sci Technol Weld Join 21(6):460–465. https://doi.org/10.1080/13621718.2015.1125406

Liu YB, Sun QJ, Liu JP, Wang SJ, Feng JC (2015) Effect of axial external magnetic field on cold metal transfer welds of aluminum alloy and stainless steel. Mater Lett 152:29–31. https://doi.org/10.1016/j.matlet.2015.03.077

Agrawal MK, Singh RP (2021) Effect of external magnetic field on impact strength and hardness of weld of shielded metal arc welding process. Mater Today Proc 45:3638–3641. https://doi.org/10.1016/j.matpr.2020.12.1219

Singh RP, Raghuvanshi D, Pal A (2021) Effect of external magnetic field on weld width and reinforcement height of shielded metal arc welded joints. Mater Today Proc 38:112–115. https://doi.org/10.1016/j.matpr.2020.06.107

Shoichi M, Yukio M, Koki T, Yasushi T, Yukinori M, Yusuke M (2013) Study on the application for electromagnetic controlled molten pool welding process in overhead and flat position welding. Sci Technol Weld Join 18(1):38–44. https://doi.org/10.1179/1362171812Y.0000000070

Ghosh PK, Dorn L, Kulkarni S, Hofmann F (2009) Arc characteristics and behaviour of metal transfer in pulsed current GMA welding of stainless steel. J Mater Process Technol 209(3):1262–1274. https://doi.org/10.1016/j.jmatprotec.2008.03.049

Sun ZS, Lu L, Bao ZY (2020) Study of the rotation mechanism of the transverse magnetic pulse MAG welding arc. Electr Weld Mach 50(10):97–102+130. https://doi.org/10.7512/j.issn.1001-2303.2020.10.20

Chang YL, Liu MX, Lu L, Babkin AS, Lee BY (2015) The influence of longitudinal magnetic field on the CO2 arc shape. Plasma Sci Technol 4:321–326. https://doi.org/10.1088/1009-0630/17/4/11

Chang YL, Liu XL, Lu L, Babkin AS, Lee BY, Gao F (2014) Impacts of external longitudinal magnetic field on arc plasma and droplet during short-circuit GMAW. Int J Adv Manuf Technol 70(9):1543–1553. https://doi.org/10.1007/s00170-013-5403-1

Jiang SY, Wang XW, Chen HM, Liu P (2012) The impact of adscititious longitudinal magnetic field on CO2 welding process. Adv Mater Res 538:1447–1450. https://doi.org/10.4028/www.scientific.net/AMR.538-541.1447

Zhang G, Goett G, Uhrlandt D (2020) Study of the anode energy in gas metal arc welding. J Phys D Appl Phys 53(39):395202. https://doi.org/10.1088/1361-6463/ab93f7

Baba H, Era T, Ueyama T, Tanaka M (2017) Single pass full penetration joining for heavy plate steel using high current GMA process. Weld World 61(1):1–7. https://doi.org/10.1007/s40194-017-0464-7

Vendan SA, Manoharan S, Buvanashekaran G, Nagamani C (2009) Development of a MIAB welding module and experimental analysis of rotational behavior of arc—simulation of electromagnetic force distribution during MIAB welding of steel pipes using finite element analysis. Int J Adv Manuf Technol 43(11):1144–1156. https://doi.org/10.1007/s00170-008-1793-x

Sun X (2020) CO2 gas shielded welding droplet transition in relation to spatter. Electr Weld Mach 50(02): 6–13

Lee SH, Kim JS, Lee BY, Lee SY (2009) The effect of external electromagnetic force in gas metal arc welding on the transfer mode. Key Eng Mater 297–300:2825–2830. https://doi.org/10.4028/www.scientific.net/KEM.297-300.2825

Luo Q, Lu D, Luo J (2010) Droplet transfer and microstructure of Q235 steel thick plate using CO2welding with additional longitudinal magnetic field controlling. Digit Des Manuf Technol 102–104. https://doi.org/10.4028/www.scientific.net/AMR.102-104.451

Zhu S, Wang QW, Yin FL, Liang YY, Wang XM (2011) Research on droplet transfer of MIG welding with alternating longitudinal magnetic field. Adv Mater Res 189–193:993–996. https://doi.org/10.4028/www.scientific.net/AMR.189-193.993

Zhang XW, Jiang SY, Dai W (2009) Effect of external longitudinal magnetic fields on the transition frequency of CO2 welding short circuits. Therm Process 38(1):136–138

Fan D, Zheng FL, Xiao L (2019) Experimental analysis of molten drop transition behaviour and alternating magnetic field control in high efficiency MAG welding. Trans China Weld Inst 40(05): 1–5+161. https://doi.org/10.12073/j.hjxb.2019400118.

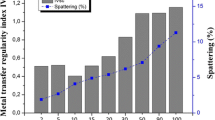

Fan D, Yang WY, Xiao L (2019) Effect of high-frequency alternating magnetic fields on melt-drop transition and sputtering rates in high-current GMAW. Trans China Weld Inst 40(07): 1–5+161. https://doi.org/10.12073/j.hjxb.2019400172.

Toivanen J, Hiltunen E, Martikainen J (2015) Use of CO2 in modified short arc MAG-welding. Mechanika Kaunas University of Technology, Kaunas, pp 244–248

Besekar N, Golghate C (2021) Process evaluation and optimization of CO2 welding parameters using Taguchi method. Int J Innov Eng Sci 6(1): 71–78. https://doi.org/10.46335/IJIES.2021.6.1.11

Math P, Kumar BSP (2021) Analysis optimization and modelling of CO2 welding process parameters in fabrication of mild steel plates. Mater Today: Proc 45:420–423. https://doi.org/10.1016/j.matpr.2020.12.1004

Souza D, Rossi ML, Keocheguerians F, Nascimento VCd, Vilarinho LO, Scotti A (2011) Influence of the welding parameter setting on the MIG/MAG process stability working with short-circuiting. Soldagem Inspeção 16(1):22–32. https://doi.org/10.1590/S0104-92242011000100004

Tesfaw T, Singh AP, Gezahegn AM, Garedew BT (2021) Optimization of MAG welding process parameters using Taguchi design method on dead mild steel used in automotive industry. Int J Syst Assur Eng Manag (4). https://doi.org/10.1007/s13198-021-01107-w

Yoon HS (2021) Joint properties of aluminum alloy and galvanized steel by AC pulse MIG braze welding. Appl Sci 11. https://doi.org/10.3390/app11115105

Wang ZL, Jung DW (2018) Horizontal welding quality control of the CO2 gas shielded welding. MATEC Web Conf 207. https://doi.org/10.1051/matecconf/201820704006

Suban M (2001) Dependence of melting rate in MIG/MAG welding on the type of shielding gas used. J Mater Process Technol 119(1):185–192. https://doi.org/10.1016/S0924-0136(01)00940-2

Gejendhiran S, Vignesh S, Kalaimani M, ArokiaAnicia S (2019) Process parameters optimization for improving the mechanical properties of IS2062 mild steel weldments by GMAW. Dimensions 9(3):180. https://doi.org/10.35940/ijitee.L3888.1081219

Li K, Gao HM, Li HC (2014) Effects of welding voltage onprocess stability in hyperbaric gas arc welding. China Weld 23(1):70–74. https://doi.org/10.3969/j.issn.1004-5341.2014.01.012

Lee Y, Jang J, Liu S (2021) Effect of chemical composition of welding consumable on slag formation and corrosion resistance. Weld World Le Soudage Dans Le Monde 65(2). https://doi.org/10.1007/s40194-020-01059-y

Ogino Y, Asai S, Hirata Y (2020) Visualization of arc plasma and molten wire behavior in CO2 arc welding process by three-dimensional numerical simulation. Weld World, Le Soudage Dans Le Monde 64(2). https://doi.org/10.1007/s40194-020-00958-4

Zhang Y, Wang B, Wang Y, Ding L (2017) Effects of shielding gas on metal transfer and arc shape of rutile type flux cored wire. Trans China Weld Inst 38(6):120–124

Wang H, Liu HY, Wang B (2012) Analysis of molten drop transition and spatter observation of metal powder cored flux cored wires. Trans China Weld Inst 33(10): 83–86+117

Wang Y, Wang B Zhang YQ (2015) Analysis of melt drop transition characteristics and processability of alkaline flux cored wires. Trans China Weld Inst 36(10): 81–86+117

Wang B, Yang L, Wang Y (2006) Observation and analysis of molten drop transition phenomenon of flux cored wire CO2 welding. Trans China Weld Inst (07): 77–80+117. https://doi.org/10.3321/j.issn:0253-360X.2006.07.020

Zhang HM, Shi Y, Gu YF, Li CK (2020) Effects of electrode polarity on the droplet transfer mode in self-shielded flux-cored arc welding. J Manuf Process 58:478–488. https://doi.org/10.1016/j.jmapro.2020.07.056

Kataoka T, Ikeda R, Ono M, Yasuda K, Hirata Y (2009) Effect of REM addition of wire on CO2 gas shielded arc phenomenon. Weld Int 23(7):517–522. https://doi.org/10.1080/09507110802543021

Methong T, Yamaguchi T, Shigeta M, Tanaka M, Ikeda R, Matsushita M, Poopat B (2017) Effect of rare earth metal on plasma properties in GMAW using CO2 shielding gas. Weld World 61(5):1039–1047. https://doi.org/10.1007/s40194-017-0491-4

Vimalraj C, Kah P, Layus P, Belinga EM, Parshin S (2019) High-strength steel S960QC welded with rare earth nanoparticle coated filler wire. Int J Adv Manuf Technol 102(3):105–119. https://doi.org/10.1007/s00170-018-3059-6

Tokihiko K, Chen JB (2010) Study on the influence of rare earth metals added to welding wire in the arc phenomenon of CO2 gas shielded welding. Metal Work 16:30–33

Chen R, Wang K, Yi YY (2017) Effect of rare earth elements of flux cored wire on the organization and mechanical properties of the weld metal of 921A steel. Thermal Process (05):9–13. https://doi.org/10.14158/j.cnki.1001-3814.2017.05.001

Liu Y, Wang XH, Zhong LL, Yang AJ, Rong MZ, Wu JH (2018) Influence of Al, Fe or Cu vapour on thermophysical properties of CO2 plasmas. Eur Phys J D 72(12):1–12. https://doi.org/10.1140/epjd/e2018-80591-3

Jia YZ, Chen SJ, Xiao J, Huang WH (2021) Process control of pulsed laser enhanced metal transfer behavior in CO2 gas shielded welding. J Laser Appl 33(2):022022. https://doi.org/10.2351/7.0000255

Zhang SW, Sun JH, Zhu MH, Zhang L, Nie PL, Li ZG (2019) Effects of shielding gases on process stability of 10CrNi3MoV steel in hybrid laser-arc welding. J Mater Process Technol 270:37–46. https://doi.org/10.1016/j.jmatprotec.2019.01.027

Pan QL, Mizutani M, Kawahito Y, Katayama S (2016) Effect of shielding gas on laser–MAG arc hybrid welding result of thick high-tensile-strength steel plates. Weld World 60(4):653–664. https://doi.org/10.1007/s40194-016-0333-9

Gheonea MC, Mihăilescu D, Florescu SN, Scutelnicu E (2018) Experimental assessment of gases and fumes developed during gas metal arc welding. IOP Conf Ser Mater Sci Eng. IOP Publishing 400(2): 022028. https://doi.org/10.1088/1757-899X/400/2/022028.

Mvola B, Kah P (2017) Effects of shielding gas control: welded joint properties in GMAW process optimization. Int J Adv Manuf Technol 88(9–12):2369–2387. https://doi.org/10.1007/s00170-016-8936-2

Teixeira GS, Mazzaferro JAE (2019) GMA welding metal transfer mode study by high-speed imaging and electrical signal acquisition. J Braz Soc Mech Sci Eng 41(8):315–327. https://doi.org/10.1007/s40430-019-1814-8

Tümer M, Yılmaz R (2016) Characterization of microstructure, chemical composition, and toughness of a multipass welded joint of austenitic stainless steel AISI316L. Int J Adv Manuf Technol 87(9):2567–2579. https://doi.org/10.1007/s00170-016-8614-4

Uddin E, Iqbal U, Arif N, Shah SR (2019) Analysis of metal transfer in gas metal arc welding. AIP Conf Proc 2116(1):030019. https://doi.org/10.1088/0022-3727/36/9/313

Tenni B, Brochu M, Godin S, Thibault D (2021) Shielding gas and inclusion content effects on impact toughness and tensile properties of 410NiMo steel welds. Weld J 100(1): 52–62. https://doi.org/10.29391/2021.100.005

Liskevych O, Scotti A (2015) Influence of the CO2 content on operational performance of short-circuit GMAW. Weld World 59(2):217–224. https://doi.org/10.1007/s40194-014-0196-x

Schafranski LL, Cunha TVD, Carlos ENB (2017) Benefits from H2 and CO2 additions in argon gas mixtures in GMAW. J Mater Process Technol 249:158–166. https://doi.org/10.1016/j.jmatprotec.2017.05.030

Haupt W, Riffel KC, Israel CL, Silva RHG, Reguly A (2018) Effect of wire electrode and shielding gas compositions on the mechanical properties of DOMEX 700 steel welded by the GMAW-P process. J Braz Soc Mech Sci Eng 40(4):174–185. https://doi.org/10.1007/s40430-018-1117-5

Zong R, Chen J, Wu C, Padhy GK (2016) Influence of shielding gas on undercutting formation in gas metal arc welding. J Mater Process Technol 234:169–176. https://doi.org/10.1016/j.jmatprotec.2016.03.020

Zhang S, Sun J, Zhu M, Zhang L, Nie P, Li Z (2019) Effects of shielding gases on process stability of 10CrNi3MoV steel in hybrid laser-arc welding. J Mater Process Technol. https://doi.org/10.1016/j.jmatprotec.2019.01.027

Cai XY, Fan CL, Lin SB, Yang CL, Ji XR, Hu L (2017) Effects of shielding gas composition on arc characteristics and droplet transfer in tandem narrow gap GMA welding. Sci Technol Weld Joining 22(5):446–453. https://doi.org/10.1080/13621718.2016.1253535

Li S, Zhou Z, Xiao G, Chen B (2019) Influence of carbon dioxide shielding gas on microstructure and corrosion property of welds. Materialwiss Werkstofftech 50(7):819–828. https://doi.org/10.1002/mawe.201800129

Cai XY, Fan CL, Lin SB, Ji X, Yang CL (2018) Optimization of shielding gas composition in narrow gap GMA welding based on response surface methodology. Int J Adv Manuf Technol 95(5):2405–2412. https://doi.org/10.1007/s00170-017-1373-z

Zhao Y, Shi X, Yan K, Wang G, Jia Z, He Y (2018) Effect of shielding gas on the metal transfer and weld morphology in pulsed current MAG welding of carbon steel. J Mater Process Technol 262:382–391. https://doi.org/10.1016/j.jmatprotec.2018.07.003

Cai XY, Fan CL, Lin SB, Yang CL, Hu H, Ji XR (2017) Effects of shielding gas composition on arc behaviors and weld formation in narrow gap tandem GMAW. Int J Adv Manuf Technol 91(9–12):3449–3456. https://doi.org/10.1007/s00170-017-9990-0

Silwal B, Nycz A, Masuo CJ, Noakes MW, Vaughan D (2020) An experimental investigation of the effectiveness of Ar-CO2 shielding gas mixture for the wire arc additive process. Int J Adv Manuf Technol 108(5–8). https://doi.org/10.1007/s00170-020-05395-7

Vade M, Gomes JFP, Scotti A (2014) The effect of metal transfer stability (spattering) on fume generation, morphology and composition in short-circuit MAG welding. J Mater Process Technol 214(7):1388–1397. https://doi.org/10.1016/j.jmatprotec.2014.02.012

Funding

The present research work was financially supported by a special project for the transformation of major scientific and technological achievements in Shenyang (Grant No. 20–203-5–01), the National Natural Science Foundation of China (Grant No. 51775354), Liaoning Revitalization Talents Program (Grant No. XLYC2007072), and the Ministry of Education and Science of Russian Federation (Grant No.11.9505.2017/8.9).

Author information

Authors and Affiliations

Contributions

Junyan Miao: conceptualization, methodology, writing—original draft. Zhihai Dong: conceptualization, collecting documents, writing—original draft. Yiwen Li: collecting documents, writing—original draft. Huifang Liu: collecting documents, supervision. Aleksandr Babkin: writing—review and editing, resources. Yunlong Chang: project administration, supervision.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

All authors agree to participate.

Consent for publication

All authors agree to publication.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Miao, J., Li, Y., Dong, Z. et al. Research progress of low spatter CO2 welding technology. Int J Adv Manuf Technol 123, 3715–3736 (2022). https://doi.org/10.1007/s00170-022-10504-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10504-9